Is Drayage the First Mile

What is Drayage and How Does It Relate to First Mile Logistics?

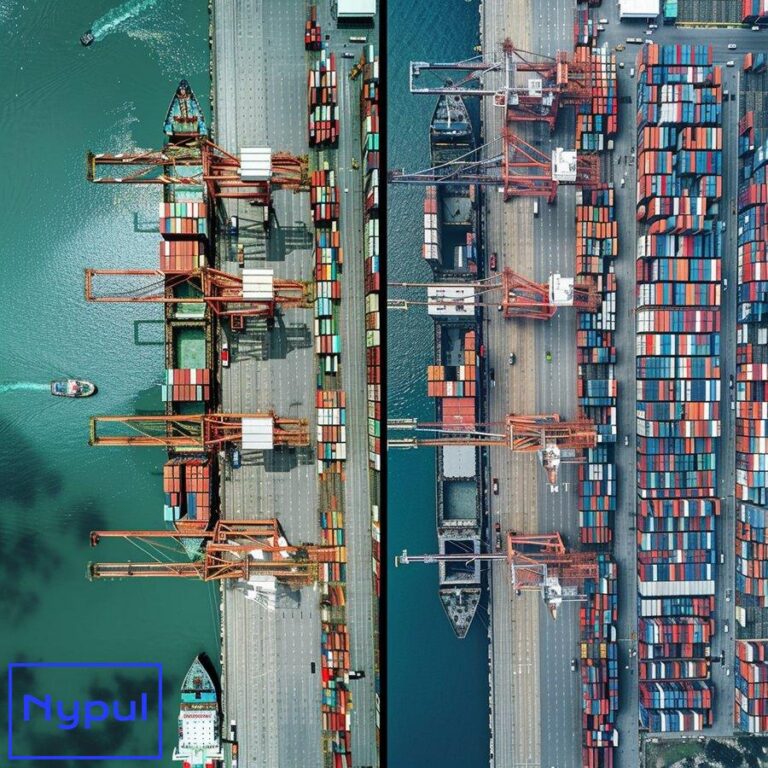

Drayage forms a critical link in the global supply chain, often serving as the initial transportation leg for containerized cargo. This short-haul trucking service moves freight from ports or rail terminals to nearby destinations, typically within a 50-mile radius. While seemingly simple, drayage plays an outsized role in logistics efficiency and cost-effectiveness.

First mile logistics refers to the initial stage of moving goods from their origin point into the broader supply chain network. For international shipments arriving by sea, drayage frequently constitutes this crucial first mile. The relationship between drayage and first mile logistics is symbiotic – efficient drayage enables smooth first mile operations, while optimized first mile processes support streamlined drayage.

Key Components of Drayage

Container pickup: Drayage begins with retrieving shipping containers from ports or rail yards. This requires coordination with terminal operators and adherence to pickup schedules.

Short-distance transport: Trucks move containers to nearby warehouses, distribution centers, or intermodal facilities. Routes are typically under 50 miles but may face urban congestion.

Container return: After unloading, empty containers are returned to designated locations. This “empty mile” adds complexity to drayage operations.

Documentation: Proper paperwork is essential for customs clearance and tracking. Drayage providers manage bills of lading, customs forms, and other required documents.

Drayage’s Role in First Mile Logistics

Port-to-warehouse movement: For ocean freight, drayage often represents the initial inland transportation after goods arrive at port. This critical step launches products into domestic supply chains.

Intermodal connections: Drayage links sea or rail transport to truck-based distribution networks. It bridges the gap between long-haul and local delivery systems.

Customs facilitation: Drayage providers navigate customs procedures, ensuring smooth clearance of international shipments entering first mile logistics flows.

Inventory staging: By moving goods to local warehouses, drayage enables efficient sorting, consolidation, and preparation for onward shipping.

The intersection of drayage and first mile logistics is particularly evident in major port cities. For example, the ports of Los Angeles and Long Beach handle approximately 40% of U.S. containerized imports. Drayage operations in this region directly impact the first mile for a vast array of products entering the country.

| Aspect | Drayage | First Mile Logistics |

|---|---|---|

| Scope | Short-haul transport (typically <50 miles) | Initial stage of product movement |

| Primary focus | Container movement | Launching products into supply chain |

| Key locations | Ports, rail yards, nearby warehouses | Origin points, ports, distribution centers |

| Typical duration | Hours to 1-2 days | Can extend to several days or weeks |

| Main challenges | Port congestion, chassis availability | Customs clearance, inventory management |

Understanding the relationship between drayage and first mile logistics is essential for supply chain professionals seeking to optimize their operations. By recognizing drayage as a critical component of the first mile, companies can better integrate these services into their broader logistics strategies, improving efficiency and reducing costs across the entire supply chain.

When Does Drayage Function as the First Mile in Supply Chains?

Drayage serves as the first mile in supply chains under specific circumstances, primarily when goods enter a country through seaports or when intermodal transportation is involved. This critical function of drayage as the initial transportation leg occurs in several scenarios:

International Ocean Freight

For containerized goods arriving via ocean freight, drayage typically constitutes the first mile of inland transportation. Once a container ship docks at a port, drayage trucks collect the containers and transport them to nearby facilities. This movement represents the first step in the domestic portion of the supply chain.

Example: A shipment of electronics from China arrives at the Port of Los Angeles. Drayage trucks pick up the containers and deliver them to a distribution center 30 miles inland, marking the first mile of U.S. transportation.

Intermodal Rail Transfers

When long-distance freight travels by rail, drayage often serves as the first mile once the train reaches its destination terminal. Trucks collect containers from the rail yard and transport them to local warehouses or distribution centers.

Example: A train carrying auto parts from Detroit arrives at an intermodal facility in Dallas. Drayage providers move the containers to nearby automotive manufacturing plants, initiating the local supply chain.

Air Freight Connections

For high-value or time-sensitive goods arriving by air, drayage can function as the first mile from airports to distribution points. While less common than seaport or rail scenarios, this still represents a critical link in certain supply chains.

Example: Pharmaceutical products flown into Miami International Airport require temperature-controlled drayage to a specialized warehouse, forming the first mile of their cold chain logistics.

Domestic Manufacturing Outputs

In some cases, drayage acts as the first mile for domestically produced goods. This occurs when manufacturers use intermodal transportation to begin their distribution process.

Example: A furniture factory in North Carolina loads its products into containers. Drayage trucks transport these containers to a nearby rail terminal, initiating the first mile of a cross-country journey.

E-commerce Fulfillment

For e-commerce operations relying on imported goods, drayage often represents the first mile in getting products from ports to fulfillment centers.

Example: An online retailer’s shipment of clothing arrives at the Port of New York. Drayage services move the containers to a New Jersey fulfillment center, starting the domestic logistics process.

| Scenario | Origin Point | Drayage Destination | First Mile Function |

|---|---|---|---|

| Ocean Freight | Seaport | Distribution Center | Port to Inland Transport |

| Intermodal Rail | Rail Terminal | Local Warehouse | Rail to Road Transfer |

| Air Freight | Airport | Specialized Facility | Air to Ground Connection |

| Domestic Manufacturing | Factory | Rail Terminal | Production to Distribution Link |

| E-commerce | Seaport | Fulfillment Center | Import to Inventory Stage |

Recognizing when drayage functions as the first mile is crucial for supply chain managers. This understanding allows for better planning, resource allocation, and integration with subsequent logistics stages. Efficient drayage in these scenarios sets the tone for the entire supply chain, impacting everything from inventory management to final delivery timelines.

Companies leveraging drayage as their first mile should focus on:

Seamless port operations: Coordinating closely with port authorities and terminal operators to minimize delays in container pickup.

Intermodal synchronization: Aligning drayage schedules with the arrival of ships, trains, or planes to reduce dwell times and optimize asset utilization.

Technology integration: Implementing tracking systems that provide visibility from the moment goods enter the drayage phase, enabling proactive management of the entire supply chain.

Customs efficiency: Streamlining customs clearance processes to ensure smooth transitions from international to domestic logistics flows.

Capacity planning: Maintaining flexible drayage capacity to handle fluctuations in import volumes and seasonal peaks.

By optimizing drayage operations in these first mile scenarios, companies can establish a strong foundation for efficient, cost-effective supply chains. This initial stage sets the pace for subsequent logistics processes, making it a critical focus area for businesses relying on international or intermodal freight transportation.

How Do Drayage and Traditional First Mile Operations Differ?

While drayage often functions as the first mile in many supply chains, it’s important to understand how it differs from traditional first mile operations. These distinctions impact logistics planning, cost structures, and operational strategies.

Geographical Scope

Drayage: Typically limited to short distances, usually within a 50-mile radius of ports or rail terminals. Focuses on moving containers between transportation hubs and nearby facilities.

Traditional First Mile: Can cover a broader geographical area, potentially including long-distance transportation from manufacturers or distribution centers to the next stage in the supply chain.

Transportation Modes

Drayage: Primarily utilizes trucks designed for short-haul container transport. Specialized equipment like chassis and container lifts are common.

Traditional First Mile: May involve various transportation modes, including trucks, trains, and even air freight, depending on the product and destination.

Operational Focus

Drayage: Concentrates on efficient container movement, often dealing with high volumes and tight schedules dictated by port or rail operations.

Traditional First Mile: Broader focus on initiating the product journey, which may include order processing, picking, packing, and initial shipment preparation.

Regulatory Environment

Drayage: Subject to specific port regulations, customs procedures, and often stricter environmental standards due to operations in urban port areas.

Traditional First Mile: Varies widely based on the industry and product type, but generally faces fewer port-specific regulations.

Asset Utilization

Drayage: High turnover of assets, with trucks often making multiple short trips per day. Efficient asset utilization is crucial due to the short distances involved.

Traditional First Mile: May involve longer trips and different asset utilization patterns, potentially with more diverse equipment needs.

Integration with Subsequent Stages

Drayage: Tightly integrated with port or rail operations upstream and distribution or warehousing downstream. Requires close coordination with multiple parties.

Traditional First Mile: Often more directly controlled by the shipper or manufacturer, with potentially simpler handoffs to subsequent supply chain stages.

Cost Structures

Drayage: Costs are often based on per-container rates and may include additional fees for wait times, chassis rental, or special handling.

Traditional First Mile: Cost structures vary widely but are typically based on distance, weight, or volume of goods transported.

Technology Requirements

Drayage: Emphasizes real-time tracking and integration with port systems. Requires technology to manage chassis pools and coordinate with terminal operations.

Traditional First Mile: Technology needs focus more on order management, inventory control, and general transportation management systems.

| Aspect | Drayage | Traditional First Mile |

|---|---|---|

| Distance | Usually <50 miles | Can be long-distance |

| Primary vehicles | Container trucks | Various (trucks, trains, planes) |

| Main focus | Container movement | Initiating product journey |

| Regulatory complexity | High (port & customs rules) | Varies by industry |

| Asset turnover | High (multiple trips/day) | Lower, longer trips |

| Cost basis | Per container, plus fees | Distance, weight, or volume |

| Key tech needs | Real-time tracking, port integration | Order & inventory management |

Operational Challenges

Drayage: Faces unique challenges such as port congestion, chassis availability, and strict appointment systems at terminals.

Traditional First Mile: Challenges often relate to order accuracy, inventory management, and coordinating with diverse customers or channels.

Environmental Considerations

Drayage: Increasing focus on reducing emissions due to operations in urban areas. Many ports implement clean truck programs or incentivize electric vehicles.

Traditional First Mile: Environmental concerns vary based on the transportation modes used but may have more flexibility in adopting alternative fuels or routes.

Labor Considerations

Drayage: Often relies on owner-operators or small fleets. Labor issues can be complex due to port regulations and the gig economy nature of some drayage work.

Traditional First Mile: Labor needs vary widely but often involve more diverse roles including warehouse staff, long-haul drivers, and logistics coordinators.

Scalability

Drayage: Scaling operations can be challenging due to physical constraints at ports and the need for specialized equipment.

Traditional First Mile: Often easier to scale, with more options for expanding capacity through additional vehicles, facilities, or outsourcing.

Customer Visibility

Drayage: End customers rarely interact directly with drayage operations, which are often seen as a “behind the scenes” process.

Traditional First Mile: May have more direct customer visibility, especially in e-commerce or direct-to-consumer models.

Understanding these differences is crucial for logistics professionals managing supply chains that involve both drayage and traditional first mile operations. Each has its unique challenges and requirements, necessitating tailored strategies for optimal performance.

For companies dealing with both types of operations, key considerations include:

Integrated planning: Developing logistics strategies that account for the distinct needs of drayage and traditional first mile operations while ensuring smooth transitions between them.

Flexible technology solutions: Implementing systems capable of managing the diverse requirements of both drayage and broader first mile logistics.

Specialized partnerships: Cultivating relationships with providers who excel in drayage operations as well as those proficient in traditional first mile logistics.

Adaptive workforce management: Creating training and staffing plans that address the unique skills needed for drayage versus other first mile operations.

Holistic performance metrics: Developing KPIs that accurately reflect the different challenges and success factors in drayage and traditional first mile logistics.

By recognizing and adapting to these differences, companies can optimize their entire supply chain, ensuring efficient operations from the very first mile, whether it involves drayage or traditional logistics processes.

What Challenges Do Companies Face in Drayage and First Mile Logistics?

Companies engaged in drayage and first mile logistics encounter a range of challenges that can impact efficiency, costs, and overall supply chain performance. Understanding these challenges is crucial for developing effective strategies to overcome them.

Port Congestion

Port congestion remains a persistent issue, particularly at major gateways like Los Angeles/Long Beach and New York/New Jersey. This congestion leads to:

Extended wait times for trucks at terminal gates

Delayed container availability

Increased operational costs due to idle time

Impact: Congestion can cause ripple effects throughout the supply chain, delaying subsequent logistics stages and increasing overall transportation costs.

Equipment Shortages

Shortages of essential equipment, particularly chassis, can severely hamper drayage operations. This issue manifests as:

Difficulty in securing chassis for container transport

Increased dwell times at ports as trucks wait for available equipment

Higher costs due to chassis rental fees or repositioning charges

Impact: Equipment shortages can lead to missed delivery windows and increased operational expenses, affecting the entire supply chain’s efficiency.

Labor Shortages and Disputes

The drayage industry often faces challenges related to workforce issues, including:

Shortage of qualified truck drivers

Labor disputes at ports leading to slowdowns or stoppages

High turnover rates among drayage operators

Impact: Labor issues can result in reduced capacity, increased costs, and potential service disruptions.

Regulatory Compliance

Drayage and first mile operations must navigate a complex regulatory landscape, including:

Emissions standards and clean truck programs at ports

Hours of Service (HOS) regulations for drivers

Customs and border protection requirements for international shipments

Impact: Compliance challenges can lead to fines, operational restrictions, and increased administrative burdens.

Technology Integration

Integrating technology across various stakeholders in drayage and first mile logistics presents challenges such as:

Incompatible systems between ports, carriers, and shippers

Difficulty in achieving end-to-end visibility

Cybersecurity concerns with increased data sharing

Impact: Technology gaps can result in inefficiencies, data silos, and missed opportunities for optimization.

Capacity Fluctuations

Drayage and first mile logistics often face significant fluctuations in demand, leading to:

Difficulty in maintaining consistent capacity

Surge pricing during peak periods

Underutilization of assets during slow periods

Impact: Capacity issues can lead to increased costs during high-demand periods and reduced profitability during lulls.

Last-Minute Changes and Exceptions

The dynamic nature of global trade often results in last-minute changes that affect drayage and first mile operations:

Sudden shifts in vessel schedules

Changes in customs clearance requirements

Unexpected road closures or traffic issues

Impact: These changes can disrupt carefully planned operations, leading to delays and additional costs.

Environmental Concerns

Increasing focus on sustainability presents challenges for drayage operations:

Pressure to adopt cleaner technologies like electric trucks

Stricter emissions regulations in urban areas

Need for sustainable practices in warehousing and distribution

Impact: Environmental initiatives often require significant investments and operational changes, impacting cost structures and operational strategies.

| Challenge | Key Impacts | Potential Solutions |

|---|---|---|

| Port Congestion | Delays, increased costs | Off-peak operations, appointment systems |

| Equipment Shortages | Operational disruptions, higher expenses | Improved chassis management, alternative equipment models |

| Labor Issues | Reduced capacity, service disruptions | Workforce development programs, automation |

| Regulatory Compliance | Fines, operational restrictions | Compliance management systems, regular training |

| Technology Integration | Inefficiencies, data silos | Standardized platforms, API integrations |

| Capacity Fluctuations | Inconsistent service, pricing volatility | Dynamic capacity management, partnerships |

| Last-Minute Changes | Operational disruptions, additional costs | Agile planning systems, real-time communication tools |

| Environmental Concerns | Investment needs, operational changes | Gradual adoption of clean technologies, sustainability programs |

Strategies for Addressing Challenges

Companies can employ various strategies to mitigate these challenges:

Collaborative Planning: Engaging in joint planning with ports, carriers, and other stakeholders to address congestion and capacity issues.

Technology Adoption: Investing in advanced TMS systems, IoT devices, and blockchain solutions to improve visibility and operational efficiency.

Flexible Workforce Management: Developing programs to attract and retain drivers, including competitive compensation and improved working conditions.

Equipment Optimization: Implementing advanced chassis management systems and exploring alternative equipment models to address shortages.

Regulatory Expertise: Building in-house expertise or partnering with compliance specialists to navigate complex regulatory environments.

Sustainability Initiatives: Gradually adopting cleaner technologies and implementing sustainability programs to meet environmental goals while managing costs.

Data Analytics: Leveraging big data and predictive analytics to anticipate and respond to capacity fluctuations and potential disruptions.

Agile Operations: Developing flexible operational models that can quickly adapt to changes in schedules, regulations, or market conditions.

Strategic Partnerships: Forming alliances with technology providers, equipment suppliers, and other logistics companies to share resources and expertise.

By addressing these challenges proactively, companies can improve the efficiency and reliability of their drayage and first mile logistics operations, setting a strong foundation for the entire supply chain.

How Does Drayage Impact Port Efficiency and Global Trade?

Drayage plays a crucial role in port operations and, by extension, global trade. Its impact is far-reaching, affecting everything from local port efficiency to international commerce flows. Understanding this impact is essential for port authorities, shippers, and logistics providers alike.

Port Throughput and Capacity

Efficient drayage operations directly contribute to a port’s ability to handle high volumes of cargo:

Faster container movement: Smooth drayage operations allow for quicker turnaround times at port terminals, increasing overall throughput.

Reduced congestion: Effective drayage prevents bottlenecks, allowing ports to operate closer to their maximum capacity.

Improved vessel turnaround: By facilitating faster unloading and loading of ships, efficient drayage contributes to quicker vessel turnaround times.

Impact on global trade: Higher port throughput enables increased trade volumes, supporting economic growth and international commerce.

Supply Chain Velocity

Drayage serves as a critical link in accelerating the movement of goods through the supply chain:

Minimized dwell times: Efficient drayage reduces the time containers spend idle at ports, speeding up the overall logistics process.

Faster time-to-market: By quickly moving goods from ports to distribution centers, drayage enables faster delivery to end consumers.

Enhanced inventory management: Speedier drayage allows for more responsive inventory strategies, reducing carrying costs and improving stock availability.

Cost Implications

The efficiency of drayage operations has significant cost implications for global trade:

Demurrage and detention charges: Effective drayage minimizes these charges, reducing overall shipping costs.

Fuel efficiency: Optimized drayage routes and reduced wait times lead to lower fuel consumption, impacting transportation costs.

Labor costs: Efficient operations can reduce overtime and idle time, controlling labor expenses in port and drayage operations.

Environmental Impact

Drayage efficiency plays a role in the environmental footprint of port operations and global trade:

Emissions reduction: Streamlined drayage operations can significantly reduce truck idling and unnecessary movements, lowering emissions.

Clean technology adoption: The drayage sector’s move towards cleaner vehicles contributes to reducing the environmental impact of port operations.

Urban air quality: Efficient drayage can help mitigate the air quality issues often associated with port cities.

Port Competitiveness

The quality of drayage services can influence a port’s competitive position:

Attracting shipping lines: Ports with efficient drayage operations are more attractive to shipping lines, potentially increasing business.

Regional economic impact: Smooth drayage operations can enhance a port’s reputation, attracting more trade and boosting the local economy.

Investment decisions: Ports with effective drayage are more likely to attract infrastructure investments, further improving their capabilities.

Global Supply Chain Resilience

Drayage efficiency contributes to the overall resilience of global supply chains:

Disruption management: Agile drayage operations can help mitigate the impact of supply chain disruptions, such as those caused by natural disasters or labor disputes.

Flexibility in routing: Efficient drayage allows for more flexible routing options, enhancing supply chain adaptability.

Buffer against volatility: Smooth drayage operations provide a buffer against the volatility inherent in global trade, helping to stabilize supply chains.

| Aspect | Impact of Efficient Drayage | Impact of Inefficient Drayage |

|---|---|---|

| Port Throughput | Increased capacity utilization | Reduced port capacity, bottlenecks |

| Supply Chain Speed | Faster time-to-market | Delays, increased lead times |

| Costs | Lower demurrage, reduced fuel use | Higher shipping and handling costs |

| Environment | Reduced emissions, better air quality | Increased pollution, higher carbon footprint |

| Port Competitiveness | Attracts more business, investment | Loss of business to more efficient ports |

| Supply Chain Resilience | Better adaptability to disruptions | Increased vulnerability to shocks |

Technology and Innovation in Drayage

The impact of drayage on port efficiency and global trade is increasingly influenced by technological advancements:

Appointment systems: Digital scheduling tools reduce truck congestion at ports, improving overall efficiency.

Real-time tracking: Enhanced visibility allows for better coordination between drayage providers, ports, and shippers.

Automated guided vehicles (AGVs): Some ports are implementing AGVs for container movement, interfacing with drayage operations to improve efficiency.

Intermodal Connectivity

Efficient drayage enhances the connection between maritime and land-based transportation:

Rail integration: Smooth drayage operations facilitate better coordination with rail services, enhancing intermodal efficiency.

Inland port development: Effective drayage supports the development of inland ports, extending port capacity and improving overall logistics networks.

Trade Policy and Regulations

Drayage efficiency can influence and be influenced by trade policies:

Customs procedures: Streamlined drayage can support more efficient customs processes, facilitating international trade.

Environmental regulations: Drayage operations must adapt to evolving environmental policies, potentially impacting port operations and trade flows.

Labor Relations and Workforce Development

The drayage sector’s labor dynamics have broader implications:

Port labor stability: Efficient drayage can help maintain positive labor relations at ports by reducing stress on port workers.

Skills development: The evolving nature of drayage operations drives workforce development in areas like technology and logistics management.

To maximize the positive impact of drayage on port efficiency and global trade, stakeholders should focus on:

Collaborative planning: Engaging all parties in the port ecosystem to develop integrated solutions for drayage efficiency.

Infrastructure investment: Continual improvement of port infrastructure to support efficient drayage operations.

Technology adoption: Embracing innovative technologies that enhance drayage performance and integration with port systems.

Sustainable practices: Implementing environmentally friendly drayage solutions that align with global sustainability goals.

Policy advocacy: Working with policymakers to develop regulations that support efficient drayage while meeting environmental and safety standards.

By recognizing and leveraging the significant impact of drayage on port efficiency and global trade, stakeholders can work towards creating more resilient, efficient, and sustainable supply chains. This not only benefits individual ports and companies but also contributes to the overall health and growth of the global economy.

What Technologies Are Revolutionizing Drayage and First Mile Operations?

The drayage and first mile logistics sectors are undergoing a technological revolution, with innovations aimed at improving efficiency, visibility, and sustainability. These advancements are transforming traditional operations and opening new possibilities for optimization.

Artificial Intelligence and Machine Learning

AI and ML are making significant inroads in drayage and first mile operations:

Predictive analytics: AI algorithms analyze historical data and real-time information to predict potential delays, optimize routes, and improve resource allocation.

Dynamic pricing: ML models enable more accurate and responsive pricing strategies for drayage services, balancing supply and demand.

Automated decision-making: AI systems can make real-time decisions on routing and scheduling, reducing human error and improving efficiency.

Impact: These technologies lead to more efficient operations, reduced costs, and improved service reliability.

Internet of Things (IoT)

IoT devices are enhancing visibility and control in drayage operations:

Container tracking: Smart sensors on containers provide real-time location and condition monitoring.

Equipment management: IoT-enabled chassis and trucks allow for better fleet management and predictive maintenance.

Environmental monitoring: Sensors can track emissions and fuel efficiency, supporting sustainability initiatives.

Impact: IoT technology improves asset utilization, reduces loss and damage, and enhances overall supply chain visibility.

Blockchain Technology

Blockchain is addressing trust and transparency issues in drayage and first mile logistics:

Documentation management: Digital ledgers streamline the handling of bills of lading, customs documents, and other paperwork.

Smart contracts: Automated execution of contract terms based on predefined conditions improves efficiency and reduces disputes.

Supply chain traceability: Blockchain enables end-to-end tracking of goods, enhancing security and compliance.

Impact: Blockchain reduces administrative costs, improves data integrity, and increases trust among stakeholders.

Autonomous Vehicles

While still in development, autonomous vehicles promise to revolutionize drayage:

Self-driving trucks: Autonomous vehicles could potentially operate 24/7, increasing capacity and efficiency.

Platooning: Convoys of semi-autonomous trucks can improve fuel efficiency and safety.

Yard automation: Autonomous vehicles for container movement within port terminals can enhance efficiency and safety.

Impact: Autonomous technology has the potential to address driver shortages, improve safety, and increase operational efficiency.

5G and Edge Computing

Advanced connectivity is enabling new capabilities in drayage operations:

Real-time communication: 5G networks allow for instant data exchange between vehicles, ports, and control centers.

Edge computing: Processing data closer to its source enables faster decision-making and reduces latency.

Enhanced visibility: High-bandwidth connections support real-time video monitoring and augmented reality applications.

Impact: These technologies enable more responsive and data-driven operations, improving coordination and efficiency.

Cloud-Based Platforms

Cloud technology is transforming how drayage and first mile operations are managed:

Transportation Management Systems (TMS): Cloud-based TMS platforms offer scalable, accessible solutions for managing drayage operations.

Collaborative platforms: Cloud systems facilitate better coordination between shippers, carriers, and port operators.

Data analytics: Cloud computing power enables advanced analytics on large datasets, driving insights and optimization.

Impact: Cloud platforms enhance collaboration, improve data accessibility, and enable more sophisticated analytics and planning.

| Technology | Key Applications | Primary Benefits |

|---|---|---|

| AI/ML | Predictive analytics, Dynamic pricing | Improved efficiency, Cost optimization |

| IoT | Asset tracking, Fleet management | Enhanced visibility, Better utilization |

| Blockchain | Documentation, Traceability | Reduced admin costs, Increased trust |

| Autonomous Vehicles | Self-driving trucks, Yard automation | Increased capacity, Improved safety |

| 5G/Edge Computing | Real-time communication, Fast processing | Responsive operations, Better coordination |

| Cloud Platforms | TMS, Collaborative tools | Enhanced collaboration, Advanced analytics |

Robotic Process Automation (RPA)

RPA is streamlining administrative tasks in drayage and first mile logistics:

Automated booking: Bots can handle routine booking processes, reducing manual effort and errors.

Invoice processing: RPA can automate the creation, validation, and processing of invoices.

Customs documentation: Automated systems can prepare and submit customs documents, speeding up clearance processes.

Impact: RPA reduces administrative overhead, improves accuracy, and allows human resources to focus on more complex tasks.

Advanced Analytics and Big Data

Sophisticated analytics are driving deeper insights and better decision-making:

Demand forecasting: Analysis of historical data and market trends enables more accurate capacity planning.

Performance optimization: Big data analytics identify inefficiencies and opportunities for improvement in drayage operations.

Risk management: Advanced analytics help predict and mitigate potential disruptions in the supply chain.

Impact: These tools enable more proactive management, improved resource allocation, and enhanced risk mitigation.

Mobile Applications

Mobile technology is empowering drivers and improving field operations:

Driver apps: Mobile applications provide real-time instructions, documentation management, and communication tools for drivers.

Digital check-in/out: Mobile apps streamline terminal processes, reducing wait times and paperwork.

Proof of delivery: Digital capture of delivery confirmation enhances accountability and speeds up billing processes.

Impact: Mobile apps improve driver productivity, enhance communication, and provide real-time visibility into field operations.

Drones and Aerial Imaging

While not yet widely implemented, drones show promise for certain drayage applications:

Yard management: Drones can conduct inventory counts and locate containers in large port yards.

Infrastructure inspection: Aerial imaging can assist in monitoring port infrastructure and identifying maintenance needs.

Security surveillance: Drones can enhance security monitoring of port and warehouse facilities.

Impact: Drone technology has the potential to improve operational visibility, enhance security, and support maintenance activities.

To fully leverage these technologies, companies involved in drayage and first mile operations should consider:

Integrated technology strategies: Developing comprehensive plans that integrate various technologies for maximum benefit.

Workforce training: Investing in training programs to ensure staff can effectively utilize new technologies.

Cybersecurity measures: Implementing robust security protocols to protect sensitive data and systems.

Collaborative implementation: Working with partners across the supply chain to ensure interoperability and shared benefits.

Regulatory compliance: Staying abreast of regulations governing the use of new technologies in transportation and logistics.

Continuous innovation: Fostering a culture of innovation to continuously explore and adopt emerging technologies.

By embracing these revolutionary technologies, drayage and first mile operations can achieve new levels of efficiency, visibility, and sustainability. This technological transformation not only improves individual company performance but also contributes to the overall advancement of global supply chain management.

Case Studies: Successful Integration of Drayage and First Mile Logistics

Examining real-world examples of successful integration between drayage and first mile logistics provides valuable insights into best practices and innovative strategies. These case studies highlight how companies have overcome challenges and leveraged technologies to optimize their operations.

Port of Rotterdam: Digital Twin Technology

The Port of Rotterdam, Europe’s largest seaport, has implemented a digital twin of its entire port complex to optimize drayage and first mile operations.

Implementation:

– Created a virtual replica of the port using IoT sensors, radar, and AI

– Integrated real-time data on ship movements, weather, and terminal operations

– Developed predictive models for optimal resource allocation and scheduling

Results:

– 20% reduction in vessel waiting times

– 15% improvement in berth utilization

– Significant decrease in drayage truck idle time and congestion

Key Takeaways:

– Digital twin technology enables proactive decision-making and resource optimization

– Integration of multiple data sources provides a comprehensive view of port operations

– Real-time adjustments based on predictive analytics can significantly improve efficiency

Maersk and IBM: TradeLens Blockchain Platform

Shipping giant Maersk collaborated with IBM to develop TradeLens, a blockchain-based platform that integrates drayage and first mile logistics with broader supply chain operations.

Implementation:

– Created a shared, immutable ledger for transaction recording

– Integrated stakeholders including shippers, freight forwarders, ports, and customs authorities

– Developed smart contracts for automated document processing and customs clearance

Results:

– 40% reduction in transit time for shipments

– Significant decrease in paperwork and administrative costs

– Enhanced visibility and traceability across the supply chain

Key Takeaways:

– Blockchain technology can streamline documentation and improve trust among stakeholders

– Collaborative platforms enhance coordination between drayage providers and other supply chain entities

– Digitalization of processes can lead to substantial time and cost savings

DP World: Automated Guided Vehicles in Port Operations

DP World implemented Automated Guided Vehicles (AGVs) at its Rotterdam World Gateway terminal to enhance the interface between maritime and drayage operations.

Implementation:

– Deployed a fleet of battery-powered AGVs for container movement within the terminal

– Integrated AGV operations with Terminal Operating System (TOS) for seamless coordination

– Implemented advanced algorithms for optimal routing and task allocation

Results:

– 30% increase in container handling speed

– Significant reduction in drayage truck turn times

– Improved safety with reduced human intervention in container movements

Key Takeaways:

– Automation can significantly enhance the efficiency of container handoffs between maritime and drayage operations

– Integration of automated systems with existing terminal operations is crucial for success

– Improved efficiency in terminal operations directly benefits drayage productivity

XPO Logistics: AI-Powered Optimization for Drayage

XPO Logistics implemented an AI-driven platform to optimize its drayage operations, focusing on improving efficiency and reducing empty miles.

Implementation:

– Developed machine learning algorithms for predictive analytics and dynamic routing

– Integrated real-time traffic and port congestion data into the decision-making process

– Implemented a mobile app for drivers to receive real-time updates and instructions

Results:

– 25% reduction in empty miles

– 15% improvement in on-time performance

– Significant increase in driver satisfaction and retention

Key Takeaways:

– AI and machine learning can dramatically improve drayage efficiency and resource utilization

– Real-time data integration is key to making informed, dynamic decisions

– Improved efficiency can lead to better working conditions and job satisfaction for driversFedEx: IoT and Predictive Analytics in First Mile Logistics

FedEx implemented an IoT-based solution combined with predictive analytics to enhance its first mile pickup operations and integration with drayage services.

Implementation:

– Deployed IoT sensors on packages and in delivery vehicles

– Developed a predictive analytics platform to optimize pickup routes and timing

– Integrated the system with local drayage providers for seamless handoffs

Results:

– 20% improvement in first-time pickup success rates

– 15% reduction in fuel consumption for pickup operations

– Enhanced coordination with drayage services, reducing delays at handoff points

Key Takeaways:

– IoT technology can provide granular visibility into package movements and vehicle locations

– Predictive analytics can significantly improve route optimization and resource allocation

– Improved coordination between first mile and drayage operations enhances overall supply chain efficiency

Port of Los Angeles: Port Optimizer Platform

The Port of Los Angeles developed the Port Optimizer, a cloud-based platform to improve cargo flow and integrate drayage operations with port activities.

Implementation:

– Created a single portal for stakeholders to access real-time data on vessel arrivals, container status, and terminal operations

– Integrated trucking company systems for better coordination of drayage services

– Implemented predictive tools for cargo volumes and potential bottlenecks

Results:

– 30% reduction in truck turn times

– Improved container dwell time, reducing it by an average of two days

– Enhanced planning capabilities for drayage companies and beneficial cargo owners

Key Takeaways:

– Centralized data platforms can significantly improve coordination among various stakeholders

– Predictive capabilities enable proactive management of potential congestion issues

– Improved visibility leads to better resource allocation and reduced waste in drayage operations

CMA CGM: Artificial Intelligence for Container Repositioning

Global shipping company CMA CGM implemented an AI-driven solution to optimize container repositioning, impacting both drayage and first mile logistics.

Implementation:

– Developed AI algorithms to predict container demand and optimal positioning

– Integrated the system with drayage providers for efficient empty container management

– Implemented a dynamic pricing model for container leasing based on AI predictions

Results:

– 25% reduction in empty container movements

– 15% improvement in container utilization rates

– Significant cost savings in drayage operations for empty container repositioning

Key Takeaways:

– AI can effectively address the chronic issue of empty container repositioning

– Improved container management directly impacts the efficiency of drayage and first mile operations

– Dynamic pricing models can incentivize more efficient use of container assets

Lessons Learned and Best Practices

From these case studies, several key lessons and best practices emerge for successful integration of drayage and first mile logistics:

Data Integration and Visibility

– Implement systems that provide real-time visibility across all stages of the supply chain

– Ensure data interoperability between different stakeholders’ systems

– Utilize cloud-based platforms for easy access and scalability

Predictive Analytics and AI

– Leverage historical data and real-time information to predict and prevent bottlenecks

– Use AI for dynamic routing and resource allocation

– Implement machine learning models for continuous improvement of operations

Collaborative Platforms

– Develop or adopt platforms that facilitate information sharing among all stakeholders

– Encourage collaborative planning between port authorities, carriers, and drayage providers

– Implement standardized communication protocols to ensure smooth data exchange

Automation and IoT

– Explore automation opportunities in terminal operations and container handling

– Deploy IoT sensors for real-time tracking of assets and environmental conditions

– Integrate automated systems with human-operated processes for optimal efficiency

Sustainability Focus

– Implement technologies that reduce empty miles and improve fuel efficiency

– Explore alternative fuel vehicles for drayage operations

– Use data analytics to identify and reduce sources of waste and inefficiency

Workforce Development

– Invest in training programs to upskill workers in new technologies

– Develop user-friendly interfaces for technology adoption by drivers and operators

– Foster a culture of innovation and continuous improvement

Regulatory Compliance and Security

– Ensure all technological implementations comply with relevant regulations

– Implement robust cybersecurity measures to protect sensitive data

– Engage with regulatory bodies to help shape future-friendly policies

By learning from these successful implementations and adopting these best practices, companies can significantly enhance the integration of their drayage and first mile logistics operations. This integration not only improves operational efficiency but also contributes to a more resilient, sustainable, and competitive supply chain ecosystem.

The future of drayage and first mile logistics lies in the continued adoption and refinement of these technologies and strategies. As the global supply chain becomes increasingly complex and interconnected, the ability to seamlessly integrate these critical first steps in the logistics process will be a key differentiator for successful companies in the industry.