What Are Drayage Operations

What is Drayage and Why is it Important in Logistics?

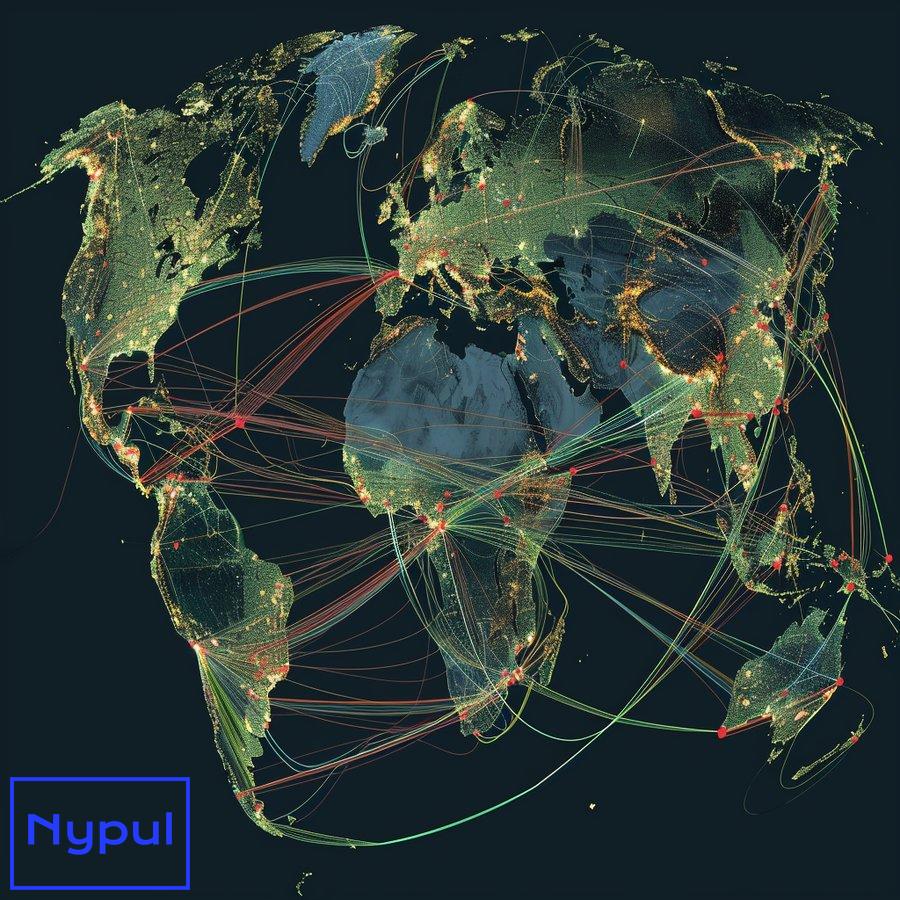

Drayage is a specialized logistics service that involves the short-distance transportation of goods, typically within a single metropolitan area. This critical component of the supply chain focuses on moving cargo from ports, rail yards, or other intermodal facilities to its next destination, which could be a warehouse, distribution center, or another mode of transportation.

The term “drayage” originates from the historical use of “dray” horses to pull heavy loads over short distances. Today, drayage operations primarily utilize trucks for these short-haul movements, forming an essential link in the intermodal transportation network.

Drayage plays a pivotal role in logistics for several reasons:

Bridging Transportation Gaps

Drayage services connect different modes of transportation, ensuring a seamless flow of goods from one point to another. For instance, when a shipping container arrives at a port, drayage trucks transport it to a rail yard or distribution center, bridging the gap between sea and land transportation.

Facilitating Intermodal Transport

Intermodal transport relies heavily on efficient drayage operations. By enabling the smooth transition of cargo between different modes of transportation, drayage enhances the overall efficiency and cost-effectiveness of the supply chain.

Reducing Congestion and Improving Efficiency

Effective drayage operations help alleviate congestion at ports and rail terminals by quickly moving containers and freight to their next destination. This rapid turnaround time is crucial for maintaining the flow of goods and preventing bottlenecks in the supply chain.

Supporting Just-in-Time Inventory Systems

Many businesses operate on just-in-time inventory systems, which require precise timing in the delivery of goods. Drayage services provide the flexibility and speed necessary to support these systems, ensuring that materials and products arrive exactly when needed.

Enhancing Supply Chain Visibility

Drayage operations often incorporate advanced tracking technologies, providing real-time visibility into the movement of goods. This transparency is invaluable for supply chain managers, allowing them to make informed decisions and respond quickly to any disruptions.

Facilitating Customs Clearance

In international trade, drayage services often include transporting goods to customs inspection facilities. This step is crucial for ensuring compliance with import/export regulations and facilitating the smooth flow of international trade.

Promoting Economic Growth

Efficient drayage operations contribute to economic growth by enabling the swift movement of goods, supporting international trade, and creating jobs in the transportation and logistics sectors.

Understanding the importance of drayage in logistics is crucial for businesses involved in supply chain management, transportation, and international trade. As global commerce continues to expand and evolve, the role of drayage in ensuring efficient, cost-effective, and timely movement of goods becomes increasingly significant.

How Does the Drayage Process Work from Port to Destination?

The drayage process from port to destination is a complex operation involving multiple steps and stakeholders. Understanding this process is essential for anyone involved in logistics, supply chain management, or international trade. Let’s break down the typical drayage journey from a port to its final destination:

Vessel Arrival and Unloading

The process begins when a cargo vessel arrives at the port. Large cranes unload containers from the ship and place them in the port’s container yard. This step involves careful coordination between the vessel crew, port authorities, and stevedores.

Customs Clearance

Before the containers can leave the port, they must clear customs. This process involves submitting necessary documentation, such as the Bill of Lading, commercial invoice, and packing list. Customs officials may inspect the cargo to ensure compliance with import regulations and assess any applicable duties or taxes.

Container Release

Once customs clearance is obtained, the container is released for pickup. The drayage company receives notification that the container is available, along with any specific instructions or requirements for pickup.

Drayage Truck Arrival

The drayage company dispatches a truck to the port. The driver must present proper documentation, including the container release order and any necessary security credentials, to gain entry to the port.

Container Pickup

At the container yard, port equipment lifts the container onto the drayage truck. The driver secures the container and verifies its seal integrity and any visible damage.

Port Exit and Transit

The truck exits the port, often passing through security checkpoints. The driver then transports the container to its designated destination, which could be a warehouse, distribution center, rail yard, or another intermodal facility.

Destination Arrival and Unloading

Upon reaching the destination, the truck driver checks in and proceeds to the unloading area. The container is then unloaded using appropriate equipment, such as forklifts or cranes.

Empty Container Return

After unloading, the empty container is typically returned to a designated container depot or back to the port, depending on the agreement with the shipping line.

Documentation and Billing

Throughout this process, various documents are generated and exchanged, including proof of delivery, gate passes, and invoices. The drayage company then bills the client for the services rendered.

To illustrate the typical timeline of a drayage operation, consider the following table:

| Stage | Typical Duration | Key Stakeholders |

|---|---|---|

| Vessel Unloading | 1-3 days | Port Authority, Stevedores |

| Customs Clearance | 1-5 days | Customs Officials, Freight Forwarders |

| Container Release | 1-2 days | Shipping Line, Terminal Operators |

| Drayage Transport | 1-2 days | Drayage Company, Truck Driver |

| Destination Unloading | 1 day | Warehouse Staff, Consignee |

| Empty Container Return | 1 day | Drayage Company, Container Depot |

It’s important to note that these timelines can vary significantly based on factors such as port congestion, customs efficiency, distance to the destination, and any unforeseen delays.

The efficiency of this process relies heavily on clear communication and coordination among all parties involved. Any delays or issues at one stage can have a ripple effect throughout the entire supply chain. Therefore, many drayage companies and logistics providers use advanced tracking systems and communication tools to monitor the progress of containers and quickly address any potential problems.

Understanding this process is crucial for businesses relying on international shipping and intermodal transportation. By grasping the intricacies of drayage operations, companies can better plan their supply chains, anticipate potential challenges, and work more effectively with their logistics partners to ensure smooth and timely delivery of their goods.

What Are the Different Types of Drayage Services?

Drayage services come in various forms, each designed to meet specific logistical needs. Understanding these different types is crucial for businesses to choose the most appropriate service for their supply chain requirements. Let’s explore the main categories of drayage services:

Inter-Carrier Drayage

This type of drayage involves moving cargo between different carriers. For example, transferring a container from a shipping line to a rail company. Inter-carrier drayage is essential for seamless intermodal transportation, ensuring that goods can transition smoothly between different modes of transport.

Intra-Carrier Drayage

Intra-carrier drayage refers to the movement of goods within the same carrier’s network. This might involve relocating containers between different terminals or facilities operated by the same shipping line or rail company. Intra-carrier drayage helps optimize the carrier’s operations and asset utilization.

Expedited Drayage

When time is of the essence, expedited drayage services come into play. This service prioritizes speed, often involving dedicated trucks and drivers to ensure rapid delivery. Expedited drayage is commonly used for time-sensitive shipments or to recover from supply chain disruptions.

Pier Drayage

Pier drayage specifically refers to the movement of containers from a port to a rail terminal or vice versa. This service is crucial in port cities where efficient transfer between sea and rail transport is necessary to prevent congestion and ensure timely onward transportation.

Shuttle Drayage

Shuttle drayage involves the repeated movement of containers between two nearby locations, such as between a port and a nearby warehouse or distribution center. This service is often used to manage high-volume cargo flows or to temporarily store containers when port space is limited.

Door-to-Door Drayage

This comprehensive service covers the entire journey from the origin (often a port or rail terminal) directly to the final destination, such as a customer’s warehouse or retail location. Door-to-door drayage provides a seamless, end-to-end solution for businesses that prefer to work with a single provider for their short-haul transportation needs.

Cross-Town Drayage

Cross-town drayage refers to the transportation of containers or cargo across a metropolitan area, typically between different intermodal facilities. This service is crucial in large cities with multiple ports, rail yards, or distribution centers.

Window Drayage

Window drayage services operate within specific time frames or “windows” set by terminals or customers. This type of service requires precise scheduling and coordination to ensure containers are picked up or delivered within the designated time slots, often to manage terminal congestion or meet specific operational requirements.

To better understand how these different types of drayage services compare, consider the following table:

| Drayage Type | Primary Use Case | Typical Distance | Key Advantage |

|---|---|---|---|

| Inter-Carrier | Intermodal transfers | Varies | Facilitates multi-modal transport |

| Intra-Carrier | Internal relocations | Short | Optimizes carrier operations |

| Expedited | Time-sensitive cargo | Any | Fastest delivery |

| Pier | Port-rail transfers | Short | Reduces port congestion |

| Shuttle | High-volume flows | Very short | Efficient for repeated moves |

| Door-to-Door | End-to-end delivery | Short to medium | Comprehensive service |

| Cross-Town | Metro area transfers | Medium | Connects urban logistics hubs |

| Window | Scheduled operations | Varies | Precise timing control |

Each type of drayage service plays a specific role in the logistics ecosystem. The choice of service depends on various factors, including:

Cargo Type and Volume

Different types of cargo may require specialized handling or equipment, influencing the choice of drayage service. High-volume shipments might benefit from shuttle drayage, while valuable or sensitive goods might require expedited services.

Distance and Geography

The distance between the origin and destination, as well as the geographical features of the area (e.g., urban density, port layout), can determine the most appropriate drayage type.

Time Sensitivity

For urgent shipments, expedited or window drayage services might be necessary to meet tight deadlines.

Intermodal Requirements

If the shipment involves multiple modes of transportation, inter-carrier drayage becomes essential to ensure smooth transitions.

Cost Considerations

Different drayage services come with varying cost structures. Businesses must balance their operational needs with budget constraints when selecting a service.

Regulatory Compliance

Certain types of cargo or routes may be subject to specific regulations, which can influence the choice of drayage service to ensure compliance.

By understanding these different types of drayage services, businesses can make informed decisions about their logistics strategies. The right choice of drayage service can significantly impact the efficiency, cost-effectiveness, and reliability of a company’s supply chain operations. As the logistics landscape continues to evolve, staying informed about these various drayage options becomes increasingly important for businesses aiming to optimize their transportation and distribution processes.

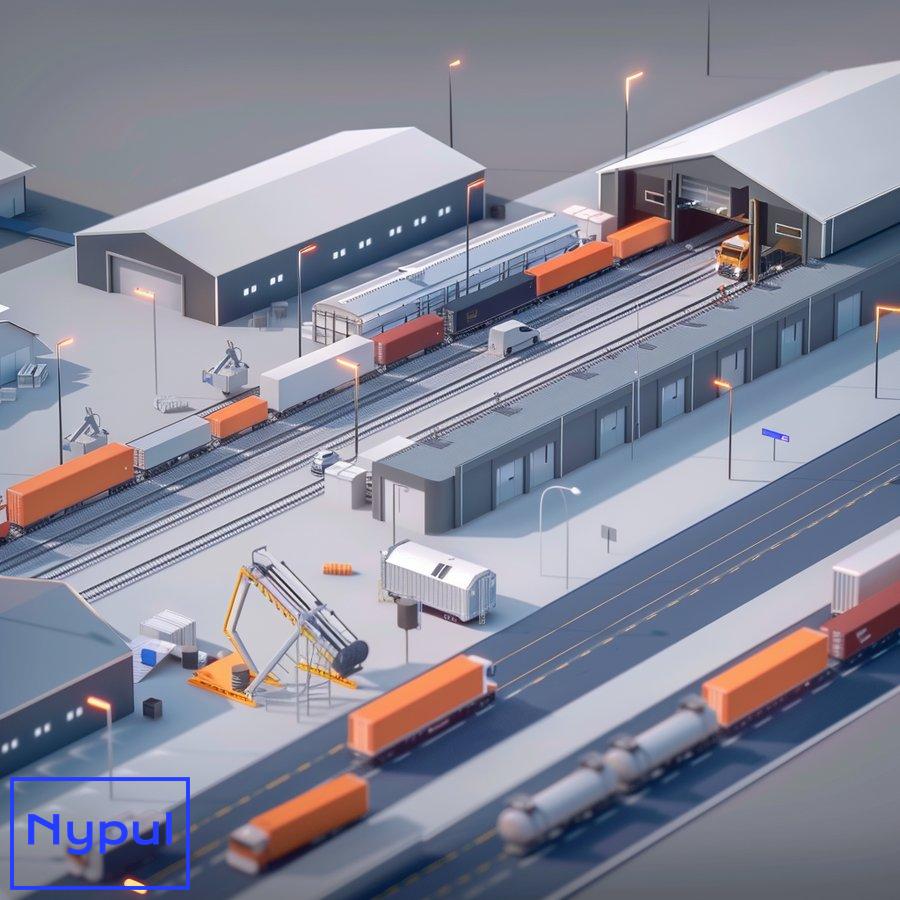

What Equipment and Infrastructure are Essential for Drayage Operations?

Efficient drayage operations rely on a combination of specialized equipment and robust infrastructure. Understanding these essential components is crucial for anyone involved in logistics, supply chain management, or transportation planning. Let’s explore the key equipment and infrastructure necessary for successful drayage operations:

Drayage Trucks

At the heart of drayage operations are the trucks specifically designed for short-haul container transport. These trucks are typically Class 8 vehicles, capable of handling the heavy loads associated with fully loaded shipping containers. Key features of drayage trucks include:

- Powerful engines to manage heavy loads

- Reinforced chassis to support container weight

- Specialized coupling systems for attaching containers

- Fuel-efficient designs for frequent short trips

- Advanced communication and tracking systems

Container Chassis

Container chassis are specialized trailers designed to carry shipping containers. They come in various configurations to accommodate different container sizes and types. Essential features of container chassis include:

- Twist locks to secure containers in place

- Adjustable length to fit different container sizes (20ft, 40ft, 45ft)

- Reinforced structure to support heavy loads

- Sliding tandem axles for weight distribution

Container Handling Equipment

Efficient loading and unloading of containers require specialized handling equipment at ports, rail yards, and distribution centers. This equipment includes:

- Gantry Cranes: Large cranes used to load and unload containers from ships

- Reach Stackers: Mobile equipment for stacking and moving containers in yards

- Straddle Carriers: Vehicles that can lift and transport containers over short distances

- Forklifts: Used for handling smaller containers or palletized cargo

Intermodal Facilities

Drayage operations heavily rely on well-designed intermodal facilities that facilitate the smooth transfer of containers between different modes of transportation. Key components of these facilities include:

- Container Yards: Large areas for storing and organizing containers

- Rail Sidings: Dedicated rail lines for loading and unloading containers onto trains

- Truck Gates: Efficient entry and exit points for drayage trucks

- Customs Inspection Areas: Designated spaces for customs clearance procedures

Information Technology Infrastructure

Modern drayage operations are increasingly reliant on advanced IT systems to manage and optimize the movement of containers. Essential IT infrastructure includes:

- Terminal Operating Systems (TOS): Software for managing container yard operations

- Transportation Management Systems (TMS): Tools for planning and executing drayage moves

- GPS Tracking Systems: Real-time location tracking for trucks and containers

- Electronic Data Interchange (EDI): Systems for sharing data between different stakeholders

- Automated Gate Systems: Technology for streamlining truck entry and exit at facilities

Road Infrastructure

Adequate road infrastructure is crucial for efficient drayage operations. This includes:

- Well-maintained highways connecting ports to inland destinations

- Dedicated truck lanes in congested areas

- Sufficient parking and staging areas for trucks

- Clear signage and traffic management systems

Safety and Security Equipment

Ensuring the safety and security of cargo and personnel is paramount in drayage operations. Essential safety and security equipment includes:

- Container seals and locks

- Surveillance cameras at facilities

- Personal protective equipment (PPE) for workers

- Fire suppression systems in storage areas

- Access control systems at entry points

To illustrate the relative importance and typical lifespan of various equipment used in drayage operations, consider the following table:

| Equipment Type | Relative Importance | Typical Lifespan | Maintenance Frequency |

|---|---|---|---|

| Drayage Trucks | High | 7-10 years | Monthly |

| Container Chassis | High | 10-15 years | Quarterly |

| Gantry Cranes | Very High | 20-30 years | Weekly |

| Reach Stackers | High | 8-12 years | Monthly |

| IT Systems | Very High | 5-7 years | Continuous updates |

| Road Infrastructure | High | 15-20 years | Annual |

The efficiency and effectiveness of drayage operations depend on the proper integration and maintenance of all these equipment and infrastructure components. Investing in high-quality equipment and regularly updating infrastructure can lead to significant improvements in operational efficiency, reduced downtime, and enhanced safety.

Moreover, as technology continues to advance, new equipment and infrastructure solutions are emerging to address the evolving challenges of drayage operations. For instance:

Electric and Autonomous Vehicles

The development of electric drayage trucks and autonomous vehicle technology promises to reduce emissions and improve operational efficiency in the future.

Smart Port Technologies

Advanced sensors, Internet of Things (IoT) devices, and artificial intelligence are being integrated into port infrastructure to optimize container handling and reduce congestion.

Blockchain for Documentation

Blockchain technology is being explored to streamline documentation processes, enhance security, and improve transparency in drayage operations.

Advanced Materials

Research into lightweight, durable materials could lead to the development of more efficient container chassis and handling equipment.

Understanding the essential equipment and infrastructure for drayage operations is crucial for logistics professionals, port authorities, and businesses involved in international trade. By recognizing the importance of each component and staying informed about technological advancements, stakeholders can make informed decisions to improve the efficiency, reliability, and sustainability of their drayage operations.

How Do Ports and Intermodal Facilities Impact Drayage Efficiency?

Ports and intermodal facilities play a pivotal role in determining the efficiency of drayage operations. These crucial nodes in the supply chain can either facilitate smooth cargo flows or create bottlenecks that ripple through the entire logistics network. Understanding how these facilities impact drayage efficiency is essential for logistics professionals, port authorities, and businesses relying on international trade.

Port Layout and Design

The physical layout of a port significantly influences drayage efficiency. Well-designed portsPort Layout and Design

The physical layout of a port significantly influences drayage efficiency. Well-designed ports feature:

- Efficient traffic flow patterns to minimize congestion

- Adequate staging areas for trucks awaiting container pickup or drop-off

- Strategically placed container yards to reduce internal transport distances

- Multiple entry and exit points to distribute traffic

Ports with optimized layouts can significantly reduce truck turn times, allowing drayage operators to complete more moves per day and improving overall supply chain efficiency.

Terminal Operating Systems (TOS)

Advanced TOS play a crucial role in port efficiency. These systems:

- Optimize container stacking and retrieval processes

- Manage truck appointments and gate operations

- Coordinate crane and equipment movements

- Provide real-time visibility into container locations and status

Efficient TOS implementation can dramatically reduce wait times for drayage trucks and improve the predictability of container availability.

Gate Operations

The efficiency of port gate operations directly impacts drayage performance. Modern ports employ:

- Automated gate systems with optical character recognition (OCR) and RFID technology

- Pre-gate parking areas to prevent street congestion

- Express lanes for pre-cleared trucks

- Mobile apps for drivers to check in and receive instructions before arrival

Streamlined gate operations can significantly reduce truck queuing times and improve overall port throughput.

Intermodal Connectivity

The seamless integration of different transportation modes at intermodal facilities is crucial for drayage efficiency. Key factors include:

- On-dock rail facilities to minimize the need for short-haul truck movements

- Efficient interfaces between maritime, rail, and road transportation

- Adequate rail capacity to handle container volumes

- Coordinated scheduling between vessel arrivals, train departures, and truck movements

Well-connected intermodal facilities can reduce dwell times for containers and optimize the use of drayage resources.

Operating Hours and Flexibility

The operational schedule of ports and intermodal facilities significantly impacts drayage efficiency:

- Extended gate hours, including nights and weekends, can spread out truck traffic and reduce peak congestion

- Flex-time programs allow truckers to pick up or drop off containers during off-peak hours

- Appointment systems help balance workload throughout the day

Flexible operating hours can lead to more efficient use of drayage assets and improved overall supply chain velocity.

Information Sharing and Visibility

Transparent and timely information sharing between ports, intermodal facilities, and drayage operators is essential for efficiency:

- Real-time updates on container availability and location

- Advance notification of delays or operational issues

- Integration of port community systems with trucking company dispatch systems

- Collaborative planning platforms for coordinating vessel, rail, and truck movements

Enhanced visibility enables better planning and resource allocation for drayage operations.

Customs and Regulatory Processes

The efficiency of customs clearance and regulatory compliance procedures at ports and intermodal facilities directly affects drayage operations:

- Streamlined documentation processes

- Pre-clearance programs for trusted shippers

- On-site customs facilities to expedite inspections

- Use of non-intrusive inspection technologies to reduce physical examination times

Efficient customs processes can significantly reduce container dwell times and improve the predictability of drayage operations.

To illustrate the impact of various port and intermodal facility factors on drayage efficiency, consider the following table:

| Factor | High Efficiency Impact | Low Efficiency Impact |

|---|---|---|

| Port Layout | Optimized traffic flow, reduced turn times | Congestion, long internal transit times |

| TOS Implementation | Quick container location, coordinated movements | Delays in container retrieval, equipment conflicts |

| Gate Operations | Rapid truck processing, minimal queuing | Long wait times, street traffic congestion |

| Intermodal Connectivity | Seamless modal transfers, reduced dwell times | Modal transfer delays, increased short-haul trucking |

| Operating Hours | Balanced workload, reduced peak congestion | Concentrated peak hours, underutilized off-peak periods |

| Information Sharing | Proactive planning, optimized resource allocation | Reactive operations, inefficient truck dispatching |

| Customs Processes | Rapid clearance, predictable release times | Extended container holds, unpredictable availability |

The efficiency of ports and intermodal facilities has far-reaching implications for the entire supply chain. Inefficiencies at these critical nodes can lead to:

- Increased drayage costs due to longer turn times and reduced productivity

- Higher inventory carrying costs as goods spend more time in transit

- Reduced reliability of supply chains, impacting production schedules and retail operations

- Increased environmental impact due to truck idling and congestion

- Higher overall logistics costs, potentially affecting the competitiveness of businesses and regions

To address these challenges and improve drayage efficiency, ports and intermodal facilities are increasingly adopting innovative solutions:

Smart Port Technologies

Implementation of IoT sensors, AI-driven predictive analytics, and blockchain for enhanced visibility and operational optimization.

Green Port Initiatives

Adoption of electric and alternative fuel vehicles, shore power for vessels, and energy-efficient equipment to reduce emissions and improve air quality.

Collaborative Platforms

Development of port community systems that facilitate information sharing and coordination among all stakeholders in the supply chain.

Infrastructure Investments

Ongoing expansion and modernization of port facilities, including deeper channels, larger cranes, and improved road and rail connections.

Workforce Development

Training programs to ensure port and intermodal facility workers are skilled in using new technologies and operating advanced equipment.

The impact of ports and intermodal facilities on drayage efficiency is a critical consideration for businesses involved in international trade and logistics. By understanding these dynamics, companies can make informed decisions about port selection, routing strategies, and logistics partnerships. Additionally, this knowledge is crucial for policymakers and port authorities as they plan infrastructure investments and operational improvements to enhance the competitiveness of their regions in global trade.

As global trade continues to grow and evolve, the role of efficient ports and intermodal facilities in supporting drayage operations will only become more critical. Stakeholders across the supply chain must work collaboratively to address challenges and implement solutions that enhance the speed, reliability, and sustainability of cargo movements through these vital logistics hubs.

What Are the Main Challenges Facing Drayage Operations?

Drayage operations, while crucial to the global supply chain, face numerous challenges that can impact efficiency, cost-effectiveness, and overall performance. Understanding these challenges is essential for logistics professionals, port authorities, and businesses relying on drayage services. Let’s explore the main challenges facing drayage operations:

Port Congestion

One of the most significant challenges for drayage operations is port congestion. This issue arises from various factors:

- Increasing vessel sizes leading to larger cargo volumes per call

- Inadequate port infrastructure to handle growing trade volumes

- Imbalanced cargo flows causing equipment shortages

- Labor disputes or shortages affecting port productivity

Port congestion results in longer wait times for trucks, increased turn times, and reduced overall efficiency of drayage operations.

Equipment Imbalances and Shortages

Drayage operations often struggle with equipment imbalances and shortages:

- Mismatched flow of containers between import and export locations

- Seasonal fluctuations in demand leading to chassis shortages

- Inefficient repositioning of empty containers

- Limited availability of specialized equipment for specific cargo types

These imbalances can lead to increased empty miles, higher operational costs, and delays in cargo movement.

Driver Shortages and Retention

The drayage industry faces ongoing challenges related to workforce:

- Aging driver population and difficulties in attracting younger workers

- Demanding work conditions, including long hours and unpredictable schedules

- Compensation issues, particularly with per-diem and misclassification concerns

- Regulatory challenges, such as hours of service restrictions

Driver shortages can lead to reduced capacity, increased costs, and potential service disruptions.

Regulatory Compliance

Drayage operations must navigate a complex regulatory landscape:

- Emissions regulations and environmental compliance requirements

- Safety regulations, including hours of service rules and vehicle inspections

- Customs and border protection regulations for international shipments

- Local restrictions on truck routes and operating hours

Compliance with these regulations can increase operational complexity and costs for drayage providers.

Technology Integration and Data Management

While technology offers solutions to many challenges, its integration presents its own set of issues:

- High costs associated with implementing new technologies

- Resistance to change among workforce and traditional operators

- Interoperability challenges between different systems and stakeholders

- Data security and privacy concerns

Effective technology integration is crucial for improving efficiency but requires significant investment and change management.

Infrastructure Limitations

The quality and capacity of infrastructure significantly impact drayage operations:

- Aging road and bridge infrastructure leading to congestion and safety concerns

- Limited capacity of rail connections at ports and intermodal facilities

- Inadequate truck parking and staging areas near ports and urban centers

- Insufficient charging infrastructure for electric drayage trucks

Infrastructure limitations can lead to delays, increased fuel consumption, and higher operational costs.

Market Volatility and Rate Fluctuations

Drayage operations are subject to market volatility:

- Fluctuating fuel prices impacting operational costs

- Seasonal demand variations affecting capacity utilization

- Economic cycles influencing overall trade volumes

- Geopolitical events disrupting global supply chains

These fluctuations can make it challenging for drayage providers to maintain stable pricing and consistent service levels.

Last-Mile Delivery Challenges

As e-commerce grows, drayage operations increasingly face last-mile delivery challenges:

- Urban congestion and parking restrictions

- Time-sensitive deliveries and narrow delivery windows

- Increased frequency of smaller shipments

- Coordination with multiple stakeholders for final delivery

Adapting to these last-mile challenges requires new strategies and potentially different equipment.

Environmental Concerns

Drayage operations face increasing pressure to reduce their environmental impact:

- Stricter emissions standards for trucks

- Push for adoption of alternative fuels and electric vehicles

- Community concerns about noise and air pollution near ports

- Carbon footprint reduction goals set by shippers and regulatory bodies

Addressing these environmental concerns often requires significant investments in new technologies and operational changes.

To illustrate the relative impact and complexity of addressing these challenges, consider the following table:

| Challenge | Impact on Operations | Complexity to Address | Potential Solutions |

|---|---|---|---|

| Port Congestion | High | High | Extended gate hours, appointment systems, improved port infrastructure |

| Equipment Imbalances | High | Medium | Collaborative equipment pools, predictive analytics for positioning |

| Driver Shortages | High | High | Improved working conditions, automation, workforce development programs |

| Regulatory Compliance | Medium | Medium | Technology for compliance management, industry advocacy |

| Technology Integration | Medium | High | Phased implementation, industry standards, workforce training |

| Infrastructure Limitations | High | Very High | Public-private partnerships, targeted infrastructure investments |

| Market Volatility | Medium | Medium | Dynamic pricing models, diversified service offerings |

| Last-Mile Delivery | Medium | High | Urban consolidation centers, alternative delivery methods |

| Environmental Concerns | Medium | High | Adoption of clean technologies, operational efficiency improvements |

Addressing these challenges requires a multi-faceted approach involving collaboration among various stakeholders:

Industry Collaboration

Drayage providers, shippers, ports, and technology companies must work together to develop integrated solutions that address systemic issues.

Government Support

Public sector involvement is crucial for infrastructure improvements, regulatory frameworks that promote efficiency, and incentives for technology adoption.

Technological Innovation

Continued investment in technologies such as AI, IoT, and blockchain can help optimize operations and address many of the challenges faced by the drayage industry.

Workforce Development

Initiatives to attract, train, and retain skilled workers are essential for addressing labor-related challenges in the drayage sector.

Sustainable Practices

Adoption of environmentally friendly technologies and practices is necessary to meet growing environmental concerns and regulatory requirements.

Flexible Business Models

Drayage providers need to develop adaptable business models that can withstand market volatility and changing customer demands.

Understanding and addressing these challenges is crucial for the future of drayage operations. As global trade continues to evolve, the ability to efficiently move goods over short distances remains a critical component of the supply chain. By tackling these challenges head-on, the drayage industry can enhance its resilience, improve operational efficiency, and continue to play its vital role in facilitating global commerce.

The future of drayage will likely see a transformation driven by technological advancements, regulatory changes, and shifting market dynamics. Successful drayage operations will be those that can adapt to these changes, leverage new technologies, and collaborate effectively with other stakeholders in the supply chain ecosystem.

How Can Technology Optimize Drayage Performance?

Technology plays a transformative role in optimizing drayage performance, offering solutions to many of the challenges faced by the industry. By leveraging advanced technologies, drayage operations can significantly improve efficiency, reduce costs, and enhance overall service quality. Let’s explore how various technologies can optimize drayage performance:

Transportation Management Systems (TMS)

TMS platforms specifically designed for drayage operations offer comprehensive solutions for managing and optimizing short-haul container movements:

- Real-time tracking and visibility of containers and trucks

- Automated dispatch and routing optimization

- Integration with port and terminal systems for seamless information flow

- Performance analytics and reporting for continuous improvement

Implementing a robust TMS can lead to improved asset utilization, reduced empty miles, and enhanced operational efficiency.

Internet of Things (IoT) and Telematics

IoT devices and telematics systems provide real-time data on vehicle and container status:

- GPS tracking for precise location information

- Sensor data on container conditions (temperature, humidity, shock)

- Vehicle performance monitoring for predictive maintenance

- Driver behavior analysis for safety and efficiency improvements

These technologies enable proactive management of assets and enhance the visibility of cargo throughout the drayage process.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML algorithms can process vast amounts of data to optimize various aspects of drayage operations:

- Predictive analytics for demand forecasting and capacity planning

- Dynamic route optimization considering real-time traffic and port conditions

- Automated appointment scheduling and gate management

- Anomaly detection for identifying potential delays or issues

AI-driven solutions can significantly improve decision-making processes and operational efficiency.

Blockchain Technology

Blockchain offers potential solutions for enhancing transparency and security in drayage operations:

- Secure and transparent documentation processes

- Smart contracts for automated execution of agreements

- Enhanced traceability of container movements and handoffs

- Streamlined customs clearance processes

Implementing blockchain can reduce paperwork, minimize disputes, and improve overall supply chain integrity.

Mobile Applications

Purpose-built mobile apps for drivers and dispatchers can streamline communication and operations:

- Real-time job assignments and updates

- Digital documentation and proof of delivery

- Turn-by-turn navigation optimized for truck routes

- Direct communication channels between drivers, dispatchers, and customers

Mobile apps enhance driver productivity and provide real-time visibility to all stakeholders.

Automated Gate Systems

Advanced gate technologies at ports and intermodal facilities can significantly reduce truck turn times:

- Optical character recognition (OCR) for automated container and license plate reading

- RFID tags for quick identification of trucks and drivers

- Biometric authentication for enhanced security

- Integration with port community systems for seamless data exchange

Automated gates can dramatically reduce processing times and improve overall port efficiency.

Predictive Analytics

Leveraging historical data and advanced analytics can improve planning and resource allocation:

- Accurate prediction of container availability and dwell times

- Forecasting of equipment needs to prevent shortages

- Identification of potential bottlenecks and congestion points

- Optimization of staffing levels based on predicted workload

Predictive analytics enable proactive management and can significantly reduce operational disruptions.

Autonomous and Electric Vehicles

While still in development, autonomous and electric vehicles hold promise for future drayage operations:

- Reduced labor costs and increased operational hours with autonomous trucks

- Lower emissions and operating costs with electric vehicles

- Improved safety through advanced driver assistance systems

- Potential for platooning to increase efficiency on longer drayage routes

These technologies could revolutionize drayage operations in the coming years, addressing both environmental concerns and efficiency challenges.

To illustrate the potential impact of these technologies on various aspects of drayage operations, consider the following table:

| Technology | Primary Benefits | Implementation Complexity | Potential ROI |

|---|---|---|---|

| TMS | Improved dispatching, reduced empty miles | Medium | High |

| IoT/Telematics | Enhanced visibility, proactive maintenance | Low to Medium | Medium |

| AI/ML | Optimized routing, predictive planning | High | Very High |

| Blockchain | Improved documentation, enhanced security | High | Medium |

| Mobile Apps | Streamlined communication, real-time updates | Low | High |

| Automated Gates | Reduced turn times, improved throughput | Medium | High |

| Predictive Analytics | Better resource allocation, reduced disruptions | Medium to High | High |

| Autonomous/Electric Vehicles | Lower costs, reduced emissions | Very High | High (Long-term) |

Implementing these technologies can lead to significant improvements in drayage performance:

Increased Efficiency

Technology-driven optimization can reduce truck turn times, minimize empty miles, and improve overall asset utilization.

Enhanced VisibilityEnhanced Visibility

Real-time tracking and data integration provide stakeholders with up-to-the-minute information on container locations and status, enabling better decision-making and proactive problem-solving.

Improved Customer Service

Advanced technologies enable more accurate ETAs, proactive notifications, and faster response times to customer inquiries, enhancing overall service quality.

Cost Reduction

Optimized routing, improved asset utilization, and reduced manual processes can lead to significant cost savings in drayage operations.

Environmental Impact

Technologies that improve efficiency and promote the use of alternative fuels can help reduce the carbon footprint of drayage operations.

Safety Enhancements

Advanced driver assistance systems, telematics-based driver monitoring, and predictive maintenance can improve safety for drivers and cargo.

While the benefits of technology in drayage are clear, implementation comes with its own set of challenges:

Integration Complexity

Integrating new technologies with existing systems and processes can be complex and time-consuming.

Initial Investment Costs

Many advanced technologies require significant upfront investment, which can be challenging for smaller drayage operators.

Data Security and Privacy Concerns

As more data is collected and shared, ensuring the security and privacy of sensitive information becomes increasingly important.

Workforce Adaptation

Implementing new technologies often requires retraining staff and overcoming resistance to change within the organization.

Standardization Issues

Lack of industry-wide standards for some technologies can lead to interoperability issues between different systems and stakeholders.

To successfully leverage technology for optimizing drayage performance, companies should consider the following strategies:

Phased Implementation

Adopt a step-by-step approach to technology implementation, starting with solutions that offer the highest immediate impact.

Collaborative Approach

Work closely with technology providers, port authorities, and other stakeholders to ensure seamless integration and maximize benefits.

Continuous Training and Support

Invest in ongoing training and support for staff to ensure effective utilization of new technologies.

Data-Driven Decision Making

Cultivate a culture of data-driven decision making to fully leverage the insights provided by advanced analytics and AI systems.

Scalable Solutions

Choose technologies that can scale with the business and adapt to future industry changes.

As the drayage industry continues to evolve, technology will play an increasingly crucial role in optimizing performance. Forward-thinking companies that embrace these technological advancements will be better positioned to overcome industry challenges, improve operational efficiency, and meet the growing demands of global supply chains.

The future of drayage lies in the intelligent integration of various technologies to create a seamless, efficient, and sustainable transportation ecosystem. As innovations continue to emerge, drayage operators must stay informed and agile, ready to adopt new solutions that can give them a competitive edge in this critical segment of the logistics industry.

What is the Economic Impact of Drayage on Supply Chains and Global Trade?

Drayage plays a pivotal role in the global supply chain, serving as a critical link between various modes of transportation. Its economic impact extends far beyond the immediate transportation costs, influencing the efficiency and competitiveness of entire supply chains and, by extension, global trade. Understanding this impact is crucial for businesses, policymakers, and logistics professionals. Let’s explore the multifaceted economic implications of drayage operations:

Facilitating Global Trade

Drayage is an essential component in the movement of international cargo:

- Enables the transfer of goods between ships, trains, and long-haul trucks

- Supports the growth of containerized trade, which has revolutionized global commerce

- Allows for efficient handling of large volumes of cargo at ports and intermodal facilities

The efficiency of drayage operations directly impacts a country’s ability to participate in global trade, affecting its economic competitiveness on the world stage.

Supply Chain Velocity

Efficient drayage operations significantly impact the speed of supply chains:

- Reduces dwell times at ports and intermodal facilities

- Enables faster transit times for goods from manufacturers to end consumers

- Supports just-in-time inventory systems, reducing warehousing costs

Increased supply chain velocity leads to reduced inventory carrying costs and improved cash flow for businesses.

Cost Implications

Drayage costs can have a substantial impact on overall logistics expenses:

- Typically represents a significant portion of the total transportation cost for containerized cargo

- Inefficiencies in drayage can lead to demurrage and detention charges

- Impacts the cost-competitiveness of goods in international markets

Optimizing drayage operations can lead to significant cost savings, potentially lowering the price of goods for consumers.

Economic Multiplier Effect

Drayage operations contribute to local and regional economies:

- Creates direct employment in trucking and related services

- Supports indirect jobs in port operations, warehousing, and logistics services

- Stimulates economic activity in areas surrounding ports and intermodal facilities

The economic activity generated by drayage operations has a multiplier effect, contributing to overall economic growth.

Trade Balance Impact

Efficient drayage can influence a country’s trade balance:

- Reduces logistics costs, making exports more competitive in global markets

- Enables faster and more reliable import processes, supporting domestic industries

- Enhances a country’s attractiveness as a logistics hub, potentially increasing trade volumes

By supporting both imports and exports, effective drayage operations can help balance trade flows and improve a nation’s economic position.

Infrastructure Investment

The demands of drayage operations drive infrastructure development:

- Encourages investment in port facilities and intermodal terminals

- Stimulates road and rail infrastructure improvements

- Promotes the development of logistics parks and distribution centers

These infrastructure investments have long-term economic benefits, improving overall transportation efficiency and attracting further business development.

Environmental Economic Impacts

The environmental aspects of drayage operations have economic implications:

- Emissions from drayage trucks contribute to air pollution, leading to health-related costs

- Inefficient operations can result in increased fuel consumption and associated environmental costs

- Investments in cleaner technologies can lead to long-term economic benefits through reduced environmental impact

Balancing economic efficiency with environmental sustainability is a growing concern with significant economic ramifications.

Supply Chain Resilience

Efficient drayage operations contribute to supply chain resilience:

- Enables quicker responses to supply chain disruptions

- Supports the ability to reroute cargo in response to port congestion or other issues

- Facilitates the implementation of risk mitigation strategies in global supply chains

Enhanced resilience reduces the economic impact of supply chain disruptions, a critical factor in today’s volatile global trade environment.

To illustrate the economic impact of drayage across various aspects of supply chains and global trade, consider the following table:

| Aspect | Direct Economic Impact | Indirect Economic Impact |

|---|---|---|

| Global Trade Facilitation | Enables efficient cargo transfers | Supports growth in international trade volumes |

| Supply Chain Velocity | Reduces transportation time and costs | Lowers inventory carrying costs, improves cash flow |

| Cost Competitiveness | Influences total logistics costs | Affects pricing and competitiveness of goods |

| Local Economic Growth | Creates direct employment | Stimulates related industries and services |

| Trade Balance | Supports export competitiveness | Enhances country’s position as logistics hub |

| Infrastructure Development | Drives investment in transportation infrastructure | Attracts further economic development |

| Environmental Considerations | Incurs costs related to emissions and congestion | Influences long-term sustainability and health costs |

| Supply Chain Resilience | Enables flexible and responsive logistics | Reduces economic impact of supply chain disruptions |

The economic impact of drayage extends beyond these quantifiable aspects. It also influences:

Business Strategy and Location Decisions

Companies often make strategic decisions about manufacturing and distribution locations based on the efficiency of drayage and overall logistics operations in different regions.

Market Access

Efficient drayage operations can open up new markets by making it economically feasible to transport goods to previously inaccessible areas.

Innovation and Technology Adoption

The drive for efficiency in drayage operations spurs innovation in logistics technology, contributing to broader technological advancements in the transportation sector.

Global Competitiveness

Countries with efficient drayage and port operations often become preferred gateways for international trade, enhancing their global economic competitiveness.

To fully leverage the economic benefits of efficient drayage operations, stakeholders across the supply chain should focus on:

Collaborative Planning

Encouraging cooperation between shippers, carriers, ports, and government agencies to optimize drayage operations and reduce inefficiencies.

Technology Investment

Supporting the adoption of advanced technologies that can improve drayage efficiency and provide better visibility across the supply chain.

Policy Development

Implementing policies that promote efficient drayage operations, such as infrastructure investment, environmental regulations, and labor standards.

Skills Development

Investing in workforce training and development to ensure a skilled labor force capable of operating in an increasingly technology-driven environment.

Sustainability Initiatives

Balancing economic efficiency with environmental sustainability to ensure long-term economic benefits and mitigate potential negative impacts.

Understanding the economic impact of drayage on supply chains and global trade is crucial for businesses, policymakers, and logistics professionals. Efficient drayage operations not only reduce direct transportation costs but also contribute to broader economic benefits, including enhanced trade competitiveness, improved supply chain resilience, and stimulated economic growth.

As global trade continues to evolve, particularly in the face of challenges such as climate change, geopolitical tensions, and technological disruptions, the role of efficient drayage operations in supporting economic growth and competitiveness will only become more critical. Stakeholders across the supply chain must work collaboratively to optimize drayage operations, recognizing their pivotal role in the broader economic landscape of global trade and commerce.