How Does Intermodal Fit Into Shipper Sustainability Strategies

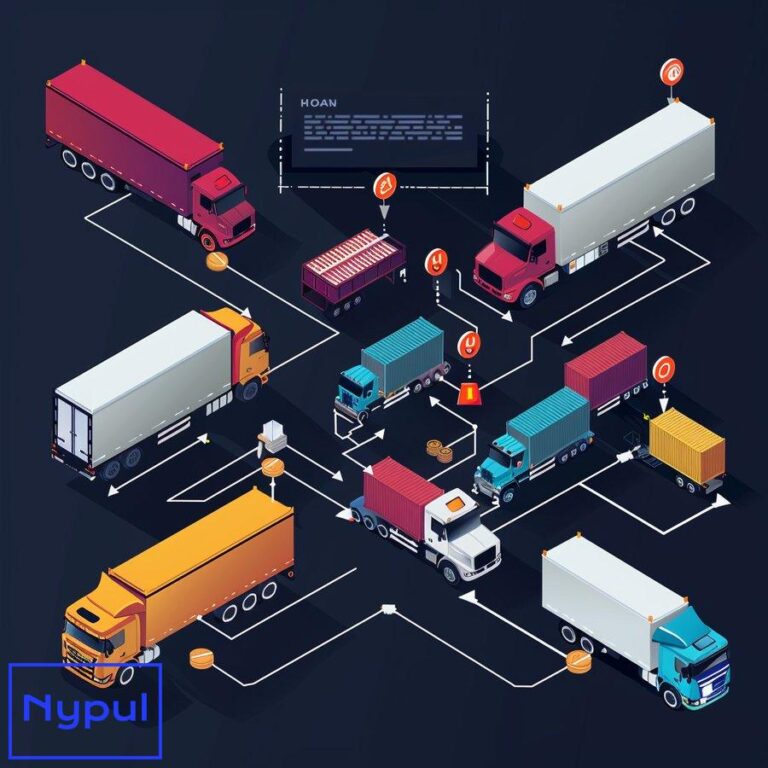

What is intermodal transportation and how does it differ from traditional shipping methods?

Intermodal transportation is a shipping method that involves using two or more modes of transport to move goods from origin to destination. Unlike traditional shipping methods that rely on a single mode, such as truck-only or rail-only, intermodal utilizes a combination of truck, rail, and sometimes ship to optimize transport efficiency and cost.

Key Differences Between Intermodal and Traditional Shipping

Containers: Intermodal shipping uses standardized containers that can be easily transferred between modes without the need to handle the goods themselves. Traditional methods often require loading and unloading goods when changing modes.

Infrastructure: Intermodal leverages existing transportation networks and infrastructure, including railroads, highways, and ports. Traditional shipping may be more limited in terms of infrastructure options.

Efficiency: By using multiple modes, intermodal can take advantage of the strengths of each – the flexibility of trucks for short hauls and the efficiency of rail for long distances. This makes intermodal more efficient overall compared to traditional single-mode transport.

Cost: Intermodal is often more cost-effective than traditional shipping, especially for long-haul routes, due to the efficiency gains from using rail for a significant portion of the journey.

Environmental Impact: Intermodal is generally more environmentally friendly than truck-only shipping, as rail and ship produce lower emissions per ton-mile than trucks.

| Characteristic | Intermodal | Traditional |

|---|---|---|

| Modes Used | Multiple (truck, rail, ship) | Single (truck, rail, or ship) |

| Handling | Standardized containers | Individual handling of goods |

| Efficiency | Optimized for each leg | Limited by single mode |

| Cost | Often lower, especially long-haul | Higher for long distances |

| Emissions | Lower per ton-mile | Higher, especially truck-only |

Intermodal transportation’s use of multiple modes, standardized containers, and optimized routing distinguishes it from traditional shipping methods. These differences enable intermodal to offer greater efficiency, lower costs, and reduced environmental impact for many shipping scenarios.

How can intermodal shipping contribute to a company’s sustainability goals?

Intermodal shipping can play a significant role in supporting a company’s sustainability goals by reducing the environmental impact of freight transportation. Here are several key ways intermodal contributes to sustainability:

Lower Emissions

Rail and ship transportation, which are major components of intermodal shipping, generate significantly lower emissions per ton-mile compared to truck-only shipping. For example:

- Rail emits 5.4 pounds of carbon dioxide (CO2) per 100 ton-miles

- Trucks emit 19.8 pounds of CO2 per 100 ton-miles

By shifting a portion of the journey from truck to rail, intermodal can substantially reduce a shipment’s carbon footprint.

Reduced Energy Consumption

Intermodal is more fuel-efficient than truck-only shipping. Trains can move one ton of freight approximately 479 miles on a single gallon of fuel, compared to about 145 miles by truck. This efficiency translates to energy savings and reduced dependence on fossil fuels.

Congestion Mitigation

Intermodal shipping can help alleviate highway congestion by shifting freight to rail, which has a much higher capacity than trucks. A single train can remove several hundred trucks from the road, reducing traffic and the associated environmental impacts of congestion.

Improved Air Quality

By reducing emissions and congestion, intermodal shipping contributes to improved air quality. This is particularly important in urban areas and port communities that are disproportionately affected by freight-related air pollution.

Supporting Circular Economy

Intermodal’s use of standardized containers facilitates the transport of waste and recycled materials, supporting circular economy initiatives. Companies can more easily integrate recycling and waste reduction into their supply chains using intermodal.

Intermodal shipping’s sustainability advantages align with corporate goals such as reducing carbon footprint, improving energy efficiency, and supporting sustainable development. By incorporating intermodal into their supply chain strategies, companies can make significant strides towards their sustainability objectives.

What are the key components of an effective intermodal sustainability strategy?

An effective intermodal sustainability strategy should encompass several key components that work together to minimize environmental impact and optimize efficiency. These components include:

Modal Shift Analysis

Identifying opportunities to shift freight from truck to rail is a foundational element of an intermodal sustainability strategy. This involves analyzing shipping lanes, volumes, and product characteristics to determine which shipments are suitable for intermodal.

Collaborative Partnerships

Developing strong partnerships with intermodal providers, including railroads, trucking companies, and logistics service providers, is essential for executing a successful strategy. Collaboration enables optimized routing, streamlined operations, and the sharing of sustainability best practices.

Sustainable Equipment and Facilities

Investing in sustainable equipment and facilities supports intermodal sustainability goals. This can include:

- Fuel-efficient and alternative fuel locomotives and trucks

- Low-emission cargo handling equipment

- LEED-certified intermodal terminals

- Solar-powered facilities

Data-Driven Optimization

Leveraging data analytics to optimize intermodal operations can drive efficiency and sustainability improvements. Key areas for data-driven optimization include:

- Route optimization to minimize miles and fuel consumption

- Load optimization to maximize container utilization

- Scheduling optimization to reduce dwell times and congestion

Continuous Improvement

Regularly assessing performance, setting targets, and implementing improvement initiatives is critical for driving ongoing progress in intermodal sustainability. This can involve:

- Benchmarking emissions and efficiency metrics against industry standards

- Setting science-based targets for emissions reduction

- Engaging stakeholders to identify improvement opportunities

Reporting and Communication

Transparent reporting on intermodal sustainability performance and communicating progress to stakeholders is important for building trust and demonstrating commitment. This can include:

- Publishing annual sustainability reports

- Participating in industry initiatives like the SmartWay Transport Partnership

- Engaging customers and investors on sustainability initiatives

By incorporating these key components, companies can develop robust intermodal sustainability strategies that deliver meaningful environmental benefits while optimizing supply chain efficiency.

How do shippers assess and identify opportunities for modal shift in their supply chain?

Assessing and identifying opportunities for modal shift to intermodal involves a systematic analysis of a company’s supply chain and shipping patterns. Here are the key steps in this process:

Data Gathering

The first step is to gather comprehensive data on current shipping operations, including:

- Shipping lanes and routes

- Freight volumes and frequencies

- Product types and characteristics

- Transportation modes used

- Costs and transit times

This data forms the foundation for the modal shift analysis.

Lane Analysis

Using the gathered data, shippers can analyze each shipping lane to determine its suitability for intermodal. Factors to consider include:

- Lane distance: Intermodal is typically most competitive for distances over 500 miles.

- Freight volume: Consistent, high-volume lanes are better candidates for intermodal.

- Product characteristics: Non-perishable, non-urgent goods are more suitable for intermodal.

Cost and Service Comparison

For lanes that appear suitable for intermodal, shippers can compare the cost and service levels of intermodal against their current shipping method. This involves:

- Requesting intermodal rates from providers

- Comparing intermodal costs to current costs, considering both transportation and inventory carrying costs

- Evaluating intermodal transit times and reliability against current service levels

Carbon Footprint Analysis

To quantify the sustainability benefits of modal shift, shippers can calculate the carbon footprint of each lane under both the current shipping method and intermodal. This involves:

- Using industry-standard emission factors for each mode

- Calculating total emissions based on distance, weight, and emission factors

- Comparing emissions to determine the potential carbon reduction from modal shift

Pilot Testing

Before fully committing to modal shift, shippers can conduct pilot tests on selected lanes to validate the feasibility and benefits of intermodal. Pilot testing allows for:

- Real-world validation of cost, service, and sustainability impacts

- Identification of any operational challenges or requirements

- Refinement of the intermodal strategy based on pilot results

By following these steps, shippers can systematically assess their supply chain and identify the most promising opportunities for modal shift to intermodal. This data-driven approach ensures that intermodal decisions are based on a solid business case and deliver the desired sustainability benefits.

What challenges do companies face when implementing intermodal solutions for sustainability?

While intermodal offers significant sustainability benefits, companies may face several challenges when implementing intermodal solutions. Understanding and addressing these challenges is critical for a successful intermodal strategy.

Infrastructure Limitations

Access to intermodal infrastructure, such as rail lines, intermodal terminals, and port facilities, can be a challenge in some regions. Shippers may face:

- Limited intermodal service in certain areas

- Capacity constraints at intermodal facilities

- Inadequate infrastructure for handling specific types of cargo

Overcoming these limitations may require collaborating with intermodal providers to expand services or investing in infrastructure improvements.

Operational Complexity

Intermodal shipping involves coordinating multiple modes and handoffs, which can increase operational complexity compared to single-mode shipping. Challenges may include:

- Ensuring seamless transitions between modes

- Managing multiple providers and contracts

- Dealing with different equipment types and requirements

To address these challenges, shippers need robust operational processes, effective communication, and strong partnerships with intermodal providers.

Transit Time and Reliability

Intermodal shipping can have longer transit times compared to truck-only shipping due to the additional handling and transfers involved. Shippers may face:

- Meeting tight delivery windows

- Dealing with variability in rail schedules

- Managing the impact of delays on inventory levels

Mitigating these challenges requires careful planning, building buffer times into schedules, and having contingency plans in place.

Cost Considerations

While intermodal is often cost-competitive, certain factors can impact its cost-effectiveness, such as:

- Drayage costs for first and last-mile delivery

- Accessorial charges for additional services

- Fluctuations in fuel prices and rail rates

To manage costs, shippers need to carefully analyze all cost components, negotiate competitive rates, and optimize their intermodal network.

Organizational Alignment

Implementing intermodal sustainability solutions requires alignment and collaboration across multiple functions within an organization, including transportation, logistics, sustainability, and finance. Challenges may include:

- Gaining internal buy-in and support for intermodal initiatives

- Aligning intermodal goals with broader corporate sustainability objectives

- Developing the necessary skills and expertise to manage intermodal operations

Overcoming these challenges requires strong leadership, effective communication, and a commitment to change management and training.

By proactively addressing these challenges through careful planning, collaboration, and continuous improvement, companies can successfully implement intermodal solutions and realize the full sustainability benefits of this approach.

How can technology enhance the sustainability benefits of intermodal shipping?

Technology plays a crucial role in enhancing the sustainability benefits of intermodal shipping by enabling greater efficiency, visibility, and optimization. Here are several key ways technology can support intermodal sustainability:

Routing and Load Optimization

Advanced routing and load optimization software can help shippers and intermodal providers to:

- Identify the most efficient intermodal routes based on cost, transit time, and carbon footprint

- Optimize container loading to maximize utilization and minimize empty miles

- Dynamically adjust routes based on real-time conditions and constraints

By optimizing routes and loads, technology can reduce miles driven, fuel consumption, and emissions.

Visibility and Tracking

Real-time visibility and tracking technologies, such as GPS, RFID, and IoT sensors, provide shippers with greater transparency into their intermodal shipments. This enables:

- Monitoring of shipment progress and delays

- Proactive management of disruptions and exceptions

- Identification of bottlenecks and inefficiencies in the intermodal network

Improved visibility supports more efficient operations, reducing waste and unnecessary emissions.

Predictive Analytics

Predictive analytics tools can leverage historical and real-time data to anticipate and mitigate sustainability challenges in intermodal shipping. Applications include:

- Predicting equipment failures and maintenance needs to avoid breakdowns and delays

- Forecasting demand to optimize asset positioning and utilization

- Identifying patterns and trends that impact fuel efficiency and emissions

By proactively addressing potential issues, predictive analytics can help to minimize the environmental impact of intermodal operations.

Automation and Electrification

Automation and electrification technologies can significantly reduce the carbon footprint of intermodal equipment and facilities. Examples include:

- Electric and autonomous trucks for drayage operations

- Automated cranes and cargo handling equipment at intermodal terminals

- Electric rail solutions, such as battery-electric and hydrogen fuel cell locomotives

These technologies can dramatically reduce or eliminate emissions from intermodal operations.

Collaborative Platforms

Collaborative technology platforms can facilitate communication, data sharing, and coordination among intermodal stakeholders. These platforms can:

- Enable real-time information exchange between shippers, carriers, and intermodal providers

- Support joint planning and optimization of intermodal operations

- Foster collaboration on sustainability initiatives and best practices

By promoting collaboration and transparency, these platforms can drive collective action towards intermodal sustainability goals.

Technology is a powerful enabler for intermodal sustainability, providing the tools and insights needed to optimize operations, reduce emissions, and drive continuous improvement. As technology continues to advance, its role in supporting intermodal sustainability will only grow in importance.

What metrics and KPIs should companies use to measure the impact of intermodal on their sustainability efforts?

To effectively measure the impact of intermodal on sustainability efforts, companies should track a range of metrics and key performance indicators (KPIs) that provide a comprehensive view of environmental performance. Here are some of the most important metrics and KPIs to consider:

Carbon Footprint

The carbon footprint is a critical metric for assessing the environmental impact of intermodal shipping. Key carbon footprint KPIs include:

- Total greenhouse gas (GHG) emissions in metric tons of CO2 equivalent

- GHG emissions per ton-mile or TEU-mile

- Percent reduction in GHG emissions compared to truck-only shipping

Tracking carbon footprint KPIs helps companies quantify the emissions reduction benefits of intermodal and monitor progress over time.

Modal Split

Modal split refers to the percentage of freight volume moved by each transportation mode. Important modal split KPIs for intermodal include:

- Percentage of total freight volume shipped via intermodal

- Percentage of truck-to-rail conversion on key lanes

- Percentage of intermodal volume by equipment type (e.g., containers, trailers)

Monitoring modal split KPIs enables companies to track their progress in shifting freight to more sustainable intermodal options.

Fuel Efficiency

Fuel efficiency is a key driver of intermodal sustainability, as it directly impacts emissions and energy consumption. Relevant fuel efficiency KPIs include:

- Miles per gallon (MPG) or gallons per thousand gross ton-miles (GTM) for intermodal shipments

- Percent improvement in fuel efficiency compared to truck-only shipping

- Percentage of intermodal volume shipped using alternative fuels or electric power

Tracking fuel efficiency KPIs helps companies identify opportunities for further optimization and emissions reduction.

Network Optimization

Network optimization metrics measure the efficiency and sustainability of a company’s intermodal network. Key network optimization KPIs include:

- Average drayage distance per intermodal load

- Percentage of empty miles in the intermodal network

- Average container utilization or load factor

Monitoring these KPIs enables companies to identify inefficiencies and optimize their intermodal network for sustainability.

Emissions Intensity

Emissions intensity metrics provide a normalized view of a company’s intermodal emissions relative to business output. Important emissions intensity KPIs include:

- GHG emissions per revenue dollar

- GHG emissions per unit of production or sales volume

- GHG emissions per employee

Tracking emissions intensity KPIs helps companies assess the sustainability of their intermodal operations in the context of overall business performance.

By regularly monitoring these metrics and KPIs, companies can gain a clear understanding of the sustainability impact of their intermodal initiatives and make data-driven decisions to drive continuous improvement. It’s important to set specific, measurable targets for each KPI and to benchmark performance against industry peers and best practices.

In addition to internal tracking, companies should also consider external reporting of intermodal sustainability metrics through frameworks such as the Global Reporting Initiative (GRI) and the Carbon Disclosure Project (CDP). This transparency helps to build stakeholder trust and demonstrate a strong commitment to sustainable transportation practices.