What Is Drayage Equipment

What is Drayage Equipment and Why is it Important?

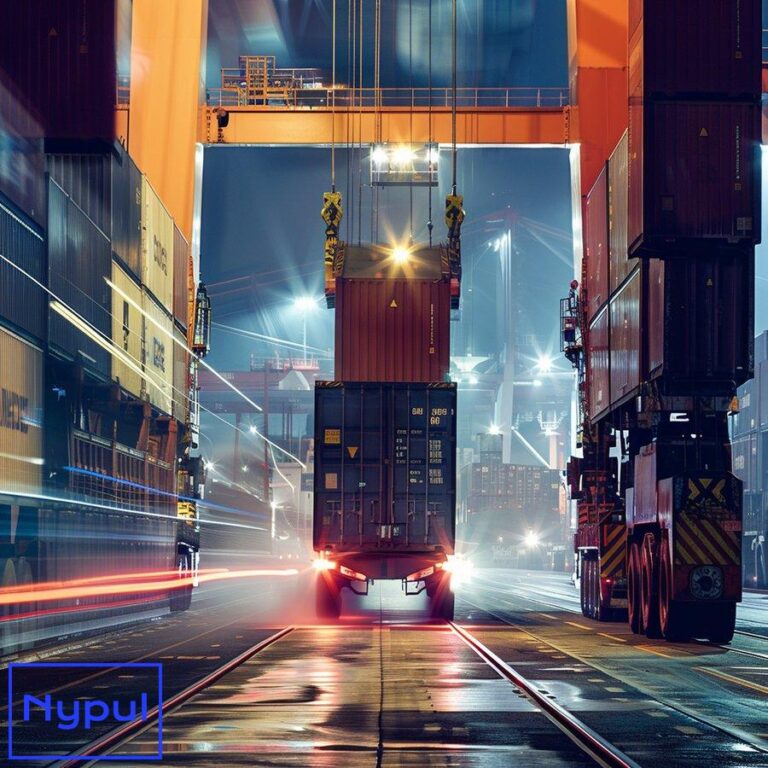

Drayage equipment is the backbone of the intermodal freight transportation industry, enabling the seamless movement of containerized cargo from ports, rail terminals, and warehouses to their final destinations. These specialized vehicles and tools are essential for efficiently transferring goods over short distances, ensuring timely deliveries and minimizing supply chain disruptions.

The importance of drayage equipment lies in its ability to connect different modes of transportation, such as ships, trains, and trucks, creating a cohesive supply chain. By utilizing drayage equipment, businesses can optimize their logistics operations, reduce costs, and improve overall efficiency.

What are the Different Types of Drayage Equipment?

Drayage operations rely on a variety of equipment to handle diverse cargo types and transportation requirements. The most common types of drayage equipment include:

Chassis

Chassis are the foundation of drayage operations, providing the base for containers to be transported by trucks. These specialized trailers are designed to accommodate various container sizes, including 20-foot, 40-foot, and 45-foot containers. Chassis are typically owned by ocean carriers or leasing companies and are interchangeable among drayage providers through the Uniform Intermodal Interchange and Facilities Access Agreement (UIIA).

| Chassis Type | Description |

|---|---|

| 20-foot Chassis | Designed for 20-foot containers |

| 40-foot Chassis | Designed for 40-foot containers |

| 45-foot Chassis | Designed for 45-foot containers |

| Extendable Chassis | Can accommodate both 20-foot and 40-foot containers |

Trucks and Tractors

Drayage operations rely on Class 8 trucks and tractors to haul containers over short distances. These powerful vehicles are equipped with the necessary equipment to connect to chassis and safely transport containerized cargo. Drayage drivers must possess a valid Commercial Driver’s License (CDL) to operate these trucks.

Specialized Equipment

Certain cargo types, such as oversized, heavy, or hazardous materials, require specialized equipment for safe transportation. Some examples of specialized drayage equipment include:

- Flatbed trailers for oversized or heavy cargo

- Tanker trucks for liquid or gas transportation

- Refrigerated trailers for temperature-sensitive goods

- Intermodal containers with built-in refrigeration units (reefers)

Lifting Equipment

Drayage operations often involve loading and unloading containers from chassis or rail cars. Specialized lifting equipment, such as forklifts, reach stackers, and gantry cranes, are used to efficiently handle these tasks, ensuring the safety of personnel and cargo.

Tracking and Monitoring Devices

To enhance visibility and efficiency, drayage equipment can be equipped with various tracking and monitoring devices. These include GPS trackers, sensors for temperature, humidity, and shock monitoring, and electronic logging devices (ELDs) to track driver hours of service.

By utilizing a diverse range of equipment, drayage providers can accommodate the unique requirements of each shipment, ensuring that cargo arrives at its destination safely and on time.

How Do Chassis and Containers Function in Drayage Operations?

Chassis and containers are the primary components of drayage operations, working together to facilitate the movement of goods from one mode of transportation to another.

Chassis

Chassis serve as the foundation for container transportation in drayage operations. They are designed to accommodate various container sizes and are equipped with features such as:

- Twist locks to secure the container

- Landing gear to support the chassis when not connected to a truck

- Brake systems and lights for safe operation on public roads

Chassis are typically owned by ocean carriers or leasing companies and are made available to drayage providers through interchange agreements. This interchangeability allows for efficient utilization of chassis across multiple drayage providers and locations.

Containers

Containers are the standardized units used for transporting goods in intermodal freight transportation. They come in various sizes, including 20-foot, 40-foot, and 45-foot, and can be made of steel, aluminum, or composite materials. Containers are designed to be easily transferable between different modes of transportation, such as ships, trains, and trucks.

During drayage operations, containers are loaded onto chassis at the port, rail terminal, or warehouse. The chassis-container combination is then transported by a drayage truck to its final destination or to another intermodal facility for further transportation.

The seamless integration of chassis and containers is crucial for efficient drayage operations, as it allows for the smooth transfer of cargo between different modes of transportation without the need for unpacking or repacking.

What Specialized Equipment is Used for Unique Cargo Types?

While standard drayage equipment is suitable for most containerized cargo, certain shipments require specialized equipment to ensure safe and efficient transportation. These unique cargo types include oversized, heavy, hazardous, and temperature-sensitive goods.

Oversized and Heavy Cargo

Oversized and heavy cargo, such as machinery, construction equipment, and large industrial parts, often exceeds the standard container dimensions or weight limits. To accommodate these shipments, drayage providers utilize specialized equipment, including:

- Flatbed trailers: These trailers have an open deck design that allows for the transportation of oversized cargo that cannot fit inside a container.

- Lowboy trailers: Also known as drop-deck trailers, these have a lower deck height compared to standard trailers, making them suitable for hauling tall or heavy equipment.

- Extendable trailers: These trailers can be extended to accommodate longer cargo, such as pipes or structural beams.

Hazardous Materials (HAZMAT)

The transportation of hazardous materials, such as chemicals, explosives, and radioactive substances, requires strict safety protocols and specialized equipment. Drayage providers that handle HAZMAT shipments must comply with various regulations and use dedicated equipment, including:

- Tanker trucks: These specialized trucks are designed to transport liquids, gases, and other hazardous materials in bulk.

- Placarded trailers: Trailers used for HAZMAT transportation are clearly marked with placards indicating the type of hazardous material being transported.

Temperature-Sensitive Cargo

Perishable goods, such as food, pharmaceuticals, and flowers, require temperature-controlled transportation to maintain product quality and safety. Drayage providers use specialized equipment to ensure the proper handling of these shipments, including:

- Refrigerated trailers (reefers): These trailers are equipped with built-in refrigeration units that maintain a specific temperature range during transportation.

- Intermodal refrigerated containers (reefers): These containers have integrated refrigeration systems that can be powered by electricity or diesel fuel, allowing for temperature-controlled transportation across different modes.

By utilizing specialized equipment tailored to unique cargo types, drayage providers can ensure the safe and efficient transportation of goods, minimizing the risk of damage or loss and maintaining product integrity throughout the supply chain.

How Does Technology Enhance Drayage Equipment Efficiency?

Technology plays a crucial role in enhancing the efficiency and performance of drayage equipment. By incorporating various technological solutions, drayage providers can optimize operations, improve visibility, and enhance safety.

Telematics and GPS Tracking

Telematics systems, which combine GPS tracking and onboard diagnostics, are widely used in drayage equipment to monitor vehicle performance and location. These systems provide real-time data on factors such as fuel consumption, engine diagnostics, and driver behavior, enabling drayage providers to optimize fleet management and maintenance.

![]()

GPS tracking, in particular, enhances visibility throughout the supply chain by providing accurate location data for drayage equipment. This information helps drayage providers communicate with customers, monitor delivery times, and respond quickly to any delays or disruptions.

Electronic Logging Devices (ELDs)

Electronic Logging Devices (ELDs) are mandatory for drayage operations in many countries, as they help ensure compliance with hours-of-service regulations for commercial drivers. ELDs automatically record driving time, enabling drayage providers to monitor driver activity and ensure compliance with safety regulations.

Automated Container Handling

Ports and intermodal facilities are increasingly adopting automated container handling systems to streamline drayage operations. These systems use advanced technologies, such as automated stacking cranes, automated guided vehicles (AGVs), and robotic systems, to efficiently load, unload, and stack containers.

Automated container handling reduces the need for manual labor, improves safety by minimizing human-equipment interactions, and increases throughput by optimizing container storage and retrieval.

Blockchain and Smart Contracts

Blockchain technology is being explored in the drayage industry to enhance transparency, security, and efficiency in intermodal freight transportation. By creating a decentralized, tamper-proof record of transactions and events, blockchain can help streamline processes such as container tracking, payment processing, and dispute resolution.

Smart contracts, which are self-executing agreements embedded in blockchain, can automate various aspects of drayage operations, such as container release, chassis allocation, and demurrage fee calculations. This automation reduces the potential for errors and disputes while improving efficiency and transparency throughout the supply chain.

By embracing technological advancements, drayage providers can enhance the performance and efficiency of their equipment, leading to improved supply chain outcomes and better service for their customers.

What are the Key Maintenance and Safety Considerations for Drayage Equipment?

Proper maintenance and safety protocols are critical for ensuring the reliable performance and longevity of drayage equipment. Drayage providers must adhere to strict maintenance schedules and safety standards to minimize downtime, reduce the risk of accidents, and comply with regulatory requirements.

Preventive Maintenance

Regular preventive maintenance is essential for maintaining the optimal performance and condition of drayage equipment. This includes:

- Routine inspections of chassis, trucks, and other equipment

- Scheduled replacement of wear-and-tear components, such as tires, brakes, and lighting systems

- Lubrication and fluid changes at recommended intervals

- Cleaning and corrosion prevention measures

By implementing a comprehensive preventive maintenance program, drayage providers can extend the lifespan of their equipment, reduce the likelihood of breakdowns, and ensure the safety of their operations.

Safety Inspections and Compliance

Drayage equipment must undergo regular safety inspections to comply with various regulations and ensure the safety of personnel and cargo. These inspections typically include:

- Pre-trip and post-trip inspections by drivers

- Periodic inspections by certified mechanics

- Compliance with federal, state, and local regulations, such as the Federal Motor Carrier Safety Administration (FMCSA) regulations in the United States

Drayage providers must also ensure that their equipment meets specific safety standards, such as the Container-Chassis Inspection Program (C-CIP) in the United States, which sets guidelines for the inspection and maintenance of chassis.

Driver Training and Certification

Drayage operations rely on skilled and trained drivers to safely operate drayage equipment. Drayage providers must ensure that their drivers possess the necessary certifications, such as a Commercial Driver’s License (CDL), and provide ongoing training on topics such as:

- Safe driving practices

- Proper loading and unloading techniques

- Hazardous materials handling (if applicable)

- Emergency response procedures

By prioritizing maintenance and safety, drayage providers can ensure the reliable performance of their equipment, protect their personnel and cargo, and maintain compliance with regulatory requirements.

How Does Drayage Equipment Impact Supply Chain Performance?

Drayage equipment plays a crucial role in the overall performance and efficiency of the supply chain. By optimizing the use of drayage equipment, businesses can improve delivery times, reduce costs, and enhance customer satisfaction.

Improved Delivery Times

Efficient drayage operations, enabled by well-maintained equipment and skilled drivers, can significantly reduce transit times for containerized cargo. By minimizing delays at ports, rail terminals, and warehouses, drayage providers can ensure that goods reach their final destinations more quickly, allowing businesses to meet customer demands and reduce inventory holding costs.

Cost Savings

Optimizing the use of drayage equipment can lead to significant cost savings for businesses. By reducing the need for storage at ports or rail terminals, minimizing the risk of demurrage and detention fees, and improving overall efficiency, drayage providers can help businesses minimize their logistics expenses.

Enhanced Visibility and Reliability

Drayage equipment equipped with tracking and monitoring devices can provide real-time visibility into the location and condition of cargo throughout the supply chain. This enhanced visibility allows businesses to make informed decisions, respond quickly to any disruptions, and improve overall reliability.

Sustainability and Environmental Impact

Many drayage providers are investing in eco-friendly equipment, such as alternative-fuel vehicles and low-emission chassis, to reduce their environmental impact. By utilizing sustainable drayage equipment, businesses can demonstrate their commitment to sustainability and contribute to a greener supply chain.

By optimizing the use of drayage equipment and embracing technological advancements, businesses can enhance the overall performance and resilience of their supply chains, ultimately leading to improved customer satisfaction and a competitive advantage in the market.