What Is Drayage in Shipping

What is drayage and why is it important in shipping?

Drayage refers to the transport of goods over a short distance, typically as part of a longer shipping process. It plays a vital role in the logistics and supply chain industries, serving as a bridge between various modes of transportation, such as from a port to a warehouse or from a rail terminal to a distribution center.

The significance of drayage lies in its ability to facilitate the smooth transition of cargo, ensuring that goods arrive at their final destination efficiently and on time. This process is crucial for maintaining the flow of goods in global trade, impacting everything from inventory management to customer satisfaction.

Drayage services are essential for several reasons:

-

Efficiency: Drayage minimizes delays in the supply chain by providing quick transport solutions for short distances.

-

Flexibility: It allows for the integration of different transportation modes, accommodating various shipping needs.

-

Cost-Effectiveness: By optimizing the movement of goods, drayage can help reduce overall shipping costs.

-

Inventory Management: Timely drayage services ensure that inventory levels are maintained, preventing stockouts or overstock situations.

Understanding drayage is fundamental for businesses involved in shipping, as it directly influences operational efficiency and customer satisfaction.

What are the different types of drayage services?

![]()

Drayage services can be categorized into several types, each tailored to specific transportation needs. Recognizing these types helps businesses choose the right service for their logistics operations.

Intermodal Drayage: This service involves the transfer of containers between different transportation modes, such as from ship to rail or truck. It is essential for moving goods across long distances while utilizing the strengths of each mode.

Pier Drayage: This type focuses on transporting cargo from the port to nearby warehouses or distribution centers. It is crucial for managing port congestion and ensuring timely delivery.

Intra-Carrier Drayage: This service is used when goods need to be moved within the same carrier’s network. It simplifies logistics by keeping the cargo under one provider’s management.

Expedited Drayage: For urgent shipments, expedited drayage offers faster transport solutions, often at a premium cost. This service is vital for time-sensitive deliveries.

Transloading Drayage: This involves transferring cargo from one container to another, often necessary when changing transportation modes. It is essential for optimizing space and ensuring the right equipment is used for the journey.

Dedicated Drayage: This service provides exclusive use of a vehicle for a specific shipment, ensuring that the cargo is prioritized and delivered without delays.

Understanding these types of drayage services allows businesses to select the most appropriate option based on their shipping requirements.

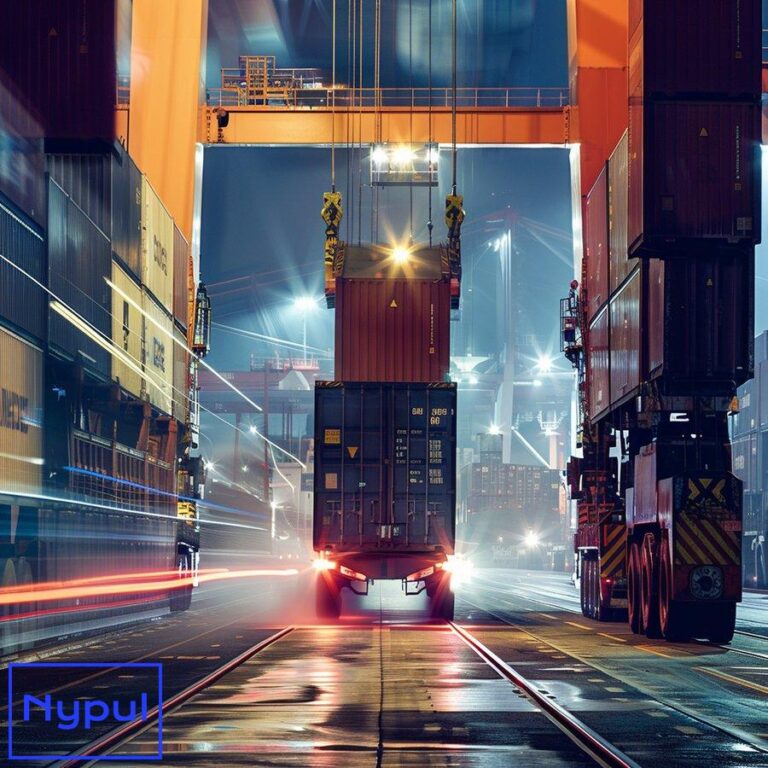

How does the drayage process work in the supply chain?

The drayage process is a critical component of the overall supply chain, involving several key steps that ensure the efficient movement of goods.

![]()

![]()

Step 1: Booking and Planning

The process begins with the booking of drayage services. Shippers must provide details about the cargo, including size, weight, and destination. Effective planning is essential to coordinate schedules and resources.

Step 2: Pickup

Once the booking is confirmed, the drayage provider arranges for the pickup of the cargo from the origin point, which could be a port, rail terminal, or warehouse. Timely pickup is crucial to avoid delays.

Step 3: Transportation

The cargo is then transported over a short distance to its next destination. This step may involve navigating through urban areas, which can present challenges such as traffic congestion.

Step 4: Delivery

Upon arrival at the destination, the cargo is unloaded and transferred to the next mode of transportation or directly to the customer. Proper handling during this step is vital to prevent damage.

Step 5: Documentation and Billing

Finally, the drayage provider completes the necessary documentation and billing processes. Accurate record-keeping is essential for tracking shipments and ensuring payment.

This structured approach to drayage ensures that goods move seamlessly through the supply chain, minimizing delays and enhancing overall efficiency.

What equipment and technology are used in drayage operations?

Drayage operations rely on a variety of equipment and technology to facilitate the efficient movement of goods. Understanding these tools is essential for optimizing logistics processes.

Trucks: The backbone of drayage services, trucks are used to transport cargo over short distances. Different types of trucks, such as flatbeds, container chassis, and refrigerated units, are employed based on the nature of the cargo.

Trailers: Specialized trailers are often used to accommodate specific types of cargo, ensuring safe and efficient transport.

Cranes and Forklifts: Heavy equipment like cranes and forklifts are essential for loading and unloading cargo at ports and warehouses. These machines help handle large containers and pallets efficiently.

Container Management Systems: Technology plays a crucial role in drayage operations. Container management systems help track cargo movement, manage inventory, and optimize routing.

GPS and Fleet Management Software: These tools enhance visibility and control over the drayage process. They allow operators to monitor vehicle locations, manage schedules, and improve overall efficiency.

Electronic Data Interchange (EDI): EDI facilitates seamless communication between shippers, carriers, and logistics providers. It streamlines documentation processes and enhances collaboration across the supply chain.

Utilizing the right equipment and technology is vital for ensuring that drayage operations run smoothly and efficiently.

What are the main challenges faced in drayage logistics?

Drayage logistics is not without its challenges, which can impact efficiency and service quality. Identifying and addressing these challenges is crucial for successful operations.

Traffic Congestion: Urban areas often experience heavy traffic, leading to delays in cargo pickup and delivery. This congestion can disrupt schedules and increase operational costs.

Port Congestion: High volumes of cargo at ports can lead to delays in loading and unloading containers. This congestion can create bottlenecks in the supply chain.

Regulatory Compliance: Drayage operators must navigate a complex landscape of regulations, including weight limits, safety standards, and environmental regulations. Non-compliance can result in fines and operational disruptions.

Equipment Availability: The availability of trucks and trailers can be a challenge, especially during peak shipping seasons. Limited equipment can lead to delays and increased costs.

Labor Shortages: The logistics industry faces ongoing labor shortages, affecting the availability of qualified drivers and support staff. This shortage can impact service levels and operational efficiency.

Cost Fluctuations: Fluctuating fuel prices and operational costs can affect the pricing of drayage services. Businesses must be prepared to manage these changes to maintain profitability.

Addressing these challenges requires proactive planning and strategic partnerships within the logistics ecosystem.

How do costs and pricing work in drayage services?

Understanding the costs and pricing structure of drayage services is essential for businesses looking to manage their logistics expenses effectively. Several factors influence the pricing of drayage services.

Distance: The distance between the pickup and delivery points is a primary factor in determining costs. Longer distances typically result in higher charges.

Type of Cargo: The nature of the cargo, including its size, weight, and handling requirements, can significantly impact pricing. Specialized cargo may incur additional fees.

Service Type: Different types of drayage services come with varying price points. For example, expedited services often carry a premium compared to standard options.

Fuel Costs: Fluctuations in fuel prices can affect overall transportation costs. Drayage providers may adjust their pricing based on current fuel rates.

Equipment Fees: Charges for the use of specialized equipment, such as cranes or refrigerated trailers, can add to the overall cost of drayage services.

Accessorial Charges: Additional fees may apply for services such as loading and unloading, waiting time, or storage. These charges should be clearly outlined in service agreements.

To provide clarity, the following table summarizes the primary factors influencing drayage pricing:

| Factor | Description |

|---|---|

| Distance | Longer distances result in higher costs. |

| Type of Cargo | Specialized cargo may incur additional fees. |

| Service Type | Expedited services typically cost more. |

| Fuel Costs | Fluctuating fuel prices impact overall transportation costs. |

| Equipment Fees | Charges for specialized equipment add to costs. |

| Accessorial Charges | Additional fees for services like loading and unloading. |

Understanding these cost components enables businesses to budget effectively for drayage services.

What factors should be considered when selecting a drayage provider?

Choosing the right drayage provider is critical for ensuring efficient logistics operations. Several factors should be evaluated to make an informed decision.

Experience and Reputation: A provider’s experience in the industry and reputation for reliability are essential indicators of service quality. Researching customer reviews and testimonials can provide valuable insights.

Service Offerings: Consider the range of services offered by the provider. A versatile provider can accommodate various shipping needs, including intermodal, expedited, and transloading services.

Technology and Equipment: Evaluate the technology and equipment used by the provider. Advanced tracking systems and well-maintained vehicles contribute to operational efficiency and cargo safety.

Pricing Structure: Understanding the provider’s pricing model is crucial for budgeting. Ensure that all potential fees are clearly outlined in service agreements to avoid unexpected costs.

Geographic Coverage: Assess the provider’s geographic reach. A provider with a broad service area can better accommodate diverse shipping needs.

Customer Support: Reliable customer support is essential for addressing issues that may arise during the shipping process. Evaluate the provider’s responsiveness and availability.

Compliance and Safety Standards: Ensure that the provider adheres to industry regulations and safety standards. Compliance is vital for minimizing risks and ensuring smooth operations.

By considering these factors, businesses can select a drayage provider that aligns with their logistics needs and enhances overall supply chain efficiency.