What Is the Difference Between Dry Van and Drayage

What is Dry Van Shipping?

Dry van shipping is a widely utilized method within the logistics and transportation sector, characterized by the use of enclosed trailers designed to transport goods that are not temperature-sensitive. This method is particularly favored for its ability to protect cargo from external elements, ensuring that products arrive at their destination in optimal condition.

****Definition and Characteristics

Dry vans are typically 53 feet long and can carry a maximum weight of approximately 45,000 to 48,000 pounds. They are constructed from durable materials, often aluminum or steel, providing a robust barrier against weather and road conditions. The enclosed nature of dry vans makes them suitable for transporting a variety of goods, including:

- Consumer products

- Electronics

- Clothing

- Non-perishable food items

****Operational Aspects

The operation of dry van shipping involves several key steps:

-

Loading and Unloading: Goods are loaded into the dry van at the origin point and unloaded at the destination. This process can involve various equipment such as forklifts and pallet jacks, depending on the nature of the cargo.

-

Transportation: Once loaded, the dry van is transported via truck to the destination. This journey can vary in length, from short regional trips to long-haul national routes.

-

Delivery: Upon arrival, the cargo is unloaded, and the dry van is either returned to the shipping company or reloaded for another trip.

Dry van shipping is integral to the supply chain, offering a reliable means of transporting goods across various distances while ensuring safety and security.

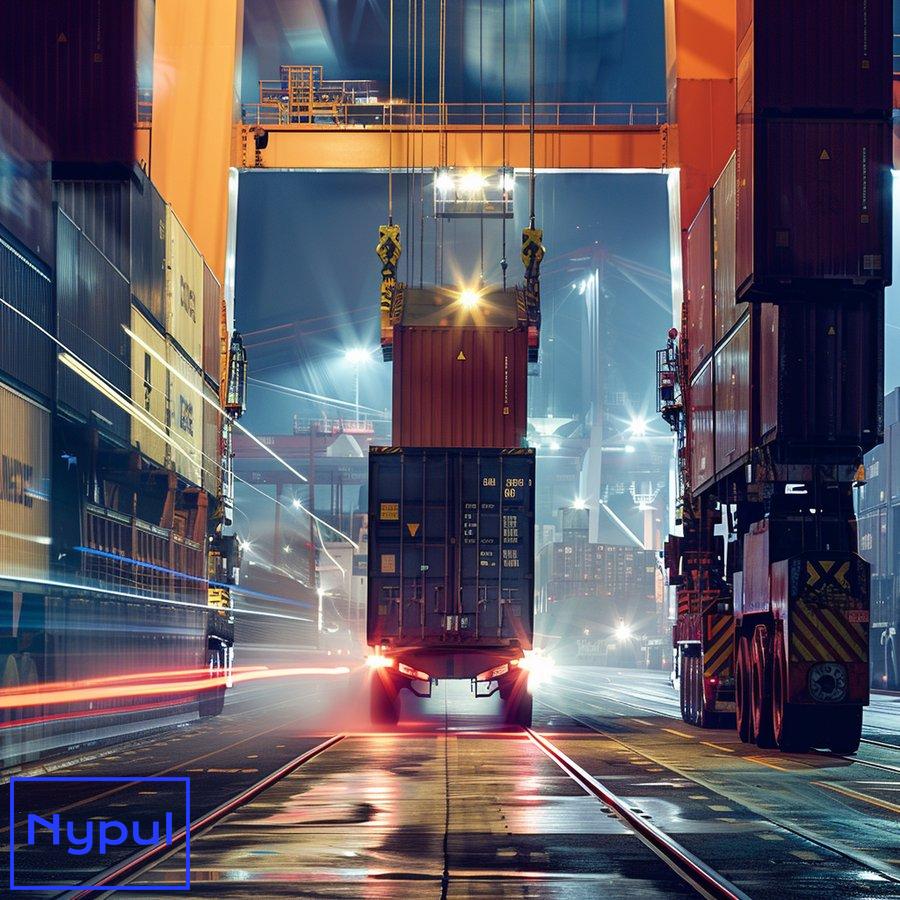

How Does Drayage Differ from Dry Van Transport?

Drayage refers to the short-distance transportation of goods, typically involving the movement of containers to and from ports, rail yards, and warehouses. While both drayage and dry van transport are essential components of the logistics industry, they serve different purposes and operate under distinct circumstances.

****Definition and Scope

Drayage is characterized by:

-

Short Distances: Usually limited to a radius of 150 miles, drayage is focused on local transportation needs, often within metropolitan areas.

-

Containerized Cargo: Drayage primarily involves transporting shipping containers, which are often transferred from ships to trucks or rail.

In contrast, dry van transport is designed for longer distances and can accommodate a broader range of cargo types.

****Key Differences

| Aspect | Dry Van Transport | Drayage |

|---|---|---|

| Distance | Long-haul, regional, or national | Short-distance, typically under 150 miles |

| Cargo Type | Non-perishable goods, general freight | Containerized cargo |

| Loading/Unloading | At warehouses or distribution centers | At ports, rail yards, or warehouses |

| Equipment Used | Dry vans (enclosed trailers) | Flatbeds, chassis, or container trucks |

The differences between these two methods highlight their unique roles in the supply chain, with dry van transport focusing on longer journeys and drayage addressing local movements.

What Types of Cargo are Best Suited for Dry Van vs. Drayage?

Selecting the appropriate transportation method depends significantly on the type of cargo being shipped. Understanding the characteristics of both dry van and drayage services can help businesses optimize their logistics strategies.

****Cargo Best Suited for Dry Van Shipping

Dry van shipping is ideal for a variety of cargo types, including:

-

Consumer Goods: Products such as clothing, household items, and electronics can be effectively transported in dry vans due to their enclosed nature.

-

Non-Perishable Food Items: Items that do not require refrigeration benefit from the protection provided by dry vans.

-

Industrial Equipment: Machinery and tools can be securely transported without exposure to elements.

****Cargo Best Suited for Drayage

Drayage is particularly effective for:

-

Shipping Containers: Drayage is specifically designed to move containers from ports to warehouses or rail yards.

-

High-Value Goods: Items that require quick turnaround or are time-sensitive often utilize drayage services to minimize delays.

-

Bulk Cargo: Drayage can efficiently handle bulk shipments that need to be moved quickly over short distances.

Understanding the types of cargo best suited for each method allows companies to make informed decisions, ensuring the safe and efficient transport of their products.

How Do Costs Compare Between Dry Van and Drayage Services?

Cost considerations play a pivotal role in determining the most suitable transportation method for businesses. Both dry van and drayage services have unique pricing structures influenced by various factors.

****Cost Factors for Dry Van Shipping

The costs associated with dry van shipping can include:

-

Fuel Charges: Fluctuating fuel prices can significantly impact overall shipping costs.

-

Distance Traveled: Longer distances typically result in higher transportation fees.

-

Loading and Unloading Fees: Charges may apply for the handling of cargo at loading docks or warehouses.

-

Insurance: Protecting valuable cargo can add to the overall cost.

****Cost Factors for Drayage

Drayage costs are influenced by:

-

Short-Distance Rates: Drayage services often charge a flat rate for short distances, making it a cost-effective option for local deliveries.

-

Container Handling Fees: Additional charges may apply for loading and unloading containers at ports or rail yards.

-

Turnaround Time: Delays can lead to increased costs, especially if containers are not moved promptly.

The following table summarizes the cost comparison between dry van and drayage services:

| Cost Factor | Dry Van Shipping | Drayage |

|---|---|---|

| Fuel Charges | Variable, based on distance | Lower, due to short distances |

| Distance Traveled | Higher costs for longer trips | Flat rates for local deliveries |

| Loading/Unloading Fees | Applicable | Often included in drayage rates |

| Insurance | Necessary for valuable cargo | May vary based on container value |

Understanding these cost factors helps businesses assess their budget and choose the most economical shipping option.

What Challenges Are Unique to Dry Van and Drayage Operations?

Both dry van and drayage operations face distinct challenges that can impact efficiency and service quality. Recognizing these challenges is essential for logistics professionals to develop effective strategies.

****Challenges in Dry Van Shipping

-

Traffic Congestion: Long-haul routes can encounter significant traffic, leading to delays and increased fuel costs.

-

Regulatory Compliance: Adhering to transportation regulations, including weight limits and safety standards, can complicate operations.

-

Weather Conditions: Adverse weather can affect delivery schedules and cargo safety.

****Challenges in Drayage

-

Port Congestion: Delays at ports can lead to increased turnaround times and additional costs.

-

Container Availability: Limited availability of containers can hinder the efficiency of drayage operations.

-

Coordination with Multiple Parties: Drayage often involves coordination between shipping lines, trucking companies, and warehouses, which can complicate logistics.

Addressing these challenges requires careful planning and collaboration among stakeholders to ensure smooth operations.

How Do Dry Van and Drayage Services Impact Supply Chain Efficiency?

The efficiency of supply chain operations is heavily influenced by the choice between dry van and drayage services. Each method plays a significant role in the overall logistics strategy.

****Impact of Dry Van Shipping on Supply Chain Efficiency

-

Reliability: Dry van shipping provides a dependable means of transporting goods over long distances, ensuring timely deliveries.

-

Versatility: The ability to transport a wide range of cargo types allows businesses to consolidate shipments, reducing costs and improving efficiency.

-

Reduced Handling: With fewer touchpoints during transportation, dry van shipping minimizes the risk of damage to goods.

****Impact of Drayage on Supply Chain Efficiency

-

Speed: Drayage services enable quick transportation of containers, facilitating faster turnaround times for shipments.

-

Local Accessibility: The short-distance nature of drayage allows for efficient movement of goods within metropolitan areas, enhancing distribution capabilities.

-

Flexibility: Drayage can adapt to changing logistics needs, providing businesses with the agility required to respond to market demands.

Understanding how these services impact supply chain efficiency enables companies to optimize their logistics strategies, ultimately enhancing customer satisfaction.

Key Considerations for Choosing Between Dry Van and Drayage

Selecting the appropriate transportation method involves careful consideration of various factors. Businesses must evaluate their specific needs to make informed decisions.

****Cargo Type and Volume

Understanding the nature of the cargo is essential. Businesses should consider whether their goods are best suited for dry van shipping or drayage based on the following:

-

Type of Cargo: Assess whether the cargo is temperature-sensitive or requires special handling.

-

Volume of Cargo: Determine if the shipment volume justifies the use of a dry van or if drayage is more appropriate for smaller, containerized shipments.

****Distance and Delivery Time

The distance between the origin and destination plays a critical role in the decision-making process:

-

Long-Distance Needs: If the shipment requires long-haul transport, dry van shipping is the preferred option.

-

Local Deliveries: For short-distance moves, drayage services offer a more efficient solution.

****Cost Considerations

Evaluating the overall costs associated with each method is vital:

-

Budget Constraints: Businesses should assess their budget and determine which option provides the best value for their specific needs.

-

Hidden Costs: Consider potential hidden costs, such as loading and unloading fees or delays, that could impact the overall expense.

By carefully considering these factors, businesses can make informed decisions that align with their logistics goals and enhance their supply chain operations.