What Is the Standard Intermodal Container

What is an intermodal container and why is it important?

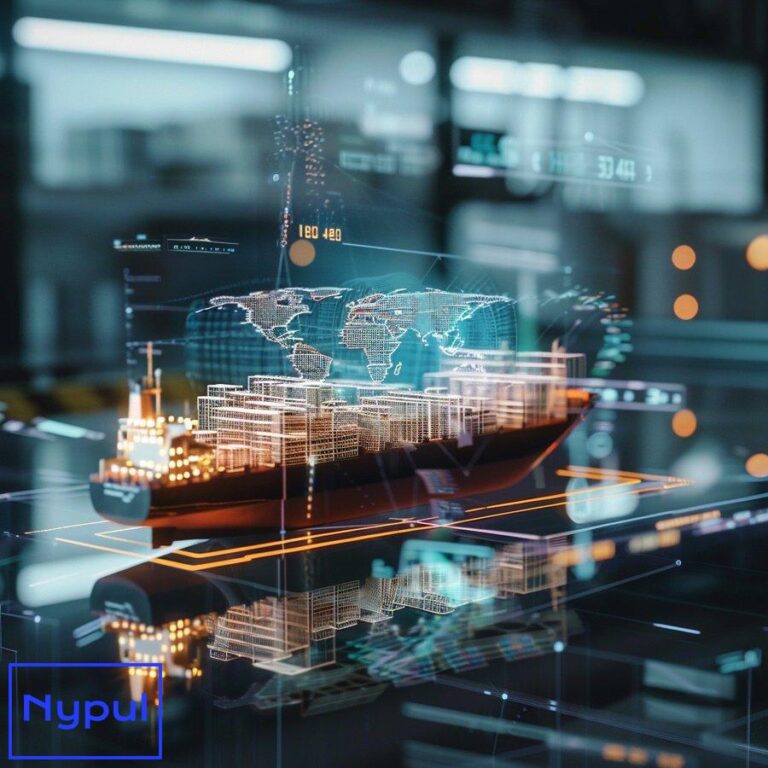

An intermodal container, also known as a shipping container or freight container, is a standardized, reusable steel box designed for the efficient transportation of goods by multiple modes of transportation, including ships, trains, and trucks. These containers are built to withstand the rigors of intermodal transportation and are designed to be easily handled, moved, and stacked.

The importance of intermodal containers cannot be overstated. They have revolutionized the global supply chain and have made international trade more efficient, cost-effective, and secure. By allowing goods to be transported in a single container from the point of origin to the final destination, intermodal containers have reduced handling costs, transit times, and the risk of damage or theft.

The standardization of intermodal containers has also enabled the development of specialized equipment and infrastructure, such as container ships, gantry cranes, and intermodal terminals, which have further streamlined the transportation process. The widespread adoption of intermodal containers has been a key driver of globalization, allowing businesses to source materials and sell products worldwide more easily.

What are the ISO standards for intermodal containers?

The International Organization for Standardization (ISO) has developed a series of standards to ensure the compatibility and safety of intermodal containers across different transportation modes and regions. The most relevant ISO standards for intermodal containers include:

- ISO 668: Specifies the classification, dimensions, and ratings of intermodal containers.

- ISO 1496: Specifies the requirements and testing procedures for different types of intermodal containers.

- ISO 6346: Establishes a system for coding, identification, and marking of intermodal containers.

These standards ensure that intermodal containers meet certain criteria for strength, durability, and safety, and that they can be easily handled and transported using standardized equipment and infrastructure. By adhering to ISO standards, intermodal containers can be seamlessly integrated into global supply chains, regardless of their origin or destination.

What are the common types and sizes of standard intermodal containers?

The most common types of intermodal containers are:

-

Dry freight containers: These are the most widely used type of intermodal containers and are designed for the transportation of general cargo. They are available in various sizes, with the most common being 20 feet and 40 feet in length.

-

Refrigerated containers: Also known as reefers, these containers are equipped with refrigeration units and are used for the transportation of perishable goods, such as food and pharmaceuticals.

-

Tank containers: These specialized containers are designed for the transportation of liquids, gases, and powders, and are often used in the chemical and petrochemical industries.

-

Open-top containers: These containers have removable roofs and are used for the transportation of oversized or heavy cargo that cannot be loaded from the top.

-

Flat rack containers: These containers have collapsible sides and are used for the transportation of heavy or oversized cargo that cannot be loaded from the top or sides.

The most common sizes of intermodal containers are:

| Size | Length | Width | Height | Capacity |

|---|---|---|---|---|

| 20 feet | 20 ft | 8 ft | 8 ft 6 in | 1,169 ft³ |

| 40 feet | 40 ft | 8 ft | 8 ft 6 in | 2,390 ft³ |

| 40 feet high cube | 40 ft | 8 ft | 9 ft 6 in | 2,660 ft³ |

The choice of container size depends on factors such as the volume and weight of the cargo, the available transportation equipment, and the specific requirements of the shipper and consignee.

What are the key technical specifications of standard containers?

Intermodal containers are designed to meet specific technical specifications to ensure their compatibility with transportation equipment and infrastructure. Some of the key technical specifications include:

-

Corner fittings: These are metal fittings located at each of the eight corners of the container and are used for lifting, stacking, and securing the container.

-

Door fittings: These include the door hinges, locking mechanisms, and seals, which are designed to provide a secure and weatherproof closure for the container.

-

Floor strength: The floor of the container must be strong enough to support the weight of the cargo and any handling equipment, such as forklifts.

-

Racking strength: The container must be able to withstand the forces exerted during transportation, such as acceleration, deceleration, and cornering, without deforming or collapsing.

-

Stacking strength: Intermodal containers must be able to support the weight of other containers stacked on top of them, both when loaded and empty.

-

Weatherproofing: The container must be designed to protect the cargo from the elements, such as rain, wind, and dust, during transportation and storage.

These technical specifications are defined in ISO standards and are regularly tested and verified to ensure the safety and reliability of intermodal containers.

How are intermodal containers constructed and marked?

Intermodal containers are typically constructed from Corten steel, which is a type of weathering steel that forms a protective oxide layer when exposed to the elements. The steel panels are welded together to form the body of the container, with reinforced corners and door fittings.

The doors of the container are usually made from steel or aluminum and are designed to provide a secure and weatherproof closure. The door hinges and locking mechanisms are also made from steel and are designed to withstand the stresses of repeated opening and closing.

The interior of the container may be lined with plywood, aluminum, or other materials to protect the cargo from damage and to provide additional strength and rigidity.

Intermodal containers are marked with a unique identification number, known as a BIC code, which is assigned by the Bureau International des Containers (BIC). The BIC code is printed on the container in large letters and numbers and is used for tracking and identification purposes.

Other markings on the container may include:

- Ownership markings: Indicating the owner of the container.

- Safety approval plates: Indicating that the container has been inspected and approved for safe transportation.

- Hazard labels: Indicating the presence of hazardous materials in the container.

- Handling symbols: Indicating the proper way to handle and move the container.

These markings are designed to provide important information about the container and its contents to transportation workers, customs officials, and other stakeholders in the supply chain.

How do standard containers ensure compatibility across transportation modes?

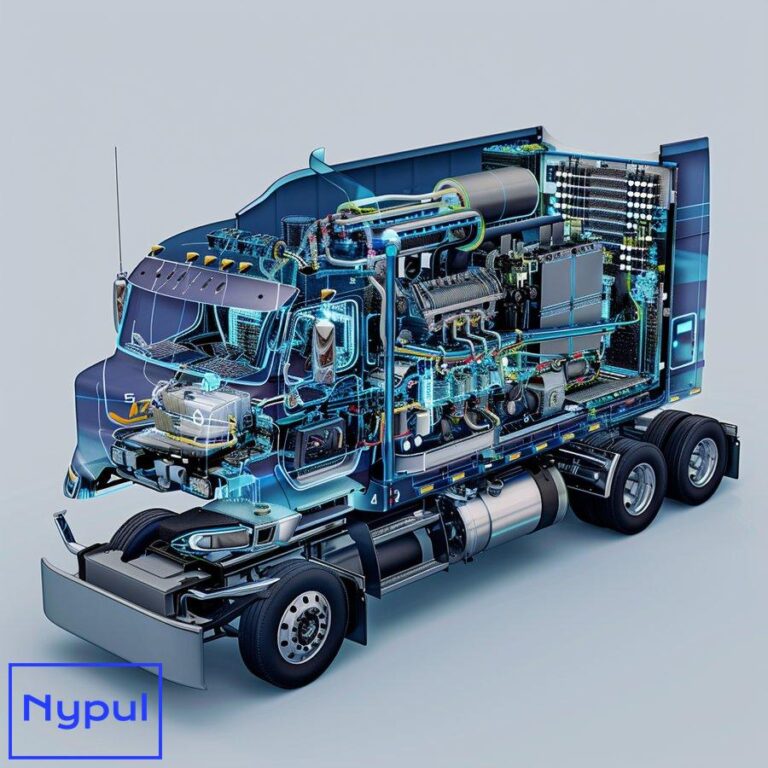

Intermodal containers are designed to be compatible with a wide range of transportation equipment and infrastructure, including ships, trains, and trucks. This compatibility is achieved through the use of standardized dimensions, fittings, and handling procedures.

The most common sizes of intermodal containers, such as 20 feet and 40 feet, are designed to fit within the dimensions of standard transportation equipment, such as ship holds, train cars, and truck trailers. This ensures that the containers can be easily loaded and unloaded without the need for specialized equipment or modifications.

The corner fittings of the container are designed to be compatible with the twistlocks and spreader bars used by container handling equipment, such as gantry cranes and reach stackers. This allows the containers to be lifted and moved quickly and efficiently, reducing handling times and costs.

The standardized lashing points and tie-down fittings on the container ensure that it can be securely fastened to the transportation equipment, preventing movement and damage during transportation.

The use of standardized procedures for loading, unloading, and securing intermodal containers also contributes to their compatibility across transportation modes. These procedures are defined in industry guidelines and regulations, and are followed by transportation workers and equipment operators to ensure the safe and efficient movement of containers.

What specialized variations of standard containers exist?

While the standard intermodal container sizes and types are widely used, there are also specialized variations designed for specific applications or cargo types. Some examples include:

-

Insulated containers: These containers are designed for the transportation of temperature-sensitive cargo, such as pharmaceuticals or chemicals, and are equipped with insulation panels to maintain a stable temperature.

-

Ventilated containers: These containers are designed for the transportation of cargo that requires ventilation, such as fresh produce or chemicals, and are equipped with vents or fans to circulate air.

-

Bulk containers: These containers are designed for the transportation of loose, granular cargo, such as grains or minerals, and are equipped with discharge hatches or liners to facilitate unloading.

-

Flat rack containers: These containers are designed for the transportation of oversized or heavy cargo that cannot be loaded from the top or sides, and are equipped with collapsible sides or ends to facilitate loading and unloading.

-

Platform containers: These containers are designed for the transportation of wheeled cargo, such as automobiles or construction equipment, and are equipped with a flat platform or deck for loading and securing the cargo.

These specialized containers are designed to meet the specific requirements of different industries and cargo types, while still maintaining compatibility with standard intermodal transportation equipment and procedures.

How are intermodal containers maintained and inspected?

Intermodal containers require regular maintenance and inspection to ensure their continued safety and reliability. The maintenance and inspection of intermodal containers is governed by international regulations and industry guidelines, such as the International Convention for Safe Containers (CSC) and the ISO standards for freight containers.

The maintenance of intermodal containers typically includes:

- Routine cleaning: To remove dirt, debris, and corrosion from the exterior and interior of the container.

- Repair and replacement: Of damaged or worn components, such as door hinges, locking mechanisms, or floor boards.

- Painting and coating: To protect the container from weathering and corrosion.

Intermodal containers are also subject to regular inspections to ensure their compliance with safety and quality standards. These inspections are typically carried out by certified inspectors and may include:

- Pre-trip inspections: Conducted before the container is loaded and transported.

- In-service inspections: Conducted during the transportation process to identify any damage or defects.

- Periodic inspections: Conducted at regular intervals, such as every 30 months, to ensure the continued safety and reliability of the container.

The results of these inspections are recorded in the container’s maintenance log and are used to determine whether the container is fit for continued use or requires repair or replacement.

By maintaining and inspecting intermodal containers in accordance with industry standards and regulations, shippers and transportation providers can ensure the safe and reliable movement of cargo across global supply chains.