What Is a Drayage Driver

What is a Drayage Driver?

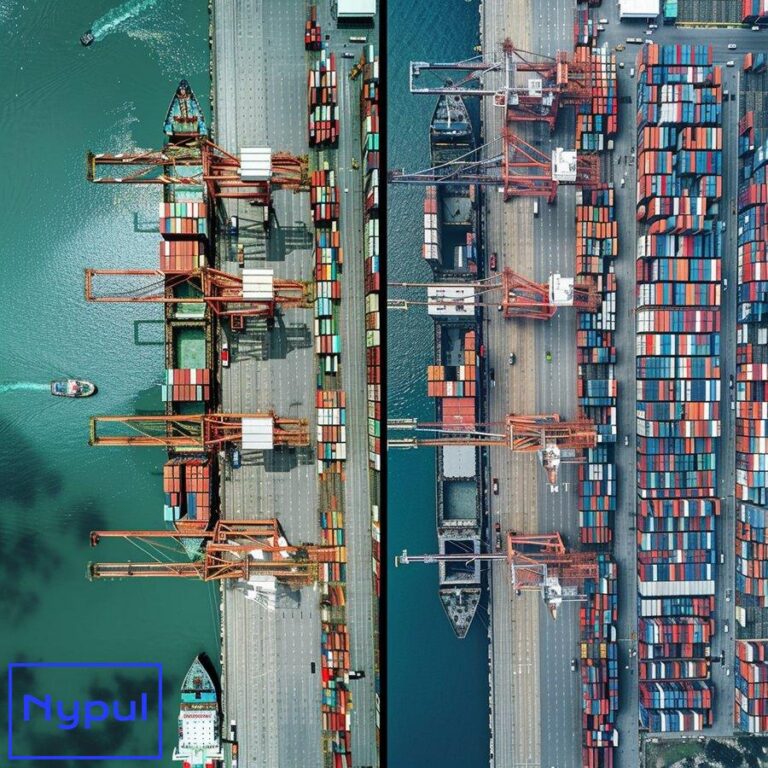

Drayage drivers are specialized truckers who transport shipping containers over short distances, typically between ports, rail yards, and local warehouses. These professionals play a vital role in the intermodal freight transportation system, serving as the crucial link between long-distance shipping methods and final destinations.

The term “drayage” originates from the old English word “dray,” referring to a low, sturdy cart used for heavy loads. In modern logistics, drayage has evolved to encompass the movement of containerized cargo across short distances, usually within a single metropolitan area.

Drayage drivers operate Class 8 trucks, also known as semi-trucks or tractor-trailers, equipped to haul standardized shipping containers. These containers, which can be easily transferred between ships, trains, and trucks, are the cornerstone of intermodal transportation.

The primary responsibilities of a drayage driver include:

Picking up containers: Drayage drivers collect containers from ports or rail yards, often navigating complex terminal operations and security procedures.

Transporting freight: They move containers to their designated locations, which may include distribution centers, warehouses, or manufacturing facilities.

Delivering cargo: Drivers ensure the safe and timely delivery of goods to their final destinations within the local area.

Managing documentation: Drayage drivers handle necessary paperwork, including customs documents, bills of lading, and delivery receipts.

Equipment maintenance: They are responsible for the upkeep and basic maintenance of their trucks and chassis.

Drayage operations are categorized into several types, each serving a specific function in the supply chain:

Inter-carrier drayage: Moving containers between different transportation carriers, such as from a shipping line to a railroad.

Intra-carrier drayage: Transporting containers within a single carrier’s network, often between different facilities or modes of transport.

Expedited drayage: Providing rapid container movement for time-sensitive cargo.

Shuttle drayage: Transferring containers between staging areas and shipping or receiving docks.

Pier drayage: Moving containers from a port to a rail terminal or nearby warehouse.

The role of drayage drivers is indispensable in maintaining the efficiency of global supply chains. They ensure the smooth transition of goods between long-haul transportation methods and local distribution networks, contributing significantly to the seamless flow of international trade.

As the demand for efficient logistics continues to grow, the importance of drayage drivers in the transportation ecosystem becomes increasingly apparent. Their work forms the foundation of the “last mile” delivery process, enabling businesses to meet consumer expectations for rapid and reliable product availability.

What Qualifications and Skills Do Drayage Drivers Need?

Drayage drivers require a specific set of qualifications and skills to perform their job effectively and safely. These requirements ensure that drivers can handle the unique challenges of short-haul container transportation and navigate the complex environments of ports and rail yards.

Educational Requirements

Formal education beyond a high school diploma or GED is not typically required for drayage drivers. However, some employers may prefer candidates with additional training or certifications related to logistics and transportation.

Licensing and Certifications

Commercial Driver’s License (CDL): A Class A CDL is mandatory for operating a tractor-trailer combination vehicle. This license requires passing both written and practical tests demonstrating knowledge of traffic laws, safe driving practices, and vehicle operation.

Transportation Worker Identification Credential (TWIC): Issued by the Transportation Security Administration (TSA), this credential is essential for accessing secure areas of maritime facilities and vessels.

Hazardous Materials Endorsement (HazMat): While not always required, this endorsement allows drivers to transport hazardous materials, expanding their job opportunities.

Port-specific credentials: Some ports may require additional certifications or registrations for drivers to access their facilities.

Skills and Abilities

Driving proficiency: Excellent driving skills are crucial, including the ability to maneuver large vehicles in tight spaces and heavy traffic.

Time management: Drayage drivers must efficiently plan routes and manage their time to meet strict delivery schedules.

Physical fitness: The job often involves physical labor, such as climbing in and out of trucks, securing loads, and occasionally assisting with loading and unloading.

Attention to detail: Accuracy in paperwork, cargo verification, and adherence to safety protocols is essential.

Communication skills: Drivers interact with various personnel, including dispatchers, port officials, and customers, requiring clear and effective communication.

Problem-solving abilities: Quick thinking and adaptability are necessary to handle unexpected situations like traffic delays or equipment issues.

Technology proficiency: Familiarity with GPS systems, electronic logging devices (ELDs), and other logistics software is increasingly important.

Physical Requirements

Vision: Good eyesight, with or without correction, is necessary for safe driving and reading documents.

Hearing: Drivers must be able to hear warning signals and communicate effectively.

Physical stamina: Long hours of sitting, combined with periods of physical activity, require good overall health and endurance.

Additional Qualifications

Clean driving record: Most employers require a clean driving record with no major violations or accidents within the past 3-5 years.

Drug and alcohol testing: Drivers must pass pre-employment and random drug and alcohol screenings.

Age requirement: While the minimum age for intrastate commercial driving is 18 in some states, most drayage jobs require drivers to be at least 21 years old to comply with interstate regulations.

Experience: Some companies prefer drivers with previous experience in trucking or logistics, though many offer entry-level positions with training.

The following table summarizes the key qualifications for drayage drivers:

| Qualification | Requirement |

|---|---|

| Education | High school diploma or GED (minimum) |

| License | Class A Commercial Driver’s License (CDL) |

| Certifications | TWIC, HazMat endorsement (optional) |

| Age | 21 years or older (typically) |

| Driving Record | Clean record for past 3-5 years |

| Physical | Pass DOT physical examination |

| Drug Testing | Pre-employment and random screenings |

Aspiring drayage drivers should focus on obtaining the necessary licenses and certifications while developing the skills and physical capabilities required for the job. As the industry evolves, staying updated with new technologies and regulations will be crucial for long-term success in this field.

How Does a Typical Day Look for a Drayage Driver?

A typical day in the life of a drayage driver is characterized by a mix of routine tasks and dynamic challenges. Unlike long-haul truckers, drayage drivers usually work within a localized area, allowing for more predictable schedules and the opportunity to return home each night. Here’s a breakdown of what a drayage driver might experience during a standard workday:

Early Morning Start

Drayage drivers often begin their day early, typically between 4:00 AM and 6:00 AM. This early start allows them to avoid peak traffic hours and maximize productivity.

Pre-trip Inspection

The day starts with a thorough pre-trip inspection of the truck and chassis. This crucial step ensures that all equipment is in proper working order and complies with safety regulations. The inspection includes:

Checking tire pressure and tread depth

Verifying that all lights and signals are functioning

Inspecting brakes and air lines

Ensuring the coupling system is secure

Reviewing fluid levels (oil, coolant, etc.)

Route Planning and Dispatch Communication

After the inspection, drivers review their assigned routes and communicate with dispatch to confirm the day’s schedule. They may use GPS systems or specialized logistics software to optimize their routes and estimate travel times.

First Pickup

The driver’s first task usually involves picking up a loaded container from a port, rail yard, or warehouse. This process includes:

Navigating terminal procedures and security checkpoints

Locating the assigned container

Inspecting the container for damage and ensuring proper sealing

Securing the container to the chassis

Completing necessary paperwork and electronic logging

Transportation to Destination

Once the container is secured, the driver transports it to its designated location. This could be a distribution center, manufacturing facility, or another intermodal terminal. During transit, the driver must:

Adhere to traffic laws and safety regulations

Monitor road conditions and adjust routes if necessary

Manage time effectively to meet delivery deadlines

Delivery and Unloading

Upon arrival at the destination, the driver coordinates with facility staff to unload the container. This may involve:

Backing the truck into a designated dock area

Overseeing the unloading process to ensure cargo safety

Obtaining necessary signatures and completing delivery documentation

Multiple Trips

Depending on the distance and efficiency of operations, a drayage driver may complete several pickup and delivery cycles in a single day. This repetition is a defining characteristic of drayage work, distinguishing it from long-haul trucking.

Equipment Return and Exchange

Throughout the day, drivers may need to return empty containers to ports or rail yards and exchange chassis as required by their assignments.

End-of-Day Procedures

As the workday concludes, typically in the late afternoon or early evening, the driver performs several wrap-up tasks:

Completing a post-trip inspection of the vehicle

Fueling the truck if necessary

Finalizing all electronic logs and paperwork

Communicating with dispatch about the day’s activities and preparing for the next day’s assignments

Continuous Communication

Throughout the day, drayage drivers maintain regular contact with dispatchers, terminal staff, and sometimes customers. This ongoing communication is essential for addressing any issues that arise and ensuring smooth operations.

Adaptability

While the above outlines a typical day, drayage drivers must be prepared for variations. Factors such as traffic congestion, port delays, or last-minute schedule changes can alter the day’s plan, requiring flexibility and quick problem-solving.

The following table illustrates a sample timeline for a drayage driver’s workday:

| Time | Activity |

|---|---|

| 5:00 AM | Begin workday, pre-trip inspection |

| 5:30 AM | Route planning and dispatch communication |

| 6:00 AM | Arrive at port for first pickup |

| 7:00 AM | Depart port with loaded container |

| 8:00 AM | Arrive at distribution center for delivery |

| 9:00 AM | Return to port for second pickup |

| 10:00 AM | Transport container to manufacturing facility |

| 11:30 AM | Lunch break |

| 12:30 PM | Pick up empty container for return to port |

| 1:30 PM | Collect new load from rail yard |

| 2:30 PM | Deliver to local warehouse |

| 4:00 PM | Final return to port with empty container |

| 5:00 PM | End-of-day procedures and preparation for next day |

This schedule demonstrates the dynamic nature of drayage work, with multiple pickups and deliveries occurring throughout the day. The ability to efficiently manage time and adapt to changing conditions is crucial for success in this role.

What Challenges Do Drayage Drivers Face?

Drayage drivers encounter a unique set of challenges in their daily operations. These challenges stem from the nature of short-haul container transportation and the complex environments in which they work. Understanding these difficulties is crucial for both drivers and industry stakeholders to develop strategies for improvement and support.

Traffic Congestion

Urban areas, where most drayage operations occur, often suffer from severe traffic congestion. This issue is particularly acute near ports and industrial zones.

Impact: Delays in pickups and deliveries, increased fuel consumption, and potential missed appointments.

Strategies: Utilizing real-time traffic information, planning alternative routes, and coordinating with dispatchers to adjust schedules when necessary.

Port and Terminal Congestion

Busy ports and rail terminals can experience significant congestion, leading to long wait times for drivers.

Causes: High volume of incoming and outgoing cargo, limited terminal capacity, and inefficient processing systems.

Consequences: Extended unpaid waiting periods, reduced number of daily trips, and increased stress for drivers.

Solutions: Implementation of appointment systems, extended gate hours, and improved terminal automation to streamline operations.

Equipment Availability and Condition

Shortages of chassis (the wheeled frame on which containers are mounted) and issues with equipment quality can hinder drayage operations.

Issues: Insufficient number of chassis, poor maintenance of available equipment, and incompatibility between chassis and containers.

Effects: Delays in picking up or dropping off containers, increased risk of breakdowns, and potential safety hazards.

Improvements: Better chassis pool management, regular equipment inspections, and investment in newer, more reliable chassis fleets.

Regulatory Compliance

Drayage drivers must navigate a complex web of federal, state, and local regulations.

Areas of regulation: Hours of service, emissions standards, port access requirements, and safety protocols.

Challenges: Keeping up with changing regulations, managing electronic logging devices (ELDs), and balancing compliance with productivity.

Support needed: Ongoing training programs, clear communication of regulatory changes, and technology solutions to aid in compliance tracking.

Environmental Concerns

Increasing focus on reducing emissions and environmental impact affects drayage operations.

Pressures: Stricter emissions standards, push for alternative fuels, and “green” port initiatives.

Adaptations: Upgrading to cleaner-burning engines, exploring electric and hydrogen-powered trucks, and implementing idle reduction strategies.

Economic Fluctuations

The drayage industry is sensitive to economic changes and trade patterns.

Factors: Global trade tensions, economic recessions, and shifts in manufacturing locations.

Impacts: Fluctuations in job availability, pressure on wages, and uncertainty in long-term career prospects.

Resilience strategies: Diversifying skill sets, staying informed about industry trends, and building relationships with multiple employers or clients.

Technology Adoption

The rapid advancement of technology in logistics presents both opportunities and challenges for drayage drivers.

Innovations: GPS tracking, automated scheduling systems, and blockchain for documentation.

Hurdles: Learning new systems, adapting to changing processes, and concerns about job security in the face of automation.

Solutions: Providing comprehensive training, phased implementation of new technologies, and involving drivers in the development of tech solutions.

Work-Life Balance

While drayage typically offers more regular hours than long-haul trucking, maintaining a healthy work-life balance can still be challenging.

Issues: Early morning starts, occasional long days due to delays, and the physical demands of the job.

Impacts: Fatigue, stress, and potential health problems.

Improvements: Implementing fair scheduling practices, promoting health and wellness programs, and ensuring adequate rest periods.

The following table summarizes the key challenges faced by drayage drivers and potential solutions:

| Challenge | Impact | Potential Solutions |

|---|---|---|

| Traffic Congestion | Delays, increased costs | Real-time route planning, flexible scheduling |

| Port/Terminal Congestion | Extended wait times, reduced productivity | Appointment systems, extended gate hours |

| Equipment Issues | Operational delays, safety risks | Improved chassis management, regular maintenance |

| Regulatory Compliance | Complexity, potential violations | Ongoing training, compliance technology |

| Environmental Concerns | Adaptation costs, operational changes | Gradual fleet upgrades, alternative fuel adoption |

| Economic Fluctuations | Job insecurity, wage pressure | Skill diversification, industry networking |

| Technology Adoption | Learning curve, job role changes | Comprehensive training, phased implementation |

| Work-Life Balance | Fatigue, health issues | Fair scheduling, wellness programs |

Addressing these challenges requires a collaborative effort from drivers, trucking companies, port authorities, and policymakers. By recognizing and proactively tackling these issues, the drayage industry can improve efficiency, driver satisfaction, and overall performance in the crucial role it plays in the global supply chain.

How Much Do Drayage Drivers Earn?

The earnings of drayage drivers can vary significantly based on several factors, including location, experience, employer, and the specific type of drayage work performed. Understanding the compensation structure and earning potential is crucial for those considering a career in drayage driving or looking to benchmark their current earnings.

Salary Range

The salary range for drayage drivers in the United States typically falls between $40,000 and $80,000 per year. However, top earners in the field can make over $100,000 annually.

Median Annual Salary: According to recent industry data, the median annual salary for drayage drivers is approximately $55,000 to $60,000.

Entry-Level Earnings: New drayage drivers can expect to start at the lower end of the scale, typically earning between $40,000 and $50,000 in their first year.

Experienced Driver Earnings: Drivers with several years of experience and a strong safety record can earn $70,000 to $80,000 or more annually.

Factors Influencing Earnings

Several key factors contribute to the variation in drayage driver salaries:

Geographic Location: Drivers in major port cities orareas with high shipping volume typically earn more due to increased demand and higher living costs.

Experience Level: As drivers gain experience, their earning potential increases. Experienced drivers are often more efficient and may be entrusted with more valuable or time-sensitive cargo.

Company Size and Type: Larger logistics companies may offer higher salaries and better benefits, while smaller operations might provide more flexibility or performance-based incentives.

Union Membership: Drivers who are part of a union often enjoy higher wages and better benefits compared to non-union drivers.

Specializations: Drivers with additional certifications, such as hazardous materials endorsements, may command higher pay rates.

Compensation Structures

Drayage drivers may be compensated through various payment models:

Hourly Rate: Some companies pay drivers an hourly wage, which can range from $18 to $30 per hour, depending on experience and location.

Per-Load or Per-Mile: Drivers may be paid a fixed rate for each container moved or based on the miles driven. This structure can be advantageous for efficient drivers but may result in lower earnings during slow periods.

Salary Plus Bonuses: Some employers offer a base salary with performance bonuses for factors such as on-time deliveries, fuel efficiency, or safety records.

Owner-Operator Model: Drivers who own their trucks can potentially earn more but also bear the costs of vehicle maintenance and business operations.

Benefits and Additional Compensation

Beyond base pay, many drayage drivers receive additional benefits that contribute to their overall compensation package:

Health Insurance: Many companies offer medical, dental, and vision coverage.

Retirement Plans: 401(k) plans with company matching are common in larger firms.

Paid Time Off: Vacation days, sick leave, and personal days are often included in compensation packages.

Performance Bonuses: Safety bonuses, fuel efficiency incentives, and on-time delivery bonuses can significantly boost earnings.

Training and Development: Some companies offer paid training programs or tuition reimbursement for relevant courses.

The following table provides a breakdown of potential earnings for drayage drivers at different experience levels:

| Experience Level | Annual Salary Range | Hourly Rate Range |

|---|---|---|

| Entry-Level (0-2 years) | $40,000 – $50,000 | $18 – $22 |

| Mid-Level (3-5 years) | $50,000 – $65,000 | $22 – $28 |

| Experienced (6+ years) | $65,000 – $80,000+ | $28 – $35+ |

Earning Potential and Career Growth

Drayage drivers have several avenues for increasing their earning potential over time:

Specialization: Obtaining additional certifications or specializing in high-value or sensitive cargo transportation can lead to higher pay.

Moving into Management: Experienced drivers may transition into roles such as dispatcher, fleet manager, or operations supervisor, often with higher salaries.

Becoming an Owner-Operator: While this path involves more risk and initial investment, successful owner-operators can earn significantly more than company drivers.

Networking and Building Relationships: Developing strong relationships with dispatchers, terminal operators, and customers can lead to more lucrative assignments and steady work.

Continuous Learning: Staying updated on industry trends, new technologies, and best practices can make drivers more valuable to employers and increase earning potential.

It’s important to note that while the earning potential for drayage drivers can be attractive, the job also comes with challenges such as irregular hours, physical demands, and the need to navigate complex port environments. Prospective drivers should weigh these factors against the potential earnings when considering a career in drayage.

As the global supply chain continues to evolve, the role of drayage drivers remains crucial. With the increasing focus on efficiency and technology in logistics, skilled and adaptable drivers are likely to see continued demand and opportunities for competitive compensation in the future.

What Technologies Do Drayage Drivers Use?

Drayage drivers increasingly rely on a variety of technologies to enhance efficiency, safety, and compliance in their daily operations. These technological tools have transformed the drayage industry, enabling drivers to navigate complex port environments, manage documentation, and optimize their routes more effectively. Here’s an overview of the key technologies used by drayage drivers:

GPS and Navigation Systems

Global Positioning System (GPS) technology is fundamental for drayage drivers, providing real-time location tracking and route optimization.

Features:

– Turn-by-turn navigation

– Real-time traffic updates

– Truck-specific routing to avoid low bridges or weight-restricted roads

– Estimated time of arrival (ETA) calculations

Benefits:

– Improved route efficiency

– Reduced fuel consumption

– Enhanced on-time performance

Electronic Logging Devices (ELDs)

ELDs have become mandatory for most commercial drivers in the United States, including drayage drivers.

Functions:

– Automatic recording of driving time and hours of service (HOS)

– Tracking of vehicle movement, miles driven, and engine hours

– Generation of reports for compliance and record-keeping

Advantages:

– Ensures compliance with HOS regulations

– Reduces paperwork and administrative burden

– Provides accurate data for payroll and performance evaluation

Mobile Communication Devices

Smartphones and tablets equipped with specialized apps are essential tools for modern drayage drivers.

Applications:

– Communication with dispatchers and terminal staff

– Access to digital load boards and job assignments

– Capture and transmission of electronic proof of delivery

– Real-time status updates and delay notifications

Impact:

– Improved coordination between drivers and other stakeholders

– Faster response to changes in schedules or routes

– Enhanced customer service through timely updates

Terminal Operating Systems (TOS)

While not directly used by drivers, TOS significantly impact drayage operations by managing container movements within ports and terminals.

Capabilities:

– Automated gate processes

– Container tracking and yard management

– Appointment scheduling for pickup and drop-off

Driver Interaction:

– Reduced wait times at terminal gates

– More predictable container availability

– Streamlined check-in and check-out procedures

Telematics Systems

These systems combine GPS technology with on-board diagnostics to provide comprehensive vehicle and driver performance data.

Monitored Aspects:

– Vehicle location and movement

– Engine performance and fuel efficiency

– Driver behavior (speed, braking patterns, idle time)

– Maintenance alerts and scheduling

Outcomes:

– Improved vehicle maintenance and reduced downtime

– Enhanced safety through driver behavior monitoring

– Optimized fuel consumption and route planning

Document Scanning and Imaging

Digital documentation systems allow drivers to manage paperwork electronically.

Uses:

– Scanning and transmitting bills of lading

– Capturing digital signatures for proof of delivery

– Storing and organizing shipping documents

Benefits:

– Reduced risk of lost or damaged paperwork

– Faster processing of deliveries and payments

– Improved accuracy in record-keeping

Chassis Tracking Systems

These systems help manage the availability and location of chassis, which are crucial for container transportation.

Features:

– Real-time tracking of chassis location and status

– Automated checkout and return processes

– Integration with terminal operating systems for seamless operations

Advantages:

– Reduced chassis shortages and improved utilization

– Minimized driver wait times for chassis availability

– Enhanced planning and forecasting of equipment needs

Automated Gate Systems

Many ports and terminals have implemented automated gate systems to streamline entry and exit processes.

Components:

– Optical character recognition (OCR) for container and license plate reading

– RFID tags for driver and vehicle identification

– Automated kiosks for driver interaction

Effects:

– Faster processing times at terminal gates

– Reduced congestion and idle time

– Improved security and access control

The following table summarizes the key technologies used by drayage drivers and their primary benefits:

| Technology | Primary Function | Key Benefits |

|---|---|---|

| GPS Navigation | Route optimization and tracking | Improved efficiency, reduced fuel costs |

| ELDs | Hours of service logging | Regulatory compliance, reduced paperwork |

| Mobile Devices | Communication and data access | Real-time updates, improved coordination |

| Telematics | Vehicle and driver performance monitoring | Enhanced safety, optimized maintenance |

| Document Scanning | Digital paperwork management | Faster processing, improved accuracy |

| Chassis Tracking | Equipment management | Reduced wait times, improved utilization |

| Automated Gates | Streamlined terminal access | Faster processing, reduced congestion |

Emerging Technologies

The drayage industry is also beginning to explore and adopt more advanced technologies:

Blockchain: For secure and transparent documentation and tracking of container movements.

Artificial Intelligence: To predict traffic patterns, optimize routes, and improve overall logistics planning.

Internet of Things (IoT): For real-time monitoring of cargo conditions and container security.

Autonomous Vehicles: While still in development, self-driving trucks could potentially transform short-haul operations in the future.

Challenges and Considerations

The adoption of these technologies brings both opportunities and challenges for drayage drivers:

Training Requirements: Drivers need ongoing training to effectively use new technologies and systems.

Technology Reliability: Dependence on electronic systems can create vulnerabilities in case of malfunctions or cyber threats.

Privacy Concerns: Increased monitoring and data collection raise questions about driver privacy and data security.

Cost of Implementation: Smaller operators may struggle with the initial investment required for some advanced technologies.

Resistance to Change: Some drivers may be hesitant to adopt new technologies, requiring careful change management strategies.

As the drayage industry continues to evolve, the effective use of technology will become increasingly important for drivers to remain competitive and efficient. Companies that invest in user-friendly, integrated technology solutions and provide comprehensive training for their drivers are likely to see significant improvements in productivity, safety, and overall performance.

The ongoing technological advancement in the drayage sector not only enhances operational efficiency but also contributes to broader goals such as reducing environmental impact, improving supply chain visibility, and meeting the growing demands of e-commerce and just-in-time inventory systems. As such, drayage drivers who embrace and master these technologies will be well-positioned for success in the evolving landscape of intermodal transportation.

How Do Drayage Drivers Impact Global Trade?

Drayage drivers play a pivotal role in the global trade ecosystem, serving as the critical link between major transportation hubs and local destinations. Their impact on international commerce is both significant and multifaceted, influencing the efficiency, cost-effectiveness, and reliability of global supply chains. Understanding the extent of this impact helps to appreciate the crucial nature of drayage operations in facilitating worldwide trade.

Facilitating Intermodal Transportation

Drayage drivers are essential in connecting different modes of transportation, ensuring the smooth flow of goods across various stages of the supply chain.

Role in the Intermodal Network:

– Bridging the gap between sea, rail, and road transportation

– Enabling the transfer of containers from ports to rail yards or distribution centers

– Facilitating the “last mile” delivery to final destinations

Impact on Global Trade:

– Enhances the flexibility and reach of international shipping

– Allows for more efficient use of long-distance transportation methods

– Reduces overall transit times for global shipments

Enhancing Port Efficiency

The efficiency of drayage operations directly affects the capacity and throughput of ports, which are critical nodes in global trade networks.

Contributions to Port Operations:

– Rapid removal of incoming containers from port terminals

– Timely delivery of outbound containers for loading onto ships

– Reduction of congestion and bottlenecks within port areas

Trade Implications:

– Increases the volume of goods that can be processed through ports

– Minimizes delays in international shipping schedules

– Improves the competitiveness of ports in attracting global trade routes

Supporting Just-In-Time Manufacturing

Drayage drivers are crucial in supporting modern manufacturing practices that rely on precise timing of component deliveries.

Role in Supply Chain Management:

– Ensuring timely delivery of raw materials and components to manufacturing facilities

– Facilitating rapid distribution of finished products to markets

– Enabling businesses to maintain lean inventories

Impact on Global Production:

– Supports the integration of global manufacturing processes

– Allows for more responsive production cycles to meet market demands

– Reduces warehousing costs and inventory holding times

Enhancing Trade Competitiveness

Efficient drayage operations contribute to the overall competitiveness of businesses engaged in international trade.

Cost Implications:

– Minimizing transportation costs through efficient routing and scheduling

– Reducing demurrage and detention charges at ports and terminals

– Lowering overall logistics expenses for importers and exporters

Trade Advantages:

– Enables businesses to offer more competitive pricing on international markets

– Improves the ability to meet tight delivery deadlines

– Enhances the reliability of supply chains, a key factor in global trade relationships

Environmental Impact and Sustainability

Drayage operations have a significant environmental footprint, and drivers play a key role in sustainability efforts.

Environmental Considerations:

– Emissions from drayage trucks contribute to air pollution in port areas

– Efficient routing and driving practices can reduce fuel consumption and emissions

Sustainability Initiatives:

– Adoption of cleaner technologies (e.g., electric or hydrogen-powered trucks)

– Implementation of idle reduction strategies

– Participation in “green port” programs

Impact on Global Trade:

– Supports the transition towards more sustainable international trade practices

– Helps meet increasingly stringent environmental regulations in global shipping

– Contributes to the reduction of the overall carbon footprint of international commerce

Facilitating Customs and Regulatory Compliance

Drayage drivers often interact with customs and regulatory processes, playing a role in ensuring compliance with international trade regulations.

Responsibilities in Compliance:

– Proper handling and transportation of bonded cargo

– Adherence to customs sealing and documentation requirements

– Coordination with customs brokers and freight forwarders

Trade Implications:

– Helps prevent delays due to regulatory issues

– Supports the integrity of international trade documentation

– Contributes to the security and traceability of global supply chains

Responding to Global Trade Fluctuations

Drayage drivers and operations must adapt to changes in global trade patterns and volumes.

Adaptability to Trade Dynamics:

– Scaling operations in response to seasonal trade fluctuations

– Adjusting to shifts in global manufacturing and sourcing locations

– Responding to disruptions caused by geopolitical events or natural disasters

Impact on Trade Resilience:

– Provides flexibility to global supply chains in times of change or crisis

– Helps maintain trade flows during periods of economic uncertainty

– Supports the redistribution of goods in response to changing market demands

The following table summarizes the key impacts of drayage drivers on various aspects of global trade:

| Aspect of Global Trade | Impact of Drayage Drivers |

|---|---|

| Intermodal Connectivity | Enables seamless transfer between transportation modes |

| Port Efficiency | Increases throughput and reduces congestion |

| Manufacturing Support | Facilitates just-in-time production and lean inventories |

| Trade Competitiveness | Reduces costs and improves delivery reliability |

| Environmental Sustainability | Contributes to emissions reduction efforts in shipping |

| Regulatory Compliance | Assists in adhering to customs and trade regulations |

| Trade Resilience | Provides flexibility in responding to global market changes |

The role of drayage drivers in global trade extends far beyond simple local transportation. Their work is integral to the functioning of complex international supply chains, influencing everything from manufacturing schedules to the environmental impact of global commerce. As international trade continues to evolve, particularly in response to technological advancements and changing consumer expectations, the importance of efficient and adaptable drayage operations is likely to grow even further.

The ongoing development of smart ports, increased automation, and the push for more sustainable logistics practices will continue to shape the role of drayage drivers in global trade. Their ability to adapt to these changes while maintaining the crucial link between global shipping networks and local economies will be vital in supporting the future of international commerce.

In conclusion, drayage drivers serve as the unsung heroes of global trade, performing a role that, while often overlooked, is indispensable to the smooth functioning of international supply chains. Their impact touches every aspect of the global trade ecosystem, from the efficiency of major ports to the competitiveness of businesses in the global marketplace. As the world becomes increasingly interconnected, the role of drayage drivers in facilitating and optimizing global trade flows will remain critical, underscoring the importance of this profession in the broader context of international commerce.