What Are the Issues With Intermodal Transportation

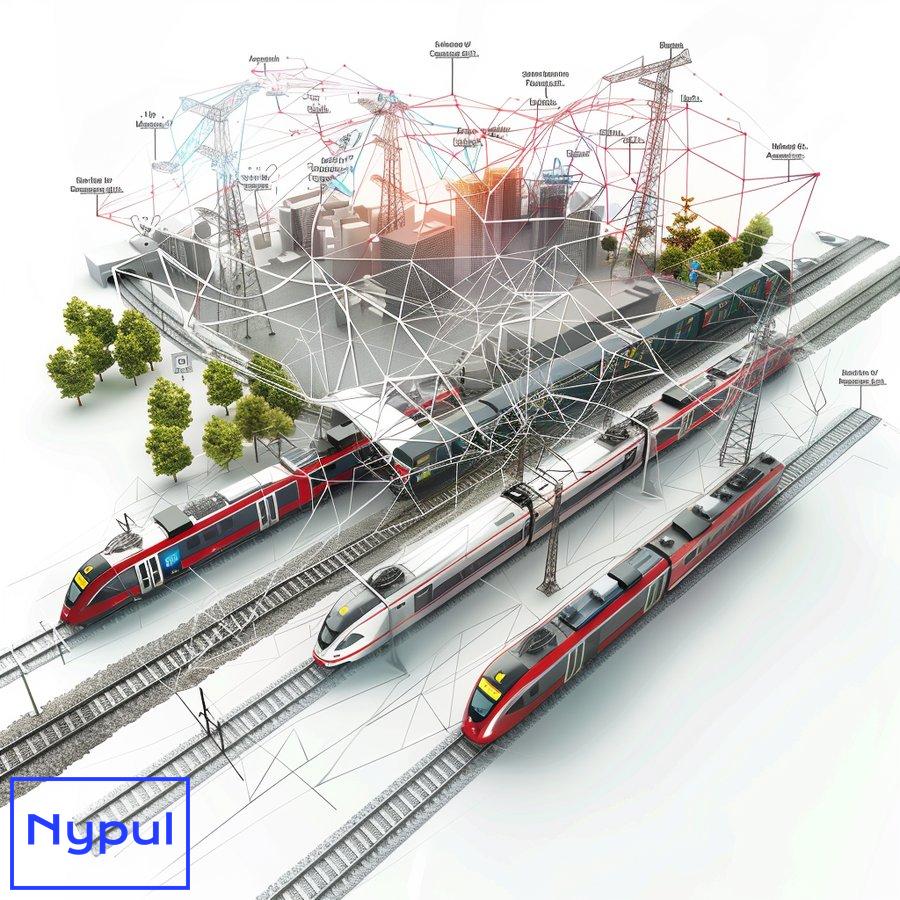

What is intermodal transportation?

Intermodal transportation is a method of shipping freight that involves using multiple modes of transport, such as trucks, trains, and ships, to move goods from their origin to their final destination. In an intermodal system, the cargo is loaded into standardized containers or trailers that can be easily transferred between different vehicles without the need to handle the goods themselves. This seamless transfer of freight across various modes allows for greater efficiency, flexibility, and cost-effectiveness compared to traditional single-mode transportation.

Key components of intermodal transportation

-

Standardized containers: Intermodal transportation relies heavily on the use of standardized containers, such as 20-foot and 40-foot shipping containers, which can be easily loaded onto trucks, trains, and ships. These containers are designed to withstand the rigors of multiple modes of transport and protect the cargo inside.

-

Specialized vehicles: Each mode of transport in an intermodal system requires specialized vehicles to accommodate the standardized containers. For example, trucks need chassis to carry the containers, while trains use flatcars or well cars specifically designed for container transport.

-

Intermodal terminals: Intermodal terminals, such as ports, rail yards, and distribution centers, serve as critical nodes in the intermodal network. These facilities are equipped with the necessary infrastructure and equipment to efficiently transfer containers between different modes of transport.

Benefits of intermodal transportation

Intermodal transportation offers several advantages over single-mode shipping:

-

Cost-effectiveness: By leveraging the strengths of each mode of transport, intermodal shipping can reduce overall transportation costs. For instance, using trains for long-distance hauls and trucks for local delivery can be more cost-effective than relying solely on trucks for the entire journey.

-

Increased efficiency: Intermodal transportation minimizes the need for cargo handling, as the standardized containers can be quickly transferred between vehicles. This reduces loading and unloading times, leading to faster and more efficient shipping.

-

Environmental benefits: Intermodal transportation can help reduce the environmental impact of freight movement by shifting a portion of the cargo from trucks to more fuel-efficient modes like trains or ships. This can lead to lower greenhouse gas emissions and reduced traffic congestion on highways.

-

Flexibility: Intermodal systems offer greater flexibility in routing and scheduling, as shippers can choose the most suitable combination of modes based on factors such as cost, speed, and accessibility.

Despite its many benefits, intermodal transportation also faces several challenges, including speed and reliability issues, infrastructure limitations, technical compatibility problems, economic hurdles, coordination and communication difficulties, and regulatory and standardization obstacles. Addressing these challenges is crucial for the continued growth and success of intermodal freight transport.

How do speed and reliability issues affect intermodal transportation?

Speed and reliability are critical factors in the success of intermodal transportation, as shippers expect their goods to be delivered on time and in good condition. However, several issues can impact the speed and reliability of intermodal freight movement, leading to delays, increased costs, and customer dissatisfaction.

Factors affecting speed in intermodal transportation

-

Modal transfer times: The process of transferring containers between different modes of transport, such as from a truck to a train or from a train to a ship, can be time-consuming. Delays at intermodal terminals due to congestion, equipment failures, or labor shortages can slow down the overall transportation process.

-

Infrastructure limitations: Inadequate or aging infrastructure, such as rail lines with limited capacity or ports with insufficient berths, can create bottlenecks in the intermodal network, leading to slower transit times.

-

Regulatory compliance: Compliance with various regulations, such as customs inspections, safety checks, and documentation requirements, can add time to the intermodal transportation process.

Factors affecting reliability in intermodal transportation

-

Weather and natural disasters: Adverse weather conditions, such as hurricanes, floods, or blizzards, can disrupt intermodal operations, causing delays or even complete shutdowns of certain routes.

-

Equipment breakdowns: Mechanical failures of trucks, trains, or ships can lead to unexpected delays and reduced reliability in the intermodal network.

-

Labor disputes: Strikes or work stoppages by transportation workers, such as truck drivers, rail workers, or port employees, can significantly impact the reliability of intermodal freight movement.

-

Capacity constraints: When demand for intermodal transportation exceeds the available capacity of vehicles, terminals, or infrastructure, it can lead to delays and reduced reliability as shippers compete for limited resources.

Mitigating speed and reliability issues

To address speed and reliability challenges in intermodal transportation, stakeholders can implement various strategies:

-

Investing in infrastructure: Upgrading and expanding intermodal infrastructure, such as rail lines, ports, and terminals, can help alleviate bottlenecks and improve the speed and reliability of freight movement.

-

Enhancing technology: Adopting advanced technologies, such as real-time tracking systems, automated terminal operations, and predictive maintenance, can help optimize intermodal processes and reduce delays.

-

Improving coordination and communication: Strengthening collaboration and information sharing among intermodal stakeholders, including shippers, carriers, and terminal operators, can help identify and resolve issues more quickly, leading to improved speed and reliability.

-

Developing contingency plans: Establishing contingency plans and alternative routes can help mitigate the impact of disruptions caused by weather events, equipment failures, or labor disputes.

Addressing speed and reliability issues in intermodal transportation is an ongoing process that requires the cooperation and commitment of all stakeholders in the supply chain. By working together to identify and overcome these challenges, the intermodal industry can continue to provide efficient and reliable freight transportation services to shippers worldwide.

What infrastructure challenges hinder efficient intermodal operations?

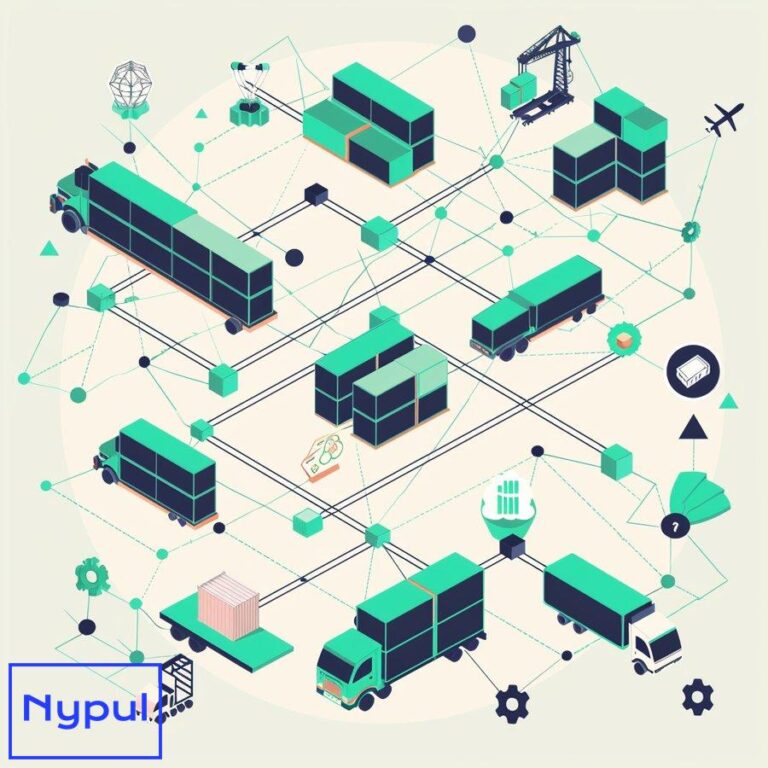

Efficient intermodal operations rely heavily on a well-developed and maintained infrastructure network. However, several infrastructure challenges can hinder the smooth flow of freight in an intermodal system, leading to delays, increased costs, and reduced competitiveness.

Capacity constraints

One of the primary infrastructure challenges facing intermodal transportation is capacity constraints. As global trade continues to grow, the demand for intermodal services often outpaces the capacity of existing infrastructure.

-

Port congestion: Many ports struggle with congestion due to limited berth space, inadequate cargo handling equipment, and insufficient storage areas. This can lead to longer dwell times for ships and delays in the transfer of containers to other modes of transport.

-

Rail network bottlenecks: Rail infrastructure, particularly in high-traffic corridors, may not have sufficient capacity to accommodate the growing volume of intermodal freight. Single-track sections, limited siding lengths, and outdated signaling systems can create bottlenecks and slow down rail operations.

-

Highway congestion: Congested highways and limited truck parking facilities can hinder the efficient movement of intermodal freight by road, leading to delays and increased costs for shippers.

Aging infrastructure

Another significant challenge is the aging and deteriorating condition of many intermodal infrastructure assets.

-

Outdated port facilities: Many ports have aging terminals, berths, and cargo handling equipment that may not be suitable for handling modern, larger vessels and the increasing volume of containerized freight.

-

Aging rail infrastructure: Older rail lines, bridges, and tunnels may have weight and clearance restrictions that limit the ability to accommodate heavier and taller intermodal loads. Additionally, aging tracks and signaling systems can lead to reduced speeds and reliability.

-

Deteriorating road infrastructure: Poorly maintained highways, bridges, and access roads can cause damage to intermodal equipment, increase the risk of accidents, and lead to delays in freight movement.

Lack of intermodal connectivity

Efficient intermodal operations require seamless connectivity between different modes of transport. However, many regions lack adequate intermodal facilities or have poorly integrated transportation networks.

-

Insufficient intermodal terminals: The absence of well-equipped intermodal terminals in strategic locations can hinder the efficient transfer of containers between modes, leading to longer transit times and increased costs.

-

Poor modal integration: Inadequate coordination and connectivity between ports, rail yards, and highway networks can create gaps in the intermodal supply chain, causing delays and reducing the overall efficiency of freight movement.

Addressing infrastructure challenges

To overcome these infrastructure challenges and improve the efficiency of intermodal operations, stakeholders must invest in upgrading and expanding the intermodal network.

-

Capacity expansion: Increasing the capacity of ports, rail lines, and highways through infrastructure projects such as berth extensions, double-tracking, and lane additions can help alleviate congestion and accommodate future growth in intermodal freight.

-

Infrastructure modernization: Upgrading aging infrastructure assets, such as port facilities, rail lines, and bridges, can improve the efficiency, reliability, and safety of intermodal operations.

-

Intermodal connectivity enhancement: Developing strategically located intermodal terminals and improving the integration of different modes of transport can create a more seamless and efficient intermodal network.

-

Technology adoption: Implementing advanced technologies, such as automation, intelligent transportation systems, and real-time data exchange, can help optimize infrastructure utilization and improve the overall performance of intermodal operations.

Addressing infrastructure challenges in intermodal transportation requires significant investments and collaboration among various stakeholders, including governments, transportation providers, and shippers. By working together to prioritize and fund critical infrastructure projects, the intermodal industry can overcome these challenges and build a more efficient, reliable, and sustainable freight transportation system.

How do technical compatibility problems impact intermodal transportation?

Technical compatibility is a crucial aspect of intermodal transportation, as it ensures that containers, vehicles, and equipment from different modes can work together seamlessly. When technical compatibility issues arise, they can significantly impact the efficiency and reliability of intermodal operations.

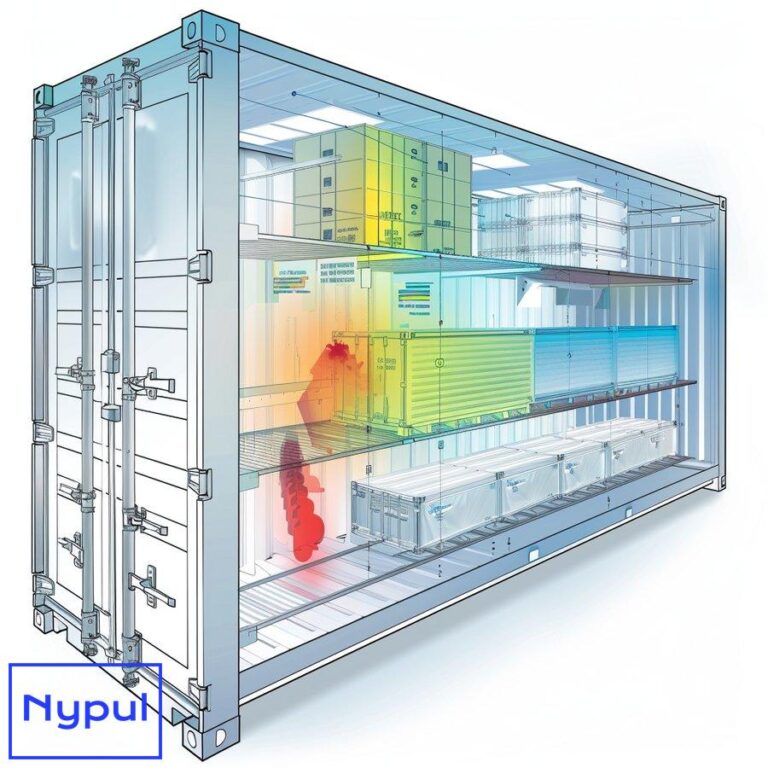

Container compatibility

Standardized containers are the backbone of intermodal transportation, allowing for the easy transfer of cargo between different modes. However, compatibility issues can still occur.

-

Container size variations: While 20-foot and 40-foot containers are the most common, there are also other sizes, such as 45-foot and 53-foot containers. Not all modes of transport or intermodal facilities may be equipped to handle these non-standard sizes, leading to compatibility issues.

-

Container type differences: Specialized containers, such as refrigerated units (reefers), tank containers, or open-top containers, may require specific handling equipment or infrastructure that is not available at all intermodal terminals, causing delays or the need for alternative routing.

Vehicle and equipment compatibility

Intermodal transportation relies on specialized vehicles and equipment to handle and transport containers. Compatibility issues can arise when these assets are not designed or maintained to work together effectively.

-

Chassis incompatibility: Truck chassis used to carry containers must be compatible with the container size and type. Mismatches between chassis and containers can lead to safety risks, damage to equipment, and delays in freight movement.

-

Rail car and terminal equipment incompatibility: Rail cars used in intermodal transportation, such as well cars or double-stack cars, must be compatible with the loading and unloading equipment at rail terminals. Incompatibilities can cause delays and increase the risk of accidents during modal transfers.

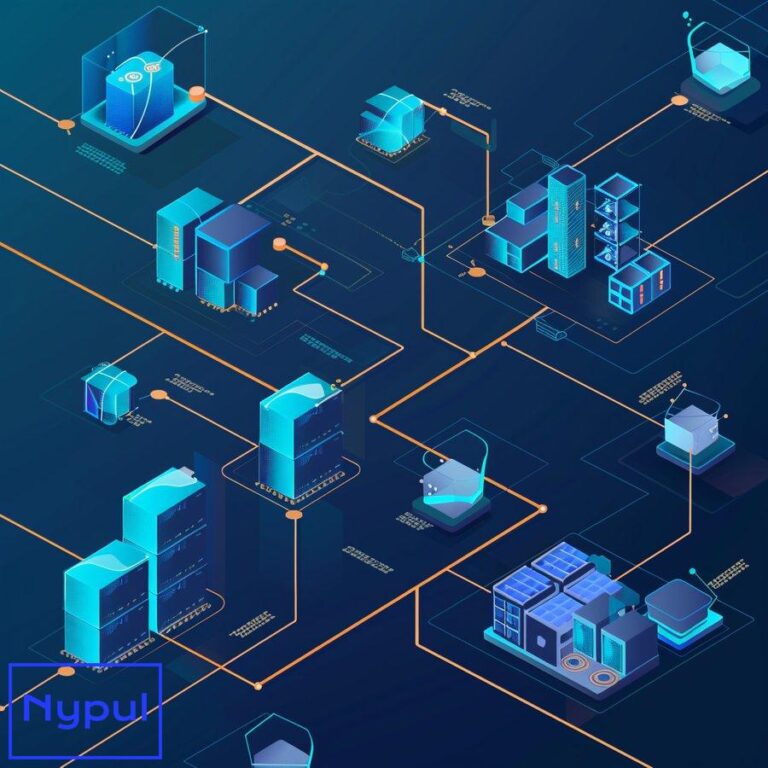

Information technology compatibility

In today’s digital age, intermodal transportation relies heavily on information technology systems for tracking, documentation, and communication. Compatibility issues between these systems can hinder the smooth flow of information and disrupt intermodal operations.

-

Electronic data interchange (EDI) incompatibility: EDI systems are used to exchange critical information, such as shipping instructions, customs documents, and billing data, between intermodal stakeholders. Incompatibilities between different EDI systems can lead to errors, delays, and increased administrative costs.

-

Tracking system incompatibility: Intermodal freight often involves multiple carriers and modes, each with their own tracking systems. Incompatibilities between these systems can make it difficult to obtain real-time visibility into the status and location of containers, leading to communication breakdowns and reduced customer satisfaction.

Mitigating technical compatibility issues

To minimize the impact of technical compatibility problems on intermodal transportation, stakeholders can implement various strategies:

-

Adherence to industry standards: Encouraging the adoption of industry-wide standards for containers, vehicles, equipment, and information technology systems can help ensure compatibility across the intermodal network.

-

Regular maintenance and upgrades: Properly maintaining and upgrading intermodal assets, such as containers, chassis, and terminal equipment, can help prevent compatibility issues and improve overall operational efficiency.

-

Collaboration and communication: Fostering strong partnerships and open communication channels among intermodal stakeholders can help identify and resolve compatibility issues more quickly and effectively.

-

Investment in technology: Adopting advanced technologies, such as the Internet of Things (IoT), blockchain, and artificial intelligence (AI), can help improve the compatibility and interoperability of information systems, leading to better data exchange and visibility in the intermodal supply chain.

Addressing technical compatibility challenges is an ongoing process that requires the commitment and cooperation of all intermodal stakeholders. By working together to identify and overcome these issues, the intermodal industry can create a more seamless, efficient, and reliable freight transportation system that benefits shippers, carriers, and consumers alike.

What are the economic challenges of implementing intermodal solutions?

Implementing intermodal transportation solutions can offer numerous benefits, such as reduced costs, improved efficiency, and lower environmental impact. However, several economic challenges must be addressed to ensure the successful adoption and long-term viability of intermodal freight movement.

High initial investment costs

One of the most significant economic challenges of implementing intermodal solutions is the high upfront investment required.

-

Infrastructure development: Building or upgrading intermodal infrastructure, such as ports, rail terminals, and inland depots, requires substantial capital investments. These costs can be a barrier for smaller transportation providers or shippers looking to enter the intermodal market.

-

Equipment acquisition: Intermodal transportation relies on specialized equipment, such as containers, chassis, and handling machinery. Acquiring this equipment can be expensive, especially for companies with limited financial resources.

-

Technology implementation: Adopting advanced technologies, such as tracking systems, automation, and data analytics tools, is crucial for efficient intermodal operations. However, the costs associated with purchasing, installing, and maintaining these technologies can be significant.

Economies of scale

Intermodal transportation often requires a certain level of scale to be economically viable, which can be challenging for smaller players in the market.

-

Volume requirements: Intermodal services are most cost-effective when there is a consistent and sufficient volume of freight to transport. Smaller shippers may struggle to meet these volume requirements, making it difficult for them to benefit from intermodal solutions.

-

Network density: A dense and well-connected intermodal network is essential for efficient and cost-effective operations. In regions with limited intermodal infrastructure or low freight volumes, it may be challenging to achieve the necessary network density to make intermodal transportation economically feasible.

Cost competitiveness

Intermodal transportation must remain cost-competitive with other modes of freight transport to attract shippers and maintain market share.

-

Fuel prices: Fluctuations in fuel prices can significantly impact the cost competitiveness of intermodal transportation, particularly in comparison to truck-only shipping. When fuel prices are low, the cost advantage of intermodal solutions may be diminished.

-

Labor costs: Intermodal operations involve multiple modes of transport and require skilled labor, such as truck drivers, rail operators, and terminal workers. Rising labor costs can increase the overall cost of intermodal transportation and reduce its competitiveness.

-

Regulatory compliance costs: Complying with various regulations, such as environmental standards, safety requirements, and customs procedures, can add significant costs to intermodal operations, affecting their cost competitiveness.

Addressing economic challenges

To overcome the economic challenges of implementing intermodal solutions, stakeholders can employ various strategies:

-

Public-private partnerships: Collaborating with governments and public agencies to invest in intermodal infrastructure can help reduce the financial burden on individual companies and encourage the adoption of intermodal solutions.

-

Collaborative equipment pooling: Establishing equipment pools, where multiple intermodal stakeholders share the costs and usage of containers, chassis, and other assets, can help reduce individual investment requirements and improve equipment utilization.

-

Technology-driven efficiency gains: Investing in advanced technologies that optimize intermodal operations, such as automation, real-time tracking, and predictive analytics, can help reduce costs and improve the overall competitiveness of intermodal transportation.

-

Targeted incentives and subsidies: Governments can offer targeted incentives, such as tax breaks or subsidies, to encourage the adoption of intermodal solutions and help offset the high initial investment costs.

Overcoming the economic challenges of implementing intermodal solutions requires a concerted effort from all stakeholders in the supply chain. By working together to develop innovative financing models, improve operational efficiency, and create a supportive policy environment, the intermodal industry can unlock the full potential of intermodal transportation and drive long-term economic growth.

How do coordination and communication issues affect intermodal efficiency?

Effective coordination and communication are essential for the smooth operation of intermodal transportation, which involves multiple stakeholders, modes of transport, and information systems. When coordination and communication issues arise, they can significantly impact the efficiency and reliability of intermodal freight movement.

Stakeholder coordination challenges

Intermodal transportation involves a complex network of stakeholders, including shippers, carriers, terminal operators, and logistics service providers. Coordination challenges among these parties can lead to inefficiencies and disruptions in the supply chain.

-

Misaligned priorities: Different stakeholders may have conflicting priorities or objectives, such as cost reduction, service quality, or environmental sustainability. These misalignments can hinder effective coordination and lead to suboptimal decision-making in intermodal operations.

-

Lack of standardized processes: The absence of standardized processes and protocols for intermodal operations can create confusion and inefficiencies when stakeholders interact. This can result in delays, errors, and increased costs.

-

Insufficient information sharing: When stakeholders do not share critical information, such as shipment status, equipment availability, or operational constraints, in a timely and transparent manner, it can hinder effective coordination and lead to poor decision-making.

Communication breakdowns

Efficient intermodal transportation relies on the seamless exchange of accurate and timely information among stakeholders. Communication breakdowns can occur due to various factors, causing disruptions and inefficiencies in the supply chain.

-

Incompatible communication systems: Stakeholders may use different communication systems, such as email, phone, or proprietary software, which can lead to difficulties in exchanging information and coordinating activities.

-

Delayed or inaccurate information: When critical information, such as shipment updates, customs documents, or booking confirmations, is not communicated promptly or accurately, it can cause delays, errors, and increased costs in intermodal operations.

-

Language and cultural barriers: In international intermodal transportation, language and cultural differences among stakeholders can create communication challenges, leading to misunderstandings and inefficiencies.

Impacts of coordination and communication issues

Coordination and communication issues can have far-reaching consequences for intermodal efficiency, including:

-

Increased dwell times: Poor coordination and communication can result in longer dwell times for containers at intermodal terminals, as stakeholders struggle to align their activities and exchange necessary information.

-

Reduced asset utilization: Inefficient coordination can lead to underutilized assets, such as containers, chassis, or handling equipment, as stakeholders fail to optimize their use across the intermodal network.

-

Higher costs: Communication breakdowns and coordination challenges can result in increased costs for stakeholders, such as demurrage and detention fees, as well as additional labor and administrative expenses.

-

Diminished customer satisfaction: Inefficiencies caused by coordination and communication issues can lead to delayed or inconsistent service, damaging customer relationships and reducing the competitiveness of intermodal transportation.

Improving coordination and communication

To enhance intermodal efficiency, stakeholders must work together to improve coordination and communication across the supply chain.

-

Collaborative platforms: Implementing collaborative platforms, such as digital freight marketplaces or port community systems, can facilitate the exchange of information and streamline coordination among stakeholders.

-

Standardization and interoperability: Adopting industry-wide standards for data exchange, operational processes, and communication protocols can help ensure seamless coordination and reduce inefficiencies.

-

Real-time visibility: Investing in real-time visibility solutions, such as IoT-enabled tracking devices and data analytics tools, can provide stakeholders with accurate and timely information, enabling better coordination and decision-making.

-

Cross-functional teams: Establishing cross-functional teams that include representatives from various stakeholder groups can foster better communication, collaboration, and problem-solving in intermodal operations.

-

Training and education: Providing training and education programs to stakeholders can help improve their understanding of intermodal processes, communication best practices, and cultural sensitivity, leading to more effective coordination.

By addressing coordination and communication challenges, intermodal stakeholders can unlock significant efficiency gains, reduce costs, and improve the overall performance of the intermodal transportation system. This requires a commitment to transparency, collaboration, and continuous improvement from all parties involved in the intermodal supply chain.

What regulatory and standardization hurdles exist in intermodal transportation?

![]()

Intermodal transportation operates within a complex regulatory and standardization landscape, which can create hurdles for the efficient and seamless movement of freight. These challenges span across various aspects of intermodal operations, from safety and security requirements to environmental regulations and international trade agreements.

Safety and security regulations

Ensuring the safety and security of intermodal transportation is a top priority for regulators and industry stakeholders. However, complying with these regulations can sometimes create operational challenges and inefficiencies.

-

Cargo screening requirements: Regulations mandating the screening of intermodal cargo for security threats, such as explosives or contraband, can slow down the flow of freight and increase costs for shippers and carriers.

-

Driver hours-of-service rules: Regulations limiting the number of hours truck drivers can operate, such as the U.S. Department of Transportation’s hours-of-service rules, can impact the efficiency of intermodal drayage operations and cause delays in the supply chain.

-

Equipment safety standards: Varying safety standards for intermodal equipment, such as containers and chassis, across different jurisdictions can create compliance challenges and hinder the smooth flow of freight.

Environmental regulations

As concerns about climate change and air quality grow, intermodal transportation is subject to an increasing number of environmental regulations, which can create compliance hurdles and impact operational efficiency.

-

Emission control areas: Regulations establishing emission control areas, such as the International Maritime Organization’s (IMO) sulfur cap, can require intermodal carriers to use cleaner fuels or emission reduction technologies, increasing costs and potentially causing disruptions in the supply chain.

-

Clean truck programs: Local and regional clean truck programs, which aim to reduce air pollution from drayage operations, can create compliance challenges for intermodal carriers and impact the efficiency of first- and last-mile delivery.

-

Noise and light pollution regulations: Regulations aimed at reducing noise and light pollution from intermodal facilities, such as ports and rail yards, can restrict operating hours and limit the capacity of these facilities, affecting the overall efficiency of intermodal transportation.

International trade agreements and customs procedures

Intermodal transportation often involves the movement of freight across international borders, subjecting it to a complex web of trade agreements and customs procedures.

-

Tariffs and trade barriers: Tariffs, quotas, and other trade barriers can increase the cost and complexity of intermodal transportation, as shippers and carriers navigate a constantly evolving landscape of international trade relations.

-

Customs documentation and inspections: Complying with customs documentation requirements and undergoing inspections can cause delays and inefficiencies in intermodal operations, particularly at border crossings and ports.

-

Rules of origin: Varying rules of origin across different trade agreements can create compliance challenges for intermodal shippers and carriers, as they must ensure that their cargo meets the necessary criteria to qualify for preferential treatment.

Standardization challenges

The lack of standardization across various aspects of intermodal transportation can create hurdles for efficiency and interoperability.

-

Equipment specifications: Variations in container and chassis specifications across different regions and transportation modes can hinder the seamless flow of intermodal freight and create compatibility issues.

-

Information exchange protocols: The absence of standardized protocols for exchanging data and documents among intermodal stakeholders can lead to communication breakdowns and inefficiencies in the supply chain.

-

Operational processes: Inconsistent operational processes across intermodal facilities, such as terminal handling procedures and gate operations, can create confusion and delays for carriers and shippers.

Overcoming regulatory and standardization hurdles

To address these challenges and promote a more efficient intermodal transportation system, stakeholders must work together to navigate the regulatory landscape and drive standardization efforts.

-

Industry collaboration: Fostering collaboration among industry stakeholders, such as carriers, shippers, and terminal operators, can help identify common challenges and develop solutions to overcome regulatory and standardization hurdles.

-

Engagement with policymakers: Actively engaging with policymakers and regulators to provide input on the development and implementation of regulations can help ensure that the unique needs and challenges of intermodal transportation are considered.

-

International harmonization: Promoting the harmonization of regulations and standards across different countries and regions can help reduce compliance complexity and improve the efficiency of international intermodal operations.

-

Technology adoption: Leveraging advanced technologies, such as blockchain and artificial intelligence, can help intermodal stakeholders navigate complex regulatory requirements, automate compliance processes, and improve data standardization.

-

Continuous improvement: Embracing a culture of continuous improvement and best practice sharing can help intermodal stakeholders identify and address regulatory and standardization challenges more effectively, leading to a more efficient and resilient transportation system.

Overcoming regulatory and standardization hurdles in intermodal transportation requires a proactive and collaborative approach from all stakeholders in the supply chain. By working together to navigate the complex landscape of regulations and drive standardization efforts, the intermodal industry can unlock significant efficiency gains and create a more seamless, sustainable, and competitive freight transportation system.