What Are the Variable Costs of a Delivery Company

What are variable costs in delivery operations?

Variable costs in delivery operations are expenses that fluctuate based on the volume of deliveries made. These costs are directly tied to the number of packages shipped, miles driven, and hours worked by delivery personnel. Examples of variable costs include fuel, labor, vehicle maintenance, packaging materials, and certain technology expenses.

Understanding variable costs is crucial for delivery companies to accurately calculate their cost per delivery and determine pricing strategies. By analyzing these costs, businesses can identify areas for optimization and make data-driven decisions to improve profitability.

Contribution Margin

The contribution margin is a key metric that helps delivery companies assess the profitability of their operations. It is calculated by subtracting variable costs from revenue. A higher contribution margin indicates that a greater portion of revenue is available to cover fixed costs and generate profit.

$$Contribution Margin = Revenue – Variable Costs$$

Break-Even Analysis

Delivery companies can use break-even analysis to determine the number of deliveries needed to cover their total costs. The break-even point is reached when total revenue equals total costs (fixed + variable). By understanding their break-even point, businesses can set sales targets and adjust pricing to ensure profitability.

$$Break-Even Point = Fixed Costs ÷ (Revenue per Delivery – Variable Cost per Delivery)$$

Monitoring and managing variable costs is essential for the financial health of delivery operations. By understanding these costs and their impact on profitability, companies can make informed decisions to optimize their operations and remain competitive in the market.

How do fuel expenses impact a delivery company’s bottom line?

Fuel expenses are a significant variable cost for delivery companies, directly impacting their bottom line. As the number of deliveries increases, so does the amount of fuel consumed by the delivery fleet. Fluctuations in fuel prices can greatly affect profitability, making it crucial for companies to monitor and manage these costs effectively.

Factors Affecting Fuel Expenses

Several factors influence fuel expenses in delivery operations:

- Distance traveled per delivery

- Vehicle fuel efficiency

- Fuel price fluctuations

- Route optimization

- Driver behavior (e.g., idling, speeding)

Strategies to Manage Fuel Expenses

Delivery companies can implement various strategies to minimize fuel expenses:

- Route optimization: Using software to plan efficient routes that minimize distance and time spent on the road.

- Vehicle maintenance: Regular maintenance, such as tire inflation and engine tune-ups, can improve fuel efficiency.

- Driver training: Educating drivers on fuel-efficient driving techniques, such as avoiding rapid acceleration and excessive idling.

- Fuel-efficient vehicles: Investing in vehicles with better fuel economy or alternative fuel options, such as electric or hybrid vehicles.

- Fuel price monitoring: Keeping track of fuel price trends and adjusting pricing or surcharges accordingly.

Impact on Profitability

To illustrate the impact of fuel expenses on profitability, consider the following example:

| Scenario | Deliveries per Month | Fuel Cost per Delivery | Total Fuel Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|

| Low Fuel Prices | 1,000 | $5 | $5,000 | $20 | $20,000 | $15,000 |

| High Fuel Prices | 1,000 | $8 | $8,000 | $20 | $20,000 | $12,000 |

In this example, a $3 increase in fuel cost per delivery results in a $3,000 decrease in monthly profit, highlighting the significance of fuel expenses in delivery operations.

By actively managing fuel expenses and implementing cost-saving strategies, delivery companies can mitigate the impact of fuel price volatility on their bottom line and maintain profitability.

What labor costs should delivery companies consider?

Labor costs are a significant variable expense for delivery companies, as they are directly tied to the volume of deliveries made. These costs include wages, benefits, and taxes for delivery drivers, dispatchers, and other personnel involved in the delivery process. Effectively managing labor costs is crucial for maintaining profitability and competitiveness in the market.

Types of Labor Costs

Delivery companies should consider the following labor costs:

- Driver wages: Hourly or per-delivery pay for drivers, which may include base pay, overtime, and performance bonuses.

- Benefits: Health insurance, retirement plans, and other employee benefits offered to delivery personnel.

- Payroll taxes: Federal and state taxes, such as Social Security and Medicare, that employers must pay based on employee wages.

- Dispatcher and support staff wages: Salaries for employees who coordinate deliveries, handle customer service, and perform administrative tasks.

Factors Affecting Labor Costs

Several factors can impact labor costs in delivery operations:

- Delivery volume and frequency

- Average time per delivery

- Local labor market conditions and minimum wage laws

- Employee turnover and training expenses

- Overtime and peak season demand

Strategies to Manage Labor Costs

Delivery companies can implement various strategies to optimize labor costs:

- Efficient scheduling: Matching staffing levels to delivery volume and minimizing overtime.

- Performance-based pay: Implementing incentive programs that reward drivers for efficiency, safety, and customer satisfaction.

- Technology adoption: Using automation and software to streamline dispatching, routing, and administrative tasks, reducing the need for manual labor.

- Employee retention: Investing in employee training, development, and competitive compensation to reduce turnover and associated costs.

- Outsourcing: Partnering with third-party logistics providers or using independent contractors for certain delivery services.

Impact on Profitability

To demonstrate the impact of labor costs on profitability, consider the following example:

| Scenario | Deliveries per Month | Labor Cost per Delivery | Total Labor Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|

| Efficient Staffing | 1,000 | $10 | $10,000 | $25 | $25,000 | $15,000 |

| Overstaffing | 1,000 | $15 | $15,000 | $25 | $25,000 | $10,000 |

In this example, a $5 increase in labor cost per delivery due to overstaffing results in a $5,000 decrease in monthly profit, emphasizing the importance of managing labor costs effectively.

By implementing strategies to optimize labor costs and maintain a balance between service quality and efficiency, delivery companies can improve their bottom line and remain competitive in the market.

How do vehicle maintenance and repairs affect variable costs?

Vehicle maintenance and repairs are significant variable costs for delivery companies, as they are directly related to the wear and tear on vehicles caused by the volume of deliveries made. As delivery vehicles accumulate miles and experience regular use, they require ongoing maintenance and occasional repairs to ensure safe and efficient operation. Neglecting these costs can lead to higher expenses and reduced profitability in the long run.

Types of Vehicle Maintenance and Repair Costs

Delivery companies should consider the following maintenance and repair costs:

- Routine maintenance: Regular oil changes, tire rotations, brake inspections, and other preventive maintenance tasks.

- Tire replacement: Replacing worn or damaged tires to ensure vehicle safety and fuel efficiency.

- Brake repairs: Addressing brake wear and replacing brake components as needed.

- Engine and transmission repairs: Repairing or replacing major vehicle components due to wear or failure.

- Body and interior repairs: Fixing damage to the vehicle’s exterior or interior caused by accidents or normal wear and tear.

Factors Affecting Maintenance and Repair Costs

Several factors can impact vehicle maintenance and repair costs in delivery operations:

- Vehicle age and condition

- Delivery route characteristics (e.g., urban vs. rural, road quality)

- Driver behavior and habits

- Maintenance schedule adherence

- Vehicle make and model

Strategies to Manage Maintenance and Repair Costs

Delivery companies can implement various strategies to optimize vehicle maintenance and repair costs:

- Preventive maintenance: Following a regular maintenance schedule to identify and address potential issues before they become costly repairs.

- Driver training: Educating drivers on proper vehicle operation and care to minimize wear and tear and prevent accidents.

- Vehicle selection: Choosing reliable, fuel-efficient vehicles with lower maintenance costs and longer service intervals.

- Fleet management software: Using technology to track vehicle maintenance schedules, monitor vehicle health, and optimize repair and replacement decisions.

- Warranty and service contracts: Leveraging manufacturer warranties and purchasing extended service contracts to cover certain repair costs.

Impact on Profitability

To illustrate the impact of vehicle maintenance and repair costs on profitability, consider the following example:

| Scenario | Deliveries per Month | Maintenance Cost per Delivery | Total Maintenance Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|

| Regular Maintenance | 1,000 | $2 | $2,000 | $25 | $25,000 | $23,000 |

| Neglected Maintenance | 1,000 | $5 | $5,000 | $25 | $25,000 | $20,000 |

In this example, a $3 increase in maintenance cost per delivery due to neglected maintenance results in a $3,000 decrease in monthly profit, highlighting the importance of proactive vehicle maintenance.

By implementing strategies to manage vehicle maintenance and repair costs effectively, delivery companies can minimize downtime, extend vehicle life, and maintain profitability in their operations.

Why are packaging and materials important variable costs?

Packaging and materials are essential variable costs for delivery companies, as they are directly tied to the volume and types of items being shipped. These costs include boxes, envelopes, labels, packing tape, and protective materials like bubble wrap or air pillows. As the number of deliveries increases, so does the consumption of packaging and materials, making it crucial for companies to manage these expenses effectively.

Types of Packaging and Material Costs

Delivery companies should consider the following packaging and material costs:

- Boxes and envelopes: Various sizes and types of containers used to package items for shipping.

- Labels and shipping documents: Address labels, packing slips, and other necessary documentation.

- Packing tape and adhesives: Materials used to seal and secure packages.

- Protective materials: Bubble wrap, air pillows, foam, or other materials used to cushion and protect items during transit.

- Specialty packaging: Insulated containers, dry ice, or other materials required for shipping perishable or temperature-sensitive items.

Factors Affecting Packaging and Material Costs

Several factors can impact packaging and material costs in delivery operations:

- Item size, weight, and fragility

- Shipping distance and method (e.g., ground, air, express)

- Customer preferences and expectations

- Packaging material quality and durability

- Supplier pricing and availability

Strategies to Manage Packaging and Material Costs

Delivery companies can implement various strategies to optimize packaging and material costs:

- Standardization: Using a limited range of box sizes and materials to simplify inventory management and reduce costs.

- Bulk purchasing: Negotiating discounts with suppliers by ordering packaging materials in large quantities.

- Packaging optimization: Selecting the most appropriate and cost-effective packaging for each item based on its characteristics and shipping requirements.

- Recycling and reuse: Implementing programs to recycle or reuse packaging materials when possible, reducing waste and costs.

- Packaging automation: Investing in equipment and technology to streamline packaging processes and reduce labor costs.

Impact on Profitability

To demonstrate the impact of packaging and material costs on profitability, consider the following example:

| Scenario | Deliveries per Month | Packaging Cost per Delivery | Total Packaging Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|

| Optimized Packaging | 1,000 | $1.50 | $1,500 | $25 | $25,000 | $23,500 |

| Inefficient Packaging | 1,000 | $3.00 | $3,000 | $25 | $25,000 | $22,000 |

In this example, a $1.50 increase in packaging cost per delivery due to inefficient packaging results in a $1,500 decrease in monthly profit, emphasizing the importance of managing packaging and material costs.

By implementing strategies to optimize packaging and material expenses, delivery companies can reduce waste, improve operational efficiency, and maintain profitability in their operations.

What technology and software costs vary with delivery volume?

Technology and software costs are variable expenses that can fluctuate based on delivery volume for companies in the logistics industry. As the number of deliveries increases, so does the need for robust technology solutions to manage operations efficiently. These costs include expenses related to routing software, mobile apps, customer communication tools, and data analytics platforms.

Types of Technology and Software Costs

Delivery companies should consider the following technology and software costs that vary with delivery volume:

- Routing and dispatch software: Platforms that optimize delivery routes, assign drivers, and monitor real-time progress.

- Mobile apps: Applications for drivers to access delivery information, capture proof of delivery, and communicate with dispatchers.

- Customer communication tools: SMS, email, or push notification services to keep customers informed about their delivery status.

- Data storage and analytics: Cloud-based storage and analytics tools to process and derive insights from delivery data.

- Integration and API costs: Expenses related to integrating delivery technology with other systems, such as e-commerce platforms or warehouse management software.

Factors Affecting Technology and Software Costs

Several factors can impact technology and software costs in delivery operations:

- Delivery volume and frequency

- Number of drivers and vehicles

- Complexity of delivery operations (e.g., multiple service levels, specialized handling requirements)

- Technology provider pricing models (e.g., per-delivery, per-user, or subscription-based)

- Customization and integration requirements

Strategies to Manage Technology and Software Costs

Delivery companies can implement various strategies to optimize technology and software costs:

- Scalable solutions: Choosing technology providers that offer pricing models that scale with delivery volume, avoiding overinvestment in low-volume periods.

- Cloud-based platforms: Leveraging cloud-based software to reduce upfront costs and ensure easy scalability as delivery volume grows.

- Consolidation and integration: Consolidating technology solutions and integrating them to reduce redundancy and improve data flow between systems.

- User training and adoption: Investing in user training to ensure efficient use of technology and maximize the return on investment.

- Regular performance review: Monitoring the effectiveness of technology solutions and adjusting as needed to optimize costs and benefits.

Impact on Profitability

To illustrate the impact of technology and software costs on profitability, consider the following example:

| Scenario | Deliveries per Month | Technology Cost per Delivery | Total Technology Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|

| Optimized Technology | 1,000 | $1.00 | $1,000 | $25 | $25,000 | $24,000 |

| Inefficient Technology | 1,000 | $2.50 | $2,500 | $25 | $25,000 | $22,500 |

In this example, a $1.50 increase in technology cost per delivery due to inefficient solutions results in a $1,500 decrease in monthly profit, highlighting the importance of managing technology and software costs effectively.

By implementing strategies to optimize technology and software expenses, delivery companies can improve operational efficiency, enhance customer experience, and maintain profitability as delivery volume grows.

How does insurance impact a delivery company’s variable costs?

Insurance is a significant variable cost for delivery companies, as it is directly tied to the number of vehicles in operation and the volume of deliveries made. As delivery volume increases, so does the exposure to potential accidents, cargo damage, and liability claims, making it crucial for companies to maintain adequate insurance coverage. The cost of insurance premiums can fluctuate based on various factors, impacting the overall profitability of delivery operations.

Types of Insurance Costs

Delivery companies should consider the following types of insurance that contribute to variable costs:

- Vehicle insurance: Coverage for damage to or theft of delivery vehicles, as well as liability protection in case of accidents.

- Cargo insurance: Coverage for damage to or loss of goods being transported,protecting the company from financial losses.

- Workers’ compensation insurance: Coverage for injuries or illnesses suffered by employees in the course of their work, including delivery drivers.

- General liability insurance: Protection against third-party claims for property damage or bodily injury arising from delivery operations.

- Umbrella insurance: Supplementary coverage that extends beyond the limits of other liability policies.

Factors Affecting Insurance Costs

Several factors can impact insurance costs for delivery companies:

- Delivery volume and frequency

- Types of goods being transported

- Geographical coverage area

- Vehicle types and values

- Driver safety records and training

- Claims history and risk management practices

Strategies to Manage Insurance Costs

Delivery companies can implement various strategies to optimize insurance costs:

- Risk management: Implementing safety protocols, driver training, and vehicle maintenance programs to reduce the likelihood of accidents and claims.

- Deductible optimization: Choosing appropriate deductible levels to balance premium costs with potential out-of-pocket expenses.

- Insurance provider selection: Shopping around for insurance providers that specialize in the delivery industry and offer competitive rates.

- Claims management: Promptly reporting and efficiently managing claims to minimize their impact on future premiums.

- Technology adoption: Using telematics and driver monitoring systems to promote safe driving habits and provide data to support favorable insurance rates.

Impact on Profitability

To demonstrate the impact of insurance costs on profitability, consider the following example:

| Scenario | Deliveries per Month | Insurance Cost per Delivery | Total Insurance Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|

| Effective Risk Management | 1,000 | $1.50 | $1,500 | $25 | $25,000 | $23,500 |

| Poor Risk Management | 1,000 | $3.00 | $3,000 | $25 | $25,000 | $22,000 |

In this example, a $1.50 increase in insurance cost per delivery due to poor risk management results in a $1,500 decrease in monthly profit, emphasizing the importance of managing insurance costs effectively.

By implementing strategies to optimize insurance expenses and minimize risks, delivery companies can protect their operations from financial losses while maintaining profitability.

What strategies can optimize variable costs in delivery operations?

Optimizing variable costs is essential for delivery companies to maintain profitability and remain competitive in the market. By implementing effective strategies to manage and reduce variable expenses, companies can improve their bottom line and allocate resources more efficiently. Here are some key strategies that delivery companies can employ to optimize variable costs:

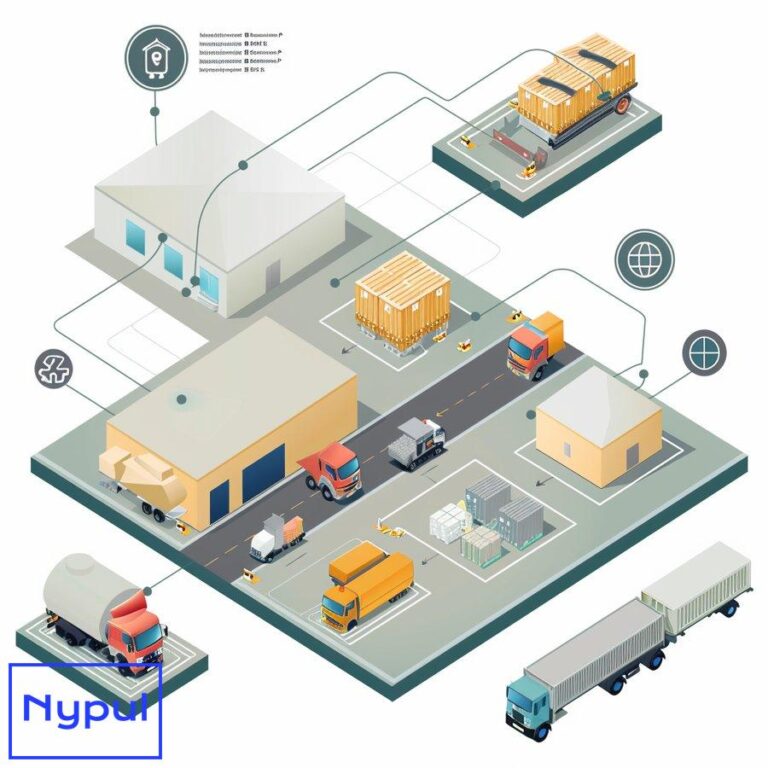

1. Route Optimization

Route optimization is a powerful strategy for reducing variable costs, particularly fuel expenses and labor costs. By using advanced algorithms and software to plan the most efficient routes, delivery companies can:

- Minimize total distance traveled

- Reduce time spent on the road

- Optimize driver schedules and workloads

- Improve delivery speed and customer satisfaction

Implementing route optimization technology can lead to significant cost savings and productivity gains, as demonstrated in the following example:

| Scenario | Deliveries per Month | Fuel Cost per Delivery | Labor Cost per Delivery | Total Variable Cost | Revenue per Delivery | Total Revenue | Profit |

|---|---|---|---|---|---|---|---|

| Optimized Routes | 1,000 | $5.00 | $10.00 | $15,000 | $25 | $25,000 | $10,000 |

| Non-Optimized Routes | 1,000 | $7.50 | $12.50 | $20,000 | $25 | $25,000 | $5,000 |

In this example, route optimization results in a $5,000 reduction in total variable costs, leading to a $5,000 increase in monthly profit.

2. Fleet Management and Maintenance

Effective fleet management and maintenance practices can help delivery companies optimize variable costs related to vehicle expenses. Key strategies include:

- Implementing preventive maintenance schedules to minimize breakdowns and extend vehicle life

- Monitoring vehicle performance and fuel efficiency using telematics data

- Providing driver training on fuel-efficient driving techniques and vehicle care

- Optimizing vehicle selection based on delivery requirements and total cost of ownership

By proactively managing fleet maintenance and performance, delivery companies can reduce repair costs, improve fuel efficiency, and minimize vehicle downtime.

3. Packaging Optimization

Optimizing packaging materials and processes can help delivery companies reduce variable costs associated with packaging expenses. Strategies to consider include:

- Standardizing packaging sizes and materials to simplify inventory management and bulk purchasing

- Using packaging automation technology to reduce labor costs and improve efficiency

- Selecting cost-effective, sustainable packaging materials that meet customer expectations

- Implementing packaging waste reduction and recycling programs

By streamlining packaging operations and minimizing waste, delivery companies can reduce material costs and improve their environmental footprint.

4. Technology Adoption

Adopting advanced technology solutions can help delivery companies optimize various aspects of their operations, leading to reduced variable costs. Examples include:

- Using mobile apps and electronic proof of delivery to reduce paperwork and improve accuracy

- Implementing warehouse management systems to optimize inventory and picking processes

- Leveraging data analytics to identify cost-saving opportunities and monitor key performance indicators

- Integrating delivery operations with e-commerce platforms to streamline order processing and customer communication

By investing in technology that automates processes, improves efficiency, and provides actionable insights, delivery companies can reduce labor costs, minimize errors, and enhance customer experience.

5. Continuous Improvement and Cost Analysis

Finally, delivery companies should foster a culture of continuous improvement and regularly analyze their variable costs to identify optimization opportunities. This involves:

- Tracking and monitoring variable cost metrics, such as cost per delivery, fuel efficiency, and packaging waste

- Conducting regular audits and performance reviews to identify areas for improvement

- Encouraging employee feedback and suggestions for cost-saving initiatives

- Benchmarking performance against industry best practices and competitors

By continuously evaluating and optimizing variable costs, delivery companies can adapt to changing market conditions, improve their bottom line, and maintain a competitive edge in the industry.