What Is Consolidation and Deconsolidation in Logistics

What are consolidation and deconsolidation in logistics?

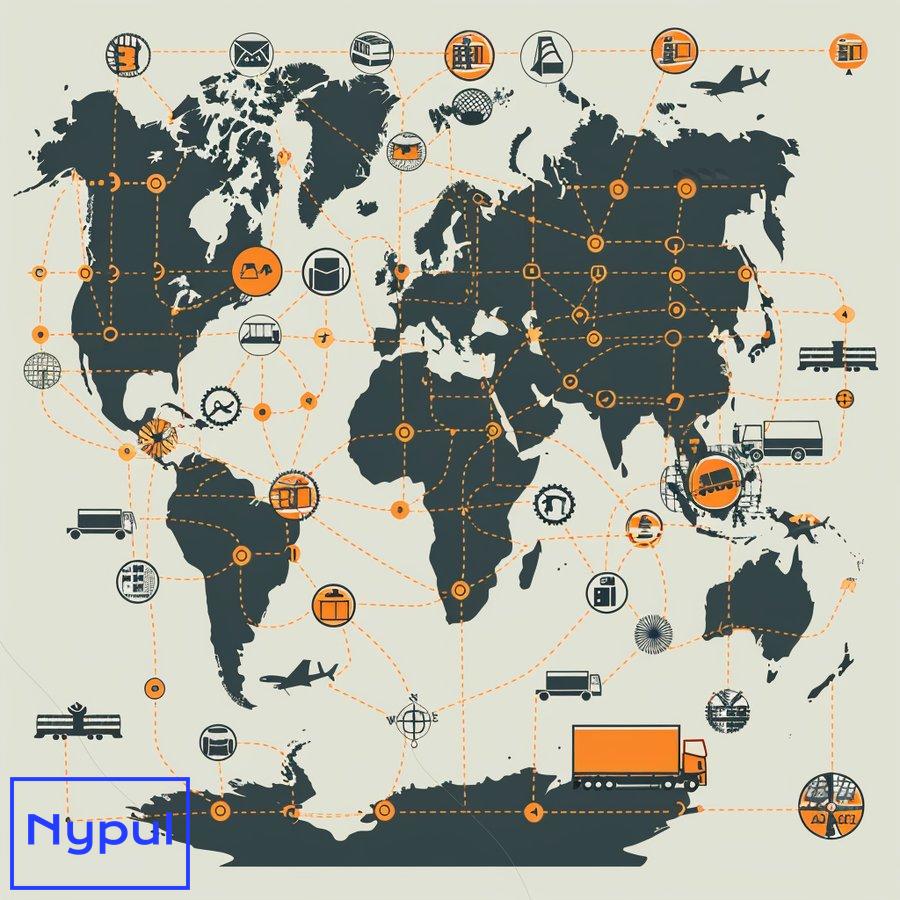

Consolidation and deconsolidation are fundamental processes in logistics that optimize the movement of goods through the supply chain. These practices allow businesses to streamline operations, reduce costs, and improve overall efficiency.

Consolidation in logistics refers to the process of combining multiple smaller shipments from various sources into a single larger shipment. This consolidated load is then transported to a common destination or distribution point. The goal is to maximize the use of available cargo space and reduce transportation costs.

For example, a consolidation center may combine partial truckloads from several manufacturers all destined for the same retail distribution center into one full truckload shipment. This eliminates the need for multiple partially-filled trucks making the same journey.

Deconsolidation in logistics is essentially the reverse process. It involves breaking down a large consolidated shipment into smaller individual shipments for final delivery to multiple end destinations. This typically occurs at a deconsolidation facility near the final delivery area.

To illustrate, a consolidated container arriving at a port may be deconsolidated, with its contents sorted and redistributed onto smaller trucks for delivery to various retail locations in the surrounding region.

The relationship between these two processes can be understood as follows:

| Process | Input | Output | Location |

|---|---|---|---|

| Consolidation | Multiple small shipments | Single large shipment | Consolidation center |

| Deconsolidation | Single large shipment | Multiple small shipments | Deconsolidation facility |

Both consolidation and deconsolidation play crucial roles in modern supply chain management, particularly for businesses dealing with less-than-truckload (LTL) shipments or those managing complex distribution networks. These practices allow companies to balance the efficiency of bulk shipping with the flexibility required to meet diverse customer needs.

The consolidation-deconsolidation cycle often forms a continuous loop in global supply chains. Goods may be consolidated at their origin, shipped in bulk across long distances, then deconsolidated for regional distribution, only to be consolidated again for local delivery routes. This cyclical process helps optimize logistics at every stage of the journey from manufacturer to end consumer.

Understanding these concepts is essential for logistics professionals, supply chain managers, and business owners looking to improve their shipping strategies. By leveraging consolidation and deconsolidation effectively, companies can significantly reduce transportation costs, minimize handling, and enhance overall supply chain performance.

How does the consolidation process work in logistics?

The consolidation process in logistics is a systematic approach to combining multiple shipments into a single, more efficient load. This process involves several steps and requires coordination among various stakeholders in the supply chain. Let’s break down how consolidation typically works:

Shipment planning and scheduling

The consolidation process begins with careful planning and scheduling. Shippers and logistics providers analyze upcoming shipments, considering factors such as:

- Destination

- Delivery timelines

- Product characteristics

- Volume and weight

This information helps determine which shipments can be effectively combined.

Routing and consolidation point selection

Based on the shipment data, optimal routes and consolidation points are identified. These consolidation points, often called cross-docking facilities or consolidation centers, serve as hubs where multiple shipments converge.

Inbound logistics

Individual shipments from various sources are transported to the designated consolidation point. This may involve local pickups or regional transportation.

Sorting and consolidation

At the consolidation center, shipments are sorted based on their final destinations and other relevant criteria. Workers or automated systems then combine compatible shipments into larger loads, optimizing space utilization in trucks, containers, or pallets.

Documentation and compliance

Consolidated shipments require updated documentation. This includes creating a master bill of lading that covers all individual shipments within the consolidated load. Customs documentation may also need to be prepared for international shipments.

Outbound transportation

The consolidated load is then loaded onto the appropriate mode of transport (e.g., truck, rail, ship, or aircraft) for long-haul transportation to its destination.

Tracking and visibility

Throughout the consolidation process and subsequent transportation, advanced tracking systems provide real-time visibility of the consolidated shipment and its individual components.

To illustrate the efficiency gains of consolidation, consider this comparison:

| Scenario | Number of Shipments | Total Volume | Number of Trucks Required |

|---|---|---|---|

| Without Consolidation | 10 separate LTL shipments | 250 cubic feet each (2500 total) | 10 partially filled trucks |

| With Consolidation | 1 consolidated shipment | 2500 cubic feet | 1 fully loaded truck |

This example demonstrates how consolidation can dramatically reduce the number of vehicles required, leading to cost savings and reduced environmental impact.

Consolidation strategies

Logistics providers and shippers may employ various consolidation strategies depending on their specific needs:

Geographic consolidation combines shipments based on their destination regions. This is particularly effective for international shipping, where goods from multiple suppliers in one country are consolidated for export to another country.

Product-based consolidation groups similar products together, which can be beneficial for items requiring specific handling or temperature control.

Time-based consolidation accumulates shipments over a set period before dispatching them as a single load. This approach balances shipping frequency with load optimization.

Multi-modal consolidation involves consolidating shipments that will use multiple transportation modes (e.g., truck to rail to ocean freight) to reach their final destination.

Challenges in the consolidation process

While consolidation offers many benefits, it also presents some challenges:

Timing coordination is critical. Delays in one shipment can impact the entire consolidated load.

Compatibility issues may arise when combining different types of products, especially those with special handling requirements.

Increased handling at consolidation points can potentially lead to damage if not managed properly.

Complex tracking of individual shipments within a consolidated load requires sophisticated logistics management systems.

Successful consolidation requires a deep understanding of supply chain dynamics, strong partnerships with carriers and consolidation facilities, and robust technology solutions. When implemented effectively, it can lead to significant improvements in logistics efficiency and cost-effectiveness.

What are the key benefits of consolidation in supply chain management?

Consolidation in supply chain management offers numerous advantages that can significantly enhance operational efficiency and cost-effectiveness. Understanding these benefits is essential for businesses looking to optimize their logistics strategies. Let’s explore the primary advantages of consolidation:

Cost reduction

One of the most significant benefits of consolidation is the potential for substantial cost savings:

Lower transportation costs: By combining multiple shipments into a single load, companies can take advantage of economies of scale. Full truckload (FTL) rates are generally lower per unit than less-than-truckload (LTL) rates.

Reduced handling fees: Fewer individual shipments mean fewer handling instances, which translates to lower overall handling costs.

Decreased packaging expenses: Consolidated shipments often require less individual packaging, reducing material costs.

To illustrate the potential savings, consider this comparison:

| Shipping Method | Number of Shipments | Cost per Shipment | Total Cost |

|---|---|---|---|

| Individual LTL | 10 | $500 | $5,000 |

| Consolidated FTL | 1 | $3,000 | $3,000 |

| Savings | $2,000 (40%) |

Improved efficiency

Consolidation streamlines various aspects of the supply chain:

Optimized warehouse operations: Consolidation centers can efficiently manage inventory from multiple sources, reducing the need for extensive warehouse space at individual locations.

Streamlined documentation: Instead of processing paperwork for numerous small shipments, consolidated loads require fewer documents, simplifying administrative tasks.

Enhanced load planning: Consolidation allows for better utilization of cargo space, leading to more efficient transportation planning.

Environmental sustainability

In an era of increasing environmental consciousness, consolidation offers significant ecological benefits:

Reduced carbon footprint: Fewer vehicles on the road mean lower overall emissions. A single fully-loaded truck produces less pollution than multiple partially-filled trucks covering the same distance.

Decreased fuel consumption: Optimized loads and routes result in more efficient use of fuel resources.

Minimized packaging waste: Consolidated shipments often require less overall packaging material, reducing waste generation.

Improved customer service

Consolidation can lead to enhanced customer satisfaction through:

Faster delivery times: By optimizing transportation routes and reducing the number of individual shipments, goods can often reach their destinations more quickly.

Increased reliability: Consolidated shipments are typically given priority and are less likely to be delayed or misplaced compared to smaller, individual shipments.

Flexibility in order fulfillment: Consolidation allows businesses to offer more frequent shipments without incurring prohibitive costs, enabling them to meet diverse customer needs more effectively.

Enhanced visibility and control

Modern consolidation practices, coupled with advanced technology, provide improved oversight of the supply chain:

Real-time tracking: Consolidated shipments are often equipped with sophisticated tracking systems, allowing for better visibility throughout the transportation process.

Simplified inventory management: By centralizing shipments at consolidation points, businesses can more easily monitor and manage their inventory levels.

Data-driven decision making: The consolidation process generates valuable data on shipping patterns and efficiencies, enabling companies to make informed decisions about their supply chain strategies.

Risk mitigation

Consolidation can help reduce various risks in the supply chain:

Decreased chances of loss or damage: Fewer handling points and more secure packaging of larger consolidated loads can reduce the risk of items being lost or damaged during transit.

Improved security: Consolidated shipments often benefit from enhanced security measures, particularly for high-value or sensitive goods.

Better insurance terms: Insuring a single large shipment can be more cost-effective than insuring multiple smaller shipments, potentially leading to better coverage at lower rates.

Competitive advantage

Effective use of consolidation can provide businesses with a competitive edge:

Ability to serve smaller markets: Consolidation makes it economically feasible to ship to locations that might not justify full truckloads on their own, allowing businesses to expand their market reach.

Improved responsiveness: By enabling more frequent shipments without increased costs, companies can respond more quickly to market demands and changes.

Enhanced global reach: For international trade, consolidation services can help smaller businesses access global markets by making overseas shipping more affordable and manageable.

While the benefits of consolidation are substantial, it’s important to note that implementing an effective consolidation strategy requires careful planning and execution. Factors such as shipment compatibility, timing coordination, and selection of appropriate consolidation partners all play crucial roles in realizing these advantages.

By leveraging consolidation effectively, businesses can not only reduce costs but also improve their overall supply chain performance, leading to increased competitiveness in the marketplace.

How does deconsolidation differ from consolidation?

While consolidation and deconsolidation are closely related processes in logistics, they serve different purposes and occur at different points in the supply chain. Understanding these differences is crucial for effective supply chain management. Let’s explore how deconsolidation differs from consolidation:

Definition and purpose

Consolidation involves combining multiple smaller shipments into a single larger shipment. Its primary purpose is to optimize transportation efficiency and reduce costs for long-distance shipping.

Deconsolidation, on the other hand, is the process of breaking down a large, consolidated shipment into smaller shipments for final distribution. Its main goal is to facilitate efficient local delivery and meet specific customer or retail requirements.

Position in the supply chain

Consolidation typically occurs at the beginning or early stages of the shipping process, often near the point of origin or at strategic consolidation centers.

Deconsolidation takes place towards the end of the shipping journey, usually at distribution centers or warehouses near the final destination markets.

Direction of goods flow

Consolidation represents a convergence of goods, with multiple shipments coming together into a single unit.

Deconsolidation represents a divergence of goods, with a single large shipment being separated into multiple smaller shipments.

To visualize these differences, consider the following table:

| Aspect | Consolidation | Deconsolidation |

|---|---|---|

| Direction of goods flow | Many to one | One to many |

| Typical location | Near origin | Near destination |

| Primary goal | Optimize long-distance transport | Facilitate local distribution |

| Effect on shipment size | Increases | Decreases |

Operational focus

Consolidation focuses on maximizing the use of available cargo space and reducing the number of individual shipments for long-haul transportation.

Deconsolidation emphasizes sorting, reorganizing, and preparing goods for final delivery, often involving repackaging or reconfiguring shipments to meet specific customer or retail requirements.

Timing considerations

Consolidation may involve holding shipments until sufficient volume is accumulated to justify a full load, potentially leading to slightly longer lead times for individual items.

Deconsolidation is often time-sensitive, aiming to quickly break down incoming consolidated shipments for prompt distribution to meet local delivery schedules or customer expectations.

Equipment and facilities

Consolidation centers typically require large warehouses with ample storage space and equipment for combining diverse shipments, such as forklifts and pallet wrappers.

Deconsolidation facilities focus more on sorting and distribution capabilities, often featuring conveyor systems, automated sorting equipment, and cross-docking areas for efficient breakdown and redistribution of goods.

Documentation and tracking

Consolidation involves creating new, comprehensive documentation for the combined shipment, such as a master bill of lading that covers all individual shipments within the consolidated load.

Deconsolidation requires breaking down the master documentation into individual shipping documents for each separated shipment, often involving the creation of new labels and tracking information for final delivery.

Cost implications

Consolidation aims to reduce overall transportation costs by leveraging economies of scale for long-distance shipping.

Deconsolidation may incur additional handling costs but can lead to more cost-effective final delivery by allowing for optimized local distribution routes.

Inventory management

Consolidation can simplify inventory management during transit by treating multiple shipments as a single unit.

Deconsolidation often involves more complex inventory management, requiring precise sorting and allocation of goods to their final destinations.

Customs and regulatory considerations

Consolidation may simplify customs processes for international shipments by allowing a single customs clearance for the entire consolidated load.

Deconsolidation of international shipments often involves more complex customs procedures, as individual items may need to be cleared separately based on their final destinations or specific regulatory requirements.

Flexibility and customization

Consolidation prioritizes standardization and efficiency in shipping large volumes.

Deconsolidation allows for greater flexibility in meeting diverse customer needs, enabling customization of final shipments based on specific requirements or local market demands.

Risk management

Consolidation can reduce certain risks by minimizing the number of individual shipments in transit, but it also concentrates risk in larger, more valuable consolidated loads.

Deconsolidation spreads risk across multiple smaller shipments but may increase the overall complexity of risk management due to the increased number of handling points and separate deliveries.

While consolidation and deconsolidation serve different purposes, they are often two sides of the same coin in efficient supply chain management. Many shipments go through both processes: consolidation for efficient long-distance transport, followed by deconsolidation for effective local distribution. Understanding the unique characteristics and requirements of each process is essential for logistics professionals seeking to optimize their supply chain operations.

When should businesses choose consolidation over deconsolidation?

The decision to choose consolidation over deconsolidation (or vice versa) depends on various factors related to a business’s specific needs, supply chain structure, and market conditions. Understanding when to opt for consolidation can significantly impact operational efficiency and cost-effectiveness. Let’s explore the scenarios and considerations that favor consolidation:

Long-distance transportation

Consolidation is particularly beneficial when shipping goods over long distances, especially in international trade. The cost savings and efficiency gains of consolidated shipments become more pronounced as the distance increases.

Example: A company exporting products from the United States to Europe would likely benefit from consolidating shipments at a U.S. port before ocean freight transport, rather than sending multiple smaller shipments individually.

Multiple suppliers in close proximity

When a business sources products from several suppliers located in the same geographical area, consolidation can streamline the collection and shipping process.

Example: A retailer purchasing goods from multiple manufacturers in China could use a consolidation service to combine all orders into a single shipment for export, reducing overall shipping costs and simplifying logistics.

Less-than-truckload (LTL) shipments

For businesses frequently dealing with LTL shipments, consolidation can offer significant cost savings by combining these partial loads into full truckloads.

Example: A distributor regularly shipping small quantities to various customers across the country could benefit from consolidating these shipments at a central hub before long-haul transport.

Seasonal or cyclical demand patterns

Industries with predictable peaks in shipping volume can use consolidation to manage these fluctuations more efficiently.

Example: A retailer preparing for the holiday shopping season might consolidate shipments from various suppliers in the months leading up to peak demand, allowing for more cost-effective bulk shipping.

Cost-sensitive operations

For businesses operating on tight margins or in highly competitive markets, thecost savings offered by consolidation can be particularly attractive.

Example: A small e-commerce business competing with larger retailers might use consolidation services to reduce shipping costs, allowing them to offer more competitive pricing to customers.

Standardized products or packaging

Consolidation is more straightforward and efficient when dealing with products that have similar handling requirements or standardized packaging.

Example: A manufacturer of electronic components shipping to multiple assembly plants could easily consolidate these standardized parts into larger shipments.

Limited warehousing capacity

Businesses with limited storage space at their own facilities can benefit from consolidation services that temporarily hold and combine shipments.

Example: A growing startup might use consolidation to manage inventory flow without investing in expanded warehouse space.

Environmental concerns

Companies prioritizing sustainability in their supply chain operations often favor consolidation due to its potential for reducing carbon emissions.

Example: A company with strong environmental policies might choose consolidation to minimize the number of vehicles required for transportation, thereby reducing their carbon footprint.

Complex supply chains

For businesses with intricate supply networks involving multiple suppliers, manufacturers, and distribution points, consolidation can simplify logistics management.

Example: An automotive manufacturer sourcing parts from hundreds of suppliers worldwide could use consolidation to streamline its inbound logistics.

High-volume, low-value goods

Products with low value relative to their shipping costs benefit significantly from the economies of scale provided by consolidation.

Example: A company importing bulk raw materials like textiles or plastics would likely find consolidation more cost-effective than shipping smaller quantities separately.

Consistent, predictable shipping needs

Businesses with steady, foreseeable shipping requirements can plan and implement consolidation strategies more effectively.

Example: A publisher distributing books to retailers on a regular schedule could establish a consistent consolidation process for these shipments.

Risk mitigation for high-value goods

Consolidation can offer enhanced security measures for valuable items, making it preferable for businesses shipping high-value products.

Example: A luxury goods manufacturer might choose to consolidate shipments to benefit from improved security protocols and reduced handling.

When consolidation may not be the best choice:

While consolidation offers many benefits, there are scenarios where it might not be the optimal choice:

Time-sensitive deliveries

For urgent shipments or industries where speed is critical, the potential delays associated with consolidation might outweigh the cost benefits.

Example: A hospital requiring immediate delivery of medical supplies would prioritize speed over the cost savings of consolidation.

Incompatible products

When shipping goods with vastly different handling requirements or regulations, consolidation may not be feasible or cost-effective.

Example: A company shipping both perishable foods and industrial chemicals would likely need to keep these shipments separate due to their incompatible nature.

Last-mile delivery

In scenarios focused on final distribution to end consumers, deconsolidation is often more appropriate than consolidation.

Example: An online retailer fulfilling individual customer orders would typically use deconsolidation strategies for efficient local delivery.

Highly variable or unpredictable shipping needs

Businesses with erratic shipping patterns or frequently changing requirements may find it challenging to implement effective consolidation strategies.

Example: A company with highly customized, made-to-order products might struggle to consistently consolidate shipments due to variability in order specifications and timing.

Local or short-distance transportation

For shipments traveling relatively short distances, the benefits of consolidation may be minimal compared to the potential added complexity.

Example: A regional distributor serving customers within a 100-mile radius might find direct shipping more efficient than consolidation for most deliveries.

In conclusion, the decision to choose consolidation should be based on a careful analysis of a business’s specific circumstances, including shipping distances, product characteristics, volume, frequency, and overall supply chain strategy. While consolidation can offer significant benefits in many scenarios, it’s essential to consider the potential trade-offs and evaluate whether it aligns with the company’s operational needs and goals.

What role does technology play in consolidation and deconsolidation?

Technology plays a pivotal role in enhancing the efficiency, accuracy, and effectiveness of both consolidation and deconsolidation processes in modern logistics. As supply chains become increasingly complex and global, advanced technological solutions have become indispensable for managing these critical operations. Let’s explore the various ways technology impacts consolidation and deconsolidation:

Transportation Management Systems (TMS)

TMS software is at the heart of efficient consolidation and deconsolidation operations:

Shipment planning and optimization: TMS algorithms can analyze multiple shipments and determine the most efficient consolidation strategies based on factors such as destination, weight, volume, and delivery timelines.

Route optimization: These systems calculate the most cost-effective routes for consolidated shipments, considering factors like traffic, weather, and fuel costs.

Carrier selection: TMS can automatically select the most suitable carriers for consolidated loads based on predefined criteria such as cost, reliability, and transit times.

Warehouse Management Systems (WMS)

WMS solutions are crucial for managing the physical aspects of consolidation and deconsolidation:

Inventory tracking: Real-time inventory management ensures that all items for consolidation are accounted for and properly allocated.

Space utilization: Advanced WMS can optimize warehouse space, suggesting the most efficient storage and staging areas for consolidation and deconsolidation activities.

Pick and pack optimization: For deconsolidation, WMS can generate optimized picking lists and packing instructions to streamline the breakdown of consolidated shipments.

Internet of Things (IoT) and Sensor Technology

IoT devices and sensors provide real-time data that is crucial for managing consolidated shipments:

Environmental monitoring: Sensors can track temperature, humidity, and other environmental factors, ensuring that consolidated goods remain in optimal condition throughout transit.

Location tracking: GPS-enabled IoT devices offer precise location data for consolidated shipments, enhancing visibility and enabling proactive management of potential delays or issues.

Shock and tilt monitoring: Sensors can detect if consolidated loads have been mishandled, allowing for immediate intervention and reducing the risk of damage.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies are revolutionizing decision-making processes in consolidation and deconsolidation:

Predictive analytics: AI algorithms can forecast shipping volumes and patterns, allowing businesses to plan consolidation strategies more effectively.

Dynamic optimization: ML models can continuously learn from historical data to improve consolidation and deconsolidation processes over time.

Anomaly detection: AI can identify unusual patterns or potential issues in consolidated shipments, flagging them for human review and intervention.

Robotics and Automation

Physical automation technologies are transforming the handling of goods in consolidation and deconsolidation facilities:

Automated guided vehicles (AGVs): These robots can efficiently move pallets and containers within warehouses, speeding up the consolidation and deconsolidation processes.

Robotic arms: Used for picking and packing, robotic arms can handle the sorting and reorganization of goods during deconsolidation with high precision and speed.

Automated storage and retrieval systems (AS/RS): These systems can quickly locate and retrieve specific items within large consolidated shipments, facilitating efficient deconsolidation.

Blockchain Technology

Blockchain offers enhanced security and transparency for consolidated shipments:

Shipment tracking: A blockchain ledger can provide an immutable record of a consolidated shipment’s journey, enhancing traceability and accountability.

Smart contracts: Automated execution of predefined rules can streamline processes like customs clearance and payment releases for consolidated shipments.

Document management: Blockchain can securely store and manage the complex documentation associated with consolidated international shipments.

Data Analytics and Visualization Tools

These tools help logistics professionals make sense of the vast amount of data generated in consolidation and deconsolidation operations:

Performance metrics: Analytics platforms can track and display KPIs related to consolidation efficiency, cost savings, and deconsolidation accuracy.

Trend analysis: Visualization tools can help identify patterns in shipping data, informing long-term consolidation strategies.

Real-time dashboards: Interactive displays provide up-to-the-minute information on consolidation and deconsolidation activities, enabling quick decision-making.

Mobile Technologies

Mobile devices and applications play a crucial role in on-the-ground management of consolidation and deconsolidation:

Barcode and QR code scanning: Mobile scanners can quickly capture data from individual items during consolidation or deconsolidation, reducing errors and speeding up processes.

Real-time communication: Mobile apps enable instant communication between warehouse staff, drivers, and logistics managers, facilitating smooth operations.

Digital signatures and proof of delivery: Mobile devices can capture electronic signatures and photographic evidence of deliveries, streamlining the final stages of deconsolidation.

Cloud Computing

Cloud-based solutions provide the infrastructure needed for managing complex consolidation and deconsolidation operations:

Data accessibility: Cloud storage ensures that all stakeholders have access to real-time information about consolidated shipments, regardless of their location.

Scalability: Cloud-based systems can easily scale to handle fluctuations in consolidation volumes without requiring significant infrastructure investments.

Integration capabilities: Cloud platforms facilitate seamless integration between various technological solutions used in consolidation and deconsolidation processes.

3D Load Planning Software

Specialized software for optimizing the loading of consolidated shipments:

Space utilization: These tools can calculate the most efficient way to load diverse items into a consolidated shipment, maximizing space usage.

Weight distribution: 3D planning software ensures proper weight distribution in consolidated loads, enhancing safety and compliance with transportation regulations.

Visual representation: These tools provide 3D visualizations of loaded containers or trucks, aiding in planning and communication.

The impact of technology on consolidation and deconsolidation is profound and multifaceted. By leveraging these advanced technological solutions, businesses can:

- Increase operational efficiency

- Reduce errors and improve accuracy

- Enhance visibility and control over shipments

- Optimize resource utilization

- Improve decision-making through data-driven insights

- Enhance customer satisfaction through improved service levels

As technology continues to evolve, we can expect even more innovative solutions to emerge, further transforming the landscape of consolidation and deconsolidation in logistics. The key for businesses is to stay informed about these technological advancements and strategically implement those that align with their specific operational needs and goals.

How do consolidation and deconsolidation impact overall supply chain efficiency?

Consolidation and deconsolidation processes have a significant and multifaceted impact on overall supply chain efficiency. These practices influence various aspects of logistics operations, from cost management to customer satisfaction. Let’s explore the ways in which consolidation and deconsolidation contribute to supply chain efficiency:

Cost optimization

One of the most direct impacts of consolidation and deconsolidation on supply chain efficiency is cost reduction:

Transportation cost savings: By combining multiple shipments into a single consolidated load, businesses can take advantage of economies of scale, reducing per-unit shipping costs.

Example: A company that previously shipped 10 partial truckloads per week might consolidate these into 3 full truckloads, significantly reducing transportation expenses.

Warehousing cost reduction: Efficient consolidation and deconsolidation processes can lead to reduced warehousing needs and associated costs.

Example: A retailer using cross-docking for deconsolidation can minimize storage requirements, potentially reducing warehouse space by up to 30%.

Labor cost efficiency: Consolidated shipments often require less overall handling, leading to reduced labor costs throughout the supply chain.

Example: A distribution center handling one large consolidated shipment instead of multiple small shipments might reduce labor hours by 20-25% for that particular set of goods.

Improved resource utilization

Consolidation and deconsolidation contribute to more efficient use of resources:

Vehicle utilization: Consolidation ensures that transportation vehicles are used to their full capacity, reducing the number of partially filled trucks or containers on the road.

Example: A logistics provider might increase their average truck fill rate from 70% to 90% through effective consolidation practices.

Warehouse space optimization: Deconsolidation facilities can be designed for rapid throughput, maximizing the use of available space.

Example: A deconsolidation center using advanced sorting technology might process 50% more volume per square foot compared to traditional warehousing.

Enhanced inventory management

These processes can lead to more effective inventory control:

Reduced inventory holding: Consolidation can enable more frequent, smaller orders from suppliers, reducing the need for large inventory buffers.

Example: A manufacturer using consolidation services might reduce their average inventory holding by 15-20%, freeing up working capital.

Improved inventory accuracy: Deconsolidation processes often involve detailed sorting and checking, which can help identify discrepancies and improve overall inventory accuracy.

Example: A retailer implementing rigorous deconsolidation procedures might see a 30% reduction in inventory discrepancies.

Streamlined operations

Consolidation and deconsolidation can simplify various aspects of supply chain operations:

Reduced paperwork: Consolidated shipments require less overall documentation, streamlining administrative processes.

Example: A company that previously processed 50 individual shipments per week might now handle just 10 consolidated shipments, reducing documentation time by 60-70%.

Simplified customs procedures: For international shipments, consolidation can simplify customs clearance by presenting a single, larger shipment instead of multiple small ones.

Example: An importer might reduce customs processing time by 40% through the use of consolidated shipments.

Enhanced supply chain visibility

These processes, when coupled with modern technology, can significantly improve supply chain transparency:

Real-time tracking: Consolidated shipments are often equipped with advanced tracking technologies, providing better visibility throughout the supply chain.

Example: A company using IoT-enabled tracking for consolidated shipments might achieve 99.9% shipment visibility, compared to 85% for non-consolidated shipments.

Data-driven insights: The data generated through consolidation and deconsolidation processes can provide valuable insights for supply chain optimization.

Example: Analysis of consolidation patterns might reveal that combining shipments from suppliers A and B consistently results in a 25% cost reduction, informing future strategies.

Improved customer service

Efficient consolidation and deconsolidation can lead to enhanced customer satisfaction:

Faster delivery times: By optimizing transportation and handling processes, goods can often reach their final destinations more quickly.

Example: A retailer using efficient deconsolidation might reduce average delivery times from 5 days to 3 days for certain product categories.

Increased order accuracy: The detailed sorting involved in deconsolidation can help catch errors before they reach the customer.

Example: A distribution center implementing advanced deconsolidation processes might see a 40% reduction in order fulfillment errors.

Environmental sustainability

Consolidation, in particular, can have positive environmental impacts:

Reduced carbon emissions: Fewer vehicles on the road lead to lower overall emissions.

Example: A company that reduces its weekly shipments from 20 to 5 through consolidation might decrease its carbon emissions from transport by 60-70%.

Decreased packaging waste: Consolidated shipments often require less overall packaging material.

Example: A manufacturer using consolidation services might reduce its packaging material usage by 25-30% for international shipments.

Risk mitigation

Consolidation and deconsolidation can help manage various supply chain risks:

Reduced handling damage: Fewer touch points in the supply chain can lead to less product damage.

Example: A company implementing consolidation might see a 20-25% reduction in transit damage claims.

Improved security: Consolidated shipments often benefit from enhanced security measures.

Example: A high-value goods manufacturer using consolidation services might experience a 50% reduction in theft or loss incidents.

Flexibility and scalability

These processes can enhance a supply chain’s ability to adapt to changing conditions:

Easier capacity management: Consolidation allows for more flexible use of transportation capacity, especially during demand fluctuations.

Example: A seasonal business might use consolidation to manage a 40% increase in shipping volume during peak periods without proportionally increasing costs.

Scalability: Deconsolidation processes can be scaled up or down more easily than individual shipment handling.

Example: A growing e-commerce company might be able to handle a 100% increase in order volume with only a 50% increase in deconsolidation facility space through optimized processes.

While the specific impacts can vary depending on the nature of the business and its supply chain, consolidation and deconsolidation generally contribute significantly to overall supply chain efficiency. By optimizing costs, improving resource utilization, enhancing visibility, and providing better customer service, these processes play a crucial role in creating lean, responsive, and competitive supply chains.

However, it’s important to note that realizing these benefits requires careful planning, appropriate technology implementation, and ongoing optimization. Companies must regularly assess their consolidation and deconsolidation strategies to ensure they continue to deliver value in an ever-changing logistics landscape.