What Is First Mile and Last-Mile Logistics

First mile and last-mile logistics are critical components of the supply chain that bookend the journey of goods from their origin to the final destination. These phases play a pivotal role in shaping customer satisfaction and operational efficiency for businesses across various industries.

What are first mile and last-mile logistics?

First mile logistics refers to the initial stage of the supply chain process, where goods are transported from the manufacturer or supplier to a distribution center or warehouse. This crucial step sets the tone for the entire logistics operation, ensuring that products are properly collected, sorted, and prepared for further distribution.

In contrast, last-mile logistics encompasses the final leg of the delivery journey, where goods are transported from a distribution hub to the end customer. This phase is often considered the most challenging and expensive part of the supply chain, as it involves navigating complex urban environments and meeting increasingly demanding customer expectations.

Both first mile and last-mile logistics are essential for ensuring the smooth flow of goods throughout the supply chain. They require careful planning, efficient execution, and often specialized resources to overcome unique challenges associated with each phase.

First Mile Logistics Process

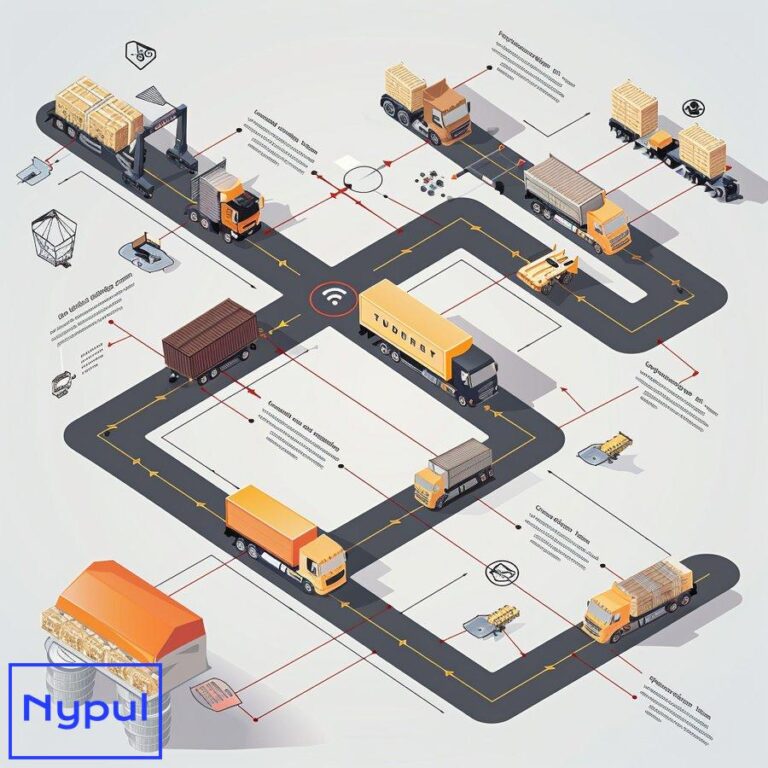

The first mile logistics process typically involves the following steps:

- Order Processing: Receiving and validating customer orders.

- Inventory Management: Locating and preparing the ordered items for shipment.

- Packaging: Properly packing goods to ensure safe transport.

- Documentation: Preparing necessary paperwork, including shipping labels and customs documents.

- Pickup: Arranging for carriers to collect the packaged goods from the origin point.

- Initial Transportation: Moving the goods to the first distribution center or consolidation point.

Last-Mile Logistics Process

The last-mile logistics process generally includes these steps:

- Order Sorting: Organizing packages at the distribution center for efficient delivery routes.

- Route Planning: Optimizing delivery routes to minimize time and fuel consumption.

- Loading: Properly loading delivery vehicles with the sorted packages.

- Transportation: Delivering packages to their final destinations.

- Proof of Delivery: Obtaining customer signatures or other forms of delivery confirmation.

- Returns Processing: Handling any return requests or failed deliveries.

Understanding these processes is crucial for businesses aiming to streamline their supply chain operations and improve customer satisfaction. By recognizing the unique challenges and opportunities presented by first mile and last-mile logistics, companies can develop strategies to enhance efficiency, reduce costs, and gain a competitive edge in the market.

How do first mile and last-mile logistics differ?

First mile and last-mile logistics, while both integral to the supply chain, differ significantly in their objectives, challenges, and execution. Understanding these differences is crucial for businesses to optimize their logistics operations effectively.

Scope and Objectives

First Mile Logistics:

– Focuses on moving goods from manufacturers or suppliers to distribution centers.

– Aims to consolidate shipments and optimize warehouse operations.

– Prioritizes bulk movement and efficient inventory management.

Last-Mile Logistics:

– Involves delivering products from distribution centers to end customers.

– Emphasizes speed, accuracy, and customer satisfaction.

– Focuses on individual package delivery and personalized service.

Transportation Methods

First Mile Logistics:

– Often utilizes large vehicles like trucks, cargo ships, or freight trains.

– Emphasizes full truckload (FTL) or less-than-truckload (LTL) shipments.

– May involve intermodal transportation for long-distance or international shipments.

Last-Mile Logistics:

– Typically uses smaller vehicles like vans, cars, or even bicycles in urban areas.

– Focuses on parcel delivery and small package handling.

– May employ innovative methods like drones or autonomous vehicles in some cases.

Operational Complexity

First Mile Logistics:

– Deals with fewer, larger shipments.

– Operates in more predictable environments (e.g., industrial areas, ports).

– Requires coordination with suppliers and manufacturers.

Last-Mile Logistics:

– Handles numerous small deliveries to diverse locations.

– Navigates complex urban environments with traffic and parking challenges.

– Requires direct interaction with end customers.

Cost Structure

First Mile Logistics:

– Generally more cost-effective due to economies of scale.

– Costs are primarily influenced by fuel prices and transportation efficiency.

– Investments focus on warehouse automation and inventory management systems.

Last-Mile Logistics:

– Often the most expensive part of the supply chain, accounting for up to 53% of total shipping costs.

– Costs are impacted by factors like failed deliveries, route inefficiencies, and labor expenses.

– Requires investments in route optimization software and customer communication tools.

Technology Integration

First Mile Logistics:

– Utilizes warehouse management systems (WMS) and transportation management systems (TMS).

– Focuses on inventory tracking and shipment consolidation technologies.

– May employ RFID and IoT devices for real-time tracking of large shipments.

Last-Mile Logistics:

– Relies heavily on GPS and route optimization software.

– Implements mobile apps for real-time tracking and customer communication.

– May use AI and machine learning for predictive delivery and demand forecasting.

Customer Interaction

First Mile Logistics:

– Limited direct customer interaction.

– Communication primarily occurs between businesses (B2B).

– Focus on meeting supplier agreements and inventory requirements.

Last-Mile Logistics:

– High level of direct customer interaction.

– Emphasis on customer experience and satisfaction.

– Requires effective communication for delivery updates and problem resolution.

Environmental Impact

First Mile Logistics:

– Larger carbon footprint due to use of heavy vehicles and long-distance transportation.

– Opportunities for eco-friendly practices through optimized loading and intermodal transport.

Last-Mile Logistics:

– Contributes significantly to urban congestion and emissions.

– Growing focus on sustainable delivery methods like electric vehicles and bicycle couriers.

Performance Metrics

First Mile Logistics:

– Key metrics include inventory accuracy, on-time pickup, and transportation costs.

– Focus on optimizing warehouse space utilization and reducing stockouts.

Last-Mile Logistics:

– Metrics center around on-time delivery rates, customer satisfaction scores, and cost per delivery.

– Emphasis on reducing failed deliveries and improving first-attempt delivery success.

Understanding these differences is essential for businesses to develop targeted strategies for each phase of their logistics operations. By recognizing the unique challenges and requirements of first mile and last-mile logistics, companies can implement tailored solutions that enhance efficiency, reduce costs, and improve overall supply chain performance.

What challenges do businesses face in first mile logistics?

First mile logistics, while often overshadowed by the complexities of last-mile delivery, presents its own set of unique challenges that can significantly impact the efficiency and cost-effectiveness of the entire supply chain. Businesses must navigate these obstacles to ensure a smooth start to their logistics operations.

Inventory Management and Accuracy

One of the primary challenges in first mile logistics is maintaining accurate inventory records. Discrepancies between physical stock and inventory systems can lead to:

- Delayed shipments due to stockouts

- Overstocking, resulting in increased storage costs

- Inefficient use of warehouse space

- Potential loss of sales and customer dissatisfaction

To address this challenge, businesses are increasingly adopting advanced inventory management systems that utilize RFID technology and AI-powered predictive analytics. These tools help improve inventory accuracy and optimize stock levels, reducing the risk of disruptions in the first mile process.

Order Fulfillment Efficiency

Efficiently processing and fulfilling orders is crucial in first mile logistics. Challenges in this area include:

- Managing high volumes of orders during peak seasons

- Coordinating multiple SKUs and product variations

- Ensuring accurate picking and packing of items

- Balancing speed and accuracy in order processing

Implementing robust warehouse management systems (WMS) and automated sorting technologies can significantly improve order fulfillment efficiency. Some businesses are also exploring the use of robotics and AI-driven picking systems to enhance speed and accuracy.

Transportation Planning and Coordination

Coordinating the movement of goods from suppliers or manufacturers to distribution centers presents several challenges:

- Optimizing transportation routes for cost-effectiveness

- Managing relationships with multiple carriers and freight forwarders

- Dealing with capacity constraints during peak shipping periods

- Ensuring compliance with transportation regulations and customs requirements

To overcome these challenges, companies are leveraging transportation management systems (TMS) that provide real-time visibility into shipping options, rates, and carrier performance. Additionally, building strong partnerships with reliable carriers and implementing flexible transportation strategies can help mitigate risks associated with capacity constraints and regulatory compliance.

Data Integration and Visibility

Lack of data integration and visibility across the supply chain can lead to inefficiencies in first mile logistics. Common issues include:

- Siloed information systems between suppliers, manufacturers, and logistics providers

- Limited real-time tracking of shipments and inventory

- Difficulty in predicting and responding to supply chain disruptions

Implementing integrated supply chain management platforms that connect all stakeholders can significantly improve visibility and decision-making. These systems often incorporate IoT devices and blockchain technology to provide real-time tracking and enhance data security.

Quality Control and Compliance

Ensuring product quality and compliance with regulations is a critical challenge in first mile logistics, particularly for industries with strict quality standards or regulatory requirements. Issues in this area include:

- Maintaining product integrity during handling and transportation

- Adhering to industry-specific regulations (e.g., cold chain requirements for pharmaceuticals)

- Managing recalls and product defects efficiently

Implementing robust quality control processes, including regular audits and inspections, is essential. Additionally, leveraging technology such as temperature-monitoring sensors and blockchain for traceability can help ensure compliance and facilitate quick responses to quality issues.

Cost Management

Controlling costs in first mile logistics is an ongoing challenge for businesses. Key cost factors include:

- Warehouse operating expenses

- Transportation and fuel costs

- Labor costs for picking, packing, and loading

- Technology investments for inventory and transportation management

To address these challenges, businesses are focusing on optimizing warehouse layouts, implementing energy-efficient practices, and exploring alternative transportation modes. Some companies are also considering nearshoring or reshoring strategies to reduce transportation distances and associated costs.

Sustainability and Environmental Concerns

As environmental awareness grows, businesses face increasing pressure to make their first mile logistics operations more sustainable. Challenges in this area include:

- Reducing carbon emissions from transportation and warehouse operations

- Minimizing packaging waste

- Implementing eco-friendly practices while maintaining efficiency

Many companies are addressing these challenges by investing in electric or hybrid vehicles, optimizing loading to reduce empty miles, and exploring sustainable packaging alternatives. Some are also implementing green warehouse practices, such as using renewable energy sources and improving insulation to reduce energy consumption.

Scalability and Flexibility

As businesses grow or face seasonal fluctuations, scaling first mile logistics operations can be challenging. Issues include:

- Adapting warehouse capacity to changing demand

- Maintaining efficiency during rapid growth or market expansion

- Responding to sudden changes in supply chain dynamics (e.g., supplier changes, new product introductions)

To address these challenges, some businesses are adopting flexible warehouse solutions, such as on-demand warehousing or multi-client distribution centers. Others are implementing modular and scalable technology solutions that can grow with the business.

Talent Acquisition and Retention

Finding and retaining skilled logistics professionals is an ongoing challenge in first mile operations. Issues include:

- Shortage of qualified warehouse managers and logistics coordinators

- High turnover rates in warehouse and transportation roles

- Need for continuous training to keep up with evolving technologies and processes

To overcome these challenges, businesses are focusing on creating attractive career paths in logistics, offering competitive compensation packages, and investing in ongoing training and development programs. Some companies are also exploring automation technologies to reduce reliance on manual labor for repetitive tasks.

By understanding and addressing these challenges in first mile logistics, businesses can lay a strong foundation for their entire supply chain operation. Implementing targeted solutions and leveraging advanced technologies can help companies overcome these obstacles, leading to improved efficiency, reduced costs, and enhanced competitiveness in the market.

Why is last-mile delivery considered the most complex part of logistics?

Last-mile delivery is often regarded as the most complex and challenging aspect of the logistics process. This final stage of the supply chain, where goods are transported from a distribution center or warehouse to the end customer, presents a unique set of challenges that can significantly impact a company’s efficiency, costs, and customer satisfaction.

Urban Density and Traffic Congestion

One of the primary factors contributing to the complexity of last-mile delivery is the urban environment in which it typically operates. Dense city centers present numerous obstacles:

- Heavy traffic leading to unpredictable delivery times

- Limited parking options for delivery vehicles

- Restricted access to certain areas due to traffic regulations or physical barriers

These urban challenges often result in increased fuel consumption, longer delivery times, and higher operational costs. To address this, some companies are exploring alternative delivery methods such as bicycle couriers or electric scooters for dense urban areas.

Customer Expectations and Delivery Windows

Modern consumers have increasingly high expectations for delivery speed and flexibility:

- Demand for same-day or next-day delivery options

- Specific delivery time windows to ensure customer availability

- Real-time tracking and communication throughout the delivery process

Meeting these expectations while maintaining cost-effectiveness is a significant challenge. Companies are investing in advanced route optimization software and customer communication tools to improve delivery accuracy and keep customers informed.

Delivery Failure and Reattempts

Failed deliveries due to customer absence or incorrect addresses are a major source of inefficiency in last-mile logistics:

- Each failed delivery increases operational costs

- Reattempts disrupt optimized delivery routes

- Customer dissatisfaction can lead to lost business

To mitigate this issue, businesses are implementing strategies such as secure drop-off locations, customer-selected delivery windows, and improved address verification systems.

Diverse Delivery Locations

Last-mile delivery often involves a wide range of delivery locations, each with its own set of challenges:

- Residential areas with specific delivery instructions

- Commercial buildings with security protocols

- Rural areas with long distances between deliveries

This diversity requires delivery personnel to be adaptable and well-informed about various delivery protocols. Many companies are providing comprehensive training and mobile apps with location-specific instructions to address this challenge.

Reverse Logistics and Returns Management

The increasing prevalence of e-commerce has led to a rise in product returns, adding another layer of complexity to last-mile operations:

- Coordinating pickup of returned items

- Processing and inspecting returned products

- Reintegrating returned items into inventory or managing disposal

Efficient reverse logistics processes are crucial for maintaining customer satisfaction and minimizing costs associated with returns. Some businesses are establishing dedicated return centers and implementing streamlined return policies to manage this challenge.

Seasonal Demand Fluctuations

Last-mile delivery operations must be able to scale rapidly to accommodate seasonal peaks:

- Holiday seasons often see dramatic increases in delivery volumes

- Weather-related events can cause sudden spikes in demand for certain products

Managing these fluctuations requires flexible capacity planning and often involves temporary hiring or partnerships with third-party logistics providers. Advanced demand forecasting tools are increasingly being used to anticipate and prepare for these fluctuations.

Technology Integration and Data Management

Effective last-mile delivery relies heavily on technology, but integrating various systems can be challenging:

- Coordinating data between order management, inventory, and delivery systems

- Ensuring real-time visibility across the delivery network

- Managing and analyzing large volumes of delivery data for optimization

Investments in robust, integrated logistics platforms and data analytics tools are essential for overcoming these technological challenges and driving continuous improvement in last-mile operations.

Environmental Concerns and Sustainability

There is growing pressure to make last-mile delivery more environmentally friendly:

- Reducing carbon emissions from delivery vehicles

- Minimizing packaging waste

- Balancing sustainability with delivery speed and efficiency

Many companies are exploring electric vehicles, optimizing delivery routes to reduce mileage, and implementing eco-friendly packaging solutions to address these concerns.

Cost Management

Last-mile delivery is often the most expensive part of the logistics process, accounting for up to 53% of the total cost of shipping. Factors contributing to high costs include:

- Labor expenses for delivery personnel

- Fuel and vehicle maintenance costs

- Investments in technology and infrastructure

Balancing cost reduction with service quality is an ongoing challenge. Strategies such as crowdsourced delivery models, automated delivery systems, and optimized routing are being explored to manage costs more effectively.

Regulatory Compliance

Last-mile delivery operations must navigate a complex landscape of regulations:

- Local traffic and parking laws

- Labor regulations affecting driver hours and working conditions

- Environmental regulations related to vehicle emissions

Staying compliant while maintaining operational efficiency requires ongoing monitoring of regulatory changes and adaptable business practices.

Security and Safety Concerns

Ensuring the security of goods and safety of delivery personnel is a critical concern in last-mile logistics:

- Preventing theft or damage of high-value items

- Ensuring driver safety in high-crime areas

- Managing contactless delivery options, especially in health-sensitive situations

Implementing robust security protocols, providing safety training for delivery personnel, and utilizing secure drop-off locations are some of the strategies used to address these concerns.

The complexity of last-mile delivery stems from the convergence of these diverse challenges, each requiring specific strategies and solutions. As e-commerce continues to grow and consumer expectations evolve, the importance of efficient and effective last-mile delivery will only increase. Companies that can successfully navigate these complexities and innovate in their last-mile operations will gain a significant competitive advantage in the marketplace.

How does technology impact first mile and last-mile logistics?

Technology plays a transformative role in both first mile and last-mile logistics, revolutionizing operations, enhancing efficiency, and improving customer satisfaction. The impact of technology on these critical phases of the supply chain is profound and multifaceted.

Artificial Intelligence and Machine Learning

AI and ML are revolutionizing first mile and last-mile logistics in several ways:

- Demand Forecasting: AI algorithms analyze historical data, market trends, and external factors to predict demand more accurately, enabling better inventory management and resource allocation.

- Route Optimization: Machine learning models process vast amounts of data to determine the most efficient delivery routes, considering factors like traffic patterns, weather conditions, and delivery time windows.

- Predictive Maintenance: AI-powered systems monitor vehicle performance and predict maintenance needs, reducing downtime and improving fleet reliability.

Internet of Things (IoT)

IoT devices are enhancing visibility and control throughout the logistics process:

- Real-time Tracking: IoT sensors provide continuous updates on the location and condition of goods, from warehouse shelves to delivery vehicles.

- Environmental Monitoring: Sensors monitor temperature, humidity, and other environmental factors crucial for sensitive goods during transport.

- Asset Management: IoT-enabled systems track the utilization and performance of logistics assets, improving efficiency and reducing losses.

Robotics and Automation

Automation technologies are streamlining operations in both first mile and last-mile logistics:

- Warehouse Automation: Robotic systems for picking, packing, and sorting improve speed and accuracy in order fulfillment.

- Autonomous Vehicles: Self-driving trucks and delivery robots are being tested for both long-haul and last-mile deliveries, potentially reducing labor costs and improving safety.

- Drone Delivery: Unmanned aerial vehicles are being explored for rapid delivery in hard-to-reach areas or during emergencies.

Big Data Analytics

The ability to process and analyze large volumes of data is transforming logistics decision-making:

- Performance Optimization: Analysis of operational data helps identify bottlenecks and inefficiencies in the logistics process.

- Customer Insights: Big data analytics provide valuable insights into customer preferences and behaviors, enabling personalized delivery experiences.

- Risk Management: Advanced analytics help predict and mitigate supply chain risks, improving resilience and reliability.

Mobile Technologies

Mobile devices and applications are enhancing communication and operational efficiency:

- Real-time Updates: Mobile apps provide drivers and customers with instant updates on delivery status and any changes to the schedule.

- Digital Proof of Delivery: Mobile devices enable electronic signature capture and photo documentation of deliveries, streamlining the process and reducing paperwork.

- Driver Performance Monitoring: Mobile apps track driver behavior and performance, promoting safety and efficiency.

Blockchain Technology

Blockchain is improving transparency and traceability in the supply chain:

- Supply Chain Visibility: Blockchain provides an immutable record of each transaction and movement in the supply chain, enhancing transparency and trust.

- Smart Contracts: Automated, blockchain-based contracts streamline transactions and ensure compliance with agreed-upon terms.

- Authenticity Verification: Blockchain can help verify the authenticity of products, reducing counterfeiting and fraud in the supply chain.

Cloud Computing

Cloud-based solutions are enabling more flexible and scalable logistics operations:

- Scalability: Cloud platforms allow logistics operations to easily scale up or down based on demand fluctuations.

- Collaboration: Cloud-based systems facilitate real-time information sharing among various stakeholders in the supply chain.

- Cost Efficiency: Cloud solutions reduce the need for extensive on-premises IT infrastructure, lowering costs and improving accessibility.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies are finding applications in logistics training and operations:

- Warehouse Navigation: AR glasses can guide warehouse workers to the correct locations for picking items, improving efficiency and accuracy.

- Training: VR simulations provide immersive training experiences for logistics personnel, improving skills without risking real-world operations.

- Last-Mile Delivery Assistance: AR can assist delivery drivers in finding optimal parking spots or locating hard-to-find addresses.

5G Technology

The rollout of 5G networks is set to further enhance logistics operations:

- Enhanced Connectivity: 5G enables faster and more reliable communication between various elements of the logistics network.

- Real-time Decision Making: The low latency of 5G allows for near-instantaneous data transmission, enabling real-time decision making and adjustments.

- IoT Expansion: 5G supports a much higher density of connected devices, allowing for more comprehensive IoT implementation in logistics.

The impact of these technologies on first mile and last-mile logistics is significant and ongoing. By improving visibility, efficiency, and decision-making capabilities, technology is helping logistics providers overcome many of the traditional challenges associated with these critical phases of the supply chain. As these technologies continue to evolve and new innovations emerge, we can expect further transformations in the logistics landscape, leading to more streamlined, cost-effective, and customer-centric operations.

What role does the middle mile play in connecting first and last-mile logistics?

The middle mile, often overlooked in discussions about logistics, plays a crucial role in connecting first mile and last-mile operations. This intermediate stage of the supply chain involves the transportation of goods between warehouses, distribution centers, and fulfillment centers before they reach the final delivery stage. Understanding the significance of the middle mile is essential for optimizing the entire logistics process.

Bridging the Gap

The middle mile serves as a vital link between the initial collection of goods (first mile) and the final delivery to customers (last mile). Its primary functions include:

- Consolidation: Combining shipments from various sources to optimize transportation efficiency.

- Sorting: Organizing goods based on destination or other criteria to facilitate efficient last-mile delivery.

- Cross-docking: Transferring goods directly from inbound to outbound vehicles with minimal storage time.

By effectively managing these functions, the middle mile ensures a smooth flow of goods throughout the supply chain, reducing bottlenecks and improving overall efficiency.

Economies of Scale

One of the key advantages of the middle mile is its ability to leverage economies of scale:

- Bulk Transportation: Moving large quantities of goods over longer distances reduces per-unit shipping costs.

- Optimized Load Capacity: Efficiently filling trucks or containers maximizes the use of transportation resources.

- Shared Infrastructure: Utilizing centralized warehouses and distribution centers spreads fixed costs across multiple shipments.

These economies of scale help offset the higher costs associated with first mile collection and last-mile delivery, contributing to overall cost-effectiveness in the logistics process.

Network Optimization

The middle mile plays a critical role in optimizing the logistics network:

- Strategic Facility Placement: Locating distribution centers and cross-docking facilities strategically to minimize transportation distances and times.

- Route Planning: Developing efficient transportation routes between facilities to reduce fuel consumption and delivery times.

- Inventory Balancing: Moving goods between locations to ensure optimal stock levels and availability across the network.

Effective middle mile management enables companies to respond more flexibly to changes in demand and supply chain disruptions.

Technology Integration

The middle mile is increasingly benefiting from technological advancements:

- Transportation Management Systems (TMS): Optimizing routes, carrier selection, and load planning for middle mile operations.

- IoT and Tracking: Providing real-time visibility of goods in transit between facilities.

- Predictive Analytics: Forecasting demand and optimizing inventory movement across the network.

These technologies enhance the efficiency and visibility of middle mile operations, contributing to a more responsive and agile supply chain.

Sustainability Initiatives

The middle mile offers significant opportunities for improving the environmental sustainability of logistics operations:

- Modal Shift: Utilizing more environmentally friendly transportation modes like rail or waterways for longer distances.

- Load Optimization: Maximizing vehicle capacity to reduce the number of trips and associated emissions.

- Alternative Fuels: Implementing cleaner fuel options for long-haul transportation.

By focusing on sustainability in the middle mile, companies can significantly reduce their overall carbon footprint in logistics operations.

Flexibility and Resilience

A well-managed middle mile enhances the flexibility and resilience of the entire supply chain:

- Buffer Capacity: Middle mile facilities can serve as buffers, absorbing fluctuations in supply and demand.

- Alternative Routing: Multiple middle mile options allow for rerouting in case of disruptions or bottlenecks.

- Scalability: The ability to adjust middle mile capacity helps companies respond to seasonal variations or sudden changes in market conditions.

This flexibility is crucial for maintaining consistent service levels in both first mile and last-mile operations.

Cost Allocation and Visibility

The middle mile provides an opportunity for more accurate cost allocation and improved visibility:

- Cost Tracking: Separating middle mile costs from first and last-mile expenses allows for more precise cost analysis and optimization.

- Performance Metrics: Tracking middle mile performance separately helps identify specific areas for improvement in the supply chain.

- End-to-End Visibility: Integrating middle mile data with first and last-mile information provides a comprehensive view of the entire logistics process.

This enhanced visibility enables more informed decision-making and continuous improvement across the supply chain.

Challenges in Middle Mile Logistics

While the middle mile offers many benefits, it also presents unique challenges:

- Capacity Utilization: Balancing the need for timely deliveries with the goal of maximizing vehicle capacity.

- Coordination: Synchronizing operations between multiple facilities and transportation modes.

- Infrastructure Limitations: Dealing with constraints in transportation infrastructure, particularly in developing regions.

Addressing these challenges is crucial for maximizing the efficiency of middle mile operations and its positive impact on the overall supply chain.

Future Trends in Middle Mile Logistics

Several trends are shaping the future of middle mile logistics:

- Automation: Increasing use of autonomous vehicles and robotics in warehousing and transportation.

- Data-Driven Decision Making: Leveraging big data and AI for more accurate demand forecasting and network optimization.

- Collaborative Networks: Developing shared logistics networks to improve efficiency and reduce costs across multiple companies.

These trends are likely to further enhance the role of the middle mile in connecting and optimizing first mile and last-mile operations.

The middle mile, often operating behind the scenes, is a critical component in the logistics ecosystem. By efficiently connecting first mile and last-mile operations, it enables companies to achieve greater efficiency, cost-effectiveness, and flexibility throughout their supply chains. As technology continues to advance and sustainability becomes increasingly important, the role of the middle mile in logistics is likely to become even more significant, driving innovations that benefit the entire logistics process.

How can companies optimize their first mile and last-mile operations?

Optimizing first mile and last-mile operations is crucial for companies looking to enhance their supply chain efficiency, reduce costs, and improve customer satisfaction. Here are comprehensive strategies and best practices for optimizing these critical phases of logistics:

First Mile Optimization Strategies

Streamline Order Processing

- Implement advanced order management systems to automate and expedite order processing.

- Use AI-powered demand forecasting to anticipate order volumes and allocate resources accordingly.

- Integrate systems across suppliers, manufacturers, and logistics providers for seamless information flow.

Enhance Warehouse Efficiency

- Optimize warehouse layout to minimize picking and packing time.

- Implement automated storage and retrieval systems (AS/RS) for faster and more accurate inventory management.

- Use voice-directed or light-directed picking technologies to improve accuracy and speed.

Improve Inventory Management

- Utilize RFID and IoT sensors for real-time inventory tracking.

- Implement cycle counting procedures to maintain inventory accuracy.

- Use predictive analytics to optimize stock levels and prevent stockouts or overstocking.

Optimize Transportation Planning

- Implement transportation management systems (TMS) for better route planning and carrier selection.

- Consolidate shipments to maximize vehicle utilization and reduce transportation costs.

- Explore intermodal transportation options for long-distance first mile movements.

Enhance Supplier Collaboration

- Establish clear communication channels and performance metrics with suppliers.

- Implement vendor-managed inventory (VMI) programs to improve stock management.

- Use collaborative planning, forecasting, and replenishment (CPFR) techniques to align supply with demand.

Implement Quality Control Measures

- Establish rigorous quality inspection processes at the point of origin.

- Use IoT sensors to monitor product conditions during first mile transport.

- Implement blockchain technology for enhanced traceability and authenticity verification.

Last-Mile Optimization Strategies

Enhance Route Optimization

- Utilize advanced route optimization software that considers real-time traffic, weather, and other variables.

- Implement dynamic routing to adjust delivery schedules based on real-time conditions.

- Use AI and machine learning algorithms to continuously improve routing efficiency.

Improve Delivery Accuracy

- Implement address verification systems to reduce failed deliveries due to incorrect addresses.

- Use GPS and geofencing technologies for precise location tracking and delivery confirmation.

- Provide delivery personnel with mobile apps for real-time navigation and delivery instructions.

Enhance Customer Communication

- Implement real-time tracking and notification systems for customers.

- Offer flexible delivery options, including time windows and alternative pickup locations.

- Use chatbots and AI-powered customer service tools to handle delivery-related inquiries efficiently.

Optimize Delivery Vehicle Fleet

- Use a mix of vehicle types (e.g., vans, cars, bicycles) to suit different delivery environments.

- Implement telematics systems for real-time vehicle tracking and performance monitoring.

- Explore electric and alternative fuel vehicles to reduce environmental impact and operating costs.

Implement Efficient Parcel Handling

- Use automated sorting systems in distribution centers to speed up parcel processing.

- Implement cross-docking strategies to minimize storage time and handling.

- Use standardized packaging to improve loading efficiency and reduce damage during transit.

Leverage Alternative Delivery Methods

- Explore drone delivery for remote or hard-to-reach areas.

- Implement autonomous delivery robots for urban deliveries.

- Utilize crowdsourced delivery platforms to handle peak demand periods.

Optimize Returns Management

- Streamline the returns process with easy-to-use return portals and clear instructions.

- Implement reverse logistics strategies to efficiently process and reintegrate returned items.

- Use data analytics to identify patterns in returns and address root causes.

Strategies Applicable to Both First Mile and Last-Mile Operations

Implement Data Analytics and AI

- Use predictive analytics to forecast demand and optimize resource allocation.

- Implement machine learning algorithms for continuous process improvement.

- Utilize big data analytics to identify inefficiencies and opportunities for optimization.

Enhance Visibility and Traceability

- Implement end-to-end tracking systems using IoT and RFID technologies.

- Use blockchain for enhanced transparency and traceability across the supply chain.

- Implement control towers for real-time visibility and decision-making capabilities.

Focus on Sustainability

- Implement eco-friendly packaging solutions.

- Optimize routes and loads to reduce fuel consumption and emissions.

- Explore renewable energy options for warehouses and distribution centers.

Invest in Employee Training and Development

- Provide comprehensive training programs for warehouse staff and delivery personnel.

- Implement performance management systems with clear KPIs and incentives.

- Foster a culture of continuous improvement and innovation.

Leverage Partnerships and Collaborations

- Explore partnerships with local businesses for urban micro-fulfillment centers.

- Collaborate with other companies to share logistics resources and infrastructure.

- Partner with technology providers to implement cutting-edge logistics solutions.

Implement Flexible Capacity Management

- Use on-demand warehousing solutions to handle fluctuations in inventory levels.

- Implement flexible labor models, including temporary staffing and gig economy workers.

- Utilize cloud-based systems for scalable IT infrastructure.

Enhance Cybersecurity and Data Protection

- Implement robust cybersecurity measures to protect sensitive logistics data.

- Ensure compliance with data protection regulations across all logistics operations.

- Regularly audit and update security protocols to address emerging threats.

By implementing these strategies, companies can significantly improve the efficiency and effectiveness of their first mile and last-mile operations. It’s important to note that the optimal mix of strategies will vary depending on the specific needs and circumstances of each business. Continuous evaluation and adaptation of these strategies are crucial to maintain a competitive edge in the ever-evolving logistics landscape.

Moreover, companies should consider the interdependencies between first mile, middle mile, and last-mile operations. Optimizing one segment of the supply chain can have ripple effects throughout the entire logistics process. Therefore, a holistic approach that considers the entire supply chain ecosystem is essential for achieving comprehensive logistics optimization.

As technology continues to advance and consumer expectations evolve, companies must remain agile and open to adopting new innovations in their first mile and last-mile operations. By staying at the forefront of logistics trends and continuously refining their strategies, businesses can create resilient, efficient, and customer-centric supply chains that drive long-term success in the competitive marketplace.