What Is Freight Drayage

What is Freight Drayage?

Freight drayage is a specialized transportation service that involves the short-distance movement of shipping containers and cargo between different points in the supply chain. This critical logistical operation typically occurs within a single metropolitan area and is usually completed within one work shift.

The term “drayage” has its roots in the 19th century, derived from the word “dray” – a low, flat-sided cart pulled by horses to transport heavy loads over short distances. Today, modern drayage utilizes trucks instead of horse-drawn carts, but the core concept remains the same: efficiently moving goods across short distances to connect different modes of transportation.

Drayage serves as the vital link between long-haul transportation methods like ocean shipping, rail, and air freight. It ensures that cargo smoothly transitions from one mode to another, playing a crucial role in the intermodal freight transportation system.

Key characteristics of freight drayage:

Short-distance transport: Drayage operations typically cover distances ranging from 5 to 100 miles, rarely exceeding this range.

Container-focused: Most drayage services involve moving standardized shipping containers, though some may handle other types of cargo.

Intermodal connectivity: Drayage connects different modes of transportation, such as moving containers from ports to rail yards or distribution centers.

Time-sensitive: Drayage operations are often subject to strict schedules and time windows to maintain the efficiency of the overall supply chain.

Local expertise: Drayage providers possess in-depth knowledge of local regulations, traffic patterns, and port/terminal operations in their service areas.

To better understand the scope of drayage, let’s examine how it differs from other transportation services:

| Service | Distance | Primary Focus | Typical Duration |

|---|---|---|---|

| Drayage | Short (5-100 miles) | Containers/intermodal | Same day |

| LTL (Less Than Truckload) | Regional/National | Palletized freight | 1-5 days |

| FTL (Full Truckload) | Regional/National | Various cargo types | 1-3 days |

| Ocean Freight | International | Containers | Weeks |

| Air Freight | International | Time-sensitive cargo | 1-3 days |

Drayage plays a vital role in maintaining the fluidity of global supply chains. Without efficient drayage services, containers and cargo would face significant delays in transitioning between transportation modes, leading to increased costs and potential disruptions in the supply chain.

For businesses involved in international trade or domestic intermodal shipping, understanding drayage is essential. It impacts everything from shipping timelines to overall logistics costs. As we delve deeper into the intricacies of drayage in the following sections, you’ll gain a comprehensive understanding of this critical component of modern freight transportation.

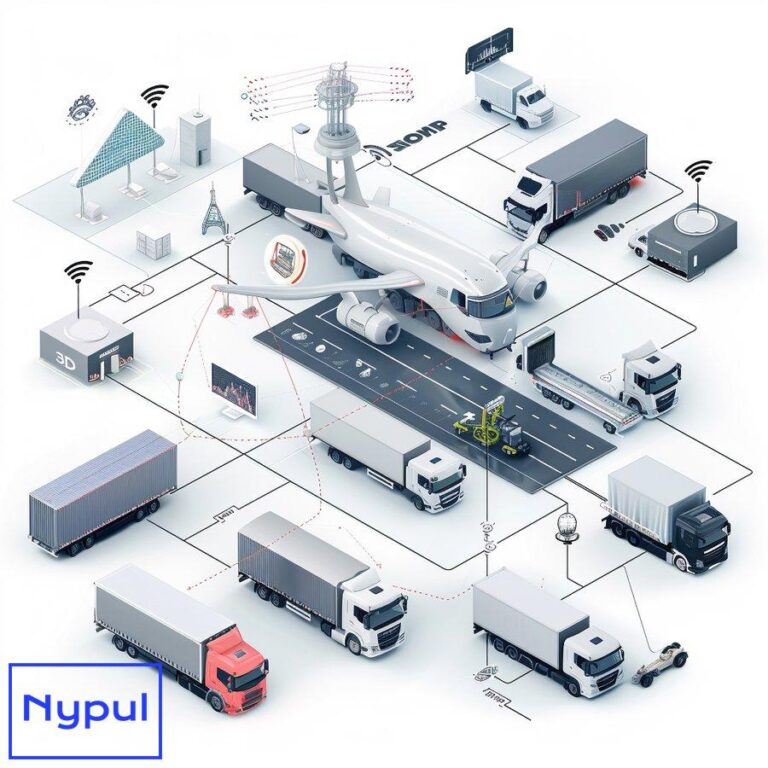

How Does Drayage Fit into the Supply Chain?

Drayage serves as a critical connector in the complex web of global supply chains, bridging the gaps between various modes of transportation and facilities. Its role is often underappreciated, yet it’s indispensable for ensuring the smooth flow of goods from origin to destination.

Intermodal connectivity

Drayage is the glue that holds intermodal transportation together. It facilitates the seamless transition of cargo between different modes of transport, such as:

Ocean to rail: When a container arrives at a seaport, drayage trucks transport it to a nearby rail yard for long-distance land transportation.

Rail to truck: At the end of a rail journey, drayage moves containers from the rail terminal to a distribution center or the final destination.

Air to ground: For air freight, drayage connects airports with ground transportation networks, moving time-sensitive cargo to its next destination.

This intermodal connectivity allows shippers to leverage the strengths of each transportation mode, optimizing for cost, speed, and efficiency.

First and last mile delivery

Drayage often represents the first and last mile of a shipment’s journey:

First mile: Drayage trucks pick up loaded containers from manufacturers or warehouses and deliver them to ports or rail terminals for long-distance transport.

Last mile: At the destination, drayage completes the final leg by moving containers from ports or rail yards to the consignee’s location.

These first and last mile services are crucial for initiating and completing the transportation cycle, ensuring that goods reach their intended destinations.

Port congestion management

Ports are often bottlenecks in the supply chain, and drayage plays a vital role in managing congestion:

Container movement: Drayage trucks quickly move containers out of the port area, freeing up space for incoming shipments.

Off-dock storage: When ports are overwhelmed, drayage services transport containers to off-site storage facilities, helping to decongest the port area.

Just-in-time delivery: Drayage enables just-in-time inventory strategies by delivering containers to manufacturers or retailers precisely when needed, reducing the need for extensive on-site storage.

Supply chain flexibility

Drayage provides flexibility to adapt to changing supply chain needs:

Transloading: Drayage facilitates the transfer of cargo from international containers to domestic trailers, allowing for optimization of load configurations and compliance with local transportation regulations.

Cross-docking: In cross-docking operations, drayage moves incoming shipments directly from receiving to shipping docks, minimizing storage time and handling.

Warehousing support: Drayage services help manage inventory levels by shuttling containers between ports, distribution centers, and warehouses as needed.

To illustrate the integral role of drayage in the supply chain, consider this simplified example of an international shipment:

| Stage | Transportation Mode | Drayage Role |

|---|---|---|

| 1. Origin | Truck | First mile delivery from factory to port |

| 2. International | Ocean vessel | N/A |

| 3. Destination port | Drayage truck | Move container from port to rail yard |

| 4. Domestic transport | Rail | N/A |

| 5. Rail terminal | Drayage truck | Transport container from rail to distribution center |

| 6. Final delivery | Local delivery truck | N/A |

In this scenario, drayage is involved in three critical stages, ensuring the smooth transition between major transportation modes and facilities.

Supply chain visibility

Drayage also contributes to supply chain visibility:

Real-time tracking: Many drayage providers offer GPS tracking of their trucks, allowing shippers and consignees to monitor the exact location of their cargo during these critical short-haul movements.

Status updates: Drayage operations often include important milestones like container pickup, delivery, and return, providing valuable data points for overall shipment tracking.

Documentation: Drayage providers handle essential documentation such as proof of delivery, contributing to the paper trail necessary for international trade and customs compliance.

By understanding how drayage fits into the broader supply chain, businesses can better appreciate its importance and make informed decisions about their logistics strategies. Effective integration of drayage services can lead to improved efficiency, reduced costs, and enhanced customer satisfaction throughout the supply chain.

What Are the Different Types of Drayage Services?

Drayage services come in various forms, each designed to meet specific logistical needs within the supply chain. Understanding these different types can help shippers and logistics professionals choose the most appropriate service for their particular requirements. Let’s explore the main categories of drayage services:

Inter-carrier drayage

Inter-carrier drayage involves the movement of cargo between different transportation carriers within the same mode of transport. This type of drayage is common in situations where shipments need to be transferred between different shipping lines or rail companies.

Example: A container arrives at a port on a Maersk vessel but needs to be transferred to a CMA CGM vessel for the next leg of its journey. Inter-carrier drayage would move the container between the two shipping lines’ terminals within the port complex.

Intra-carrier drayage

Intra-carrier drayage refers to the movement of cargo between different facilities owned or operated by the same carrier. This type of service helps carriers optimize their operations and asset utilization.

Example: A rail company uses drayage to reposition empty containers between its various rail yards in a metropolitan area to meet demand fluctuations.

Expedited drayage

Expedited drayage services prioritize speed and time-sensitivity. These services are used for urgent shipments that require immediate attention and faster-than-usual processing.

Example: A manufacturing plant urgently needs a shipment of components to avoid a production line shutdown. Expedited drayage ensures the container is quickly retrieved from the port and delivered to the plant, potentially bypassing usual queues and processes.

Port drayage

Port drayage specifically refers to the movement of containers to and from seaports. This is one of the most common forms of drayage and is critical for international trade operations.

Example: A container of electronics arrives at the Port of Los Angeles. Port drayage services transport the container from the port to a nearby distribution center for further processing and distribution.

Rail drayage

Rail drayage involves the transportation of containers to and from rail terminals. This service is essential for intermodal shipments that combine long-distance rail transport with local truck delivery.

Example: A container arrives at a rail terminal in Chicago after a cross-country journey. Rail drayage moves the container from the rail yard to a local warehouse for unloading.

Shuttle drayage

Shuttle drayage involves the continuous movement of containers between two nearby facilities, often used to manage overflow or optimize space utilization.

Example: During peak season, a port uses shuttle drayage to move containers to an off-site storage yard, helping to alleviate congestion at the main terminal.

Door-to-door drayage

Door-to-door drayage provides a complete service from the initial pickup point to the final delivery location, often combining multiple drayage types.

Example: A drayage company picks up a container from a manufacturer’s facility, delivers it to the port for export, then picks up an import container from the same port and delivers it to a local distribution center.

Pier drayage

Pier drayage specifically refers to the movement of containers between a pier or dock and another nearby location, such as a rail terminal or warehouse.

Example: A container is unloaded from a ship at a pier and needs to be transported to a nearby customs inspection facility. Pier drayage handles this short movement.

To better understand how these different types of drayage services might be applied in a real-world scenario, consider the following table illustrating a hypothetical supply chain involving multiple drayage types:

| Stage | Drayage Type | Description |

|---|---|---|

| 1 | Door-to-door | Pick up container from manufacturer |

| 2 | Port drayage | Deliver container to export terminal |

| 3 | Inter-carrier | Transfer container to another shipping line |

| 4 | Pier drayage | Move container from ship to customs inspection |

| 5 | Expedited | Rush delivery of cleared container to rail yard |

| 6 | Rail drayage | Transport container from rail to distribution center |

| 7 | Shuttle | Regular movements between DC and local retailers |

This example demonstrates how various drayage services can be combined to create a comprehensive logistics solution tailored to specific supply chain needs.

By understanding these different types of drayage services, businesses can make informed decisions about which services best suit their logistics requirements. Each type of drayage plays a unique role in the supply chain, and the right combination of services can significantly enhance the efficiency and effectiveness of freight movement.

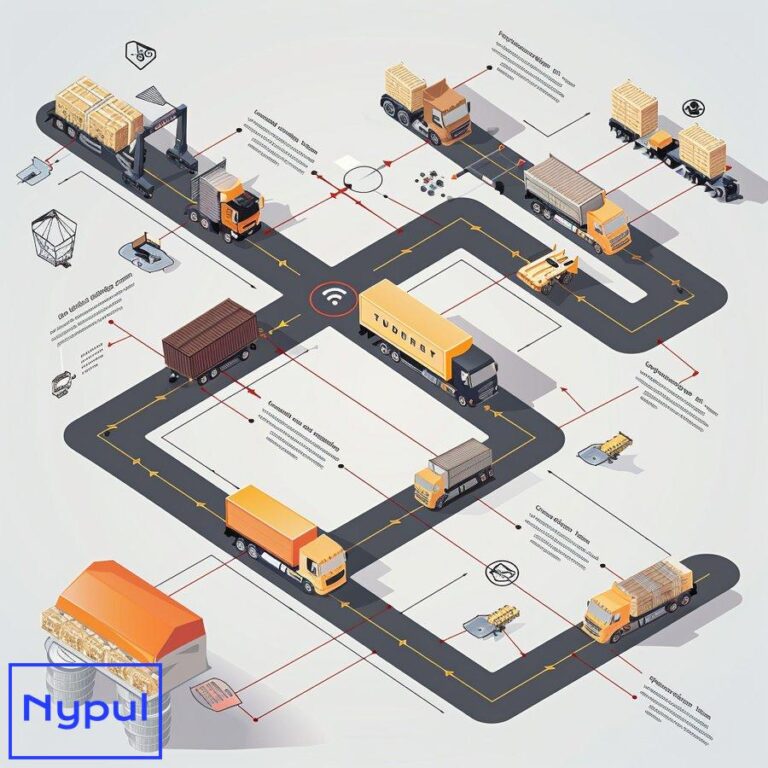

How Does the Drayage Process Work?

The drayage process, while focused on short-distance transportation, involves several intricate steps and coordination among various parties. Understanding this process is crucial for anyone involved in logistics or supply chain management. Let’s break down the typical drayage process:

![]()

Pre-drayage planning

Before the physical movement of containers begins, several planning steps take place:

Booking: The shipper or freight forwarder books drayage services, providing details such as container numbers, pickup and delivery locations, and required timeframes.

Documentation: Necessary paperwork is prepared, including delivery orders, customs documents, and any special instructions.

Scheduling: The drayage provider coordinates pickup and delivery appointments, considering factors like port/terminal operating hours and the consignee’s receiving schedule.

Container pickup

Once planning is complete, the actual drayage movement begins:

Dispatching: The drayage company assigns a driver and truck for the job.

Port/terminal arrival: The driver arrives at the designated pickup location, often a port or rail terminal.

Check-in: The driver presents necessary documentation and goes through security procedures.

Container location: The driver is directed to the specific area where the container is stored.

Loading: The container is loaded onto the truck chassis using port equipment like gantry cranes or reach stackers.

Transportation

With the container secured, the driver begins the journey to the destination:

Route planning: The driver follows a predetermined route, considering factors like traffic, road restrictions, and delivery windows.

Real-time tracking: Many drayage providers offer GPS tracking, allowing customers to monitor the container’s progress.

Communication: The driver stays in contact with dispatch to report any issues or delays.

Delivery

Upon reaching the destination, the final steps of the drayage process occur:

Arrival: The driver reaches the delivery location, which could be a warehouse, distribution center, or another intermodal facility.

Check-in: The driver reports to the receiving office and presents delivery documents.

Unloading: The container is removed from the truck using on-site equipment.

Inspection: The receiving party may conduct a visual inspection of the container and its seals.

Documentation: Proof of delivery is obtained, often in the form of a signed delivery receipt.

Post-delivery

After the container is delivered, several wrap-up activities take place:

Return of empty container: If required, the driver returns the empty container to a designated location, often the original port or a container depot.

Paperwork submission: The driver submits all relevant documents to the drayage company for processing and billing.

Invoicing: The drayage company prepares and sends an invoice for the completed service.

To illustrate how these steps fit together in a typical drayage operation, consider the following timeline for a port-to-warehouse drayage movement:

| Time | Activity | Location | Responsible Party |

|---|---|---|---|

| 08:00 | Driver check-in | Port gate | Driver, Port staff |

| 08:30 | Container pickup | Port yard | Driver, Port equipment operators |

| 09:00 | Depart port | Port exit | Driver |

| 10:00 | Arrive at warehouse | Warehouse gate | Driver |

| 10:15 | Check-in and paperwork | Receiving office | Driver, Warehouse staff |

| 10:30 | Container unloading | Warehouse dock | Warehouse staff |

| 11:00 | Obtain POD, depart | Warehouse gate | Driver, Warehouse staff |

| 12:00 | Return empty container | Container depot | Driver, Depot staff |

This timeline demonstrates the various touchpoints and interactions involved in a single drayage move, highlighting the need for efficient coordination and communication throughout the process.

Challenges in the drayage process

While the steps outlined above represent an ideal scenario, the drayage process often faces various challenges:

Port congestion: High volumes of container traffic can lead to long wait times at ports, affecting the entire drayage schedule.

Equipment availability: Shortages of chassis or containers can cause delays in pickup and delivery.

Traffic and road conditions: Urban congestion and road construction can impact transit times and route planning.

Documentation issues: Incomplete or incorrect paperwork can lead to delays at various points in the process.

Appointment systems: Many ports and warehouses use appointment systems, which can be inflexible and lead to inefficiencies if there are any delays in the process.

Regulatory compliance: Drivers must adhere to hours-of-service regulations, which can impact scheduling and delivery times.

Understanding these potential challenges allows stakeholders to better prepare and develop contingency plans to ensure smooth drayage operations.

The drayage process, while seemingly straightforward, requires careful coordination and attention to detail at every step. By comprehending this process, shippers, consignees, and logistics professionals can better manage their supply chains, anticipate potential issues, and work more effectively with drayage providers to ensure efficient and timely movement of goods.

Who Are the Key Players in Drayage Operations?

Drayage operations involve a network of interconnected stakeholders, each playing a crucial role in ensuring the smooth movement of containers and cargo. Understanding these key players and their responsibilities is essential for anyone involved in logistics or supply chain management. Let’s examine the primary participants in drayage operations:

Drayage companies

Drayage companies are at the core of drayage operations. These specialized trucking firms focus on short-distance container movements.

Responsibilities:

– Provide and maintain a fleet of trucks and chassis

– Employ and manage qualified drivers

– Coordinate- Coordinate pickups and deliveries

– Ensure compliance with local regulations and port/terminal procedures

– Offer real-time tracking and status updates

– Handle documentation and invoicing

Drivers

Drayage drivers are the frontline workers who physically move containers from one location to another.

Responsibilities:

– Operate trucks and handle containers safely

– Navigate local roads and terminal facilities

– Manage paperwork and documentation at pickup and delivery points

– Adhere to hours-of-service regulations and safety standards

– Communicate with dispatchers and customers as needed

Port authorities

Port authorities oversee the operations of seaports and play a significant role in drayage activities.

Responsibilities:

– Manage port infrastructure and facilities

– Implement and enforce port regulations and procedures

– Coordinate vessel arrivals and departures

– Oversee terminal operations and equipment

– Implement port appointment systems and truck routing

Terminal operators

Terminal operators manage the day-to-day operations of container terminals at ports and rail yards.

Responsibilities:

– Load and unload containers from ships and trains

– Store and organize containers within the terminal

– Operate terminal equipment like gantry cranes and reach stackers

– Process incoming and outgoing trucks

– Manage terminal appointment systems

Customs and border protection

For international shipments, customs agencies play a critical role in the drayage process.

Responsibilities:

– Inspect incoming containers and cargo

– Clear goods for entry into the country

– Enforce import/export regulations

– Collect duties and taxes

– Manage documentation related to international trade

Shippers and consignees

Shippers (exporters) and consignees (importers) are the ultimate customers of drayage services.

Responsibilities:

– Book drayage services

– Provide accurate shipment information and documentation

– Coordinate pickup and delivery schedules

– Ensure facilities are prepared for container receipt or dispatch

– Pay for drayage services

Freight forwarders and 3PLs

These intermediaries often coordinate drayage as part of broader logistics services.

Responsibilities:

– Arrange drayage services on behalf of shippers or consignees

– Coordinate with multiple parties in the supply chain

– Manage documentation and customs clearance

– Provide visibility and tracking information to clients

– Optimize logistics processes, including drayage

Chassis providers

Chassis are essential equipment for moving containers, and specialized providers manage these assets.

Responsibilities:

– Maintain a fleet of chassis in good working condition

– Provide chassis to drayage companies and drivers

– Manage chassis pools at ports and terminals

– Ensure compliance with safety regulations

– Implement chassis reservation and tracking systems

To illustrate the interactions between these key players, consider the following table depicting a typical drayage operation:

| Stage | Primary Players | Interaction |

|---|---|---|

| Booking | Shipper, Freight Forwarder, Drayage Company | Service request and confirmation |

| Pre-arrival | Port Authority, Terminal Operator | Vessel and container information exchange |

| Container Discharge | Terminal Operator, Customs | Container unloading and customs clearance |

| Drayage Pickup | Driver, Terminal Operator | Container retrieval from terminal |

| Transportation | Driver, Drayage Company | Container movement to destination |

| Delivery | Driver, Consignee | Container delivery and documentation |

| Empty Return | Driver, Chassis Provider | Return of empty container and chassis |

This table demonstrates the complex web of interactions that occur during a single drayage move, highlighting the need for seamless coordination among all parties involved.

Emerging players in drayage operations

As the logistics industry evolves, new players are entering the drayage space:

Technology providers: Companies offering software solutions for drayage management, including booking platforms, visibility tools, and optimization algorithms.

Autonomous vehicle developers: Firms working on self-driving truck technology that could revolutionize drayage operations in the future.

Electric vehicle manufacturers: Companies developing electric trucks suitable for drayage, addressing environmental concerns in port areas.

Data analytics firms: Businesses specializing in analyzing drayage data to identify inefficiencies and improve operations.

These emerging players are likely to play an increasingly important role in shaping the future of drayage operations.

Understanding the roles and responsibilities of each key player in drayage operations is crucial for effective supply chain management. Each participant contributes to the overall efficiency of the process, and successful drayage relies on smooth collaboration and communication among all parties involved. As the industry continues to evolve, staying informed about both traditional and emerging players will be essential for anyone involved in logistics and transportation.

What Challenges Does the Drayage Industry Face?

The drayage industry, despite its critical role in global supply chains, faces numerous challenges that impact its efficiency, profitability, and sustainability. Understanding these challenges is crucial for stakeholders to develop effective strategies and solutions. Let’s explore the major issues confronting the drayage sector:

Port congestion

Port congestion is one of the most significant challenges facing the drayage industry.

Causes:

– Increasing vessel sizes leading to larger cargo volumes per ship

– Imbalanced trade flows causing equipment shortages

– Limited port infrastructure and capacity

– Inefficient port operations and outdated technologies

Impacts:

– Extended wait times for trucks at port terminals

– Reduced number of trips per day for drayage operators

– Increased costs due to idle time and missed appointments

– Delays in cargo delivery affecting the entire supply chain

Driver shortage and retention

The drayage industry, like the broader trucking sector, struggles with attracting and retaining qualified drivers.

Causes:

– Aging workforce and lack of new entrants

– Challenging working conditions, including long hours and unpredictable schedules

– Competition from other sectors of the trucking industry

– Regulatory barriers, such as minimum age requirements for interstate drivers

Impacts:

– Reduced capacity to meet drayage demand

– Increased labor costs as companies compete for available drivers

– Potential safety concerns due to overworked or less experienced drivers

– Pressure to explore alternative solutions like autonomous vehicles

Equipment imbalances and shortages

Drayage operations are often hampered by imbalances in container and chassis availability.

Causes:

– Uneven trade flows leading to accumulation of containers in some areas and shortages in others

– Inefficient repositioning of empty containers

– Limited chassis availability, especially during peak seasons

– Lack of standardization in chassis types and conditions

Impacts:

– Delays in container pickup and delivery

– Increased costs for repositioning empty containers and chassis

– Reduced efficiency and productivity for drayage operators

– Potential for cargo backlogs and supply chain disruptions

Regulatory compliance

The drayage industry must navigate a complex landscape of regulations at federal, state, and local levels.

Key regulatory areas:

– Hours of service rules limiting driver work hours

– Electronic logging device (ELD) mandates

– Emissions standards and environmental regulations

– Safety regulations and inspections

– Licensing and insurance requirements

Impacts:

– Increased operational costs to ensure compliance

– Reduced flexibility in scheduling and routing

– Potential for fines and penalties for non-compliance

– Need for ongoing driver training and education

Environmental concerns

As awareness of environmental issues grows, the drayage industry faces pressure to reduce its carbon footprint.

Challenges:

– Transitioning to cleaner fuel technologies (e.g., electric or hydrogen-powered trucks)

– Meeting increasingly stringent emissions standards

– Balancing environmental goals with operational efficiency

– Managing the costs associated with adopting new, greener technologies

Impacts:

– Increased capital expenditures for new, cleaner vehicles

– Potential operational limitations of alternative fuel vehicles

– Need for new infrastructure (e.g., charging stations for electric trucks)

– Reputational risks for companies perceived as environmentally unfriendly

Technology adoption and integration

While technology offers solutions to many drayage challenges, its adoption and integration present their own hurdles.

Areas of technological change:

– Terminal appointment systems

– Real-time tracking and visibility platforms

– Automated gate systems at ports and terminals

– Blockchain for documentation and transactions

– Artificial intelligence for route optimization and predictive analytics

Challenges:

– High initial costs of implementing new technologies

– Resistance to change from traditional operators

– Need for staff training and adaptation

– Ensuring interoperability between different systems and stakeholders

Impacts:

– Potential for increased efficiency and reduced costs in the long term

– Short-term disruptions during technology implementation

– Competitive advantage for early adopters

– Risk of obsolescence for companies slow to adapt

Infrastructure limitations

The drayage industry relies heavily on public infrastructure, which often struggles to keep pace with growing demand.

Issues:

– Aging road and bridge infrastructure

– Limited capacity of urban roads around ports

– Insufficient parking and rest areas for trucks

– Inadequate rail connections to ports for intermodal operations

Impacts:

– Increased transit times and reduced reliability

– Higher maintenance costs for vehicles due to poor road conditions

– Safety concerns related to inadequate infrastructure

– Limitations on the use of high-capacity vehicles in some areas

To illustrate the interconnected nature of these challenges, consider the following table showing how different issues can compound each other:

| Primary Challenge | Related Challenges | Compounding Effects |

|---|---|---|

| Port Congestion | Driver Shortage, Equipment Imbalances | Longer wait times, fewer trips per day, increased costs |

| Environmental Regulations | Technology Adoption, Infrastructure Limitations | Need for new vehicles, charging infrastructure, potential operational constraints |

| Driver Shortage | Regulatory Compliance, Technology Adoption | Pressure to automate, increased training costs, potential safety issues |

| Equipment Shortages | Port Congestion, Infrastructure Limitations | Delays in cargo movement, increased repositioning costs, reduced efficiency |

This table demonstrates how addressing one challenge in isolation may not be sufficient, as multiple issues often interact to create complex problems for the drayage industry.

The drayage industry’s challenges are multifaceted and interconnected, requiring collaborative efforts from all stakeholders to develop comprehensive solutions. Addressing these issues is crucial not only for the health of the drayage sector but also for the efficiency of global supply chains as a whole. As the industry continues to evolve, finding innovative ways to overcome these challenges will be key to ensuring the sustainable growth and resilience of drayage operations.

How is Technology Transforming Drayage?

Technology is rapidly reshaping the drayage industry, offering solutions to long-standing challenges and creating new opportunities for efficiency and innovation. This digital transformation is touching every aspect of drayage operations, from booking and planning to execution and analysis. Let’s explore the key technological advancements that are revolutionizing the drayage sector:

Digital booking platforms

Digital platforms are streamlining the process of booking drayage services, making it easier for shippers and freight forwarders to connect with drayage providers.

Features:

– Real-time rate quotes

– Capacity availability information

– Automated booking and confirmation

– Integration with other logistics systems

Benefits:

– Reduced booking time and effort

– Increased transparency in pricing

– Improved capacity utilization for drayage companies

– Enhanced ability to compare and select optimal services

Real-time tracking and visibility

Advanced tracking technologies provide stakeholders with up-to-the-minute information on container locations and status.

Technologies used:

– GPS tracking devices

– Mobile apps for drivers

– IoT sensors on containers and chassis

– Integration with port and terminal systems

Benefits:

– Improved planning and coordination

– Proactive management of delays and exceptions

– Enhanced customer service through real-time updates

– Better utilization of assets and resources

Artificial Intelligence and Machine Learning

AI and ML algorithms are being applied to various aspects of drayage operations to optimize processes and predict outcomes.

Applications:

– Predictive maintenance for trucks and equipment

– Dynamic route optimization

– Forecasting of port congestion and wait times

– Automated dispatching and load matching

Benefits:

– Reduced downtime and maintenance costs

– Improved fuel efficiency and reduced emissions

– More accurate planning and scheduling

– Enhanced decision-making based on data-driven insights

Blockchain technology

Blockchain is being explored for its potential to streamline documentation and increase transparency in drayage transactions.

Use cases:

– Digital bill of lading

– Smart contracts for service agreements

– Secure sharing of shipment data

– Tracking of container ownership and history

Benefits:

– Reduced paperwork and administrative costs

– Increased security and reduced fraud

– Faster payment processing

– Improved traceability and accountability

Automated gate systems

Ports and terminals are implementing automated gate systems to speed up truck processing and reduce congestion.

Components:

– Optical character recognition (OCR) for container and license plate reading

– RFID tags for truck and driver identification

– Automated kiosks for driver interaction

– Integration with terminal operating systems

Benefits:

– Reduced gate processing times

– Improved accuracy in container and truck identification

– Enhanced security through automated checks

– Decreased congestion at terminal entrances

Electric and autonomous vehicles

While still in the early stages, electric and autonomous vehicle technologies are poised to transform drayage operations in the coming years.

Developments:

– Electric trucks for short-haul drayage

– Platooning technology for semi-autonomous convoys

– Fully autonomous trucks for terminal-to-warehouse movements

– Charging infrastructure at ports and logistics hubs

Potential benefits:

– Reduced emissions and environmental impact

– Increased safety through advanced driver assistance systems

– Potential solution to driver shortage issues

– 24/7 operations without hours-of-service limitations

Data analytics and business intelligence

Advanced analytics tools are helping drayage companies and their customers make sense of the vast amounts of data generated in operations.

Applications:

– Performance benchmarking

– Capacity planning and forecasting

– Identification of inefficiencies and bottlenecks

– Customer behavior analysis

Benefits:

– Data-driven decision making

– Continuous improvement of operations

– Better alignment of resources with demand

– Enhanced strategic planning capabilities

To illustrate how these technologies are being integrated into drayage operations, consider the following table showing a hypothetical technology-enabled drayage process:

| Stage | Technology Used | Benefits |

|---|---|---|

| Booking | Digital platform | Instant quotes, automated matching |

| Pre-arrival | AI predictive analytics | Accurate ETA, congestion forecasting |

| Gate-in | Automated gate system | Faster processing, reduced queues |

| Container pickup | IoT sensors, mobile app | Real-time location updates, paperless process |

| Transportation | Electric truck, route optimization | Lower emissions, optimal path selection |

| Delivery | Blockchain-enabled PoD | Instant verification, automated payment trigger |

| Performance review | Data analytics dashboard | KPI tracking, improvement identification |

This table demonstrates how various technologies can be integrated throughout the drayage process to create a more efficient, transparent, and sustainable operation.

Challenges in technology adoption

While the benefits of these technologies are significant, their adoption in the drayage industry faces several challenges:

Cost of implementation: Many new technologies require substantial upfront investment, which can be challenging for smaller drayage operators.

Integration with legacy systems: Ensuring new technologies work seamlessly with existing systems and processes can be complex and time-consuming.

Training and change management: Adopting new technologies often requires significant training efforts and may face resistance from employees accustomed to traditional methods.

Data privacy and security concerns: As more data is collected and shared, ensuring its security and compliance with privacy regulations becomes increasingly important.

Standardization issues: Lack of industry-wide standards for some technologies can lead to interoperability problems and fragmented adoption.

Despite these challenges, the pace of technological change in the drayage industry continues to accelerate. Companies that successfully navigate these challenges and embrace new technologies are likely to gain significant competitive advantages in terms of efficiency, cost-effectiveness, and customer satisfaction.

The transformation of drayage through technology is an ongoing process that promises to address many of the industry’s long-standing challenges. From reducing congestion and improving visibility to enhancing sustainability and operational efficiency, these technological advancements are reshaping the future of drayage. As the industry continues to evolve, staying informed about and adapting to these technological trends will be crucial for all stakeholders in the drayage ecosystem.

What Factors Influence Drayage Costs?

Drayage costs can vary significantly based on a multitude of factors, making it crucial for shippers, consignees, and logistics professionals to understand these influences. By comprehending the elements that impact drayage pricing, stakeholders can better manage their expenses and make informed decisions about their supply chain strategies. Let’s explore the key factors that influence drayage costs:

Distance and location

The distance between pickup and delivery points is a fundamental factor in determining drayage costs.

Considerations:

– Mileage between port/rail terminal and final destination

– Urban vs. rural routes

– Traffic congestion in the service area

– Accessibility of pickup and deliverylocations

Impact on costs:

– Longer distances generally result in higher costs due to increased fuel consumption and driver time

– Urban locations may incur higher costs due to traffic and complex routing

– Remote or hard-to-access locations may require special equipment or additional time, increasing costs

Time factors

Various time-related elements can significantly impact drayage costs.

Key time factors:

– Wait times at ports or terminals

– Delivery appointment windows

– Rush hour traffic considerations

– Seasonal peak periods

Impact on costs:

– Extended wait times at ports can lead to detention charges

– Tight delivery windows may require premium pricing for guaranteed service

– After-hours or weekend deliveries often incur surcharges

Container type and weight

The characteristics of the container being transported affect drayage pricing.

Container variables:

– Size (20-foot, 40-foot, 45-foot)

– Type (standard, high-cube, refrigerated, etc.)

– Weight of the loaded container

– Special handling requirements (e.g., hazardous materials)

Impact on costs:

– Larger containers typically cost more to transport

– Overweight containers may require special permits or equipment, increasing costs

– Refrigerated containers (reefers) incur higher costs due to power requirements and monitoring

Equipment availability

The availability of necessary equipment can influence drayage costs, especially during peak seasons.

Equipment considerations:

– Chassis availability

– Specialized equipment needs (e.g., tri-axle chassis for heavy loads)

– Seasonal fluctuations in equipment demand

Impact on costs:

– Chassis shortages can lead to additional fees or split moves

– Specialized equipment often comes with premium pricing

– Peak season surcharges may apply when equipment is in high demand

Fuel prices

Fuel costs are a significant component of drayage pricing and can fluctuate based on market conditions.

Fuel-related factors:

– Current diesel prices

– Fuel surcharges implemented by drayage companies

– Efficiency of the trucks used

Impact on costs:

– Higher fuel prices directly increase drayage costs

– Some companies use fuel surcharge mechanisms to adjust pricing dynamically

– More fuel-efficient vehicles can help mitigate the impact of fuel price increases

Regulatory compliance

Compliance with various regulations can add to the cost of drayage operations.

Regulatory areas:

– Emissions standards and clean truck programs

– Hours of service regulations

– Port and terminal security requirements

– Weight and size restrictions on roads

Impact on costs:

– Compliance with stricter emissions standards may require investment in newer, cleaner trucks

– Security credentials and background checks for drivers add administrative costs

– Adhering to hours of service rules may necessitate additional drivers or equipment

Market conditions

Overall market dynamics in the logistics industry can influence drayage pricing.

Market factors:

– Supply and demand for drayage services

– Competition among drayage providers

– Economic conditions affecting trade volumes

– Labor market conditions for drivers

Impact on costs:

– High demand periods can lead to increased pricing

– Competitive markets may result in more favorable rates for shippers

– Economic downturns might lead to reduced rates due to overcapacity

Additional services

Many drayage moves involve additional services that can affect the overall cost.

Common additional services:

– Container transloading

– Customs examination coordination

– Storage or detention of containers

– Pre-pull services to expedite delivery

Impact on costs:

– Each additional service typically incurs its own fee

– Complex moves requiring multiple services can significantly increase total costs

– Some services may be subject to hourly rates rather than flat fees

To illustrate how these factors can interact to influence drayage costs, consider the following table comparing two hypothetical drayage scenarios:

| Factor | Scenario A | Scenario B | Cost Impact |

|---|---|---|---|

| Distance | 20 miles | 50 miles | Higher for B |

| Time | Off-peak, flexible | Peak hours, tight window | Higher for B |

| Container | 20-foot standard | 40-foot reefer | Higher for B |

| Equipment | Standard chassis available | Specialized chassis needed | Higher for B |

| Fuel prices | Current market rate | 10% increase | Higher for B |

| Regulations | Standard compliance | Clean truck program | Higher for B |

| Market conditions | Balanced supply/demand | High demand season | Higher for B |

| Additional services | None | Customs exam required | Higher for B |

This comparison demonstrates how various factors can compound to create significant cost differences between seemingly similar drayage moves.

Strategies for managing drayage costs

Understanding these cost factors allows stakeholders to develop strategies for managing and potentially reducing drayage expenses:

Optimize scheduling: Plan moves during off-peak hours when possible to avoid congestion and reduce wait times.

Consolidate shipments: Combine multiple containers into full truckloads to maximize efficiency.

Leverage technology: Use digital platforms and real-time tracking to improve planning and reduce inefficiencies.

Negotiate contracts: Establish long-term relationships with drayage providers to secure more favorable rates and terms.

Improve facility efficiency: Streamline loading and unloading processes to reduce dwell times and potential detention charges.

Consider alternative routes: Explore different port or rail terminal options that may offer more cost-effective drayage solutions.

Stay informed: Keep abreast of market conditions, regulatory changes, and technological advancements that may impact drayage costs.

By carefully considering these factors and implementing strategic approaches, businesses can better manage their drayage costs while maintaining efficient and reliable supply chain operations. As the drayage industry continues to evolve, staying informed about these cost influences and adapting strategies accordingly will be crucial for optimizing logistics expenses and maintaining competitive advantage in the global marketplace.