What Is Real-Time Visibility in SCM

What is Real-Time Visibility in Supply Chain Management?

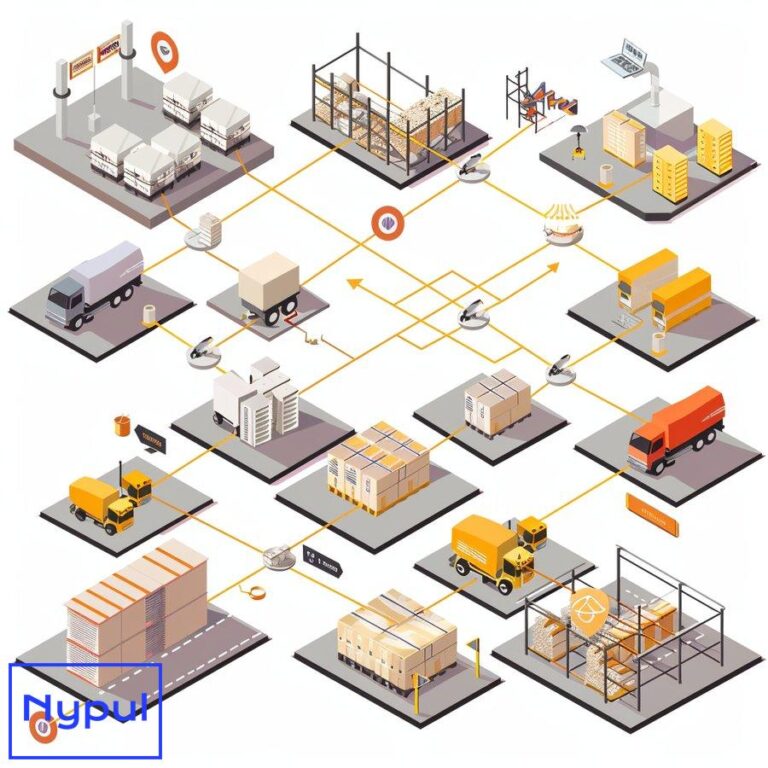

Real-time visibility in supply chain management (SCM) refers to the ability to track and monitor the movement of goods, inventory, and information across the entire supply chain in real time. It provides businesses with a clear, up-to-date view of their supply chain operations from end to end, enabling them to make informed decisions, optimize processes, and quickly respond to potential issues.

Real-time visibility leverages technologies such as GPS tracking, RFID, IoT sensors, and sophisticated software to allow businesses to plan, schedule, and monitor their logistics processes at every stage. This live information empowers supply chain managers to understand what is happening, under what conditions, and to identify any problems as they occur.

By harnessing real-time data, businesses gain valuable insights that drive operational efficiency and enhance customer satisfaction. Real-time visibility helps companies:

Reduce Costs

Real-time visibility enables businesses to optimize routes, reduce fuel consumption, avoid damaged goods, and minimize wasted employee time.

Improve Product Quality

Live data allows companies to detect and resolve quality issues faster, leading to improved product quality.

Ensure Compliance

Real-time monitoring helps businesses maintain compliance with regulatory requirements throughout the supply chain, such as import/export regulations, environmental standards, and worker safety protocols.

Enhance Customer Experience

In today’s on-demand economy, real-time tracking of supply chain operations enables businesses to reliably meet increasing customer expectations around delivery time and product quality.

Real-time supply chain visibility is becoming increasingly crucial for businesses looking to gain a competitive edge in today’s fast-paced, global marketplace. By investing in real-time visibility solutions, companies can boost productivity, increase transparency, reduce disruptions, and ultimately, drive profitability.

Why is Real-Time Visibility Critical for Modern Supply Chains?

In the modern business landscape, real-time visibility has become a critical component of effective supply chain management. As customer expectations continue to rise and supply chains grow more complex, the ability to track and monitor operations in real time is essential for staying competitive. Here are some key reasons why real-time visibility is so important:

Agility and Responsiveness

Real-time data enables businesses to react quickly to disruptions, market trends, or potential issues, providing a significant competitive advantage over those relying on outdated information. With live insights, companies can make informed decisions and adjust their strategies on the fly.

Risk Mitigation

Real-time visibility helps businesses detect potential problems before they escalate, allowing for proactive risk management. By identifying issues early, companies can take corrective action to minimize the impact on their supply chain and avoid costly disruptions.

Improved Collaboration

Real-time data sharing fosters better collaboration among supply chain partners, enabling them to work together more effectively. With everyone operating from the same up-to-date information, communication becomes clearer, and decision-making is more aligned.

Enhanced Customer Service

In today’s fast-paced, customer-centric business environment, meeting or exceeding customer expectations is crucial. Real-time visibility allows businesses to provide accurate, timely information to customers about their orders, improving satisfaction and building trust.

Increased Efficiency

By leveraging real-time data, companies can optimize their supply chain processes, reducing waste, minimizing delays, and improving overall efficiency. This leads to cost savings, increased productivity, and a more streamlined operation.

Competitive Advantage

As more businesses adopt real-time visibility solutions, those that fail to keep up risk falling behind. Investing in real-time visibility technology positions companies to stay ahead of the curve and maintain a competitive edge in their industry.

| Benefit | Description |

|---|---|

| Agility and Responsiveness | React quickly to disruptions and market trends |

| Risk Mitigation | Detect and address potential issues early |

| Improved Collaboration | Foster better communication and alignment among partners |

| Enhanced Customer Service | Provide accurate, timely information to customers |

| Increased Efficiency | Optimize processes, reduce waste, and minimize delays |

| Competitive Advantage | Stay ahead of the curve and maintain market position |

In today’s dynamic business environment, real-time visibility is no longer a luxury—it’s a necessity. By embracing real-time supply chain visibility, companies can position themselves for success, drive continuous improvement, and build resilience in the face of an ever-changing market.

What Are the Key Components of a Real-Time Visibility System?

To achieve effective real-time visibility in supply chain management, businesses must implement a comprehensive system that integrates various technologies and processes. The following are the key components of a robust real-time visibility system:

Data Collection Devices

At the foundation of any real-time visibility system are the devices used to collect data from across the supply chain. These may include GPS trackers, RFID tags, IoT sensors, and other technologies that capture information about the location, condition, and status of goods, vehicles, and assets.

Integration Platform

A centralized integration platform is essential for aggregating data from multiple sources and systems, such as ERP, WMS, and TMS. This platform should be able to handle large volumes of data in real time and provide a single, unified view of the supply chain.

Data Analytics

Advanced data analytics capabilities are crucial for turning raw data into actionable insights. Real-time visibility systems should incorporate powerful analytics tools that can process and analyze data in real time, enabling businesses to make informed decisions and respond quickly to changing conditions.

Visualization Tools

To make real-time data accessible and understandable, a visibility system must include intuitive visualization tools. These may include dashboards, maps, and other graphical interfaces that present information in a clear, concise manner, allowing users to quickly identify trends, anomalies, and areas for improvement.

Alerts and Notifications

Real-time visibility systems should have the ability to generate alerts and notifications based on predefined criteria or thresholds. This ensures that relevant stakeholders are promptly informed of any issues or deviations from the plan, enabling them to take corrective action in a timely manner.

Security and Access Controls

Given the sensitive nature of supply chain data, real-time visibility systems must incorporate robust security measures and access controls. This includes encryption, secure data transmission protocols, and user authentication to ensure that data remains confidential and protected from unauthorized access.

Scalability and Flexibility

As businesses grow and their supply chains evolve, real-time visibility systems must be able to scale and adapt accordingly. Cloud-based architectures and modular designs enable companies to easily expand their visibility capabilities and integrate with new technologies as needed.

By incorporating these key components into a comprehensive real-time visibility system, businesses can gain a clear, up-to-date view of their supply chain operations, enabling them to make informed decisions, optimize processes, and respond quickly to any challenges that arise.

How Does Real-Time Visibility Enhance Decision-Making in SCM?

Real-time visibility plays a crucial role in enhancing decision-making within supply chain management. By providing businesses with up-to-date, accurate information about their operations, real-time visibility empowers managers to make informed, data-driven decisions that optimize performance and mitigate risks. Here’s how real-time visibility improves decision-making in SCM:

Proactive Problem-Solving

With real-time data at their fingertips, supply chain managers can identify potential issues before they escalate into major problems. This proactive approach allows businesses to take corrective action quickly, minimizing the impact on operations and preventing costly disruptions.

Informed Resource Allocation

Real-time visibility provides insights into the performance and utilization of resources across the supply chain, such as vehicles, personnel, and inventory. This information enables managers to make informed decisions about resource allocation, ensuring that assets are deployed efficiently and effectively.

Dynamic Route Optimization

Real-time data on traffic conditions, weather patterns, and other external factors allows businesses to dynamically optimize their transportation routes. By making data-driven routing decisions, companies can reduce fuel consumption, minimize delays, and improve overall delivery performance.

Inventory Management

Real-time visibility into inventory levels, demand patterns, and supplier performance enables businesses to make more accurate forecasting and replenishment decisions. This helps to prevent stockouts, reduce excess inventory, and improve overall inventory turnover.

Collaborative Decision-Making

Real-time data sharing fosters better collaboration among supply chain partners, enabling them to make decisions together based on a shared understanding of the situation. This collaborative approach leads to more aligned, effective decision-making that benefits the entire supply chain.

Continuous Improvement

By analyzing real-time data over time, businesses can identify trends, patterns, and areas for improvement within their supply chain operations. This insight enables managers to make data-driven decisions that drive continuous improvement initiatives, leading to increased efficiency and competitiveness.

| Decision-Making Area | Real-Time Visibility Benefit |

|---|---|

| Problem-Solving | Identify and address issues proactively |

| Resource Allocation | Optimize deployment of assets and personnel |

| Route Optimization | Dynamically adjust routes based on real-time conditions |

| Inventory Management | Improve forecasting and replenishment accuracy |

| Collaborative Decision-Making | Foster aligned, effective decisions among partners |

| Continuous Improvement | Identify trends and drive data-driven improvements |

Real-time visibility is a powerful tool for enhancing decision-making in supply chain management. By leveraging up-to-date, accurate data, businesses can make informed, proactive decisions that optimize performance, mitigate risks, and drive continuous improvement. As the complexity of modern supply chains continues to grow, the ability to make data-driven decisions in real time will become increasingly critical for success.

What Challenges Do Companies Face When Implementing Real-Time Visibility?

While the benefits of real-time visibility in supply chain management are clear, implementing these solutions can present several challenges for businesses. Understanding and addressing these challenges is crucial for ensuring a successful adoption of real-time visibility technology. Here are some of the main obstacles companies face:

Data Integration

One of the most significant challenges in implementing real-time visibility is integrating data from multiple sources and systems. Supply chains often involve a complex network of partners, each with their own technologies and data formats. Bringing all this information together into a single, unified platform can be a daunting task that requires significant time and resources.

Technology Infrastructure

Implementing real-time visibility solutions often requires upgrading or replacing existing technology infrastructure. This may include investing in new hardware, such as IoT sensors and GPS trackers, as well as software platforms that can handle large volumes of real-time data. For many businesses, the cost and complexity of these infrastructure changes can be a significant barrier to adoption.

Change Management

Adopting real-time visibility technology often requires significant changes to existing processes, roles, and responsibilities within the organization. Managing this change effectively is crucial for ensuring buy-in from employees and minimizing disruption to operations. Companies must invest in training, communication, and support to help their teams adapt to new ways of working.

Data Quality and Accuracy

Real-time visibility is only as valuable as the data that powers it. Ensuring the quality and accuracy of data across the supply chain can be a challenge, particularly when dealing with multiple partners and legacy systems. Companies must establish clear data governance policies and invest in data cleansing and validation processes to maintain the integrity of their real-time information.

Cybersecurity Risks

As businesses increasingly rely on real-time data to drive their supply chain decisions, the risk of cyber attacks and data breaches grows. Protecting sensitive information and ensuring the security of real-time visibility systems is a critical challenge that requires robust cybersecurity measures, such as encryption, access controls, and regular security audits.

Scalability and Flexibility

As supply chains evolve and grow, real-time visibility solutions must be able to scale and adapt accordingly. Ensuring that these systems are flexible enough to accommodate new partners, technologies, and business requirements can be a challenge, particularly for companies with complex, global supply chains.

| Challenge | Description |

|---|---|

| Data Integration | Unifying data from multiple sources and formats |

| Technology Infrastructure | Upgrading hardware and software to support real-time data |

| Change Management | Adapting processes and roles to new ways of working |

| Data Quality and Accuracy | Ensuring the integrity and reliability of real-time information |

| Cybersecurity Risks | Protecting sensitive data from cyber threats |

| Scalability and Flexibility | Accommodating growth and changes in the supply chain |

While implementing real-time visibility in supply chain management can present significant challenges, the benefits of these solutions often far outweigh the obstacles. By understanding and proactively addressing these challenges, businesses can set themselves up for success and unlock the full potential of real-time visibility in driving supply chain performance and competitiveness.

How Can Organizations Measure the ROI of Real-Time Visibility Solutions?

Investing in real-time visibility solutions can provide significant benefits for supply chain management, but it’s essential for businesses to measure the return on investment (ROI) of these initiatives to justify the costs and ensure ongoing support. Here are some key metrics and approaches for measuring the ROI of real-time visibility in SCM:

Cost Savings

One of the most tangible ways to measure the ROI of real-time visibility is by tracking cost savings across the supply chain. This may include reductions in transportation costs, inventory carrying costs, and labor costs resulting from improved efficiency and decision-making. By comparing costs before and after implementing real-time visibility, businesses can quantify the financial impact of these solutions.

On-Time Delivery Performance

Real-time visibility can significantly improve on-time delivery performance by enabling businesses to proactively identify and address potential delays. Measuring the percentage of shipments delivered on time before and after implementing real-time visibility can demonstrate the impact of these solutions on customer satisfaction and loyalty.

Inventory Turnover

By providing real-time data on inventory levels and demand patterns, real-time visibility solutions can help businesses optimize their inventory management. Measuring improvements in inventory turnover rates can showcase the effectiveness of these solutions in reducing carrying costs and improving cash flow.

Asset Utilization

Real-time visibility enables businesses to track the performance and utilization of their assets, such as vehicles and equipment, in real time. Measuring improvements in asset utilization rates can demonstrate how these solutions help companies maximize the value of their resources and reduce waste.

Customer Satisfaction

Ultimately, the success of real-time visibility initiatives should be measured by their impact on customer satisfaction. Conducting surveys and analyzing customer feedback can provide valuable insights into how real-time visibility is affecting the customer experience and driving loyalty.

Time to Resolution

Real-time visibility can help businesses identify and resolve supply chain issues more quickly. Measuring the average time to resolution for incidents before and after implementing real-time visibility can demonstrate the impact of these solutions on problem-solving efficiency and risk mitigation.

| Metric | Description |

|---|---|

| Cost Savings | Reductions in transportation, inventory, and labor costs |

| On-Time Delivery Performance | Percentage of shipments delivered on time |

| Inventory Turnover | Rate at which inventory is sold and replaced |

| Asset Utilization | Percentage of time assets are in productive use |

| Customer Satisfaction | Surveys and feedback on the customer experience |

| Time to Resolution | Average time to identify and resolve supply chain issues |

To effectively measure the ROI of real-time visibility solutions, businesses should establish clear baselines for these metrics before implementation and track progress over time. It’s also important to consider both the direct and indirect benefits of these initiatives, such as improved collaboration and decision-making, which may be harder to quantify but still contribute to overall supply chain performance.

By taking a comprehensive approach to measuring the ROI of real-time visibility, businesses can build a strong case for continued investment in these solutions and ensure that they are delivering tangible value to the organization.

Real-World Examples: Success Stories in Real-Time SCM Visibility

To illustrate the transformative power of real-time visibility in supply chain management, let’s explore some real-world success stories from companies that have implemented these solutions:

Walmart

Retail giant Walmart has long been a pioneer in supply chain innovation, and their adoption of real-time visibility technology is no exception. By implementing IoT sensors and advanced analytics, Walmart has gained real-time insights into the location and condition of their products from the point of manufacture to the store shelf. This has enabled them to optimize inventory management, reduce waste, and improve on-time delivery performance, resulting in significant cost savings and enhanced customer satisfaction.

Cisco Systems

Global technology leader Cisco Systems has leveraged real-time visibility to transform its complex, global supply chain. By implementing a centralized platform that integrates data from multiple sources, Cisco has gained real-time insights into the status of their orders, inventory, and shipments. This has enabled them to proactively identify and address potential issues, optimize transportation routes, and improve collaboration with their supply chain partners. As a result, Cisco has reduced inventory carrying costs, improved on-time delivery performance, and increased overall supply chain efficiency.

Procter & Gamble

Consumer goods giant Procter & Gamble (P&G) has used real-time visibility to optimize its global supply chain and improve customer service. By implementing a real-time transportation management system, P&G has gained visibility into the location and status of their shipments across all modes of transportation. This has enabled them toreduce transportation costs, improve on-time delivery performance, and enhance collaboration with their logistics partners. P&G has reported significant improvements in customer satisfaction and supply chain efficiency as a result of these initiatives.

DHL

Global logistics provider DHL has implemented real-time visibility solutions to enhance its service offerings and improve operational efficiency. By leveraging IoT sensors, GPS tracking, and advanced analytics, DHL has gained real-time insights into the location and condition of shipments across its global network. This has enabled them to provide customers with accurate, up-to-date information on their shipments, optimize routing and scheduling, and proactively address potential delays or issues. As a result, DHL has improved customer satisfaction, reduced costs, and strengthened its competitive position in the logistics industry.

Caterpillar

Heavy equipment manufacturer Caterpillar has used real-time visibility to optimize its global supply chain and improve customer service. By implementing a comprehensive visibility platform, Caterpillar has gained real-time insights into the status of its parts inventory, production schedules, and customer orders. This has enabled them to reduce lead times, improve inventory management, and provide more accurate delivery estimates to customers. Caterpillar has reported significant improvements in customer satisfaction and supply chain efficiency as a result of these initiatives.

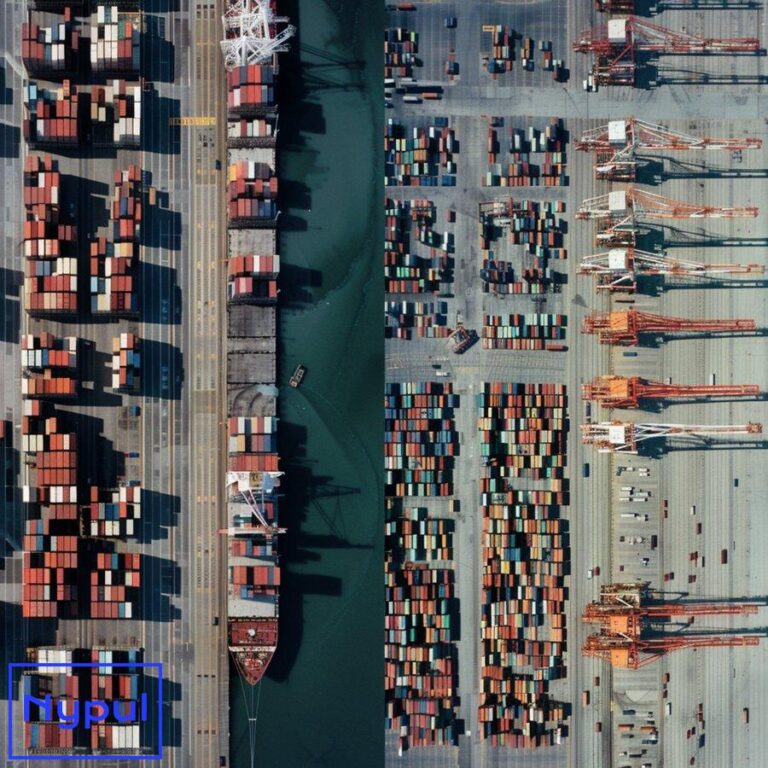

Maersk

Global shipping company Maersk has leveraged real-time visibility to transform its operations and enhance customer service. By implementing IoT sensors and blockchain technology, Maersk has gained real-time visibility into the location and condition of its shipping containers across its global network. This has enabled them to optimize vessel utilization, reduce delays, and provide customers with accurate, up-to-date information on their shipments. Maersk has reported significant improvements in operational efficiency and customer satisfaction as a result of these initiatives.

These success stories demonstrate the tangible benefits that real-time visibility can bring to supply chain management across various industries. By providing accurate, up-to-date information on supply chain operations, real-time visibility enables businesses to make informed decisions, optimize processes, and improve customer service.

Key takeaways from these success stories include:

Improved Efficiency

Real-time visibility enables companies to optimize their operations, reduce waste, and improve resource utilization.

Enhanced Customer Service

By providing accurate, timely information to customers, businesses can improve satisfaction and build stronger relationships.

Proactive Problem-Solving

Real-time visibility allows companies to identify and address potential issues before they escalate, minimizing disruptions and improving overall supply chain performance.

Better Collaboration

Real-time data sharing fosters improved collaboration among supply chain partners, leading to more aligned decision-making and better overall performance.

Cost Reduction

By optimizing processes and reducing waste, real-time visibility initiatives often lead to significant cost savings across the supply chain.

As these success stories illustrate, implementing real-time visibility in supply chain management can drive significant improvements in efficiency, customer service, and overall competitiveness. While the specific benefits may vary depending on the industry and individual business needs, the potential for transformative impact is clear.

For businesses considering implementing real-time visibility solutions, these success stories provide valuable insights and inspiration. By learning from the experiences of industry leaders, companies can develop effective strategies for leveraging real-time visibility to drive their own supply chain performance and achieve their business goals.

In conclusion, real-time visibility has become a critical component of modern supply chain management. As these success stories demonstrate, businesses that invest in real-time visibility solutions can gain a significant competitive advantage, driving improvements in efficiency, customer service, and overall supply chain performance. As technology continues to evolve and supply chains become increasingly complex, the importance of real-time visibility is likely to grow, making it an essential consideration for businesses looking to stay competitive in today’s fast-paced, global marketplace.