What Is the Most Common Type of Intermodal Container Used in Transportation

What is the most common type of intermodal container used in transportation?

The most common type of intermodal container used in transportation is the general purpose container, also known as a dry container. These versatile steel boxes form the backbone of global shipping and logistics, accounting for approximately 90% of the world’s container fleet. General purpose containers offer a standardized, cost-effective solution for transporting a wide variety of non-perishable goods across different modes of transport, including ships, trains, and trucks.

What are general purpose containers and why are they the most common?

General purpose containers are large, standardized steel boxes designed to transport dry, non-perishable cargo securely across various modes of transportation. These containers feature a simple yet robust design with solid walls, a roof, and a floor, along with doors typically located at one end for easy loading and unloading.

Several factors contribute to the widespread use and popularity of general purpose containers:

Versatility

General purpose containers can accommodate a vast array of goods, from manufactured products and raw materials to consumer goods and industrial equipment. This flexibility makes them suitable for diverse industries and shipping needs.

Standardization

The uniform design of general purpose containers, adhering to International Organization for Standardization (ISO) specifications, ensures compatibility across different transportation modes and handling equipment worldwide. This standardization streamlines logistics operations and reduces complexity in global supply chains.

Durability

Constructed from corrosion-resistant steel, general purpose containers withstand harsh weather conditions and the rigors of long-distance transportation. Their robust build protects cargo from damage during transit and storage.

Cost-effectiveness

The simplicity and mass production of general purpose containers make them more affordable compared to specialized container types. Their widespread availability also contributes to lower overall shipping costs.

Ease of handling

The standardized design of general purpose containers allows for efficient loading, unloading, and transfer between different modes of transport using standardized equipment like cranes, forklifts, and container chassis.

Stackability

General purpose containers can be stacked securely on ships and in storage yards, maximizing space utilization and reducing transportation costs.

These attributes make general purpose containers the go-to choice for most shipping needs, explaining their dominance in the global container fleet.

What are the standard dimensions of general purpose containers?

General purpose containers come in standardized dimensions to ensure compatibility across different transportation modes and handling equipment. The most common sizes are 20-foot and 40-foot containers, with variations in height also available. Here’s a breakdown of the standard dimensions:

| Container Type | Length | Width | Height | Internal Volume | Max Gross Weight |

|---|---|---|---|---|---|

| 20-foot standard | 20′ (6.1m) | 8′ (2.44m) | 8’6″ (2.59m) | 1,169 ft³ (33.1 m³) | 52,910 lbs (24,000 kg) |

| 40-foot standard | 40′ (12.2m) | 8′ (2.44m) | 8’6″ (2.59m) | 2,385 ft³ (67.5 m³) | 67,200 lbs (30,480 kg) |

| 40-foot high cube | 40′ (12.2m) | 8′ (2.44m) | 9’6″ (2.89m) | 2,690 ft³ (76.2 m³) | 67,200 lbs (30,480 kg) |

20-foot standard container

This container size is often referred to as a Twenty-foot Equivalent Unit (TEU), which serves as a standard measure of container capacity. It’s particularly useful for dense, heavy cargo due to its lower volume-to-weight ratio.

40-foot standard container

Also known as a Forty-foot Equivalent Unit (FEU), this container offers double the capacity of a 20-foot container. It’s ideal for larger shipments or bulky items that require more space.

40-foot high cube container

This variant provides an additional foot of height compared to the standard 40-foot container, offering extra vertical space for taller cargo or to maximize volume for lighter goods.

These standardized dimensions facilitate efficient space utilization on ships, trains, and in storage yards. They also enable seamless transfers between different modes of transport, as handling equipment and vehicles are designed to accommodate these specific sizes.

The uniform external dimensions ensure that containers can be stacked securely, with corner castings at each corner allowing for easy locking and lifting. The internal dimensions may vary slightly between manufacturers, but they generally provide ample space for a wide range of cargo types.

Understanding these standard dimensions is crucial for shippers and logistics professionals when planning cargo loads, optimizing space utilization, and calculating shipping costs. The choice between 20-foot and 40-foot containers often depends on the volume and weight of the cargo, as well as considerations such as port restrictions or inland transportation limitations.

How do general purpose containers enhance intermodal efficiency?

General purpose containers significantly enhance intermodal efficiency by facilitating seamless transitions between different modes of transport. This efficiency is achieved through several key aspects:

Standardized design

The uniform dimensions and construction of general purpose containers allow for consistent handling across various transportation modes. This standardization eliminates the need for cargo repackaging or transfer between different container types, reducing handling time and labor costs.

Interchangeability

General purpose containers can be easily transferred between ships, trains, and trucks without the need to unload and reload the cargo. This interchangeability minimizes transit times and reduces the risk of damage or loss during cargo transfers.

Compatibility with handling equipment

The standardized design ensures that general purpose containers are compatible with a wide range of handling equipment, including gantry cranes, reach stackers, and container chassis. This compatibility streamlines loading and unloading processes at ports, rail yards, and distribution centers.

Efficient space utilization

The ability to stack general purpose containers securely allows for optimal use of space on ships, trains, and in storage yards. This efficient space utilization reduces transportation costs and increases overall cargo capacity.

Simplified documentation and tracking

The use of standardized containers simplifies documentation processes and enables more efficient cargo tracking. Each container has a unique identification number, facilitating easier management and monitoring throughout the supply chain.

Reduced cargo handling

By keeping goods in the same container throughout the journey, general purpose containers minimize the need for direct cargo handling. This reduction in handling not only speeds up the transportation process but also decreases the risk of damage or theft.

Flexibility in routing

The versatility of general purpose containers allows for greater flexibility in routing options. Shippers can easily switch between different modes of transport or carriers without concerns about container compatibility.

Enhanced security

The sealed nature of general purpose containers provides a secure environment for cargo throughout its journey. This security feature is particularly valuable when goods are transferred between different modes of transport or stored temporarily.

Faster turnaround times

The efficiency gained through standardized handling and reduced cargo transfers leads to faster turnaround times at ports and terminals. This increased speed benefits the entire supply chain, allowing for more frequent shipments and improved inventory management.

Cost-effective transportation

By enabling the seamless integration of different transport modes, general purpose containers allow shippers to optimize their transportation strategies. This optimization often results in cost savings through the use of more efficient routes or combinations of transport modes.

The intermodal efficiency provided by general purpose containers has revolutionized global trade, enabling the movement of goods across vast distances with unprecedented speed and reliability. This efficiency has played a crucial role in the growth of international commerce and the development of complex, interconnected supply chains that characterize modern global trade.

What makes general purpose containers cost-effective for global shipping?

General purpose containers offer a highly cost-effective solution for global shipping due to several factors that contribute to reduced expenses and improved operational efficiency:

Mass production and economies of scale

The widespread use of general purpose containers allows for large-scale manufacturing, resulting in lower production costs per unit. This economy of scale translates to more affordable container prices for shipping companies and ultimately, lower shipping costs for customers.

![]()

Standardization reduces handling costs

The uniform design of general purpose containers simplifies handling procedures across different ports, terminals, and modes of transport. This standardization reduces the need for specialized equipment or training, leading to lower operational costs and faster turnaround times.

Efficient space utilization

The ability to stack general purpose containers securely on ships and in storage yards maximizes the use of available space. This efficient space utilization allows carriers to transport more cargo per journey, effectively reducing the cost per unit of cargo shipped.

Minimized cargo damage

The robust construction of general purpose containers provides excellent protection for goods during transit. This protection reduces the likelihood of cargo damage, resulting in fewer insurance claims and lower overall shipping costs.

Reduced packaging requirements

The secure environment provided by general purpose containers often allows for simpler, less expensive packaging of goods. This reduction in packaging materials and labor can lead to significant cost savings for shippers.

Flexibility in transportation options

The versatility of general purpose containers allows shippers to choose the most cost-effective combination of transportation modes for their specific needs. This flexibility can result in optimized routing and reduced overall shipping expenses.

Lower insurance premiums

The enhanced security and reduced risk of damage associated with general purpose containers often lead to lower insurance premiums for shipped goods. These savings contribute to the overall cost-effectiveness of container shipping.

Faster transit times

The efficiency of intermodal transport using general purpose containers results in faster overall transit times. This speed not only improves supply chain performance but can also lead to reduced inventory holding costs for businesses.

Reusability and long lifespan

General purpose containers are designed for repeated use over many years. This longevity spreads the initial cost of the container over numerous shipments, making each individual shipment more cost-effective.

Simplified documentation and customs processes

The standardized nature of general purpose containers often leads to more streamlined documentation and customs procedures. This simplification can result in faster clearance times and reduced administrative costs.

Reduced labor costs

The ease of handling general purpose containers with standardized equipment reduces the need for manual labor in loading, unloading, and transferring cargo. This reduction in labor requirements contributes to overall cost savings in the shipping process.

Economies of route

The widespread use of general purpose containers allows shipping lines to establish regular, high-volume routes. These established routes often benefit from economies of scale, resulting in lower per-unit shipping costs.

The cost-effectiveness of general purpose containers has played a significant role in enabling global trade on an unprecedented scale. By reducing transportation costs and improving efficiency, these containers have made it economically viable to ship goods over long distances, connecting manufacturers, suppliers, and consumers across the world. This cost-effectiveness has been a driving force behind the globalization of supply chains and the growth of international commerce.

How do general purpose containers compare to specialized container types?

General purpose containers, while versatile and widely used, differ from specialized container types in several aspects. Understanding these differences is crucial for shippers to choose the most appropriate container for their specific cargo needs. Here’s a comparison of general purpose containers with some common specialized container types:

![]()

General Purpose vs. Refrigerated (Reefer) Containers

General Purpose Containers:

– Suitable for non-perishable goods

– No temperature control

– Lower operating costs

– More readily available

Refrigerated Containers:

– Designed for temperature-sensitive cargo

– Precise temperature control (-65°C to 40°C)

– Higher operating costs due to power requirements

– Less common, may require advance booking

General Purpose vs. Open Top Containers

General Purpose Containers:

– Enclosed on all sides

– Loaded through end doors

– Suitable for most dry cargo

Open Top Containers:

– Removable roof for top loading

– Ideal for tall or oversized cargo

– Allows for crane or forklift loading from above

– May require additional securing measures

General Purpose vs. Flat Rack Containers

General Purpose Containers:

– Fully enclosed

– Protection from weather and theft

– Limited to cargo that fits through doors

Flat Rack Containers:

– No sides or roof

– Suitable for oversized or irregularly shaped cargo

– Easier loading of heavy machinery or vehicles

– Less protection from elements

General Purpose vs. Tank Containers

General Purpose Containers:

– Suitable for packaged goods

– Dry cargo only

Tank Containers:

– Designed for liquid, gas, or powder bulk cargo

– Built-in safety features for hazardous materials

– Require specialized handling and cleaning

General Purpose vs. Insulated Containers

General Purpose Containers:

– No insulation

– Subject to temperature fluctuations

Insulated Containers:

– Thermal insulation to maintain consistent temperature

– No active cooling or heating system

– Suitable for temperature-sensitive, non-perishable goods

Here’s a comparison table summarizing key differences:

| Feature | General Purpose | Refrigerated | Open Top | Flat Rack | Tank | Insulated |

|---|---|---|---|---|---|---|

| Cargo Type | Dry, non-perishable | Temperature-sensitive | Oversized, top-loading | Heavy, oversized | Liquid, gas, powder | Temperature-sensitive, non-perishable |

| Temperature Control | No | Yes | No | No | No | Passive |

| Weather Protection | Full | Full | Partial | Minimal | Full | Full |

| Loading Method | End doors | End doors | Top or end | Side or top | Valves | End doors |

| Availability | High | Medium | Low | Low | Low | Low |

| Relative Cost | Low | High | Medium | Medium | High | Medium |

General purpose containers offer a balance of versatility, cost-effectiveness, and widespread availability, making them suitable for a broad range of shipping needs. However, specialized containers provide targeted solutions for specific cargo requirements, such as temperature control, unique loading needs, or the transport of bulk liquids.

The choice between general purpose and specialized containers depends on factors such as:

- Nature of the cargo (perishable, oversized, liquid, etc.)

- Required level of environmental control

- Loading and unloading requirements

- Transportation route and modes

- Budget constraints

- Availability of container types

While general purpose containers dominate the market due to their versatility, specialized containers play a crucial role in enabling the safe and efficient transport of goods that require specific handling or environmental conditions. Shippers must carefully consider their cargo requirements to determine whether a general purpose container suffices or if a specialized container type is necessary to ensure the safe and efficient delivery of their goods.

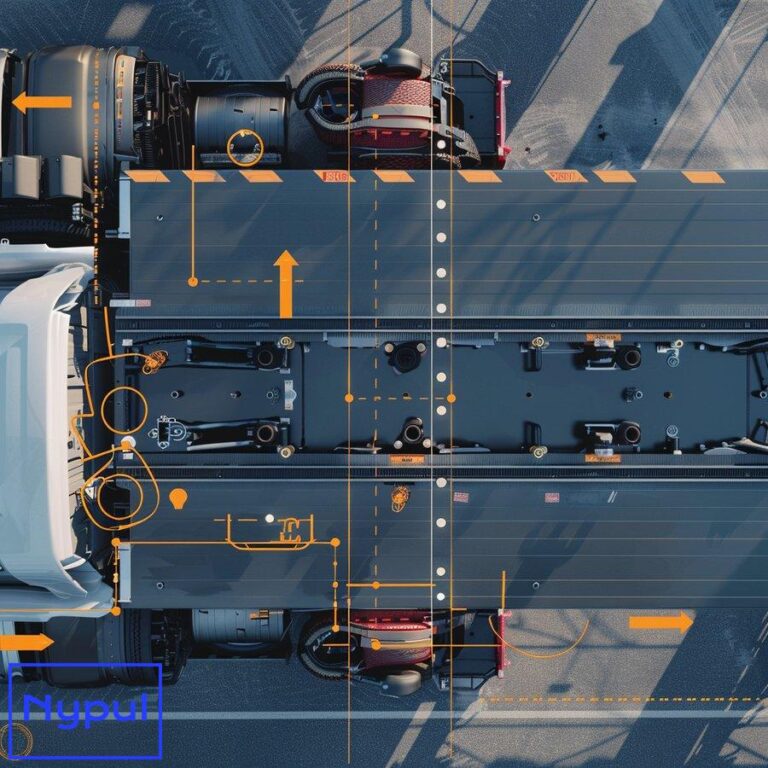

What are the key security features of general purpose containers?

General purpose containers incorporate several security features designed to protect cargo from theft, tampering, and environmental damage during transit and storage. These features play a crucial role in maintaining the integrity of shipments throughout the supply chain. Here are the key security features of general purpose containers:

Robust construction

General purpose containers are built with strong, corrosion-resistant steel walls, roof, and floor. This durable construction provides a solid barrier against forced entry and helps protect the cargo from external impacts and weather conditions.

Secure locking mechanisms

Containers are equipped with heavy-duty locking bars and padlock hasps on the doors. These locking systems can accommodate high-security seals or locks, making unauthorized access difficult without leaving evidence of tampering.

Tamper-evident seals

While not a permanent part of the container, the use of tamper-evident seals is a standard practice in container shipping. These seals are designed to break if the container is opened, providing clear evidence of any unauthorized access attempts.

Corner castings

The standardized corner fittings at each corner of the container serve multiple purposes, including security. They allow for secure stacking and locking of containers, making it difficult to remove a container from a stack without proper equipment.

Unique identification numbers

Each container has a unique identification number prominently displayed on its exterior. This number is used for tracking and verification purposes, making it easier to identify and locate specific containers throughout their journey.

Reinforced door frames

The door frame area, often a vulnerable point in container security, is reinforced to resist attempts at forced entry. This reinforcement includes strong hinges and locking rod assemblies.

Weather-tight seals

Rubber gaskets around the doors provide a weather-tight seal when closed, protecting cargo from moisture, dust, and pests. This feature not only protects against environmental damage but also makes it more difficult to introduce contaminants or pests into the container.

Vents and pressure release valves

Some general purpose containers are equipped with vents or pressure release valves. These features help regulate internal air pressure and prevent moisture buildup while maintaining security by being designed to prevent unauthorized access.

Internal lashing points

Many containers feature internal lashing points or rings welded to the walls and floor. These allow cargo to be securely fastened inside the container, preventing movement during transit and reducing the risk of damage or theft.

High-visibility markings

Containers often feature high-visibility markings or reflective tape, making them easier to monitor in storage yards or during nighttime operations. This visibility enhances security by making unauthorized movement more noticeable.

Optional security add-ons

While not standard features, many shippers and carriers use additional security measures such as:

– Electronic seals (e-seals) that provide real-time monitoring and alerts

– GPS tracking devices for continuous location monitoring

– Security cameras or motion sensors for high-value cargo## Global Usage and Market Share of General Purpose Containers

The global usage and market share of general purpose containers reflect their dominance in the international shipping industry. These containers form the backbone of intermodal transportation, facilitating the movement of goods across oceans, railways, and highways.

Market size and growth

As of 2024, the global container fleet exceeds 50 million TEUs (Twenty-foot Equivalent Units), with general purpose containers accounting for approximately 90% of this total. The market for general purpose containers continues to grow, driven by increasing global trade volumes and the expansion of e-commerce.

Regional distribution

The distribution of general purpose containers varies by region, reflecting global trade patterns:

Asia-Pacific: This region dominates the container market, with China being the largest manufacturer and user of general purpose containers. Major ports in China, Singapore, and South Korea handle millions of TEUs annually.

Europe: European ports, particularly those in Rotterdam, Hamburg, and Antwerp, are significant hubs for general purpose container traffic, serving as gateways for trade between Europe, Asia, and the Americas.

North America: Major container ports on both the East and West coasts of the United States handle millions of general purpose containers each year, facilitating trade with Asia, Europe, and Latin America.

Middle East: Ports in Dubai and other Gulf states have become important transshipment hubs, handling a growing number of general purpose containers.

Latin America: While the container market in this region is smaller compared to Asia and Europe, it’s experiencing steady growth, particularly in ports serving Brazil, Mexico, and Panama.

Industry sectors

General purpose containers are used across various industry sectors, including:

Manufacturing: Transport of finished goods and components

Retail: Movement of consumer products and apparel

Agriculture: Shipping of non-perishable agricultural products

Construction: Transportation of building materials and equipment

Automotive: Shipping of car parts and accessories

Market players

The container leasing and shipping industry is dominated by several key players:

Container leasing companies: Triton International, Textainer, and CAI International control a significant portion of the global container fleet.

Shipping lines: Major carriers like Maersk, MSC, CMA CGM, and COSCO operate large fleets of general purpose containers.

Container manufacturers: Chinese companies such as CIMC and CXIC produce the majority of new containers entering the market.

Future trends

The market for general purpose containers is expected to continue growing, influenced by several factors:

Technological advancements: Integration of IoT devices and smart technologies for improved tracking and security.

Sustainability initiatives: Development of more environmentally friendly container designs and materials.

Trade patterns: Shifts in global trade routes and the emergence of new manufacturing hubs may influence container distribution.

E-commerce growth: The continued expansion of online retail is likely to drive demand for general purpose containers.

In conclusion, general purpose containers remain the most common type of intermodal container used in transportation due to their versatility, cost-effectiveness, and standardization. Their widespread adoption has revolutionized global trade, enabling efficient and secure movement of goods across various transportation modes. As international commerce continues to evolve, general purpose containers will undoubtedly play a crucial role in shaping the future of global logistics and supply chain management.