Where Does Port Congestion Come From

What Causes Port Congestion?

Port congestion occurs when the volume of cargo arriving at a port exceeds the port’s capacity to efficiently handle and process the cargo. This imbalance between supply and demand leads to bottlenecks, delays, and increased costs throughout the supply chain.

Insufficient Infrastructure

One major contributor to port congestion is insufficient infrastructure. When ports lack adequate berths, cranes, storage facilities, and intermodal connections, they struggle to keep pace with the influx of cargo. Outdated or poorly maintained equipment can further exacerbate the problem, leading to slower loading and unloading times.

Labor Shortages and Disputes

Labor plays a critical role in port operations, and any disruptions to the workforce can have significant ripple effects. Labor shortages, whether due to a lack of skilled workers or ongoing disputes between unions and port management, can severely limit a port’s ability to process cargo efficiently. Work slowdowns, strikes, or lockouts can bring operations to a standstill, causing cargo to pile up and congestion to worsen.

Demand Surges and Vessel Bunching

Unexpected spikes in demand, such as those seen during peak shipping seasons or in the aftermath of global disruptions like the COVID-19 pandemic, can overwhelm ports that are not prepared to handle the sudden increase in cargo volume. Additionally, vessel bunching, where multiple ships arrive at a port simultaneously due to weather delays or schedule changes, can create sudden congestion as the port struggles to accommodate the influx of cargo.

How Do Labor Issues Contribute to Port Congestion?

Labor is a critical component of port operations, and any disruptions to the workforce can have significant impacts on port efficiency and congestion levels.

Skilled Labor Shortages

Ports rely on a skilled workforce to operate complex equipment, coordinate logistics, and ensure the smooth flow of cargo. However, many ports face shortages of qualified workers, particularly in specialized roles like crane operators and truck drivers. These shortages can lead to slower processing times, increased errors, and ultimately, greater congestion as cargo backs up.

Labor Disputes and Work Stoppages

Disagreements between port workers, unions, and management can escalate into labor disputes that disrupt port operations. Work slowdowns, where employees intentionally reduce their productivity, can significantly decrease a port’s capacity to handle cargo. In more severe cases, strikes or lockouts can bring port operations to a complete halt, causing cargo to accumulate and congestion to worsen rapidly.

Impact on Supply Chains

Labor issues at ports can have far-reaching effects on global supply chains. Delays in cargo processing and increased dwell times can disrupt production schedules, cause inventory shortages, and increase costs for shippers and consumers alike. The uncertainty created by labor disputes can also make it difficult for companies to plan and adjust their supply chain strategies effectively.

What Role Does Infrastructure Play in Port Congestion?

Port infrastructure encompasses the physical assets and facilities necessary for the efficient operation of a port, including berths, cranes, storage areas, and intermodal connections. The quality and capacity of a port’s infrastructure play a crucial role in determining its ability to handle cargo volumes and prevent congestion.

Berth and Crane Capacity

Berth capacity refers to the number and size of ships that a port can accommodate simultaneously. Insufficient berth capacity can lead to vessel queues and delays, as ships are forced to wait for an available berth. Similarly, a lack of crane capacity can slow down the loading and unloading process, increasing the time ships spend at berth and contributing to congestion.

Storage and Yard Space

Adequate storage facilities and yard space are essential for the efficient flow of cargo through a port. When ports lack sufficient storage capacity, containers can pile up, making it difficult to locate and retrieve specific shipments. This can lead to longer dwell times, increased congestion, and delays in the overall supply chain.

Intermodal Connectivity

Efficient intermodal connections, such as rail links and truck access, are crucial for moving cargo in and out of ports quickly. Poor connectivity can create bottlenecks, as cargo accumulates waiting for transportation to its next destination. Investing in infrastructure improvements, such as expanding rail networks and optimizing truck routes, can help alleviate congestion by ensuring a smooth flow of cargo from the port to inland locations.

How Do Demand Surges Affect Port Operations?

Demand surges, whether due to seasonal peaks, global events, or shifts in consumer behavior, can put significant strain on port operations and contribute to congestion.

Peak Shipping Seasons

Many industries experience predictable peaks in demand, such as the holiday season for retail or the summer months for agricultural products. During these periods, ports can face a significant influx of cargo, which can strain their capacity and lead to congestion. Ports that are not adequately prepared to handle these seasonal surges may struggle to process cargo efficiently, resulting in delays and increased costs.

Global Disruptions and Shifts in Demand

Unexpected events, such as natural disasters, trade disputes, or pandemics like COVID-19, can cause sudden shifts in global demand patterns. These disruptions can lead to a surge in cargo volume at certain ports, as shippers seek alternative routes or stockpile inventory. Ports that are not flexible enough to adapt to these changes can quickly become overwhelmed, leading to congestion and delays.

Vessel Bunching and Schedule Reliability

Demand surges can also contribute to vessel bunching, where multiple ships arrive at a port simultaneously due to changes in schedules or delays caused by weather or other factors. This can create a sudden spike in cargo volume that the port may not be prepared to handle, leading to congestion and longer wait times for vessels. Poor schedule reliability, where ships consistently arrive outside of their designated time slots, can further exacerbate the problem by making it difficult for ports to plan and allocate resources effectively.

What Are the Consequences of Port Congestion on Supply Chains?

Port congestion can have significant and far-reaching consequences for global supply chains, affecting shippers, carriers, and consumers alike.

Increased Costs

Congestion at ports can lead to increased costs throughout the supply chain. Shippers may face higher demurrage and detention fees as containers spend more time at the port, while carriers may need to pay additional fuel costs and port fees due to longer wait times. These increased costs are often passed on to consumers in the form of higher prices for goods.

Delayed Shipments and Longer Lead Times

As cargo backs up at congested ports, shipments can face significant delays, leading to longer lead times for goods to reach their final destinations. These delays can disrupt production schedules, cause inventory shortages, and frustrate customers who are waiting for their orders. In some cases, shippers may need to seek alternative, more expensive transportation options to meet deadlines, further increasing costs.

Reduced Schedule Reliability

Port congestion can also impact schedule reliability, making it difficult for shippers and carriers to plan and execute their operations effectively. When vessels are consistently delayed due to congestion, it becomes challenging to maintain accurate schedules and provide reliable service to customers. This uncertainty can lead to a loss of trust and damage long-term business relationships.

Ripple Effects on the Global Economy

The effects of port congestion can extend far beyond the immediate supply chain, impacting the global economy as a whole. Delays in the movement of goods can slow down production, reduce economic growth, and contribute to inflationary pressures. In an interconnected global economy, congestion at a single major port can have cascading effects on industries and consumers worldwide.

How Can Technology Help Mitigate Port Congestion?

Technology can play a crucial role in mitigating port congestion by improving efficiency, transparency, and communication throughout the supply chain.

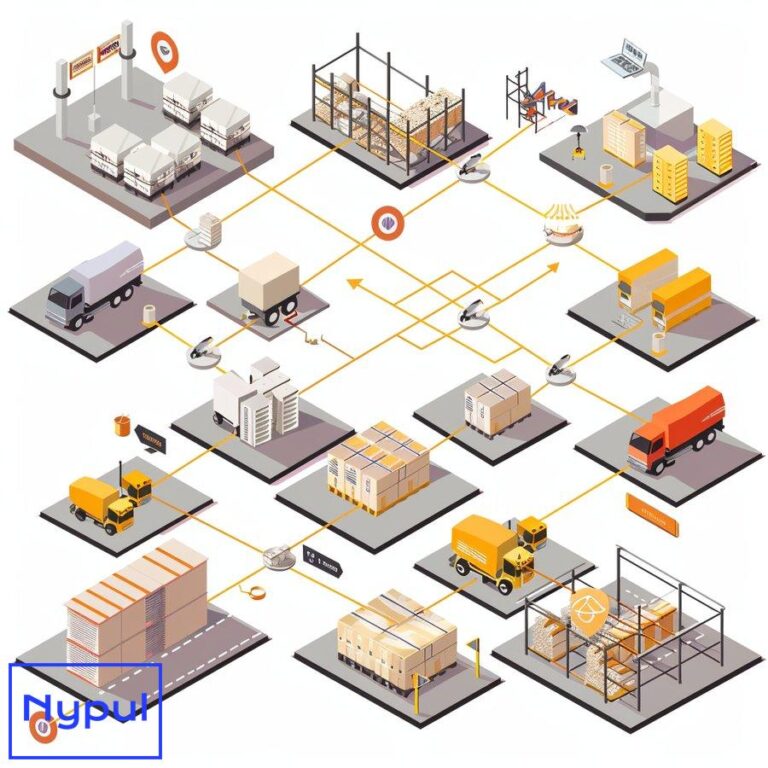

Port Community Systems

Port Community Systems (PCS) are digital platforms that enable the secure and efficient exchange of information between all stakeholders involved in port operations, including shippers, carriers, terminals, and government agencies. By providing a single, centralized source of data, PCS can streamline processes, reduce paperwork, and improve coordination, ultimately helping to alleviate congestion.

Automation and Robotics

Automating port processes, such as container handling and yard operations, can significantly increase efficiency and reduce the risk of human error. Automated guided vehicles (AGVs) and robotic cranes can operate 24/7, improving productivity and reducing the impact of labor shortages. By streamlining operations and minimizing downtime, automation can help ports handle higher cargo volumes and reduce congestion.

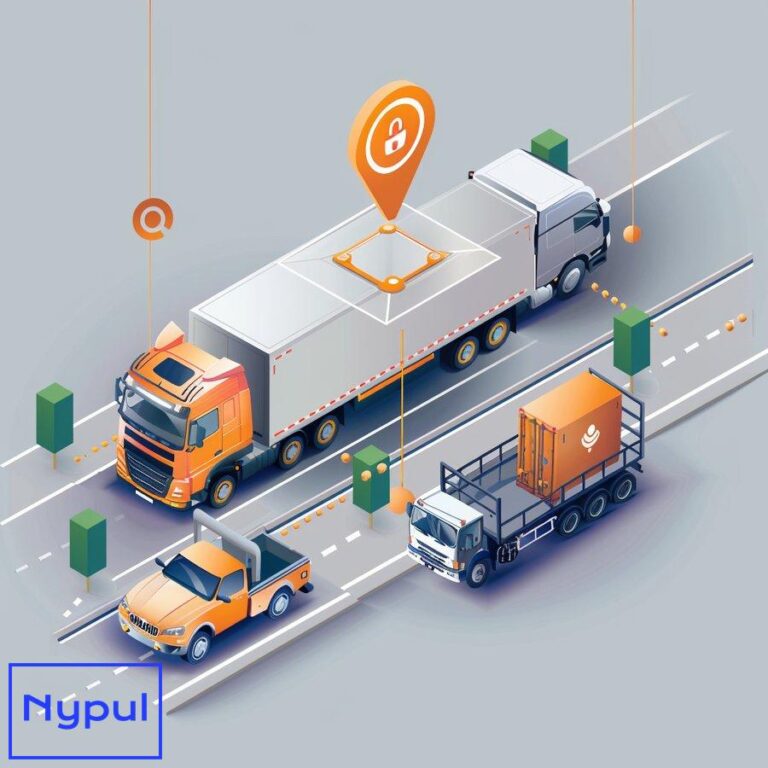

Internet of Things (IoT) and Real-Time Tracking

IoT devices, such as sensors and GPS trackers, can provide real-time visibility into the location and status of cargo, equipment, and vessels. This information can help ports optimize resource allocation, reduce idle time, and improve overall efficiency. Real-time tracking can also enable shippers and carriers to make informed decisions and adjust their plans in response to congestion or delays.

Predictive Analytics and Machine Learning

Predictive analytics and machine learning algorithms can help ports anticipate and prepare for demand surges, equipment failures, and other potential disruptions. By analyzing historical data and real-time information, these technologies can identify patterns and trends, enabling ports to make proactive decisions and allocate resources more effectively. This can help prevent congestion before it occurs and ensure a more resilient supply chain.

What Strategies Can Shippers Use to Navigate Port Congestion?

Shippers can employ various strategies to navigate port congestion and minimize its impact on their supply chains.

Diversifying Ports and Routes

One effective strategy for mitigating the risk of port congestion is to diversify shipping routes and ports of call. By utilizing multiple ports and routes, shippers can reduce their reliance on a single congested port and ensure a more resilient supply chain. This approach allows for greater flexibility in the face of disruptions and can help shippers avoid the worst impacts of congestion.

Improving Forecasting and Planning

Accurate forecasting and planning can help shippers anticipate demand surges and allocate resources more effectively. By collaborating closely with suppliers, carriers, and other partners, shippers can gain a better understanding of potential disruptions and develop contingency plans. Investing in advanced forecasting tools and technologies can also help shippers make more informed decisions and adapt to changing conditions.

Embracing Flexibility and Agility

In an era of increasing supply chain disruptions, flexibility and agility are essential for navigating port congestion. Shippers should be prepared to adjust their plans and strategies in response to changing circumstances, such as shifting to alternative ports or transportation modes when necessary. Embracing a more agile approach can help shippers minimize the impact of congestion and ensure the timely delivery of goods.

Collaborating with Partners and Stakeholders

Effective collaboration and communication among all stakeholders, including shippers, carriers, ports, and government agencies, can help mitigate the effects of port congestion. By sharing information, coordinating efforts, and working together to identify solutions, stakeholders can improve efficiency, reduce delays, and ensure a more resilient supply chain. Establishing strong partnerships and fostering a culture of collaboration can help shippers navigate the challenges of port congestion more effectively.

Port congestion is a complex and multifaceted issue that can have significant impacts on global supply chains. By understanding the root causes of congestion, such as infrastructure limitations, labor issues, and demand surges, stakeholders can develop targeted strategies to mitigate its effects. Leveraging technology, such as port community systems, automation, and predictive analytics, can help ports improve efficiency and reduce the risk of congestion. Shippers, too, can take proactive steps to navigate congestion, such as diversifying routes, improving forecasting, and collaborating with partners. Ultimately, addressing port congestion requires a concerted effort from all stakeholders to build a more resilient, flexible, and efficient global supply chain.