What Is the Drayage Process

How does the drayage process work?

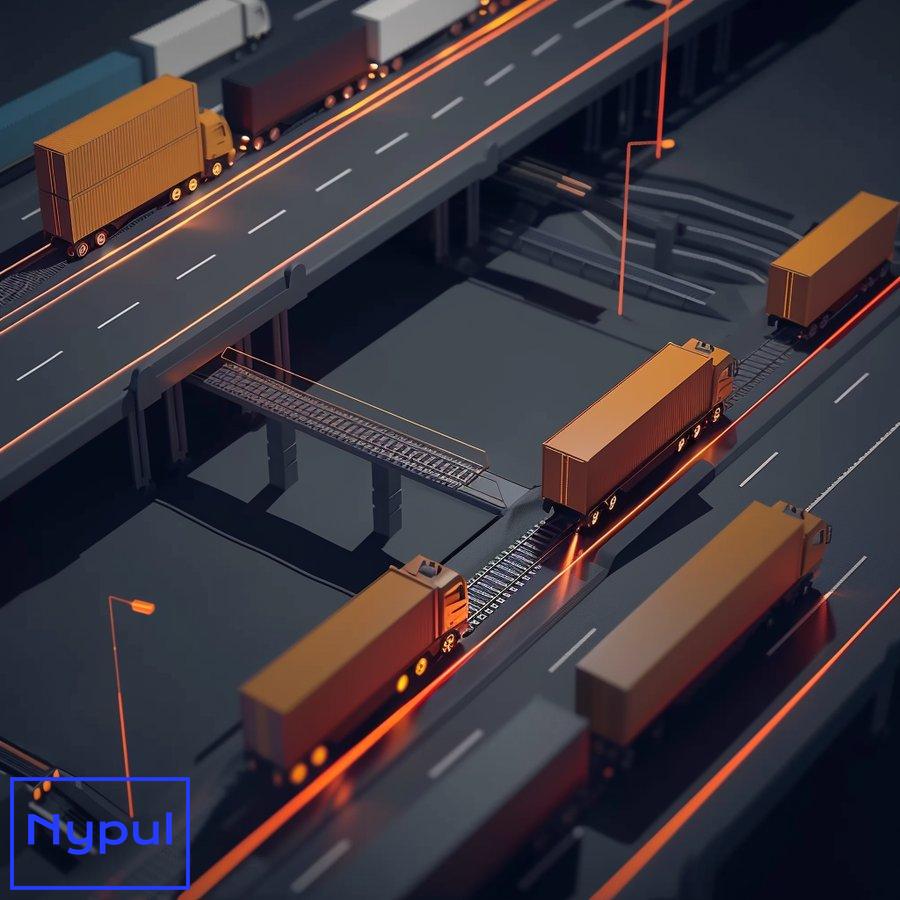

The drayage process is a critical component of the global supply chain, responsible for the short-distance transportation of goods, primarily between ports, rail yards, and warehouses. This process involves moving cargo from its arrival point to its next destination within the same metropolitan area, ensuring the efficient flow of goods throughout the logistics network.

The drayage process typically involves the following steps:

-

Cargo arrives at the port or rail yard via ship or train, where it is unloaded and placed on a chassis or trailer.

-

A drayage truck, operated by a licensed and bonded drayage carrier, arrives at the port or rail yard to pick up the cargo.

-

The drayage truck transports the cargo to its next destination, which could be a warehouse, distribution center, or another transportation hub, such as an intermodal facility or another port.

-

Upon arrival at the destination, the cargo is unloaded from the drayage truck and prepared for the next stage of its journey.

-

If the cargo is being transported to a warehouse or distribution center, it may be stored temporarily before being loaded onto another truck or rail car for long-haul transportation.

-

If the cargo is being transported to an intermodal facility, it may be transferred to a train or another truck for the next leg of its journey.

-

Once the cargo has been unloaded, the drayage truck returns to the port or rail yard to pick up another load, completing the round-trip.

The drayage process is designed to be efficient and cost-effective, with drayage carriers using specialized equipment and technology to ensure the timely and secure delivery of cargo. By leveraging their expertise and resources, drayage carriers help to minimize delays and reduce the risk of damage or loss during the short-distance transportation of goods.

What are the different types of drayage operations?

Drayage operations can be classified into several categories based on the type of cargo being transported, the mode of transportation used, and the specific requirements of the shipper. Some of the most common types of drayage operations include:

-

Container drayage: This type of drayage involves the transportation of containerized cargo, typically between ports and nearby warehouses or distribution centers. Container drayage is a critical component of the global container shipping industry, with drayage carriers playing a key role in the efficient movement of goods.

-

Bulk drayage: Bulk drayage involves the transportation of non-containerized cargo, such as raw materials or commodities, using specialized equipment like dump trucks or tankers. Bulk drayage is commonly used in industries such as construction, agriculture, and mining.

-

Intermodal drayage: Intermodal drayage refers to the transportation of cargo using multiple modes of transportation, such as truck and rail or truck and ship. This type of drayage is often used for long-haul transportation, with drayage carriers responsible for the short-distance movement of goods between transportation hubs.

-

Expedited drayage: Expedited drayage involves the rapid transportation of time-sensitive cargo, such as perishable goods or emergency shipments. Drayage carriers offering expedited services often use specialized equipment and prioritize the timely delivery of cargo.

-

Intra-carrier drayage: Intra-carrier drayage refers to the transportation of cargo between different facilities owned by the same carrier, such as between a rail yard and a warehouse operated by the same company.

-

Inter-carrier drayage: Inter-carrier drayage involves the transportation of cargo between facilities owned by different carriers, such as between a port operated by one company and a rail yard operated by another.

The type of drayage operation chosen will depend on the specific requirements of the shipper, the characteristics of the cargo being transported, and the overall logistics strategy of the company. By understanding the different types of drayage operations available, shippers can make informed decisions about the best way to move their goods through the supply chain.

What equipment and technology are used in drayage?

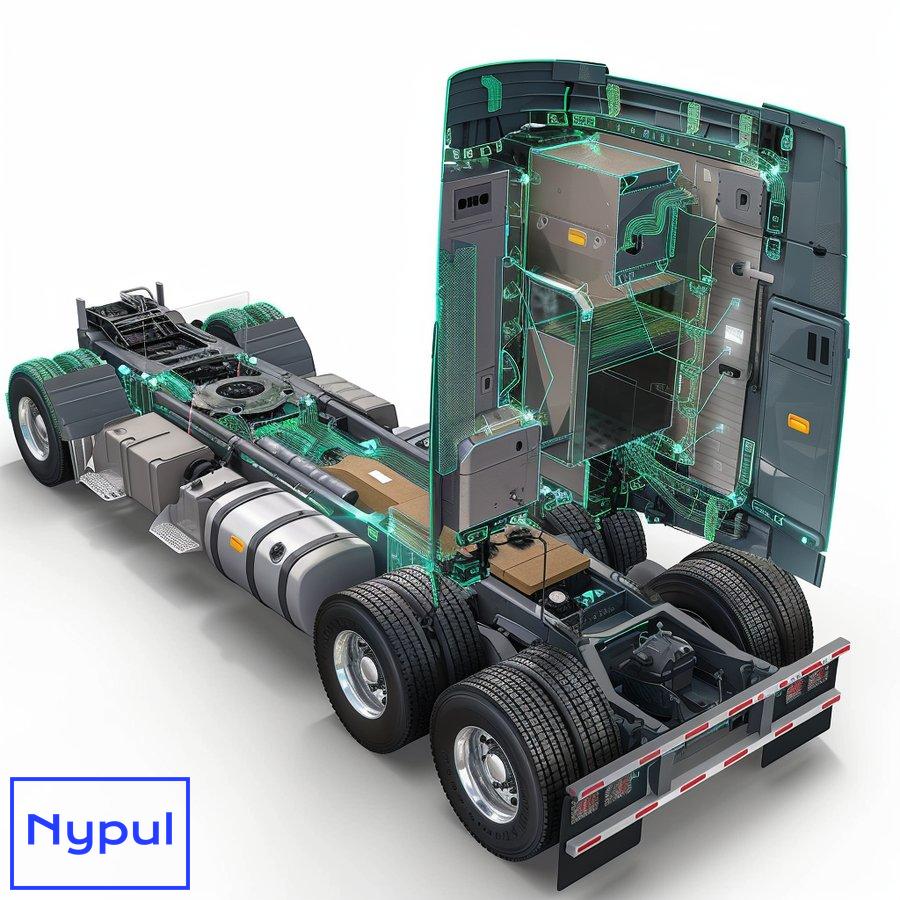

Drayage operations rely on a variety of specialized equipment and technology to ensure the efficient and safe transportation of goods. Some of the most commonly used equipment and technology in drayage include:

-

Drayage trucks: Drayage trucks are specially designed for the short-distance transportation of cargo, often equipped with features such as air ride suspension, automatic transmissions, and GPS tracking systems. These trucks are typically operated by licensed and bonded drayage carriers.

-

Chassis and trailers: Drayage operations often use specialized chassis and trailers designed for the transportation of containerized cargo. These chassis and trailers are typically owned by the ocean carriers and leased to drayage carriers through interchange agreements.

-

Intermodal containers: Intermodal containers are standardized steel boxes used for the transportation of goods by multiple modes of transportation, such as ship, rail, and truck. These containers are designed to be easily transferred between different modes of transportation, reducing the risk of damage or loss during the transportation process.

-

Yard management systems: Yard management systems are software platforms used by drayage carriers and port operators to optimize the movement of cargo within a facility. These systems use real-time data and advanced algorithms to streamline operations, reduce wait times, and improve overall efficiency.

-

GPS tracking and telematics: Many drayage carriers use GPS tracking and telematics systems to monitor the location and performance of their trucks in real-time. These systems provide valuable data on factors such as fuel consumption, driver behavior, and route optimization, helping carriers to improve their operations and reduce costs.

-

Electronic data interchange (EDI): EDI is a standard for the electronic exchange of data between different parties in the supply chain, such as shippers, carriers, and consignees. EDI systems are commonly used in drayage operations to facilitate the exchange of shipping documents, track cargo, and streamline the overall transportation process.

The use of specialized equipment and technology in drayage operations is essential for ensuring the efficient and reliable transportation of goods. By leveraging these tools, drayage carriers can reduce costs, improve customer service, and contribute to the overall success of the global supply chain.

What challenges do drayage operations face?

Drayage operations face a variety of challenges that can impact the efficiency and reliability of the transportation process. Some of the most significant challenges include:

-

Port and terminal congestion: Ports and terminals can often become congested due to factors such as increased cargo volumes, labor shortages, and infrastructure limitations. This congestion can lead to delays in the loading and unloading of cargo, resulting in increased wait times and higher costs for drayage carriers and shippers.

-

Chassis shortages: Drayage operations rely on the availability of chassis and trailers to transport containerized cargo. However, chassis shortages can occur due to factors such as equipment imbalances, maintenance issues, and increased demand. These shortages can lead to delays and additional costs for drayage carriers and shippers.

-

Driver shortages: The drayage industry, like many other transportation sectors, faces a shortage of qualified drivers. This shortage can be attributed to factors such as high turnover rates, strict regulations, and the physical demands of the job. Driver shortages can lead to delays in the transportation of cargo and increased costs for drayage carriers.

-

Regulatory compliance: Drayage operations are subject to a variety of regulations, including those related to safety, environmental protection, and labor laws. Compliance with these regulations can be challenging and time-consuming, requiring drayage carriers to invest in training, equipment, and administrative resources.

-

Unpredictable weather and traffic conditions: Drayage operations are often affected by unpredictable weather and traffic conditions, which can lead to delays and disruptions in the transportation process. Drayage carriers must be prepared to respond quickly to these challenges in order to minimize the impact on their operations and their customers.

-

Lack of visibility and transparency: Drayage operations can often lack visibility and transparency, with shippers and consignees unsure of the location and status of their cargo at any given time. This lack of visibility can lead to delays, miscommunications, and increased costs throughout the supply chain.

Despite these challenges, drayage carriers and shippers are working to develop innovative solutions to improve the efficiency and reliability of drayage operations. These solutions may include investments in technology, collaboration between industry stakeholders, and the development of new operational strategies.

How does drayage fit into intermodal transportation?

Drayage is a critical component of intermodal transportation, which involves the movement of cargo using two or more modes of transportation, such as truck, rail, and ship. In an intermodal transportation system, drayage plays a key role in connecting the different modes of transportation and ensuring the smooth flow of goods throughout the supply chain.

Here are some of the ways in which drayage fits into intermodal transportation:

-

Port drayage: Port drayage involves the transportation of cargo from a port to a nearby rail yard, warehouse, or distribution center. This type of drayage is essential for connecting ocean freight with other modes of transportation, such as rail or truck.

-

Rail drayage: Rail drayage involves the transportation of cargo from a rail yard to a nearby warehouse, distribution center, or another transportation hub. This type of drayage is critical for connecting rail freight with other modes of transportation and ensuring the efficient movement of goods throughout the supply chain.

-

Warehouse drayage: Warehouse drayage involves the transportation of cargo from a warehouse or distribution center to a nearby port, rail yard, or another transportation hub. This type of drayage is essential for connecting different modes of transportation and ensuring the efficient flow of goods throughout the supply chain.

-

Intermodal drayage: Intermodal drayage refers to the transportation of cargo using multiple modes of transportation, such as truck and rail or truck and ship. In an intermodal transportation system, drayage carriers are responsible for the short-distance movement of cargo between transportation hubs, ensuring the efficient transfer of goods between different modes of transportation.

-

Expedited drayage: Expedited drayage involves the rapid transportation of time-sensitive cargo, such as perishable goods or emergency shipments, in an intermodal transportation system. Drayage carriers offering expedited services help to ensure the timely delivery of cargo and minimize the risk of delays or disruptions throughout the supply chain.

By connecting different modes of transportation and ensuring the efficient movement of goods throughout the supply chain, drayage plays a critical role in the success of intermodal transportation. As the global economy continues to grow and the demand for efficient and reliable transportation services increases, the importance of drayage in intermodal transportation is likely to continue to increase in the years to come.

What is the economic impact of drayage?

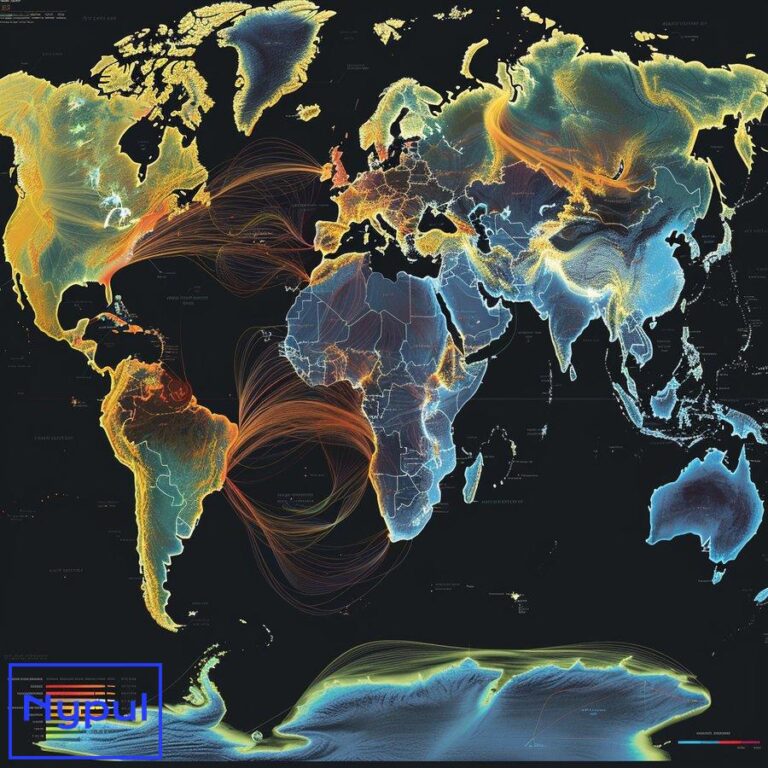

Drayage operations have a significant economic impact on the global economy, contributing to the efficient movement of goods throughout the supply chain and supporting the growth of international trade. Here are some of the key ways in which drayage operations contribute to economic growth and development:

-

Job creation: Drayage operations support the creation of thousands of jobs in the transportation and logistics industry, including truck drivers, dispatchers, and administrative staff. These jobs provide income and economic opportunities for workers and their families, contributing to the overall economic well-being of communities.

-

Support for international trade: By facilitating the efficient movement of goods between different modes of transportation, drayage operations support the growth of international trade and help to ensure that goods reach their final destination in a timely and cost-effective manner. This, in turn, supports economic growth and development in both exporting and importing countries.

-

Reduction in transportation costs: Drayage operations help to reduce transportation costs by optimizing the movement of goods throughout the supply chain. By minimizing delays, reducing wait times, and improving overall efficiency, drayage carriers help to lower the cost of goods for consumers and businesses alike.

-

Increased productivity: Drayage operations contribute to increased productivity throughout the supply chain by ensuring that goods move quickly and efficiently from one mode of transportation to another. This increased productivity helps to support economic growth and development by enabling businesses to produce more goods and services with fewer resources.

-

Environmental benefits: Drayage operations can also contribute to environmental benefits by reducing the number of trucks on the road and minimizing the amount of fuel consumed during the transportation process. By using more efficient equipment and optimizing routes, drayage carriers can help to reduce greenhouse gas emissions and support the development of a more sustainable transportation system.

Overall, the economic impact of drayage operations is significant and far-reaching, contributing to job creation, international trade, cost savings, and environmental benefits throughout the global economy. As the demand for efficient and reliable transportation services continues to grow, the importance of drayage operations in supporting economic growth and development is likely to continue to increase in the years to come.

How do you choose the right drayage provider?

Choosing the right drayage provider is critical for ensuring the efficient and reliable transportation of goods throughout the supply chain. When selecting a drayage provider, there are several key factors to consider:

-

Reputation and experience: Look for a drayage provider with a strong reputation in the industry and a track record of reliable service. Consider factors such as the provider’s years of experience, customer reviews, and industry awards or certifications.

-

Service area and capabilities: Ensure that the drayage provider offers service in the geographic areas where you need transportation services. Also, consider the provider’s capabilities in terms of equipment, technology, and specialized services such as expedited delivery or temperature-controlled transportation.

-

Pricing and fees: Compare pricing and fees across multiple drayage providers to ensure that you are getting a fair and competitive rate. Be sure to understand any additional fees or surcharges that may apply, such as fuel surcharges or detention fees.

-

Communication and customer service: Choose a drayage provider that prioritizes communication and customer service. Look for a provider that is responsive to your needs, provides regular updates on the status of your shipments, and is willing to work with you to resolve any issues that may arise.

-

Technology and visibility: Consider the drayage provider’s use of technology to improve efficiency and provide visibility into the transportation process. Look for providers that offer features such as GPS tracking, electronic data interchange (EDI), and online portals for tracking shipments and managing transportation activities.

-

Compliance and safety: Ensure that the drayage provider is compliant with all relevant regulations and prioritizes safety in its operations. Look for providers that have a strong safety record, provide regular training for their drivers, and maintain their equipment to the highest standards.

-

Flexibility and adaptability: Choose a drayage provider that is flexible and adaptable to your changing needs. Look for a provider that is willing to work with you to develop customized solutions and that can respond quickly to changes in the market or your business requirements.

By considering these factors and conducting thorough research, you can choose a drayage provider that meets your needs and supports the success of your business. Remember to regularly evaluate your drayage provider’s performance and be willing to make changes if necessary to ensure that your transportation needs are being met.