What Are the Measures of Port Efficiency

What defines port efficiency?

Port efficiency is a multifaceted concept that encompasses various aspects of port operations and performance. At its core, port efficiency refers to the ability of a port to handle cargo and vessels quickly, safely, and cost-effectively while maximizing the use of available resources.

The definition of port efficiency includes several key components:

Throughput: This measures the volume of cargo a port can handle in a given time period. Efficient ports can process large quantities of cargo with minimal delays.

Turnaround time: The speed at which ships can be loaded, unloaded, and sent back out to sea is crucial. Shorter turnaround times indicate higher efficiency.

Resource utilization: Efficient ports make optimal use of their infrastructure, equipment, and labor to maximize productivity.

Cost-effectiveness: Ports that can provide high-quality services at competitive prices are considered more efficient.

Reliability: Consistent performance and adherence to schedules contribute to a port’s efficiency rating.

Safety and security: Efficient ports maintain high safety standards without compromising on speed or productivity.

Environmental impact: Modern definitions of port efficiency also consider a port’s ability to operate sustainably and minimize environmental harm.

To illustrate the relationship between these components, consider the following table:

| Component | Description | Impact on Efficiency |

|---|---|---|

| Throughput | Volume of cargo handled | Higher throughput indicates greater efficiency |

| Turnaround time | Speed of ship processing | Faster turnaround times boost efficiency |

| Resource utilization | Optimal use of assets | Better utilization improves overall efficiency |

| Cost-effectiveness | Competitive pricing | Lower costs for same service level increase efficiency |

| Reliability | Consistent performance | Higher reliability enhances efficiency perception |

| Safety and security | Maintaining standards | Safe operations without delays contribute to efficiency |

| Environmental impact | Sustainable practices | Eco-friendly operations are part of modern efficiency |

Port efficiency is not a static concept but evolves with technological advancements and changing industry standards. For instance, the introduction of automated container handling systems has redefined efficiency benchmarks for many ports.

The International Maritime Organization (IMO) and other global bodies play a significant role in setting standards that influence port efficiency definitions. These standards often focus on safety, environmental protection, and operational best practices.

Port managers and stakeholders use various metrics to quantify efficiency. These include:

Container moves per hour: This metric measures how quickly containers can be loaded or unloaded from a vessel.

Berth occupancy rate: This indicates how effectively a port utilizes its berthing space.

Dwell time: The average time cargo spends in port before being shipped out or collected.

Equipment downtime: Minimizing equipment failures and maintenance periods contributes to overall efficiency.

Efficiency in ports is not just about speed but also about providing value-added services. Many efficient ports offer services such as cargo consolidation, customs clearance, and intermodal connections to enhance their overall efficiency profile.

The concept of port efficiency is closely tied to the idea of competitiveness in the global shipping industry. Ports that can demonstrate high efficiency levels are more likely to attract shipping lines and cargo owners, leading to increased business and economic benefits for the port and surrounding region.

Understanding port efficiency requires considering both operational and financial aspects. While operational metrics focus on the physical handling of cargo and vessels, financial efficiency looks at the economic performance of the port, including profitability and return on investment.

As global trade patterns evolve, so does the definition of port efficiency. Factors such as the ability to handle larger vessels, accommodate new types of cargo, and integrate with digital supply chains are becoming increasingly important in assessing a port’s efficiency.

How are vessel and cargo handling times measured?

Vessel and cargo handling times are critical metrics in assessing port efficiency. These measurements provide insight into how quickly and effectively a port can process ships and their cargo, which directly impacts the port’s productivity and competitiveness.

Vessel handling time is typically broken down into several components:

Waiting time: The period a vessel spends waiting for a berth to become available. This is measured from the time a ship arrives at the port’s designated waiting area until it is given permission to proceed to the berth.

Maneuvering time: The time taken for a vessel to move from the waiting area to the berth, including any time spent with pilots or tugs.

Berthing time: The actual time the vessel spends at the berth, which includes the time for mooring and unmooring.

Working time: The period during which cargo operations (loading and unloading) are actively taking place.

Idle time: Any time during the berthing period when no cargo operations are occurring, such as breaks or equipment downtime.

Ports and shipping lines use sophisticated systems to track these times accurately. Automatic Identification System (AIS) data is often used to monitor vessel movements and calculate precise timings for each phase of a port call.

Cargo handling time measurements focus on the efficiency of loading and unloading operations. Key metrics include:

Moves per hour: For container operations, this measures how many containers can be loaded or unloaded in an hour. It can be calculated per crane (gross moves per crane hour) or for the entire ship operation (berth productivity).

Tons per hour: For bulk cargo, the rate at which cargo is loaded or unloaded is measured in tons per hour.

Dwell time: The average time cargo spends in the port area before being loaded onto a ship or collected by inland transportation.

To illustrate how these metrics are used, consider the following table showing hypothetical data for a container terminal:

| Metric | Value | Target | Performance |

|---|---|---|---|

| Average waiting time | 6 hours | 4 hours | Below target |

| Berth productivity | 120 moves/hour | 150 moves/hour | Below target |

| Container dwell time | 3 days | 2 days | Below target |

| Gross crane rate | 30 moves/hour | 35 moves/hour | Below target |

This table quickly shows areas where the terminal is underperforming against its targets, providing clear indicators for improvement efforts.

Ports use various technologies to measure and record these times accurately:

Terminal Operating Systems (TOS): These comprehensive software solutions track all aspects of terminal operations, including vessel and cargo handling times.

Optical Character Recognition (OCR): Used at gate entrances and on cranes to automatically identify and track containers, speeding up processing times.

Radio-Frequency Identification (RFID): Tags on containers or vehicles allow for real-time tracking of cargo movements within the port.

Global Positioning System (GPS): Used to track the precise location of equipment and cargo within the port area.

The measurement of vessel and cargo handling times is not just about collecting data; it’s about using that data to improve operations. Ports analyze these metrics to:

Identify bottlenecks: By pinpointing where delays occur most frequently, ports can focus their improvement efforts.

Plan resource allocation: Understanding peak times and typical handling durations helps in scheduling labor and equipment more efficiently.

Set and monitor Key Performance Indicators (KPIs): These metrics form the basis of many port KPIs, which are used to track performance over time and set improvement goals.

Benchmark against other ports: Comparing handling times with those of competitor ports helps in understanding relative performance and setting appropriate targets.

Accurate measurement of these times is crucial for several stakeholders:

Port authorities: Use the data to assess overall port performance and plan infrastructure investments.

Terminal operators: Rely on these metrics to optimize their operations and demonstrate their efficiency to potential customers.

Shipping lines: Consider port handling times when planning their schedules and choosing which ports to call at.

Cargo owners: Use this information to estimate transit times for their goods and make logistics decisions.

It’s important to note that raw handling time data doesn’t always tell the full story. Factors such as vessel size, cargo type, weather conditions, and labor issues can all impact handling times. Therefore, sophisticated ports often use normalized or adjusted metrics to ensure fair comparisons across different scenarios.

As ports continue to evolve, new technologies are emerging to enhance the measurement of vessel and cargo handling times:

Internet of Things (IoT) sensors: These can provide real-time data on equipment performance and cargo movements, allowing for even more precise timing measurements.

Artificial Intelligence (AI) and Machine Learning (ML): These technologies can analyze vast amounts of handling time data to predict potential delays and suggest optimizations.

Blockchain: Some ports are exploring blockchain technology to create tamper-proof records of cargo movements and handling times, increasing transparency and trust in the data.

The ongoing digitalization of ports is leading to more accurate, real-time measurements of vessel and cargo handling times. This trend is expected to continue, with increasing integration of data across the entire supply chain, providing a more comprehensive view of efficiency beyond just the port boundaries.

What financial metrics indicate port efficiency?

Financial metrics play a crucial role in assessing port efficiency from an economic perspective. These metrics provide insights into how well a port is utilizing its resources to generate revenue and profit, which is essential for long-term sustainability and competitiveness. Here are the key financial metrics that indicate port efficiency:

Return on Investment (ROI): This metric measures the profitability of investments made in port infrastructure and equipment. A higher ROI indicates that the port is efficiently using its capital to generate returns.

ROI = (Net Profit / Total Investment) x 100

Operating Margin: This shows the percentage of revenue that remains after covering operating expenses. A higher operating margin suggests that the port is managing its costs efficiently.

Operating Margin = (Operating Income / Revenue) x 100

Revenue per TEU (Twenty-foot Equivalent Unit): For container ports, this metric indicates how much revenue is generated for each standard container handled. It reflects the port’s pricing power and ability to attract high-value cargo.

Revenue per TEU = Total Revenue / Total TEUs Handled

EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization) Margin: This metric provides a clear view of a port’s operational profitability by excluding the effects of financing and accounting decisions.

EBITDA Margin = (EBITDA / Revenue) x 100

Asset Turnover Ratio: This measures how efficiently a port is using its assets to generate revenue. A higher ratio indicates better asset utilization.

Asset Turnover Ratio = Revenue / Total Assets

Labor Cost per TEU: This metric helps in assessing the efficiency of labor utilization in container handling operations.

Labor Cost per TEU = Total Labor Cost / Total TEUs Handled

Capital Expenditure (CAPEX) Efficiency: This measures how effectively capital investments translate into increased throughput or revenue.

CAPEX Efficiency = (Increase in Throughput or Revenue) / CAPEX

To illustrate how these metrics might be used to compare port efficiency, consider the following table showing hypothetical data for three ports:

| Financial Metric | Port A | Port B | Port C |

|---|---|---|---|

| ROI | 12% | 15% | 10% |

| Operating Margin | 25% | 30% | 22% |

| Revenue per TEU | $150 | $180 | $140 |

| EBITDA Margin | 35% | 40% | 32% |

| Asset Turnover Ratio | 0.8 | 1.2 | 0.7 |

| Labor Cost per TEU | $20 | $18 | $22 |

| CAPEX Efficiency | 1.5 | 1.8 | 1.3 |

In this comparison, Port B appears to be the most financially efficient across most metrics, suggesting better overall financial performance and resource utilization.

Debt-to-Equity Ratio: This metric indicates the port’s financial leverage and risk. A lower ratio generally suggests better financial health and efficiency in capital structure management.

Debt-to-Equity Ratio = Total Liabilities / Shareholders’ Equity

Working Capital Turnover: This measures how efficiently a port is using its working capital to generate revenue. A higher ratio indicates more efficient use of short-term assets and liabilities.

Working Capital Turnover = Revenue / Average Working Capital

Cash Conversion Cycle: This metric shows how quickly a port can convert its investments in inventory and other resources into cash flows from sales. A shorter cycle indicates greater efficiency in managing working capital.

Cash Conversion Cycle = Days Inventory Outstanding + Days Sales Outstanding – Days Payables Outstanding

Revenue per Employee: This metric provides insight into labor productivity from a financial perspective.

Revenue per Employee = Total Revenue / Number of Employees

Cost per Ton Handled: For bulk cargo ports, this metric is crucial in assessing operational efficiency from a cost perspective.

Cost per Ton Handled = Total Operating Costs / Total Tons Handled

Return on Assets (ROA): This metric shows how efficiently a port is using its assets to generate profit.

ROA = (Net Income / Total Assets) x 100

When analyzing these financial metrics, it’s important to consider several factors:

Port size and type: Larger ports may benefit from economies of scale, while specialized ports might have different financial profiles.

Geographic location: Ports in different regions may face varying operational costs and revenue potentials.

Ownership structure: Public, private, or public-private partnership models can affect financial metrics.

Investment cycle: Ports undergoing significant infrastructure upgrades may temporarily show lower efficiency in some metrics.

Market conditions: Economic cycles and trade patterns can impact a port’s financial performance.

Port authorities and operators use these financial metrics to:

Benchmark performance: Comparing metrics with industry standards or competitor ports helps identify areas for improvement.

Make investment decisions: Financial metrics guide decisions on infrastructure upgrades, equipment purchases, and expansion projects.

Set pricing strategies: Understanding costs and profitability per unit helps in setting competitive yet profitable tariffs.

Attract investors: Strong financial metrics can make a port more attractive to private investors or lenders.

Optimize operations: Identifying areas of financial inefficiency can lead to targeted operational improvements.

It’s crucial to note that while financial metrics are important indicators of port efficiency, they should be considered alongside operational and environmental metrics for a comprehensive assessment. A port that appears financially efficient may be achieving this at the cost of environmental sustainability or long-term infrastructure maintenance.

Moreover, the interpretation of these metrics can vary depending on the port’s strategic goals. For instance, a port focused on rapid growth might prioritize metrics like Revenue per TEU or CAPEX Efficiency, while a port aiming for stability might focus more on Operating Margin or Debt-to-Equity Ratio.

As the shipping industry evolves, new financial metrics are emerging to capture efficiency in areas such as environmental sustainability and digital transformation. These might include metrics related to carbon efficiency (e.g., Revenue per Ton of CO2 Emitted) or digital investment returns (e.g., ROI on IT Infrastructure).

How is operational productivity assessed in ports?

Operational productivity in ports is a critical measure of efficiency that focuses on the actual handling of cargo and vessels. It assesses how effectively a port utilizes its resources to move cargo quickly and safely. Here’s a comprehensive look at how operational productivity is assessed in ports:

Container handling metrics:

Gross Crane Rate (GCR): This measures the number of container moves per crane per hour, including all delays.

GCR = Total container moves / (Number of cranes x Working hours)

Net Crane Rate (NCR): Similar to GCR, but excludes operational and non-operational delays.

NCR = Total container moves / (Number of cranes x Actual working hours)

Berth Productivity: This measures the number of container moves per hour a ship is at berth.

Berth Productivity = Total container moves / Total hours at berth

Ship Productivity: This metric focuses on the number of container moves per hour while the ship is actually being worked on.

Ship Productivity = Total container moves / Ship working hours

Yard Productivity: This assesses how efficiently containers are moved within the port’s storage areas.

Yard Productivity = Container moves in yard / Total yard equipment hours

To illustrate these metrics, consider the following table showing hypothetical data for a container terminal over a week:

| Day | GCR | NCR | Berth Productivity | Ship Productivity | Yard Productivity |

|---|---|---|---|---|---|

| Mon | 25 | 30 | 80 | 100 | 15 |

| Tue | 28 | 32 | 85 | 105 | 16 |

| Wed | 26 | 31 | 82 | 102 | 14 |

| Thu | 27 | 33 | 86 | 108 | 17 |

| Fri | 29 | 34 | 88 | 110 | 18 |

| Sat | 24 | 29 | 78 | 98 | 13 |

| Sun | 23 | 28 | 75 | 95 | 12 |

This table allows for quick identification of productivity trends and potential areas for improvement.

Bulk cargo handling metrics:

Tons per Ship Hour: This measures the rate at which bulk cargo is loaded or unloaded from a ship.

Tons per Ship Hour = Total tons handled / Total ship hours at berth

Tons per Gang Hour: This assesses the productivity of labor gangsin handling bulk cargo.

Tons per Gang Hour = Total tons handled / (Number of gangs x Working hours)

Equipment utilization metrics:

Quay Crane Utilization: This measures the percentage of time quay cranes are actively working.

Quay Crane Utilization = Actual working time / Available time

Yard Equipment Utilization: Similar to quay crane utilization but for yard equipment like straddle carriers or rubber-tyred gantry cranes.

Berth utilization: This assesses how effectively the port uses its berthing space.

Berth Utilization = Total time berths occupied / Total berth hours available

Land utilization: This metric evaluates how efficiently the port uses its land area for cargo handling and storage.

Land Utilization = Cargo throughput / Total port land area

Labor productivity metrics:

TEUs per Employee: This measures overall labor productivity for container terminals.

TEUs per Employee = Total TEUs handled / Number of employees

Revenue per Employee: This assesses labor productivity from a financial perspective.

Revenue per Employee = Total revenue / Number of employees

Vessel turnaround time: This crucial metric measures the total time a vessel spends in port, from arrival to departure.

Vessel Turnaround Time = Time of departure – Time of arrival

Truck turnaround time: This assesses how quickly trucks can enter the port, collect or deliver cargo, and exit.

Truck Turnaround Time = Exit time – Entry time

Intermodal transfer efficiency: This measures how quickly and efficiently cargo can be transferred between different modes of transport (e.g., ship to rail or truck).

Intermodal Transfer Time = Time cargo leaves port – Time cargo unloaded from ship

Dwell time: This metric assesses how long cargo remains in the port before being shipped out or collected.

Dwell Time = Time cargo leaves port – Time cargo arrives at port

Ports use various tools and technologies to collect data for these productivity assessments:

Terminal Operating Systems (TOS): These comprehensive software solutions track and manage all aspects of port operations, providing real-time data on productivity metrics.

Automated Gate Systems: These systems use technologies like optical character recognition (OCR) and RFID to automate truck processing and collect accurate timing data.

Equipment Telematics: GPS and IoT sensors on port equipment provide real-time data on equipment location, status, and productivity.

Automated Guided Vehicles (AGVs) and Automated Stacking Cranes (ASCs): These automated systems not only improve productivity but also provide precise data on their operations.

The assessment of operational productivity in ports is not just about collecting data but also about analyzing and acting on it:

Benchmarking: Ports often compare their productivity metrics with industry standards or competitor ports to identify areas for improvement.

Continuous Improvement Programs: Many ports use methodologies like Lean or Six Sigma to drive ongoing productivity enhancements.

Simulation and Modeling: Advanced ports use computer simulations to test different operational scenarios and optimize productivity.

Training and Skill Development: Productivity assessments often inform training programs for port workers to improve their skills and efficiency.

It’s important to note that productivity metrics should be interpreted in context. Factors that can influence productivity include:

Vessel size and type: Larger vessels may have different productivity profiles compared to smaller ones.

Cargo mix: The types of cargo handled can significantly impact productivity metrics.

Weather conditions: Adverse weather can affect port operations and productivity.

Labor relations: Strikes or work slowdowns can dramatically impact productivity metrics.

Equipment reliability: Frequent breakdowns or maintenance issues can reduce overall productivity.

As ports continue to evolve, new productivity metrics are emerging:

Energy efficiency: Measuring productivity in terms of cargo handled per unit of energy consumed.

Environmental productivity: Assessing how much cargo is handled relative to environmental impacts like emissions or noise.

Digital efficiency: Evaluating how effectively digital technologies are improving overall port productivity.

The ongoing digitalization of ports is leading to more sophisticated productivity assessments:

Big Data Analytics: Ports are using advanced analytics to gain deeper insights from their operational data.

Artificial Intelligence and Machine Learning: These technologies are being employed to predict productivity bottlenecks and suggest optimizations.

Digital Twins: Some ports are creating digital replicas of their operations to test and optimize productivity in a virtual environment.

Operational productivity assessment in ports is a complex but crucial process. It provides the data needed to make informed decisions about resource allocation, investment priorities, and operational strategies. As global trade continues to grow and evolve, ports that can accurately assess and continuously improve their operational productivity will be best positioned to succeed in an increasingly competitive market.

What role does intermodal connectivity play in port efficiency?

Intermodal connectivity is a critical factor in port efficiency, playing a pivotal role in the seamless movement of cargo between different modes of transportation. It refers to the ability of a port to efficiently transfer cargo between ships, trucks, trains, and sometimes even airplanes. The importance of intermodal connectivity in port efficiency cannot be overstated, as it directly impacts the speed, cost, and reliability of cargo movement through the port and into the broader supply chain.

Key aspects of intermodal connectivity:

Infrastructure: This includes the physical connections between different modes of transport, such as on-dock rail facilities, truck gates, and inland waterway connections.

Information systems: Efficient intermodal connectivity relies on integrated information systems that allow for smooth data exchange between different transportation modes and stakeholders.

Operational procedures: Streamlined processes for transferring cargo between modes, including documentation and customs procedures, are essential for efficient intermodal connectivity.

Equipment: Specialized equipment like intermodal containers, chassis, and handling equipment facilitates quick and easy transfer between modes.

The impact of intermodal connectivity on port efficiency can be measured through several metrics:

Intermodal transfer time: The time taken to transfer cargo from one mode to another (e.g., ship to rail).

Modal split: The proportion of cargo handled by different transport modes (e.g., percentage of containers leaving the port by rail vs. truck).

Dwell time: The time cargo spends in the port before being transferred to the next mode of transport.

Total logistics cost: The overall cost of moving cargo through the port and to its final destination, which is often reduced with efficient intermodal connections.

To illustrate the importance of intermodal connectivity, consider the following table comparing two hypothetical ports:

| Metric | Port A (Strong Intermodal) | Port B (Weak Intermodal) |

|---|---|---|

| Intermodal transfer time | 2 hours | 6 hours |

| Rail modal split | 40% | 10% |

| Average container dwell time | 3 days | 7 days |

| Truck turn time | 30 minutes | 90 minutes |

| Annual TEU throughput | 5 million | 3 million |

This comparison clearly shows how strong intermodal connectivity (Port A) contributes to better overall port efficiency and higher throughput.

Benefits of strong intermodal connectivity:

Reduced congestion: Efficient intermodal connections help distribute cargo across different transport modes, reducing congestion at port gates and on nearby roads.

Extended hinterland: Good intermodal links allow ports to serve a larger geographic area, increasing their market reach and potential cargo volumes.

Improved reliability: Seamless transfers between modes lead to more predictable transit times and better overall supply chain reliability.

Environmental benefits: Efficient intermodal systems often allow for greater use of more environmentally friendly transport modes like rail or inland waterways.

Cost savings: Smooth intermodal operations can reduce overall logistics costs by minimizing delays and optimizing transport mode choices.

Capacity increase: Effective intermodal connectivity can increase a port’s effective capacity without necessarily expanding its physical footprint.

Ports around the world are investing heavily in improving their intermodal connectivity:

On-dock rail facilities: Many ports are developing or expanding rail facilities within the port area to allow for direct ship-to-rail transfers.

Inland ports: Some ports are establishing inland port facilities connected by dedicated rail or barge services, extending their reach into the hinterland.

Dedicated freight corridors: Investments in dedicated rail or road corridors connecting ports to key inland markets improve the speed and reliability of intermodal connections.

Port community systems: These digital platforms facilitate information exchange between different stakeholders in the intermodal chain, improving coordination and efficiency.

The role of intermodal connectivity in port efficiency is influenced by several factors:

Geographic location: A port’s natural hinterland and proximity to major transportation networks affect its intermodal potential.

Government policies: Regulations and investments in national transportation infrastructure can significantly impact a port’s intermodal capabilities.

Market demand: The types of cargo and trade patterns served by a port influence the optimal mix of intermodal connections.

Technology adoption: The use of advanced technologies like IoT, blockchain, and AI can enhance the efficiency of intermodal operations.

Challenges in improving intermodal connectivity include:

High capital costs: Developing robust intermodal infrastructure often requires significant investment.

Coordination complexity: Efficient intermodal systems require close coordination between multiple stakeholders, including port authorities, terminal operators, shipping lines, rail companies, and trucking firms.

Land availability: Expanding intermodal facilities often requires additional land, which can be scarce in densely developed port areas.

Regulatory hurdles: Cross-border intermodal connections may face regulatory challenges related to customs procedures and differing national standards.

As global trade patterns evolve, the importance of intermodal connectivity in port efficiency is likely to grow:

E-commerce growth: The rise of e-commerce is increasing demand for fast, reliable intermodal connections to support rapid delivery times.

Sustainability pressures: Environmental concerns are driving greater interest in intermodal solutions that can reduce the carbon footprint of freight transport.

Supply chain resilience: In the wake of recent global disruptions, efficient intermodal systems are seen as key to building more resilient supply chains.

Digitalization: The ongoing digital transformation of logistics is enabling more sophisticated intermodal solutions, such as synchromodal transport where mode choice can be flexibly adjusted in real-time based on current conditions.

Ports that excel in intermodal connectivity often become key nodes in global supply chains, attracting more cargo and investment. This creates a virtuous cycle where improved efficiency leads to higher volumes, which in turn justify further investments in intermodal capabilities.

The future of intermodal connectivity in ports is likely to be shaped by emerging technologies:

Autonomous vehicles: Self-driving trucks and automated guided vehicles (AGVs) could revolutionize the movement of cargo within ports and to inland destinations.

Hyperloop and other novel transport modes: New transportation technologies could create entirely new paradigms for intermodal connectivity.

5G and Internet of Things (IoT): These technologies promise to enable real-time tracking and coordination of intermodal cargo movements at an unprecedented scale.

Artificial Intelligence and Machine Learning: These technologies could optimize intermodal connections in real-time, predicting and preventing bottlenecks before they occur.

In conclusion, intermodal connectivity plays a crucial role in port efficiency by enabling the smooth, cost-effective, and rapid movement of cargo between different transportation modes. Ports that prioritize and excel in intermodal connectivity are better positioned to meet the evolving needs of global trade, enhance their competitiveness, and contribute to more efficient and sustainable supply chains. As technology continues to advance and global trade patterns shift, the importance of robust and flexible intermodal connections in driving port efficiency is only likely to increase.

How do ports measure equipment utilization?

Equipment utilization is a critical aspect of port efficiency, directly impacting operational productivity and financial performance. Ports invest heavily in various types of equipment, from massive ship-to-shore cranes to smaller yard vehicles, and measuring their utilization is crucial for optimizing operations and justifying capital expenditures. Here’s a comprehensive look at how ports measure equipment utilization:

Key equipment types in ports:

Quay cranes: Used for loading and unloading containers from ships.

Yard cranes: Including rubber-tyred gantry cranes (RTGs) and rail-mounted gantry cranes (RMGs) for stacking and retrieving containers in the yard.

Straddle carriers: Used for moving containers within the terminal.

Reach stackers and forklifts: For handling containers and other types of cargo.

Automated guided vehicles (AGVs): Used in automated terminals for moving containers between quayside and yard.

Tractors and trailers: For horizontal transportation within the port.

Bulk handling equipment: Such as conveyors, grab cranes, and pneumatic systems for bulk cargo.

Core metrics for measuring equipment utilization:

Utilization rate: This is the most basic and widely used metric, calculated as:

Utilization Rate = Actual working time / Available time

Idle time: The amount of time equipment is operational but not actively working.

Downtime: Time when equipment is not operational due to maintenance, repairs, or other issues.

Moves per hour: For container handling equipment, this measures productivity.

Tons per hour: For bulk handling equipment, this is the equivalent productivity measure.

To illustrate how these metrics might be used, consider the following table showing hypothetical data for different types of equipment in a port:

| Equipment Type | Utilization Rate | Idle Time (hrs/day) | Downtime (hrs/month) | Moves/Tons per Hour |

|---|---|---|---|---|

| Quay Cranes | 75% | 4 | 48 | 30 moves |

| RTGs | 70% | 5 | 72 | 20 moves |

| Straddle Carriers | 80% | 3 | 36 | 15 moves |

| Reach Stackers | 65% | 6 | 60 | 12 moves |

| Bulk Conveyors | 85% | 2 | 24 | 500 tons |

This table provides a quick overview of how different equipment types are performing across various utilization metrics.

Advanced utilization metrics:

Peak utilization rate: Measures utilization during the busiest periods, helping to identify capacity constraints.

Utilization variability: Assesses how utilization fluctuates over time, which can inform staffing and maintenance scheduling.

Equipment productivity index: Combines utilization rate with productivity measures to give a more comprehensive view of equipment performance.

Cycle time: Measures the time taken for equipment to complete a full operational cycle (e.g., from picking up a container to setting it down).

Energy efficiency: Increasingly important, this metric looks at productivity relative to energy consumption.

Methods for collecting utilization data:

Terminal Operating Systems (TOS): Modern TOS platforms automatically track equipment usage and generate utilization reports.

IoT sensors: Attached to equipment to provide real-time data on operational status and performance.

GPS tracking: Used particularly for mobile equipment to monitor location and movement.

RFID technology: Can be used to track equipment movement and cargo handling.

Operator logs: While less automated, these can provide valuable insights, especially for older equipment.

Optical Character Recognition (OCR): Used in conjunction with cameras to automatically record container movements and equipment activity.

Ports use various strategies to improve equipment utilization:

Predictive maintenance: Using data analytics to predict when equipment is likely to fail and scheduling maintenance proactively.

Dynamic allocation: Using real-time data to allocate equipment where it’s most needed at any given time.

Training programs: Improving operator skills to increase efficiency and reduce idle time.

Process optimization: Redesigning workflows to minimize equipment idle time and improve overall utilization.

Equipment pooling: Sharing equipment across different terminals or operations to maximize utilization.

Challenges in measuring and improving equipment utilization include:

Data quality: Ensuring that the data collected is accurate and comprehensive.

Integration of legacy equipment: Older equipment may lack built-in sensors or connectivity, making data collection more challenging.

Balancing utilization and maintenance: Pushing for very high utilization rates can lead to increased wear and tear and potential breakdowns.

Seasonal and daily variations: Utilization can vary significantly based on time of day, day of the week, and season, making it challenging to optimize across all periods.

Labor considerations: In some ports, labor agreements may limit the flexibility to optimize equipment utilization.

As ports continue to evolve, new approaches to measuring and improving equipment utilization are emerging:

Digital twins: Creating virtual replicas of port operations to simulate and optimize equipment utilization.

Artificial Intelligence and Machine Learning: Using advanced algorithms to predict equipment needs and optimize allocation in real-time.

Autonomous equipment: Self-driving vehicles and automated cranes can potentially operate for longer hours with more consistent performance.

Blockchain: Some ports are exploring blockchain technology to create tamper-proof records of equipment usage and maintenance history.

5G connectivity: High-speed, low-latency 5G networks can enable more sophisticated real-time tracking and control of port equipment.

The importance of measuring equipment utilization extends beyond operational efficiency:

Financial planning: Utilization data informs decisions about equipment purchases, leases, and retirements.

Capacity planning: Understanding equipment utilization helps ports plan for future growth and identifypotential bottlenecks.

Environmental impact: Efficient equipment utilization can lead to reduced energy consumption and lower emissions.

Benchmarking: Ports often compare their equipment utilization metrics with industry standards or competitor ports to gauge their performance.

Contract negotiations: Utilization data can be used in negotiations with equipment suppliers and maintenance contractors.

As global trade patterns evolve, the importance of efficient equipment utilization is likely to grow:

Larger vessels: The trend towards larger container ships puts pressure on ports to handle more cargo in shorter time windows, making efficient equipment use crucial.

24/7 operations: Many ports are moving towards round-the-clock operations, requiring new approaches to equipment utilization and maintenance scheduling.

Sustainability goals: As ports face increasing pressure to reduce their environmental impact, optimizing equipment utilization becomes a key strategy for reducing energy consumption and emissions.

In conclusion, measuring equipment utilization is a complex but essential task for modern ports. It requires a combination of advanced technologies, data analytics, and operational expertise. Ports that excel in this area can achieve significant improvements in efficiency, cost-effectiveness, and environmental performance, positioning themselves as leaders in the competitive global shipping industry.

What are the key performance indicators for berth management?

Berth management is a critical aspect of port operations, directly impacting a port’s capacity, efficiency, and ability to serve shipping lines. Key Performance Indicators (KPIs) for berth management provide crucial insights into how well a port is utilizing its berthing facilities and serving vessels. Here are the primary KPIs used in berth management:

Berth Occupancy Rate (BOR): This fundamental metric measures the percentage of time berths are occupied.

BOR = (Total time berths are occupied / Total time berths are available) x 100

A high BOR indicates efficient use of berth space but may also suggest potential congestion.

Berth Productivity: This measures the amount of cargo handled per unit of time at a berth.

Berth Productivity = Total cargo handled / Total berth hours

For container terminals, this is often expressed in TEUs (Twenty-foot Equivalent Units) per berth hour.

Vessel Turnaround Time: This crucial metric measures the total time a vessel spends in port, from arrival to departure.

Vessel Turnaround Time = Time of departure – Time of arrival

Waiting Time: The time a vessel spends waiting for a berth to become available.

Waiting Time = Time of berthing – Time of arrival at port limits

Service Time: The actual time a vessel spends at the berth.

Service Time = Time of departure from berth – Time of berthing

To illustrate how these KPIs might be used, consider the following table showing hypothetical data for different berths in a port:

| Berth | BOR | Berth Productivity (TEU/hour) | Avg. Vessel Turnaround Time (hours) | Avg. Waiting Time (hours) | Avg. Service Time (hours) |

|---|---|---|---|---|---|

| A | 85% | 80 | 36 | 4 | 32 |

| B | 75% | 75 | 30 | 2 | 28 |

| C | 90% | 85 | 40 | 6 | 34 |

| D | 70% | 70 | 28 | 1 | 27 |

This table provides a quick overview of how different berths are performing across various KPIs, helping to identify high-performing berths and those that may need improvement.

Additional berth management KPIs:

Berth Throughput: The total amount of cargo handled at a berth over a specific period.

Berth Utilization Factor: Similar to BOR but takes into account the actual cargo handling time versus total time at berth.

Berth Utilization Factor = Actual working time / Total time at berth

Berth Deviation Factor: Measures how actual berth time deviates from planned berth time.

Berth Deviation Factor = (Actual berth time – Planned berth time) / Planned berth time

Berth Work Rate: Measures the speed of cargo handling operations at the berth.

Berth Work Rate = Total cargo handled / Working time at berth

Berth Allocation Efficiency: Assesses how well berths are allocated to maximize overall port efficiency.

Vessel Queuing Time: The average time vessels spend in queue waiting for a berth.

Berth Change Rate: The frequency of vessels needing to change berths during their port call, which can indicate inefficiencies in initial berth allocation.

Ports use various strategies to improve berth management KPIs:

Dynamic berth allocation: Using real-time data and predictive analytics to optimize berth assignments.

Vessel prioritization: Implementing systems to prioritize vessels based on factors like size, cargo type, and contractual agreements.

Collaborative planning: Working closely with shipping lines to improve arrival time accuracy and reduce waiting times.

Infrastructure investments: Upgrading berth facilities to handle larger vessels or improve cargo handling speeds.

24/7 operations: Extending operating hours to maximize berth utilization and reduce congestion.

Challenges in managing and improving berth KPIs include:

Vessel size variations: The trend towards larger vessels can complicate berth management and impact KPIs.

Weather disruptions: Adverse weather conditions can significantly affect berth operations and KPIs.

Labor availability: Shortages or inefficiencies in labor can impact service times and overall berth productivity.

Equipment reliability: Breakdowns or maintenance issues with quayside equipment can affect berth KPIs.

Cargo mix: Different types of cargo require different handling times, impacting berth productivity metrics.

As ports continue to evolve, new approaches to berth management are emerging:

Artificial Intelligence and Machine Learning: Using advanced algorithms to predict vessel arrivals, optimize berth allocations, and improve overall efficiency.

Digital twins: Creating virtual replicas of port operations to simulate and optimize berth management strategies.

Blockchain: Some ports are exploring blockchain technology to create transparent and efficient systems for berth reservations and documentation.

IoT and sensor technology: Implementing advanced sensing systems to provide real-time data on berth status, vessel positions, and cargo movements.

The importance of effective berth management extends beyond operational efficiency:

Customer satisfaction: Efficient berth management leads to reduced waiting times and faster turnarounds, improving relationships with shipping lines.

Environmental impact: Optimizing berth usage can reduce vessel idling times, leading to lower emissions in port areas.

Financial performance: Improved berth KPIs often translate into higher revenues and better cost management for ports.

Competitive advantage: Ports with superior berth management can attract more shipping lines and cargo, enhancing their market position.

As global trade patterns continue to evolve, the importance of efficient berth management is likely to grow:

Mega-vessels: The increasing size of container ships puts pressure on ports to handle more cargo in shorter time windows, making efficient berth management crucial.

Just-in-time shipping: Growing emphasis on supply chain efficiency is driving demand for more precise and reliable berth management.

Green port initiatives: Environmental concerns are pushing ports to optimize berth usage to reduce emissions from idling vessels.

In conclusion, Key Performance Indicators for berth management are essential tools for modern ports to measure, analyze, and improve their operations. By focusing on these KPIs, ports can enhance their efficiency, reduce costs, improve customer satisfaction, and strengthen their competitive position in the global shipping industry. As technology continues to advance, ports that leverage data analytics and innovative solutions for berth management will be best positioned to meet the evolving challenges of maritime trade.

How is port efficiency benchmarked globally?

Port efficiency benchmarking on a global scale is a complex process that involves comparing various performance metrics across different ports worldwide. This benchmarking is crucial for ports to understand their competitive position, identify areas for improvement, and set strategic goals. Here’s a comprehensive look at how port efficiency is benchmarked globally:

Key organizations involved in global port benchmarking:

World Bank: Produces the Logistics Performance Index (LPI) which includes port efficiency as a component.

UNCTAD (United Nations Conference on Trade and Development): Publishes the Liner Shipping Connectivity Index (LSCI) and other maritime statistics.

International Association of Ports and Harbors (IAPH): Facilitates sharing of best practices and performance data among member ports.

Journal of Commerce (JOC): Publishes annual rankings of port productivity, particularly for container terminals.

Global benchmarking metrics:

Container throughput: Measured in Twenty-foot Equivalent Units (TEUs) per year, this is a basic measure of port size and activity.

Vessel turnaround time: The average time ships spend in port from arrival to departure.

Berth productivity: Often measured in moves per hour per ship while at berth.

Crane productivity: Typically measured in moves per hour per crane.

Dwell time: The average time containers spend in the port before being shipped out or collected.

Truck turnaround time: The average time trucks spend in the port for cargo pickup or delivery.

Cost efficiency: Measures like cost per TEU handled or revenue per ton of cargo.

To illustrate how these metrics might be used in global benchmarking, consider the following table comparing hypothetical data for major ports:

| Port | Annual TEU Throughput (millions) | Avg. Vessel Turnaround Time (hours) | Berth Productivity (moves/hour) | Crane Productivity (moves/hour) | Avg. Dwell Time (days) |

|---|---|---|---|---|---|

| A | 40 | 24 | 150 | 35 | 3 |

| B | 35 | 28 | 140 | 32 | 4 |

| C | 30 | 30 | 130 | 30 | 5 |

| D | 25 | 32 | 120 | 28 | 6 |

This table provides a quick comparison of key efficiency metrics across different ports, helping to identify leaders and laggards in various aspects of port performance.

Methodologies for global benchmarking:

Data Envelopment Analysis (DEA): A non-parametric method used to evaluate the relative efficiency of decision-making units (in this case, ports) with multiple inputs and outputs.

Stochastic Frontier Analysis (SFA): A parametric method that estimates the efficiency frontier and allows for random errors.

Balanced Scorecard Approach: Considers multiple dimensions of port performance, including financial, customer, internal processes, and learning and growth perspectives.

Total Factor Productivity (TFP): Measures the overall productivity of ports by considering all inputs and outputs.

Challenges in global port efficiency benchmarking:

Data consistency: Ensuring that data from different ports is collected and reported in a consistent manner.

Contextual differences: Accounting for variations in port size, cargo mix, geographic location, and regulatory environments.

Technological disparities: Comparing ports with different levels of automation and technological advancement.

Definitional issues: Ensuring that metrics are defined and calculated consistently across different ports and regions.

Data availability: Some ports may be reluctant to share certain performance data, leading to incomplete comparisons.

Emerging trends in global port benchmarking:

Environmental performance: Incorporating metrics related to environmental sustainability, such as carbon footprint per TEU.

Safety and security: Including indicators of port safety records and security measures.

Supply chain integration: Assessing how well ports integrate with broader supply chain networks.

Resilience: Measuring a port’s ability to maintain operations during disruptions or recover quickly from them.

Digital maturity: Evaluating the level of digitalization and smart port initiatives.

Best practices in global port benchmarking:

Standardization: Developing and adhering to standardized definitions and calculation methods for key metrics.

Regular updates: Conducting benchmarking exercises at regular intervals to track progress over time.

Peer grouping: Comparing ports with similar characteristics (e.g., size, cargo type, region) for more meaningful insights.

Comprehensive approach: Considering a wide range of metrics to get a holistic view of port efficiency.

Transparency: Sharing benchmarking results openly to foster a culture of continuous improvement across the industry.

Stakeholder involvement: Engaging various stakeholders, including port authorities, terminal operators, and shipping lines, in the benchmarking process.

The impact of global benchmarking on port efficiency:

Competitive pressure: Benchmarking results can drive ports to improve their performance to remain competitive.

Investment decisions: Identifying areas of underperformance can guide investment in infrastructure and technology.

Policy making: Governments and regulatory bodies use benchmarking data to inform port development policies.

Customer expectations: Shipping lines and cargo owners use benchmarking data to select ports and negotiate service levels.

Continuous improvement: Regular benchmarking encourages a culture of ongoing efficiency enhancement in ports.

As the global shipping industry continues to evolve, port efficiency benchmarking is likely to become even more sophisticated:

Real-time benchmarking: Advancements in data analytics and IoT may enable more frequent or even real-time comparisons of port performance.

AI-driven insights: Artificial intelligence could be used to analyze vast amounts of port data and provide deeper insights into efficiency drivers.

Blockchain for data integrity: Blockchain technology could be used to ensure the accuracy and immutability of benchmarking data.

Integration with supply chain metrics: Port efficiency benchmarking may increasingly be linked to broader supply chain performance indicators.

In conclusion, global benchmarking of port efficiency is a crucial tool for driving improvements in the maritime industry. It provides ports with valuable insights into their performance relative to peers, helps identify best practices, and guides strategic decision-making. As the shipping industry continues to face challenges such as increasing vessel sizes, environmental regulations, and digital transformation, effective benchmarking will play an increasingly important role in ensuring ports can meet these challenges efficiently and remain competitive in the global marketplace.

What challenges exist in measuring port efficiency?

Measuring port efficiency is a complex task fraught with various challenges. These challenges stem from the multifaceted nature of port operations, the diversity of ports worldwide, and the rapidly evolving maritime industry. Understanding these challenges is crucial for developing more accurate and meaningful efficiency measurements. Here’s a comprehensive look at the challenges that exist in measuring port efficiency:

Data collection and quality:

Inconsistent data collection methods: Different ports may use varying methods to collect and report data, making direct comparisons difficult.

Data accuracy: Ensuring the accuracy of reported data, especially when it comes from multiple sources within a port.

Data gaps: Some ports may not collect or report certain types of data, leading to incomplete efficiency assessments.

Real-time data challenges: The difficulty in collecting and processing real-time data for immediate efficiency assessments.

Standardization issues:

Lack of universal metrics: The absence of globally accepted standard metrics for port efficiency.

Varying definitions: Different interpretations of efficiency metrics across ports and regions.

Diverse reporting periods: Inconsistencies in the time periods over which efficiency data is reported.

Contextual differences:

Port size and type: Comparing efficiency between ports of vastly different sizes or specializations can be misleading.

Geographic and environmental factors: Ports in different locations face unique challenges (e.g., weather patterns, tidal variations) that affect efficiency.

Economic context: The economic environment in which a port operates can significantly impact its efficiency metrics.

Regulatory differences: Varying regulations across countries can affect port operations and efficiency measurements.

To illustrate how these contextual differences can impact efficiency measurements, consider the following table comparing hypothetical data for ports of different types:

| Port Type | Annual Throughput (TEU) | Berth Productivity (moves/hour) | Avg. Vessel Turnaround Time (hours) | Main Challenges |

|---|---|---|---|---|

| Large Container | 10 million | 150 | 24 | Handling mega-ships |

| Small Container | 500,000 | 80 | 12 | Limited infrastructure |

| Bulk Port | N/A | 1000 tons/hour | 48 | Weather sensitivity |

| Multi-purpose | 2 million | 100 | 36 | Diverse cargo types |

This table highlights how different port types can have vastly different efficiency metrics due to their unique characteristics and challenges.

Technological disparities:

Automation levels: Comparing efficiency between highly automated ports and those with minimal automation can be problematic.

IT system differences: Variations in the sophistication of port management systems can affect efficiency measurements.

Emerging technologies: The adoption of new technologies (e.g., blockchain, AI) by some ports can create disparities in efficiency metrics.

Operational complexities:

Cargo mix: Ports handling diverse types of cargo may have efficiency metrics that are difficult to compare with specialized ports.

Vessel size variations:The trend towards larger vessels can skew efficiency metrics, particularly for smaller ports.

Labor practices: Differences in labor arrangements and productivity can impact efficiency measurements.

Intermodal connections: The efficiency of a port’s connections to inland transportation networks can be challenging to quantify and compare.

Financial and economic factors:

Cost structures: Variations in operating costs across different regions can make financial efficiency metrics difficult to compare.

Exchange rate fluctuations: For global comparisons, currency exchange rate variations can complicate financial efficiency metrics.

Economic cycles: The impact of economic booms and busts on port efficiency can make year-over-year comparisons challenging.

Stakeholder perspectives:

Differing priorities: Various stakeholders (port authorities, terminal operators, shipping lines, cargo owners) may have different views on what constitutes efficiency.

Competitive concerns: Ports may be reluctant to share certain efficiency data due to competitive pressures.

Environmental and social factors:

Environmental impact: Incorporating environmental efficiency into overall port efficiency measurements is complex.

Social responsibility: Balancing efficiency metrics with social responsibility measures (e.g., job creation, community impact) is challenging.

Safety and security: Integrating safety and security measures into efficiency metrics without compromising these critical aspects.

Measurement methodology challenges:

Choosing appropriate benchmarks: Selecting suitable peer ports for comparison can be difficult given the unique characteristics of each port.

Weighting of factors: Determining the relative importance of different efficiency metrics in an overall assessment.

Dynamic nature of efficiency: Port efficiency can vary significantly over short periods, making it challenging to capture in static measurements.

Data analysis complexities:

Big data challenges: Managing and analyzing the vast amounts of data generated by modern port operations.

Interpreting complex metrics: Some advanced efficiency metrics (e.g., Data Envelopment Analysis results) can be difficult to interpret and communicate.

Correlation vs. causation: Distinguishing between factors that are correlated with efficiency and those that actually cause improved efficiency.

Future challenges:

Adapting to technological changes: As ports adopt new technologies, efficiency measurement methods will need to evolve.

Climate change impacts: Incorporating the effects of climate change and extreme weather events into long-term efficiency assessments.

Changing trade patterns: Shifts in global trade routes and patterns may require adjustments to how port efficiency is measured.

Cybersecurity considerations: As ports become more digitalized, measuring the efficiency of cybersecurity measures will become increasingly important.

Addressing these challenges requires a multi-faceted approach:

Standardization efforts: International organizations and industry bodies are working to develop standardized efficiency metrics and data collection methods.

Advanced analytics: Utilizing big data analytics and artificial intelligence to process and interpret complex efficiency data.

Holistic approaches: Developing comprehensive efficiency measurement frameworks that consider operational, financial, environmental, and social factors.

Collaborative platforms: Creating industry-wide platforms for sharing best practices and standardized efficiency data.

Continuous improvement: Regularly reviewing and updating efficiency measurement methodologies to reflect industry changes.

Contextual analysis: Developing methods to account for port-specific factors when making efficiency comparisons.

Transparency initiatives: Encouraging greater openness in sharing efficiency data across the industry.

In conclusion, measuring port efficiency is a complex task that faces numerous challenges. These range from data collection and standardization issues to the complexities of accounting for diverse port characteristics and evolving industry trends. Overcoming these challenges is crucial for developing meaningful efficiency metrics that can drive improvements across the global port industry. As the maritime sector continues to evolve, so too must the approaches to measuring and benchmarking port efficiency. By addressing these challenges head-on, the industry can develop more accurate, comprehensive, and useful efficiency measurements that will help ports improve their operations, enhance their competitiveness, and better serve the needs of global trade.

How can technology enhance port efficiency measurement?

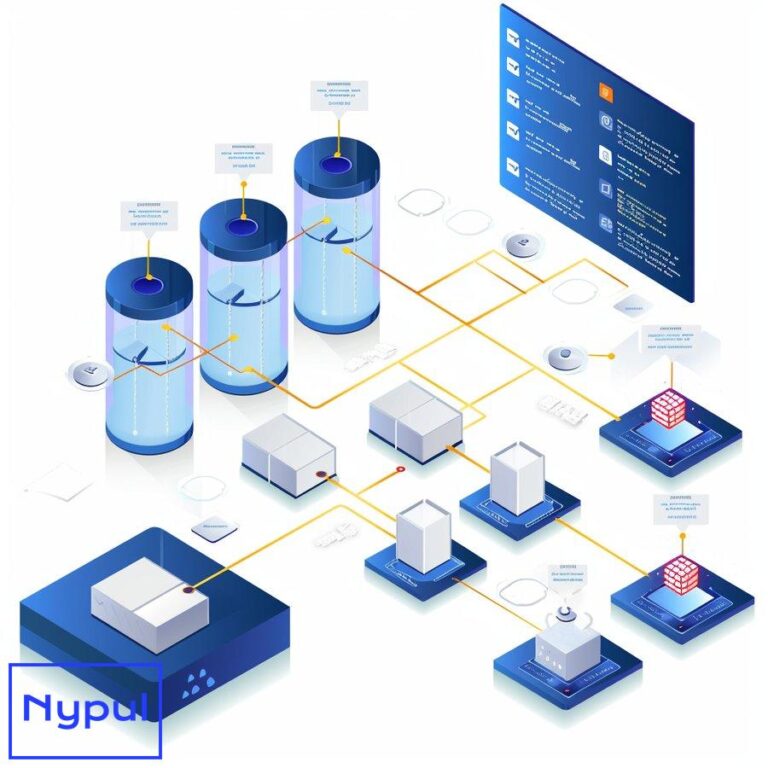

Technology plays a pivotal role in enhancing port efficiency measurement, offering new ways to collect, analyze, and interpret data. As ports become increasingly digitalized, the potential for technology to improve efficiency measurement grows exponentially. Here’s a comprehensive look at how various technologies can enhance port efficiency measurement:

Internet of Things (IoT) and Sensors:

Real-time data collection: IoT sensors on equipment, vehicles, and cargo can provide continuous, real-time data on port operations.

Predictive maintenance: Sensors can monitor equipment health, enabling predictive maintenance that improves overall efficiency.

Environmental monitoring: IoT devices can measure air and water quality, noise levels, and energy consumption for environmental efficiency metrics.

Asset tracking: RFID and GPS technologies enable precise tracking of containers, vehicles, and equipment, improving utilization metrics.

Artificial Intelligence (AI) and Machine Learning (ML):

Pattern recognition: AI can identify patterns in vast amounts of operational data, revealing efficiency trends and anomalies.

Predictive analytics: ML algorithms can forecast future efficiency levels based on historical data and current trends.

Optimization algorithms: AI can optimize berth allocation, yard operations, and equipment deployment in real-time.

Natural Language Processing (NLP): Can analyze unstructured data from reports and communications to extract efficiency insights.

Big Data Analytics:

Data integration: Combines data from various sources (e.g., terminal operating systems, vessel tracking, weather data) for comprehensive efficiency analysis.

Advanced visualization: Creates intuitive dashboards and reports that make complex efficiency data easier to understand and act upon.

Benchmarking: Enables more sophisticated benchmarking by processing large datasets from multiple ports.

Scenario modeling: Allows ports to model different operational scenarios and their impact on efficiency metrics.

To illustrate the impact of these technologies, consider the following table comparing efficiency measurement capabilities before and after implementing advanced technologies:

| Aspect | Traditional Measurement | Technology-Enhanced Measurement |

|---|---|---|

| Data Collection | Manual, periodic | Automated, real-time |

| Data Accuracy | Prone to human error | High accuracy, sensor-based |

| Analysis Speed | Days or weeks | Minutes or seconds |

| Predictive Capability | Limited | Advanced forecasting |

| Scope of Analysis | Limited metrics | Comprehensive, multi-factor |

| Optimization | Static, rule-based | Dynamic, AI-driven |

| Visualization | Basic charts and tables | Interactive, real-time dashboards |

This comparison highlights the significant improvements that technology can bring to port efficiency measurement.

Blockchain Technology:

Data integrity: Ensures the immutability and traceability of efficiency data.

Smart contracts: Automates and streamlines processes related to efficiency measurement and reporting.

Supply chain visibility: Enhances end-to-end visibility, allowing for more comprehensive efficiency metrics.

Stakeholder collaboration: Facilitates secure sharing of efficiency data among various port stakeholders.

5G and Advanced Connectivity:

High-speed data transmission: Enables real-time data collection and analysis from numerous devices simultaneously.

Low latency: Supports instant communication between systems, crucial for real-time efficiency optimization.

Edge computing: Allows for processing of efficiency data closer to the source, reducing delays and bandwidth requirements.

Augmented and Virtual Reality (AR/VR):

Training and simulation: Improves worker efficiency through immersive training experiences.

Remote inspections: Enables efficient remote monitoring and inspection of port operations.

Visualization of efficiency data: Provides intuitive, 3D visualizations of port operations and efficiency metrics.

Autonomous Vehicles and Robotics:

Consistent performance measurement: Autonomous equipment provides consistent operational data for efficiency analysis.

24/7 operations: Enables round-the-clock operations, providing more comprehensive efficiency data.

Reduced human error: Minimizes errors in data collection and operational execution.

Drones and Computer Vision:

Aerial surveys: Drones can quickly survey large port areas, providing data on yard utilization and congestion.

Security monitoring: Enhances port security efficiency through automated surveillance.

Cargo and asset inspection: Improves the speed and accuracy of cargo and equipment inspections.

Digital Twin Technology:

Virtual modeling: Creates a digital replica of port operations for advanced simulation and optimization.

What-if analysis: Allows testing of different scenarios to identify efficiency improvements without disrupting actual operations.

Predictive maintenance: Enhances equipment efficiency by predicting maintenance needs based on virtual model data.

Cloud Computing:

Scalable data storage: Provides flexible storage solutions for the vast amounts of data generated by modern ports.

Distributed processing: Enables complex efficiency calculations and analytics to be performed quickly and cost-effectively.

Collaborative platforms: Facilitates sharing of efficiency data and best practices across multiple ports and stakeholders.

Cybersecurity Technologies:

Data protection: Ensures the security of sensitive efficiency data.

System integrity: Protects the systems used for efficiency measurement from cyber threats.

Resilience measurement: Provides metrics on the port’s ability to maintain efficiency in the face of cyber threats.

The implementation of these technologies for enhancing port efficiency measurement faces several challenges:

Integration complexity: Integrating new technologies with existing port systems can be technically challenging.

Cost considerations: The initial investment in advanced technologies can be significant.

Skills gap: Ports may lack the in-house expertise to fully leverage these technologies.

Data privacy concerns: Collecting and sharing vast amounts of operational data raises privacy and competitive concerns.

Standardization issues: Lack of industry-wide standards for technology implementation and data sharing.

To maximize the benefits of technology in port efficiency measurement, ports should consider the following strategies:

Phased implementation: Gradually introduce new technologies, starting with those that offer the most immediate benefits.

Collaborative approach: Work with technology providers, academia, and other ports to develop and implement solutions.

Continuous learning: Invest in training and development to build in-house expertise in emerging technologies.

Open architecture: Adopt open, interoperable systems that can easily integrate with new technologies as they emerge.

Data governance: Establish clear policies on data collection, usage, and sharing to address privacy and security concerns.

As technology continues to evolve, the future of port efficiency measurement looks increasingly sophisticated:

AI-driven autonomous ports: Fully automated ports where AI systems continuously measure and optimize efficiency.

Quantum computing: May enable complex efficiency calculations that are currently infeasible.

Advanced materials and nanotechnology: Could lead to new types of sensors and equipment that provide even more detailed efficiency data.

Holographic displays: Might offer new ways to visualize and interact with port efficiency data.

In conclusion, technology has the potential to revolutionize how port efficiency is measured and improved. From IoT and AI to blockchain and digital twins, these technologies offer ports unprecedented capabilities to collect, analyze, and act upon efficiency data. As the maritime industry continues to evolve, embracing these technological advancements will be crucial for ports seeking to enhance their efficiency, competitiveness, and overall performance in the global trade landscape. The key to success will lie in thoughtful implementation, continuous innovation, and a willingness to adapt to the rapidly changing technological environment.