What Is Freight Capacity Management

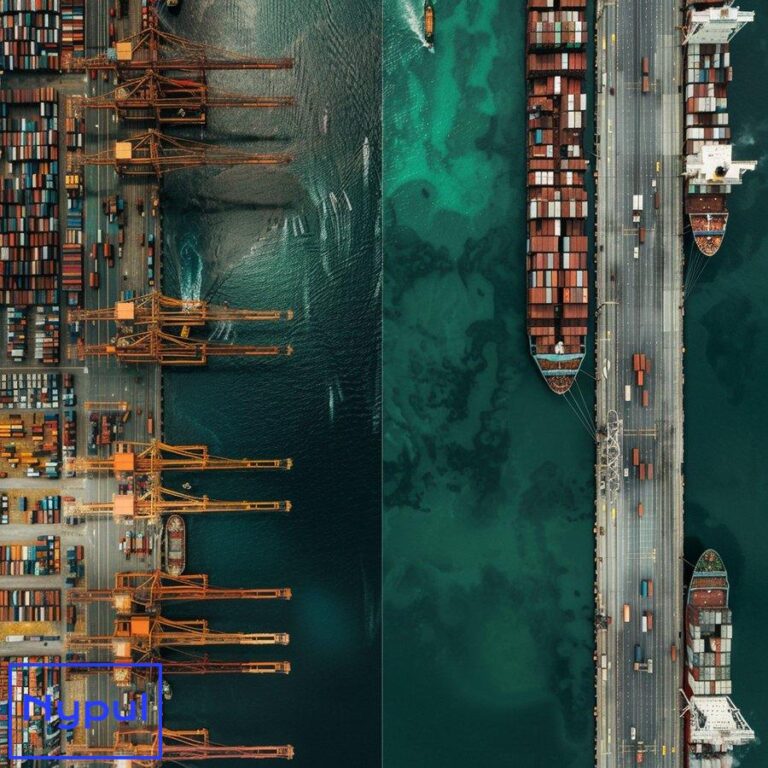

Freight capacity management is a critical component of logistics and supply chain operations. This strategic approach involves efficiently allocating and utilizing available transportation resources to meet shipping demands while minimizing costs and maximizing efficiency. The process encompasses a wide range of activities, from forecasting demand to optimizing load planning and route selection.

At its core, freight capacity management aims to strike a balance between supply and demand in the transportation sector. This balance is crucial for ensuring that goods are moved efficiently from origin to destination, meeting customer expectations while keeping operational costs in check. The concept applies to various modes of transportation, including trucking, rail, air, and ocean freight.

Key Components of Freight Capacity Management

Demand Forecasting: Accurate prediction of shipping needs is fundamental to effective capacity management. This involves analyzing historical data, market trends, and seasonal fluctuations to anticipate future demand.

Resource Allocation: Once demand is forecasted, resources such as vehicles, containers, and personnel must be allocated efficiently. This ensures that the right assets are available at the right time and place to meet shipping requirements.

Load Optimization: Maximizing the use of available space in vehicles and containers is crucial for cost-effective transportation. This involves careful planning of cargo placement and consolidation of shipments when possible.

Route Planning: Selecting the most efficient routes for freight movement helps minimize transit times and fuel consumption, contributing to overall capacity optimization.

Real-time Monitoring and Adjustment: The ability to track shipments and adjust plans in response to unforeseen circumstances is essential for maintaining efficiency in freight operations.

Carrier Management: Effective relationships with carriers and the strategic selection of transportation providers play a significant role in capacity management.

Freight capacity management is not a static process but a dynamic one that requires continuous monitoring and adjustment. As market conditions, customer demands, and operational factors change, capacity management strategies must evolve to maintain efficiency and competitiveness.

The importance of freight capacity management has grown significantly in recent years, driven by factors such as globalization, e-commerce growth, and increasing customer expectations for fast and reliable deliveries. Companies that excel in this area can gain a significant competitive advantage by reducing costs, improving service levels, and enhancing overall supply chain performance.

Understanding the nuances of freight capacity management is crucial for logistics professionals, supply chain managers, and business leaders involved in transportation and distribution. By mastering this discipline, organizations can navigate the complexities of modern logistics, adapt to market changes, and deliver value to their customers while maintaining operational efficiency.

Why is freight capacity management crucial for supply chains?

Freight capacity management plays a pivotal role in the success and efficiency of supply chains. Its importance cannot be overstated, as it directly impacts various aspects of business operations, customer satisfaction, and overall competitiveness in the market. Let’s delve into the reasons why freight capacity management is crucial for supply chains.

Cost Optimization

Effective freight capacity management leads to significant cost savings throughout the supply chain. By optimizing the use of transportation resources, companies can reduce unnecessary expenses associated with underutilized assets or inefficient routing. This cost optimization extends beyond just transportation costs:

Inventory Carrying Costs: Improved capacity management allows for more precise inventory control, reducing the need for excessive safety stock and the associated carrying costs.

Labor Costs: Efficient capacity utilization can lead to better workforce planning, reducing overtime and idle time for logistics personnel.

Fuel Costs: Optimized routes and load planning result in reduced fuel consumption, a significant expense in transportation operations.

Enhanced Customer Service

In today’s competitive business environment, customer expectations for fast, reliable deliveries are higher than ever. Freight capacity management directly impacts a company’s ability to meet these expectations:

On-Time Deliveries: Proper capacity planning ensures that goods are delivered within promised timeframes, enhancing customer satisfaction and loyalty.

Flexibility: Effective capacity management allows companies to respond quickly to changes in demand or unexpected events, maintaining service levels even in challenging circumstances.

Improved Supply Chain Visibility: Advanced capacity management systems often provide real-time tracking and status updates, allowing customers to stay informed about their shipments.

Operational Efficiency

Freight capacity management streamlines supply chain operations, leading to improved overall efficiency:

Resource Utilization: By maximizing the use of available transportation assets, companies can do more with less, improving their return on investment in logistics resources.

Reduced Bottlenecks: Proper capacity planning helps identify and address potential bottlenecks in the supply chain before they cause disruptions.

Improved Coordination: Effective capacity management facilitates better coordination between different supply chain partners, from suppliers to carriers to end customers.

Risk Mitigation

In an increasingly complex and volatile global business environment, freight capacity management serves as a crucial tool for risk mitigation:

Demand Fluctuations: By improving demand forecasting and capacity planning, companies can better handle seasonal peaks and unexpected surges in demand.

Supply Chain Disruptions: Effective capacity management strategies provide the flexibility to adapt to disruptions caused by natural disasters, geopolitical events, or other unforeseen circumstances.

Carrier Performance: Proper management of carrier relationships and performance monitoring helps mitigate risks associated with unreliable or underperforming transportation providers.

Competitive Advantage

Companies that excel in freight capacity management can gain a significant edge over their competitors:

Market Responsiveness: Efficient capacity management allows companies to respond quickly to market opportunities, launching new products or entering new markets with greater agility.

Cost Leadership: By optimizing transportation costs, companies can offer more competitive pricing to their customers without sacrificing profitability.

Service Differentiation: Superior delivery performance enabled by effective capacity management can be a key differentiator in crowded markets.

Environmental Impact

As sustainability becomes an increasingly important concern for businesses and consumers alike, freight capacity management plays a crucial role in reducing the environmental impact of supply chain operations:

Reduced Emissions: Optimized routing and load planning lead to fewer empty miles and more efficient use of fuel, reducing greenhouse gas emissions.

Waste Reduction: Better capacity utilization can lead to less packaging waste and more efficient use of resources throughout the supply chain.

Sustainability Reporting: Improved capacity management provides data that can be used to demonstrate a company’s commitment to environmental sustainability, an increasingly important factor for many stakeholders.

The importance of freight capacity management in supply chains is multifaceted, touching on financial, operational, customer-focused, and environmental aspects of business. As supply chains become more complex and global, the ability to effectively manage freight capacity becomes not just an operational necessity but a strategic imperative for companies looking to thrive in competitive markets.

By investing in robust freight capacity management practices and technologies, companies can position themselves to meet the challenges of modern supply chain management, deliver superior value to their customers, and achieve sustainable growth in an ever-changing business landscape.

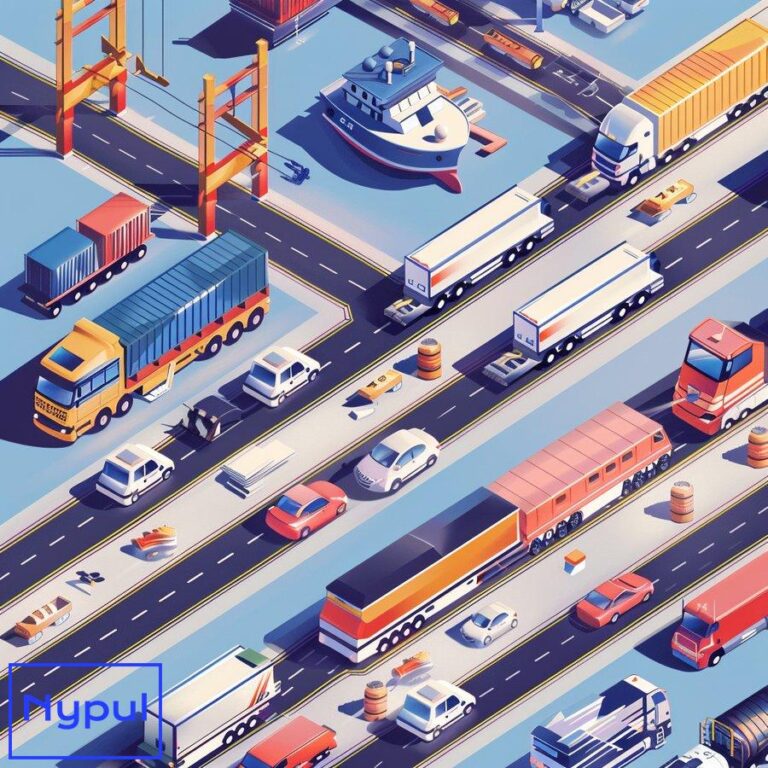

How does freight capacity management optimize transportation resources?

Freight capacity management is a powerful tool for optimizing transportation resources, enabling companies to maximize efficiency, reduce costs, and improve overall supply chain performance. This optimization process involves several key strategies and techniques that work together to ensure the most effective use of available transportation assets. Let’s explore how freight capacity management achieves this optimization:

Load Consolidation and Optimization

One of the primary ways freight capacity management optimizes transportation resources is through effective load consolidation and optimization:

Maximizing Vehicle Utilization: By consolidating smaller shipments into full truckloads or container loads, companies can significantly reduce the number of trips required, leading to better utilization of vehicles and containers.

3D Load Planning: Advanced load planning software uses algorithms to optimize the placement of cargo within vehicles or containers, maximizing space utilization while considering factors such as weight distribution and handling requirements.

Multi-Stop Route Planning: Combining multiple deliveries into a single trip reduces empty miles and improves overall vehicle utilization.

Dynamic Routing and Scheduling

Freight capacity management systems use sophisticated algorithms to optimize routing and scheduling:

Real-Time Route Optimization: By considering factors such as traffic conditions, weather, and delivery time windows, these systems can dynamically adjust routes to minimize travel time and fuel consumption.

Backhaul Planning: Identifying opportunities for return loads reduces empty miles and improves overall fleet efficiency.

Time-Slot Management: Coordinating pickup and delivery time slots helps reduce wait times at loading docks and improves overall fleet productivity.

Mode Selection and Intermodal Optimization

Effective freight capacity management involves choosing the most appropriate transportation mode for each shipment:

Mode Comparison: By analyzing factors such as cost, transit time, and cargo characteristics, companies can select the optimal mode of transportation for each shipment.

Intermodal Solutions: Combining different transportation modes (e.g., truck and rail) can lead to cost savings and improved efficiency for long-distance shipments.

Carrier Selection and Performance Management

Optimizing transportation resources also involves strategic management of carrier relationships:

Carrier Performance Tracking: By monitoring and analyzing carrier performance metrics, companies can identify the most reliable and efficient transportation providers.

Dynamic Carrier Selection: Advanced systems can automatically select the best carrier for each shipment based on factors such as cost, transit time, and historical performance.

Capacity Forecasting and Demand Planning

Accurate forecasting is crucial for optimizing transportation resources:

Predictive Analytics: By analyzing historical data and market trends, companies can better predict future capacity needs and plan accordingly.

Seasonal Planning: Understanding and preparing for seasonal fluctuations in demand helps ensure that appropriate transportation resources are available when needed.

Asset Utilization and Fleet Management

For companies with their own transportation assets, freight capacity management optimizes fleet utilization:

Vehicle Tracking and Telematics: Real-time tracking of vehicles allows for better coordination and utilization of fleet assets.

Maintenance Scheduling: Predictive maintenance based on usage data helps minimize vehicle downtime and extend asset lifecycles.

Network Optimization

Freight capacity management also involves optimizing the overall transportation network:

Distribution Center Placement: Strategic location of distribution centers can significantly reduce transportation distances and improve overall network efficiency.

Cross-Docking: Implementing cross-docking strategies can reduce the need for storage and handling, streamlining the flow of goods through the supply chain.

Collaborative Transportation Management

Optimization extends beyond individual companies through collaborative approaches:

Shipper Collaboration: Companies with complementary shipping needs can collaborate to share transportation resources, reducing costs and improving utilization.

Carrier Collaboration: Facilitating collaboration between carriers can lead to more efficient use of transportation assets across the industry.

Data-Driven Decision Making

The optimization of transportation resources is underpinned by data-driven decision making:

Performance Metrics: Tracking key performance indicators (KPIs) such as on-time delivery rates, cost per mile, and asset utilization rates provides insights for continuous improvement.

Scenario Planning: Advanced analytics tools allow companies to model different scenarios and make informed decisions about resource allocation.

To illustrate the impact of these optimization strategies, consider the following table comparing key metrics before and after implementing comprehensive freight capacity management:

| Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Vehicle Utilization Rate | 65% | 85% | +20% |

| Empty Miles | 25% | 10% | -15% |

| On-Time Delivery Rate | 88% | 97% | +9% |

| Transportation Cost (per unit) | $1.20 | $0.95 | -20.8% |

| CO2 Emissions (tons per year) | 10,000 | 8,000 | -20% |

This table demonstrates the significant improvements that can be achieved through effective freight capacity management across various key performance indicators.

Freight capacity management optimizes transportation resources by leveraging a combination of advanced technologies, data-driven strategies, and collaborative approaches. By implementing these optimization techniques, companies can significantly improve the efficiency of their transportation operations, reduce costs, enhance service levels, and minimize environmental impact.

The optimization of transportation resources through freight capacity management is not a one-time effort but an ongoing process of continuous improvement. As new technologies emerge and market conditions evolve, companies must continually refine their strategies to maintain and enhance their competitive edge in the dynamic world of logistics and supply chain management.

What are the key strategies in freight capacity management?

Effective freight capacity management relies on a set of key strategies that, when implemented cohesively, can significantly enhance the efficiency and performance of transportation operations. These strategies are designed to address various aspects of capacity management, from planning and execution to monitoring and improvement. Let’s explore these key strategies in detail:

Demand Forecasting and Capacity Planning

Accurate demand forecasting is the foundation of effective capacity management:

Historical Data Analysis: Utilizing past shipping data to identify patterns and trends in demand.

Market Intelligence: Incorporating market insights and economic indicators to predict future shipping needs.

Collaborative Planning: Working closely with customers and suppliers to align capacity plans with their forecasts and production schedules.

Scenario Modeling: Developing multiple demand scenarios to prepare for various potential outcomes.

Network Optimization

Optimizing the transportation network is crucial for efficient capacity utilization:

Strategic Facility Location: Placing distribution centers and warehouses in optimal locations to minimize transportation distances and times.

Lane Analysis: Identifying high-volume lanes and optimizing capacity allocation for these routes.

Multi-Modal Planning: Leveraging different transportation modes to create the most efficient network configuration.

Cross-Docking Implementation: Utilizing cross-docking facilities to reduce storage needs and expedite shipments.

Load Optimization and Consolidation

Maximizing the use of available space in vehicles and containers is a critical strategy:

3D Load Planning: Using advanced software to optimize cargo placement within vehicles or containers.

Shipment Consolidation: Combining multiple smaller shipments into full truckloads or container loads.

Product Mixing: Strategically mixing different types of products to maximize space utilization while adhering to handling requirements.

Packaging Optimization: Redesigning packaging to improve space efficiency in transportation.

Dynamic Routing and Scheduling

Flexible and responsive routing strategies are essential for optimizing capacity:

Real-Time Route Optimization: Adjusting routes based on current traffic conditions, weather, and other real-time factors.

Dynamic Appointment Scheduling: Implementing flexible appointment systems to reduce wait times and improve dock utilization.

Continuous Move Planning: Creating efficient multi-stop routes to minimize empty miles and maximize vehicle utilization.

Carrier Management and Collaboration

Effective management of carrier relationships is crucial for capacity optimization:

Performance-Based Carrier Selection: Choosing carriers based on key performance indicators such as on-time delivery rates and cost-effectiveness.

Capacity Sharing Agreements: Establishing partnerships with carriers to ensure access to capacity during peak periods.

Collaborative Transportation Management: Working with other shippers to consolidate loads and share transportation resources.

Technology Integration

Leveraging advanced technologies is key to modern freight capacity management:

Transportation Management Systems (TMS): Implementing comprehensive TMS solutions to automate and optimize various aspects of capacity management.

Internet of Things (IoT) and Telematics: Using IoT devices and telematics to track assets and monitor performance in real-time.

Artificial Intelligence and Machine Learning: Employing AI algorithms for predictive analytics and decision support in capacity planning.

Blockchain Technology: Utilizing blockchain for improved transparency and efficiency in capacity allocation and utilization tracking.

Flexible Capacity Strategies

Developing strategies to handle fluctuations in demand is crucial:

Spot Market Utilization: Leveraging the spot market to handle unexpected capacity needs or take advantage of favorable rates.

Dedicated Fleet Management: Maintaining a core fleet for consistent capacity while using third-party carriers for flexibility.

Intermodal Solutions: Utilizing a mix of transportation modes to adapt to changing capacity needs and market conditions.

Seasonal Planning: Developing specific strategies to manage capacity during peak seasons or promotional periods.

Performance Monitoring and Continuous Improvement

Ongoing analysis and improvement are essential for long-term success:

Key Performance Indicator (KPI) Tracking: Regularly monitoring and analyzing key metrics such as on-time delivery rates, asset utilization, and cost per mile.

Root Cause Analysis: Investigating the causes of capacity-related issues and implementing corrective actions.

Benchmarking: Comparing performance against industry standards and best practices to identify areas for improvement.

Continuous Training: Providing ongoing education and training for staff involved in capacity management to keep skills up-to-date.

Risk Management and Contingency Planning

Preparing for potential disruptions is a critical aspect of capacity management:

Diversification of Carriers: Maintaining relationships with multiple carriers to mitigate the risk of capacity shortages.

Alternative Route Planning: Developing backup plans for key shipping lanes in case of disruptions.

Capacity Buffer Management: Maintaining a strategic buffer of capacity to handle unexpected surges in demand or disruptions.

Sustainability Integration

Incorporating sustainability into capacity management strategies is increasingly important:

Green Transportation Options: Prioritizing eco-friendly transportation modes and carriers with strong sustainability practices.

Emissions Tracking and Reduction: Implementing systems to monitor and reduce carbon emissions associated with transportation activities.

Circular Economy Initiatives: Developing strategies to optimize reverse logistics and support circular economy principles.

To illustrate the impact of these strategies, consider the following table comparing the effectiveness of different capacity management approaches:

| Strategy | Impact on Capacity Utilization | Cost Reduction Potential | Service Level Improvement |

|---|---|---|---|

| Demand Forecasting | High | Medium | High |

| Load Optimization | Very High | High | Medium |

| Dynamic Routing | High | High | High |

| ———- | ——————————– | ————————– | ————————— |

| Demand Forecasting | High | Medium | High |

| Load Optimization | Very High | High | Medium |

| Dynamic Routing | High | High | High |

| Carrier Collaboration | Medium | Medium | High |

| Technology Integration | High | High | High |

| Risk Management | Medium | Low | Medium |

The above table illustrates how different strategies in freight capacity management can significantly impact capacity utilization, cost reduction, and service level improvement. By focusing on these key strategies, companies can develop a comprehensive approach to managing freight capacity effectively.

Which tools and technologies enhance freight capacity management?

The landscape of freight capacity management has been transformed by the advent of various tools and technologies designed to enhance efficiency, visibility, and decision-making capabilities. These technological innovations play a crucial role in optimizing transportation resources, improving service levels, and reducing costs. Below are some of the most impactful tools and technologies that enhance freight capacity management:

Transportation Management Systems (TMS)

A robust Transportation Management System (TMS) is essential for effective freight capacity management:

-

Centralized Platform: TMS provides a centralized platform for managing all transportation activities, from planning and execution to monitoring and reporting.

-

Load Optimization: Advanced TMS solutions include algorithms for optimizing load planning and consolidation, ensuring maximum utilization of transportation assets.

-

Carrier Management: TMS facilitates the selection and management of carriers, allowing companies to track performance and negotiate rates effectively.

-

Real-Time Visibility: Many TMS platforms offer real-time tracking of shipments, enabling proactive management of delays and disruptions.

Supply Chain Visibility Tools

Visibility tools enhance transparency across the supply chain, allowing companies to monitor and manage freight capacity more effectively:

-

IoT Devices: Internet of Things (IoT) devices can track the location and condition of shipments in real-time, providing valuable data for capacity planning.

-

Dashboard Analytics: Visualization tools and dashboards help logistics managers monitor key performance indicators (KPIs) related to capacity utilization, delivery performance, and costs.

-

Collaboration Platforms: Tools that facilitate collaboration between shippers, carriers, and other stakeholders enhance communication and coordination, improving overall capacity management.

Load Optimization Software

Specialized load optimization software is critical for maximizing the efficiency of cargo placement:

-

3D Load Planning: These tools use advanced algorithms to determine the optimal arrangement of cargo within vehicles or containers, maximizing space utilization.

-

Weight Distribution Analysis: Load optimization software ensures that weight is evenly distributed, improving safety and compliance with regulations.

-

Automated Load Planning: Automation features allow for quick adjustments to load plans based on changing shipment requirements.

Route Optimization Tools

Route optimization tools help companies determine the most efficient paths for transportation:

-

Dynamic Routing Algorithms: These algorithms consider real-time traffic, weather conditions, and delivery windows to create optimal routes.

-

Multi-Stop Routing: Tools that facilitate multi-stop routing help reduce empty miles and improve overall fleet efficiency.

-

Geospatial Analytics: Geographic information systems (GIS) provide valuable insights into route planning and optimization, helping companies visualize and analyze transportation networks.

Artificial Intelligence and Machine Learning

AI and machine learning technologies are increasingly being integrated into freight capacity management:

-

Predictive Analytics: Machine learning algorithms analyze historical data to forecast demand and optimize capacity planning.

-

Automated Decision Making: AI can automate decision-making processes, such as carrier selection and route planning, based on predefined criteria and real-time data.

-

Anomaly Detection: AI systems can identify unusual patterns in transportation data, allowing companies to proactively address potential issues.

Blockchain Technology

Blockchain technology is emerging as a powerful tool for enhancing transparency and trust in freight capacity management:

-

Immutable Records: Blockchain creates a secure, tamper-proof record of transactions, improving accountability and traceability in the supply chain.

-

Smart Contracts: Automated smart contracts can streamline processes such as carrier payments and capacity agreements, reducing administrative overhead.

-

Collaborative Networks: Blockchain enables secure collaboration between multiple stakeholders, enhancing communication and information sharing.

Telematics and Fleet Management Solutions

Telematics systems provide real-time data on vehicle performance and location, enhancing fleet management:

-

Vehicle Tracking: Real-time tracking of vehicles allows for better coordination and utilization of fleet assets.

-

Driver Behavior Monitoring: Telematics can monitor driver behavior, helping to identify areas for improvement and reduce fuel consumption.

-

Maintenance Alerts: Predictive maintenance features alert fleet managers to potential issues before they lead to costly breakdowns.

Data Analytics and Business Intelligence Tools

Data analytics tools are essential for informed decision-making in freight capacity management:

-

KPI Dashboards: Business intelligence tools provide dashboards that visualize key performance indicators, enabling quick assessment of capacity management effectiveness.

-

Scenario Analysis: Advanced analytics allow companies to model different scenarios and assess the potential impact on capacity and costs.

-

Benchmarking: Analytics tools enable companies to benchmark their performance against industry standards and identify areas for improvement.

The integration of these tools and technologies into freight capacity management processes can lead to significant improvements in efficiency, cost-effectiveness, and service levels. As the logistics landscape continues to evolve, companies that leverage these innovations will be better positioned to meet the challenges of modern supply chain management.

How can companies overcome challenges in freight capacity management?

Freight capacity management presents various challenges that can hinder operational efficiency and impact service levels. However, companies can implement effective strategies to overcome these challenges and enhance their capacity management processes. Below are some common challenges in freight capacity management and strategies to address them:

Demand Fluctuations

Demand fluctuations can create uncertainty in capacity planning, leading to either excess capacity or shortages:

-

Implement Advanced Forecasting Techniques: Utilizing predictive analytics and machine learning can improve demand forecasting accuracy, allowing companies to better anticipate fluctuations.

-

Collaborate with Customers and Suppliers: Engaging in collaborative planning with key stakeholders can provide valuable insights into upcoming demand changes.

-

Maintain Flexible Capacity Options: Establishing relationships with multiple carriers and utilizing spot market options can provide the flexibility needed to respond to sudden demand changes.

Capacity Constraints

Limited transportation capacity can lead to delays and increased costs:

-

Optimize Load Planning: Implementing load optimization software can help maximize the use of available capacity and reduce empty miles.

-

Utilize Intermodal Solutions: Combining different transportation modes can alleviate capacity constraints, especially during peak periods.

-

Enhance Carrier Relationships: Building strong relationships with carriers can improve access to capacity and facilitate better negotiation of rates and terms.

Inefficient Routing and Scheduling

Poor routing and scheduling can lead to increased transit times and costs:

-

Adopt Dynamic Routing Technologies: Implementing real-time route optimization tools can help identify the most efficient paths for transportation.

-

Utilize Appointment Scheduling Systems: Implementing dynamic appointment scheduling can reduce wait times at loading docks and improve overall operational efficiency.

-

Conduct Regular Route Audits: Periodically reviewing and analyzing routing strategies can identify areas for improvement and enhance overall efficiency.

Technology Integration Challenges

Integrating new technologies into existing systems can be complex and resource-intensive:

-

Conduct Thorough Needs Assessments: Before implementing new technologies, companies should assess their specific needs and ensure that the chosen solutions align with their operational goals.

-

Provide Comprehensive Training: Ensuring that employees are well-trained in new technologies is crucial for successful implementation and adoption.

-

Start with Pilot Programs: Implementing new technologies on a smaller scale through pilot programs can help identify potential issues and refine processes before full-scale deployment.

Visibility Issues

Lack of visibility into the supply chain can hinder effective capacity management:

-

Invest in Visibility Tools: Implementing IoT devices and supply chain visibility platforms can provide real-time tracking and monitoring of shipments.

-

Enhance Communication with Stakeholders: Improving communication channels between shippers, carriers, and customers can enhance visibility and coordination.

-

Utilize Data Analytics: Leveraging data analytics tools can help companies gain insights into their supply chain performance and identify areas for improvement.

Cost Pressures

Rising transportation costs can impact profitability and competitiveness:

-

Implement Cost-Reduction Strategies: Focusing on load optimization, route planning, and carrier collaboration can help reduce overall transportation costs.

-

Explore Alternative Transportation Modes: Utilizing intermodal solutions and alternative carriers can provide cost-effective options for freight movement.

-

Monitor and Analyze Costs: Regularly tracking and analyzing transportation costs can help identify trends and areas for improvement.

Regulatory Compliance

Navigating complex regulatory requirements can pose challenges for freight capacity management:

-

Stay Informed about Regulations: Keeping abreast of regulatory changes and compliance requirements is essential for avoiding penalties and disruptions.

-

Implement Compliance Management Systems: Utilizing technology solutions that help track and manage compliance can streamline the process and reduce risks.

-

Provide Employee Training: Training employees on regulatory requirements and best practices can enhance compliance efforts.

By proactively addressing these challenges through strategic planning, technology adoption, and collaboration, companies can enhance their freight capacity management processes and improve overall supply chain performance. Overcoming these challenges is essential for maintaining competitiveness in a rapidly evolving logistics landscape.

What metrics measure the success of freight capacity management?

Measuring the success of freight capacity management is essential for understanding performance, identifying areas for improvement, and making data-driven decisions. Various metrics can be used to assess the effectiveness of capacity management strategies. Below are some key metrics that companies should consider when evaluating their freight capacity management efforts:

Capacity Utilization Rate

The capacity utilization rate measures the extent to which available transportation capacity is being utilized:

-

Formula:

$$\text{Capacity Utilization Rate} = \left( \frac{\text{Actual Capacity Used}}{\text{Total Capacity Available}} \right) \times 100$$ -

Importance: A high capacity utilization rate indicates efficient use of transportation resources, while a low rate may suggest underutilization or inefficiencies.

On-Time Delivery Rate

The on-time delivery rate assesses the percentage of shipments delivered within the promised timeframe:

-

Formula:

$$\text{On-Time Delivery Rate} = \left( \frac{\text{Number of On-Time Deliveries}}{\text{Total Deliveries}} \right) \times 100$$ -

Importance: Timely deliveries are crucial for customer satisfaction and retention. A high on-time delivery rate reflects effective capacity management and operational efficiency.

Cost per Mile or Cost per Shipment

Cost metrics help evaluate the financial efficiency of transportation operations:

-

Formula:

$$\text{Cost per Mile} = \frac{\text{Total Transportation Costs}}{\text{Total Miles Driven}}$$ -

Formula:

$$\text{Cost per Shipment} = \frac{\text{Total Transportation Costs}}{\text{Total Shipments}}$$ -

Importance: Monitoring these costs allows companies to identify trends, assess the impact of capacity management strategies, and make informed decisions about pricing and resource allocation.

Empty Miles Percentage

The empty miles percentage measures the proportion of miles traveled without cargo:

-

Formula:

$$\text{Empty Miles Percentage} = \left( \frac{\text{Empty Miles}}{\text{Total Miles Driven}} \right) \times 100$$ -

Importance: Reducing empty miles is crucial for improving capacity utilization and minimizing costs. A lower percentage indicates more efficient routing and load planning.

Freight Claims Ratio

The freight claims ratio assesses the percentage of shipments that result in claims for loss or damage:

-

Formula:

$$\text{Freight Claims Ratio} = \left( \frac{\text{Number of Claims}}{\text{Total Shipments}} \right) \times 100$$ -

Importance: A high claims ratio may indicate issues with carrier performance or handling practices, highlighting the need for improved capacity management and carrier selection.

Lead Time

Lead time measures the total time taken from order placement to delivery:

-

Formula:

$$\text{Lead Time} = \text{Delivery Date} – \text{Order Date}$$ -

Importance: Shorter lead times enhance customer satisfaction and can be indicative of effective capacity management practices.

Inventory Turnover Ratio

The inventory turnover ratio assesses how efficiently inventory is managed in relation to sales:

-

Formula:

$$\text{Inventory Turnover Ratio} = \frac{\text{Cost of Goods Sold}}{\text{Average Inventory}}$$ -

Importance: A higher turnover ratio indicates efficient inventory management, which is closely linked to effective freight capacity management.

Carrier Performance Metrics

Evaluating carrier performance is essential for effective capacity management:

-

On-Time Delivery Rate: Measures the percentage of on-time deliveries by each carrier.

-

Claims Rate: Assesses the percentage of shipments that result in claims for loss or damage.

-

Cost per Shipment: Evaluates the cost-effectiveness of each carrier.

Customer Satisfaction Metrics

Customer satisfaction is a critical indicator of the success of freight capacity management:

-

Net Promoter Score (NPS): Measures customer loyalty and satisfaction based on their likelihood to recommend the company.

-

Customer Feedback Surveys: Collecting feedback on delivery performance, communication, and overall service can provide valuable insights.

By monitoring these metrics, companies can gain a comprehensive understanding of their freight capacity management performance. Regular analysis of these metrics enables organizations to identify trends, address inefficiencies, and continuously improve their capacity management strategies.

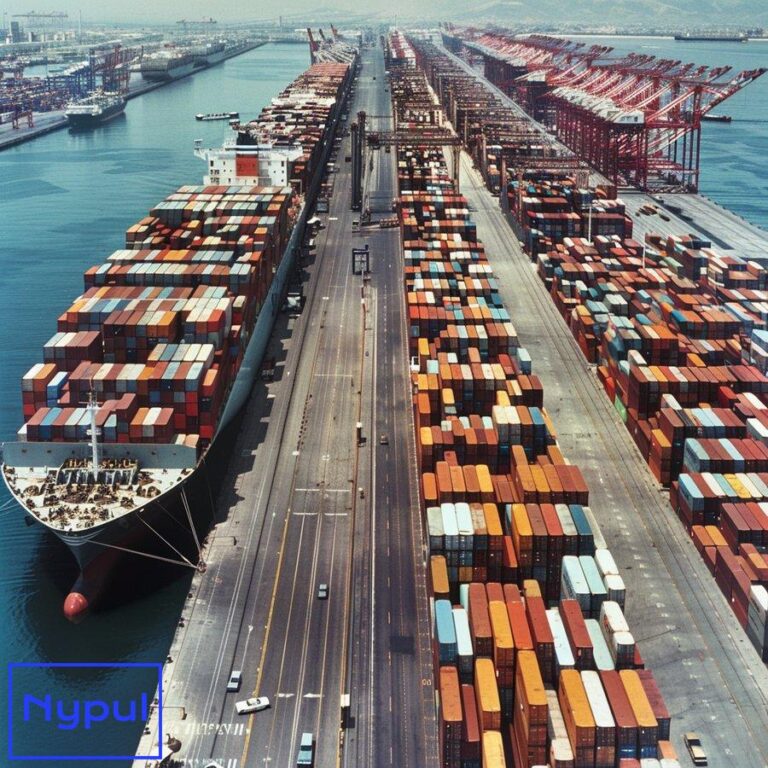

How do real-world companies implement freight capacity management?

Real-world companies across various industries have successfully implemented freight capacity management strategies to enhance their logistics operations, reduce costs, and improve service levels. Here are some examples of how companies implement freight capacity management in practice:

Case Study: Amazon

Amazon is a prime example of a company that excels in freight capacity management:

-

Advanced Technology Integration: Amazon utilizes sophisticated algorithms and machine learning to optimize its logistics network, ensuring efficient routing and load planning.

-

Dynamic Fulfillment Centers: The company strategically locates fulfillment centers based on demand patterns, allowing for faster deliveries and reduced transportation costs.

-

Real-Time Visibility: Amazon’s logistics platform provides real-time tracking of shipments, enabling proactive management of delays and enhancing customer satisfaction.

-

Collaborative Partnerships: Amazon collaborates with a network of carriers and logistics providers to ensure access to capacity during peak periods, such as holiday seasons.

Case Study: Walmart

Walmart has implemented effective freight capacity management strategies to optimize its supply chain:

-

Cross-Docking: The company utilizes cross-docking facilities to streamline the flow of goods, reducing storage needs and improving delivery efficiency.

-

Data-Driven Decision Making: Walmart leverages data analytics to monitor transportation costs, assess carrier performance, and optimize routing.

-

Collaborative Logistics: Walmart collaborates with suppliers and carriers to share transportation resources, reducing costs and improving capacity utilization.

-

Sustainability Initiatives: The company focuses on reducing carbon emissions by optimizing routes and utilizing fuel-efficient transportation modes.

Case Study: Coca-Cola

Coca-Cola has successfully implemented freight capacity management strategies to enhance its distribution network:

-

Route Optimization: Coca-Cola uses advanced routing software to identify the most efficient delivery routes, reducing fuel consumption and improving delivery times.

-

Load Consolidation: The company consolidates shipments to maximize vehicle utilization and minimize transportation costs.

-

Performance Monitoring: Coca-Cola tracks key performance indicators related to transportation efficiency, enabling continuous improvement in capacity management.

-

Collaboration with Distributors: The company works closely with distributors to align capacity planning and improve overall supply chain efficiency.

Case Study: Unilever

Unilever has adopted innovative freight capacity management practices to optimize its logistics operations:

-

Sustainable Transportation: Unilever prioritizes eco-friendly transportation options and works with carriers that adhere to sustainability practices.

-

Predictive Analytics: The company uses predictive analytics to forecast demand and optimize capacity planning, reducing excess inventory and transportation costs.

-

Supplier Collaboration: Unilever collaborates with suppliers to align production schedules and transportation capacity, enhancing overall supply chain efficiency.

-

Continuous Improvement: The company regularly reviews its logistics processes and metrics to identify areas for improvement and implement best practices.

Case Study: FedEx

FedEx is a leader in logistics and freight capacity management:

-

Advanced Technology Solutions: FedEx employs advanced technology for real-time tracking, route optimization, and load planning.

-

Dynamic Capacity Management: The company utilizes a combination of dedicated and contracted capacity to ensure flexibility in meeting customer demands.

-

Data-Driven Insights: FedEx leverages data analytics to monitor performance metrics, assess carrier effectiveness, and optimize transportation costs.

-

Customer-Centric Approach: The company focuses on understanding customer needs and preferences, allowing for tailored logistics solutions that enhance service levels.

These case studies illustrate how companies across various industries implement freight capacity management strategies to optimize their logistics operations. By leveraging technology, data analytics, collaboration, and continuous improvement, these organizations can enhance their capacity management processes, reduce costs, and improve customer satisfaction.

Through effective freight capacity management, companies can navigate the complexities of modern logistics, adapt to changing market conditions, and maintain a competitive edge in their respective industries. The ongoing evolution of freight capacity management practices and technologies will continue to shape the future of supply chain operations, enabling organizations to achieve greater efficiency and sustainability.