What Mode of Transportation Is Covered for Hazardous Materials

What are hazardous materials and why is their transportation regulated?

Hazardous materials, often referred to as hazmat, are substances or materials that pose risks to health, safety, property, or the environment during transportation. These materials can be in various forms – liquids, solids, gases, or even energy-releasing substances. The U.S. Department of Transportation (DOT) defines hazardous materials as those capable of posing an unreasonable risk to health, safety, and property when transported in commerce.

The transportation of hazardous materials is heavily regulated due to the potential dangers they present. A single incident involving hazardous materials can have catastrophic consequences, including loss of life, environmental damage, and significant economic impacts. Regulations aim to minimize these risks and ensure safe transport across various modes.

Types of Hazardous Materials

The DOT classifies hazardous materials into nine primary classes:

Class 1: Explosives

Materials that can explode, deflagrate, or produce pyrotechnic effects.

Class 2: Gases

Compressed, liquefied, or dissolved under pressure gases.

Class 3: Flammable Liquids

Liquids with a flash point of 60°C (140°F) or lower.

Class 4: Flammable Solids

Solids that can easily ignite or contribute to fire through friction.

Class 5: Oxidizing Substances and Organic Peroxides

Materials that yield oxygen, potentially causing or enhancing combustion.

Class 6: Toxic and Infectious Substances

Materials that can cause death or serious injury if swallowed, inhaled, or contacted.

Class 7: Radioactive Materials

Substances that emit ionizing radiation.

Class 8: Corrosive Substances

Materials that can destroy living tissue or corrode metals.

Class 9: Miscellaneous Hazardous Materials

Materials that present a hazard during transport but do not meet the criteria of other classes.

Regulatory Framework

The transportation of hazardous materials in the United States is primarily governed by the Hazardous Materials Transportation Act (HMTA). This act gives the DOT the authority to regulate the movement of hazardous materials across all modes of transportation. The Pipeline and Hazardous Materials Safety Administration (PHMSA), an agency within the DOT, is responsible for developing and enforcing regulations.

Key regulations include:

49 CFR Parts 100-185

These parts of the Code of Federal Regulations contain the Hazardous Materials Regulations (HMR), which detail requirements for classification, packaging, hazard communication, and transportation of hazardous materials.

International Regulations

For international transport, additional regulations come into play:

- International Maritime Dangerous Goods (IMDG) Code for sea transport

- International Civil Aviation Organization (ICAO) Technical Instructions for air transport

- European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) for road transport in Europe

Importance of Regulation

Regulation of hazardous materials transportation serves several critical purposes:

Safety

Regulations establish standards for packaging, handling, and transporting hazardous materials to minimize the risk of accidents or releases.

Emergency Response

Proper labeling and documentation requirements ensure that emergency responders can quickly identify hazards and take appropriate action in case of an incident.

Environmental Protection

Regulations aim to prevent spills or releases that could harm ecosystems or contaminate water sources.

Public Health

By controlling the movement of toxic or infectious substances, regulations protect public health from potential exposures.

Economic Considerations

While regulations impose costs on shippers and carriers, they also prevent costly accidents and ensure the smooth flow of essential materials.

The transportation of hazardous materials is an essential part of many industries, from manufacturing to healthcare. Effective regulation ensures that these materials can be moved safely and efficiently, balancing the needs of commerce with the imperative of public and environmental safety.

How is road transportation used for hazardous materials?

Road transportation plays a crucial role in the movement of hazardous materials, offering flexibility and accessibility that other modes often cannot match. Trucks can reach almost any destination, making them indispensable for last-mile delivery and for transporting hazardous materials to and from facilities not served by rail or waterways.

Types of Road Vehicles Used

![]()

Several types of vehicles are employed in the road transportation of hazardous materials:

Tank Trucks

Used for transporting liquids and gases. These can be pressurized or non-pressurized, depending on the material being carried.

Box Trucks

Suitable for transporting packaged hazardous materials, often used for smaller quantities or mixed loads.

Flatbed Trucks

Used for large containers or oversized hazardous materials that require special handling.

Specialized Vehicles

Some hazardous materials require custom-designed vehicles, such as those used for transporting radioactive materials or explosives.

Key Considerations for Road Transport

Route Selection

Carriers must carefully plan routes to avoid populated areas, sensitive environmental zones, and areas with challenging road conditions when possible. Some jurisdictions have designated hazardous materials routes.

Driver Qualifications

Drivers transporting hazardous materials must have a Commercial Driver’s License (CDL) with a hazardous materials endorsement. This requires additional training and background checks.

Vehicle Placarding

Vehicles carrying hazardous materials must display appropriate placards indicating the nature of the hazard. This is crucial for emergency responders in case of an incident.

Documentation

Proper shipping papers must accompany all hazardous materials shipments, detailing the materials being transported and emergency response information.

Loading and Unloading

Special procedures are often required for loading and unloading hazardous materials to prevent spills or accidents.

Advantages of Road Transportation for Hazardous Materials

Flexibility

Trucks can adapt to changing routes or schedules more easily than other modes of transportation.

Door-to-Door Service

Road transport can often provide direct service from origin to destination without the need for intermodal transfers.

Speed for Short to Medium Distances

For shorter distances, road transport is often faster than rail or water alternatives.

Capacity for Smaller Shipments

Road transport is well-suited for smaller quantities of hazardous materials that might not be economical to ship by rail or sea.

Challenges in Road Transportation of Hazardous Materials

Traffic Congestion

Delays due to traffic can increase the time hazardous materials are in transit, potentially increasing risk.

Weather Conditions

Road transport is vulnerable to adverse weather conditions, which can increase the risk of accidents.

Infrastructure Limitations

Poor road conditions or weight restrictions on bridges can complicate route planning.

Public Perception

The visible presence of hazardous materials on public roads can lead to public concern and opposition to certain routes.

Regulatory Compliance for Road Transport

Road transportation of hazardous materials in the United States is primarily regulated by the Department of Transportation (DOT) through the Federal Motor Carrier Safety Administration (FMCSA) and the Pipeline and Hazardous Materials Safety Administration (PHMSA).

Key regulations include:

49 CFR Part 397

This part of the Code of Federal Regulations outlines transportation of hazardous materials by highway, including routing requirements and driver training.

Hours of Service Regulations

These rules limit the number of hours a driver can operate a vehicle, which is particularly important for hazardous materials transport where driver fatigue can have severe consequences.

Vehicle Inspection Requirements

Vehicles transporting hazardous materials are subject to more frequent and rigorous inspections.

Emergency Response Preparedness

Carriers must have plans in place for responding to accidents or spills involving hazardous materials.

Future Trends in Road Transportation of Hazardous Materials

Technology Integration

The use of GPS tracking, real-time monitoring, and electronic logging devices is increasing, improving safety and efficiency.

Alternative Fuels

There’s growing interest in using alternative fuels for hazardous materials transport to reduce environmental impact.

Autonomous Vehicles

While still in early stages, autonomous vehicle technology could potentially revolutionize hazardous materials transport by road.

Road transportation remains a critical component in the movement of hazardous materials. Its flexibility and accessibility make it indispensable, particularly for smaller shipments and last-mile delivery. However, the unique risks associated with transporting hazardous materials on public roads necessitate stringent regulations and careful planning to ensure safety for drivers, the public, and the environment.

What role does rail play in hazardous materials transportation?

Rail transportation plays a significant role in the movement of hazardous materials, particularly for large volume shipments over long distances. The rail system’s ability to handle bulk quantities efficiently makes it an attractive option for many shippers of hazardous materials.

Types of Rail Cars Used for Hazardous Materials

Several specialized types of rail cars are used for transporting hazardous materials:

Tank Cars

These are the most common type used for liquid and gaseous hazardous materials. They come in various designs, including pressurized and non-pressurized versions.

Hopper Cars

Used for dry bulk hazardous materials such as certain chemicals or minerals.

Box Cars

Employed for packaged hazardous materials or those requiring protection from the elements.

Flat Cars

Used for large containers or oversized hazardous materials that don’t fit in standard rail cars.

Advantages of Rail Transportation for Hazardous Materials

Large Capacity

A single train can transport the equivalent of hundreds of truckloads, making it efficient for large volume shipments.

Energy Efficiency

Rail transport is generally more fuel-efficient than road transport, particularly for long-distance shipments.

Safety Record

Statistically, rail has a lower accident rate per ton-mile than road transport, which can be particularly important for hazardous materials.

Reduced Traffic Congestion

Rail transport helps keep hazardous materials off highways, reducing road congestion and the associated risks.

Long-Distance Capability

Trains can cover long distances without the need for driver rest periods, making them efficient for cross-country transport.

Challenges in Rail Transportation of Hazardous Materials

Fixed Infrastructure

Rail transport is limited to existing track networks, which may not reach all desired destinations.

Scheduling and Transit Times

Rail shipments often have less flexible schedules than truck shipments and may take longer due to switching and classification operations.

Intermodal Transfers

Many rail shipments require truck transport at one or both ends, introducing additional handling and potential risk.

Public Concern

High-profile rail accidents involving hazardous materials have led to increased public scrutiny and concern.

Regulatory Framework for Rail Hazmat Transport

Rail transportation of hazardous materials in the United States is regulated primarily by the Department of Transportation (DOT) through the Federal Railroad Administration (FRA) and the Pipeline and Hazardous Materials Safety Administration (PHMSA).

Key regulations include:

49 CFR Part 174

This part of the Code of Federal Regulations specifically addresses carriage of hazardous materials by rail.

HM-251 Rule

This rule, implemented in 2015, introduced enhanced standards for certain flammable liquid shipments by rail, including improved tank car designs.

Positive Train Control (PTC)

This advanced system for monitoring and controlling train movements is required on many rail lines carrying hazardous materials.

Rail Routing Regulations

Carriers must analyze safety and security risks along rail routes used for certain hazardous materials and select the safest and most secure routes.

Key Safety Measures in Rail Hazmat Transport

Tank Car Design

Continuous improvements in tank car design, including stronger shells and enhanced protection features, have increased safety.

Train Composition

Regulations dictate how trains carrying hazardous materials should be assembled, including the placement of buffer cars.

Speed Restrictions

Trains carrying certain hazardous materials are subject to speed restrictions, particularly in high-threat urban areas.

Emergency Response Information

Detailed information about the hazardous materials being transported must be readily available to train crews and emergency responders.

Track Maintenance and Inspection

Rigorous track inspection and maintenance programs are crucial for preventing derailments.

Future Trends in Rail Hazmat Transportation

Enhanced Monitoring Technology

Increased use of sensors and real-time monitoring systems to detect potential issues before they lead to accidents.

Automated Inspection Systems

Development of automated systems for inspecting rail cars and tracks to improve safety and efficiency.

Alternative Fuel Locomotives

Exploration of cleaner fuel options for locomotives to reduce environmental impact.

Risk-Based Routing

More sophisticated analysis of route risks to optimize safety and security in hazardous materials transport.

Rail transportation continues to be a crucial mode for moving large quantities of hazardous materials across long distances. Its efficiency and relatively strong safety record make it an attractive option for many shippers. However, the potential consequences of a rail accident involving hazardous materials necessitate ongoing efforts to enhance safety measures and improve emergency response capabilities. As technology advances and regulations evolve, the rail industry is likely to see continued improvements in the safe and efficient transport of hazardous materials.

How are hazardous materials transported by air?

Air transportation of hazardous materials, while less common than road or rail, plays a crucial role in the global movement of certain types of dangerous goods. The speed of air transport makes it particularly valuable for time-sensitive shipments, including some hazardous materials.

Types of Air Transport for Hazardous Materials

Cargo Aircraft

Dedicated cargo planes are the primary means of transporting hazardous materials by air. These aircraft are designed to handle a wide range of cargo types and can accommodate larger quantities of hazardous materials.

Passenger Aircraft

Some hazardous materials are permitted on passenger aircraft, but in limited quantities and under strict conditions. These are typically carried in the cargo hold, not in the passenger cabin.

Advantages of Air Transport for Hazardous Materials

Speed

Air transport is the fastest mode for long-distance shipments, crucial for time-sensitive materials.

Global Reach

Air transport can reach almost any part of the world, often more quickly than other modes.

Security

Airport and airline security measures provide an additional layer of protection for hazardous materials shipments.

Reduced Handling

Long-distance air shipments often require less handling and fewer transfers than other modes, potentially reducing risk.

Challenges in Air Transport of Hazardous Materials

Quantity Limitations

Strict limits on the quantities of hazardous materials that can be carried on aircraft, particularly passenger planes.

Pressurization and Temperature Concerns

The pressurized environment and temperature fluctuations in aircraft can affect certain hazardous materials.

Cost

Air transport is generally more expensive than other modes, limiting its use to high-value or time-critical shipments.

Public Perception

Concerns about the safety of transporting hazardous materials on aircraft, especially passenger planes.

Regulatory Framework for Air Transport of Hazardous Materials

Air transport of hazardous materials is subject to both national and international regulations:

ICAO Technical Instructions

The International Civil Aviation Organization (ICAO) Technical Instructions for the Safe Transport of Dangerous Goods by Air serve as the global standard.

IATA Dangerous Goods Regulations

The International Air Transport Association (IATA) publishes these regulations, which are based on the ICAO Technical Instructions but may be more restrictive.

49 CFR Parts 171-180

In the United States, these parts of the Code of Federal Regulations govern hazardous materials transport, including by air.

Key Considerations for Air Transport of Hazardous Materials

Classification and Identification

Proper classification of hazardous materials is crucial for air transport, as it determines packaging, labeling, and quantity limitations.

Packaging

Specialized packaging is often required for air transport to withstand pressure changes and protect against leakage.

Documentation

Detailed documentation, including the Shipper’s Declaration for Dangerous Goods, must accompany hazardous materials shipments.

Training

Personnel involved in preparing or handling hazardous materials for air transport must undergo specific training.

Passenger Notification

When hazardous materials are carried on passenger aircraft, the pilot-in-command must be informed.

Limitations and Prohibitions

Some hazardous materials are completely prohibited from air transport, while others face significant restrictions:

Forbidden Materials

Certain extremely dangerous materials, such as unstable explosives or infectious substances of the highest risk group, are forbidden on aircraft under any circumstances.

Cargo Aircraft Only

Many hazardous materials are restricted to cargo aircraft and prohibited on passenger planes.

State and Operator Variations

Individual countries and airlines may impose additional restrictions beyond the international regulations.

Future Trends in Air Transport of Hazardous Materials

Enhanced Screening Technologies

Development of more sophisticated detection and screening methods for hazardous materials at airports.

Data Sharing and Tracking

Improved systems for real-time tracking and information sharing about hazardous materials shipments.

Sustainable Packaging

Research into more environmentally friendly packaging solutions that still meet safety requirements.

Automation in HandlingExploration of automated systems for handling hazardous materials at airports to reduce human error and increase efficiency.

Drone Delivery

Potential use of drones for transporting small quantities of hazardous materials, particularly in remote or hard-to-reach areas.

Air transport of hazardous materials, while subject to strict regulations and limitations, remains an essential component of the global supply chain for certain types of dangerous goods. Its speed and global reach make it invaluable for time-sensitive shipments, but the unique challenges of the aviation environment necessitate careful planning, packaging, and handling. As technology advances and regulations evolve, the air transport industry continues to work towards enhancing safety and efficiency in the movement of hazardous materials.

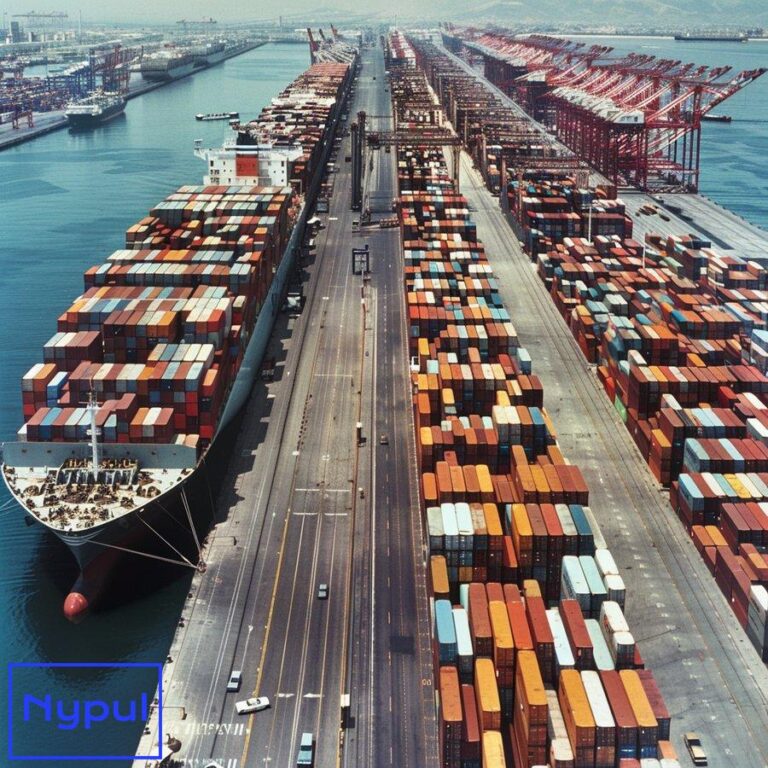

What are the key considerations for maritime hazardous materials transport?

Maritime transport plays a crucial role in the global movement of hazardous materials, handling large volumes over long distances. This mode of transportation is particularly important for international trade and the transport of bulk chemicals and petroleum products.

Types of Vessels Used for Hazardous Materials

Chemical Tankers

Specialized vessels designed to transport a wide range of liquid chemicals. They often have multiple segregated tanks to carry different products simultaneously.

Oil Tankers

Used for transporting crude oil and refined petroleum products. These range from small coastal tankers to massive supertankers.

Container Ships

Carry hazardous materials in specialized containers, allowing for the transport of a diverse range of packaged dangerous goods.

Gas Carriers

Designed to transport liquefied gases such as LNG (Liquefied Natural Gas) or LPG (Liquefied Petroleum Gas) under high pressure or low temperature.

Bulk Carriers

Used for solid hazardous materials in bulk form, such as certain ores or chemicals.

Advantages of Maritime Transport for Hazardous Materials

Large Capacity

Ships can transport enormous quantities of hazardous materials in a single voyage, making it highly efficient for bulk shipments.

Cost-Effectiveness

For long-distance international transport, maritime shipping is often the most economical option.

Environmental Efficiency

On a per-ton-mile basis, ships generally have a lower carbon footprint compared to other modes of transport.

Reduced Population Exposure

Ocean transport keeps hazardous materials away from populated areas for much of the journey.

Challenges in Maritime Hazardous Materials Transport

Weather and Sea Conditions

Ships are exposed to potentially severe weather conditions, which can pose risks to hazardous cargo.

Piracy and Security Concerns

In some parts of the world, ships carrying valuable or dangerous cargo may be targets for piracy.

Environmental Risks

A maritime accident involving hazardous materials can have severe and wide-ranging environmental impacts.

Long Transit Times

Maritime transport is generally slower than other modes, which can be a concern for time-sensitive materials.

Regulatory Framework for Maritime Hazmat Transport

Maritime transport of hazardous materials is governed by both international and national regulations:

IMDG Code

The International Maritime Dangerous Goods (IMDG) Code, developed by the International Maritime Organization (IMO), is the primary global standard for maritime transport of hazardous materials.

SOLAS Convention

The International Convention for the Safety of Life at Sea (SOLAS) includes provisions related to the carriage of dangerous goods.

MARPOL Convention

The International Convention for the Prevention of Pollution from Ships (MARPOL) addresses pollution prevention and response.

National Regulations

Individual countries may have additional regulations governing the transport of hazardous materials in their waters.

Key Safety Measures in Maritime Hazmat Transport

Vessel Design and Construction

Ships carrying hazardous materials must meet specific design criteria, including double hulls for many tankers.

Segregation and Stowage

Proper segregation of incompatible materials and careful stowage to prevent shifting or damage during transit.

Crew Training

Specialized training for crew members on handling hazardous materials and emergency response procedures.

Emergency Response Equipment

Ships must carry appropriate firefighting and spill response equipment based on the materials being transported.

Vessel Traffic Services

Many busy waterways have monitoring systems to help prevent collisions and other incidents.

Future Trends in Maritime Hazmat Transportation

Autonomous Vessels

Development of autonomous or semi-autonomous ships could potentially improve safety and efficiency.

Alternative Fuels

Exploration of cleaner fuel options for ships to reduce environmental impact.

Enhanced Monitoring Systems

Implementation of more sophisticated real-time monitoring of cargo conditions and vessel performance.

Improved Container Design

Development of smarter, safer containers for transporting hazardous materials.

Maritime transport of hazardous materials, while facing unique challenges, remains a cornerstone of global trade in dangerous goods. Its ability to move large volumes efficiently over long distances makes it indispensable for many industries. However, the potential for significant environmental impact in case of an accident necessitates ongoing efforts to enhance safety measures, improve vessel design, and refine regulatory frameworks. As technology advances and environmental concerns grow, the maritime industry is likely to see continued evolution in how hazardous materials are transported across the world’s oceans.

How does intermodal transportation handle hazardous materials?

Intermodal transportation, which involves the use of two or more modes of transport in a single journey, plays a significant role in the efficient movement of hazardous materials across long distances and varied terrains. This approach combines the strengths of different transportation modes to optimize the overall shipping process.

Key Components of Intermodal Hazmat Transport

Containers

Specialized intermodal containers designed for hazardous materials ensure consistent containment across different modes of transport.

Transfer Points

Facilities where hazardous materials are transferred between modes, such as ports or rail yards, require specific safety measures and equipment.

Documentation

Comprehensive and consistent documentation is crucial as the shipment moves across different modes and potentially different jurisdictions.

Tracking Systems

Advanced tracking technologies allow for real-time monitoring of hazardous materials throughout the intermodal journey.

Advantages of Intermodal Transport for Hazardous Materials

Efficiency

Combines the strengths of different modes (e.g., the flexibility of trucks with the long-distance capacity of ships or trains).

Cost-Effectiveness

Can reduce overall transportation costs by optimizing the use of each mode.

Reduced Handling

Use of standardized containers minimizes the need to handle the hazardous materials directly during mode transfers.

Flexibility

Allows for adaptation to various geographic and infrastructure constraints.

Challenges in Intermodal Hazmat Transport

Coordination

Requires careful coordination between different carriers, modes, and regulatory regimes.

Transfer Risks

Each transfer point introduces potential risks of accidents or releases.

Regulatory Complexity

Must comply with regulations for each mode of transport used, which can vary.

Equipment Compatibility

Ensuring that containers and handling equipment are compatible across all modes used.

Common Intermodal Combinations for Hazardous Materials

Truck-Rail

Often used for long-distance domestic transport, combining the flexibility of trucks for pickup and delivery with the efficiency of rail for long hauls.

Truck-Ship

Frequently employed for international transport, with trucks handling inland transport and ships covering ocean segments.

Rail-Ship

Used for bulk hazardous materials moving between inland production or consumption points and coastal ports.

Truck-Air

While less common due to air transport restrictions, this combination is used for time-sensitive hazardous materials over long distances.

Regulatory Considerations in Intermodal Hazmat Transport

Intermodal transport of hazardous materials must comply with regulations for each mode used:

International Regulations

– IMDG Code for maritime segments

– IATA Dangerous Goods Regulations for air segments

– RID regulations for international rail transport in Europe

National Regulations

– In the U.S., 49 CFR governs hazardous materials transport across all modes

– Individual countries may have additional regulations for specific modes or materials

Safety Measures in Intermodal Hazmat Transport

Container Inspection

Rigorous inspection of containers at each transfer point to ensure integrity.

Secure Sealing

Use of tamper-evident seals to maintain security throughout the journey.

Emergency Response Planning

Comprehensive plans that account for potential incidents at any point in the intermodal journey.

Training

Specialized training for personnel involved in handling and transferring hazardous materials containers.

Future Trends in Intermodal Hazmat Transportation

Blockchain Technology

Potential use of blockchain for secure, transparent documentation and tracking across the entire intermodal journey.

IoT and Smart Containers

Development of containers with built-in sensors to monitor conditions and detect potential issues in real-time.

Automated Transfer Systems

Exploration of automated systems for transferring hazardous materials containers between modes to reduce human error.

Standardization Efforts

Ongoing work to further standardize container designs and handling procedures across different modes and regions.

Intermodal transportation of hazardous materials offers a flexible and efficient approach to moving these critical but dangerous goods across long distances and varied terrains. By leveraging the strengths of different transportation modes, it can optimize the balance between safety, cost, and speed. However, the complexity of coordinating across multiple modes and regulatory regimes presents unique challenges. As technology advances and global trade continues to grow, the intermodal approach to hazardous materials transport is likely to become increasingly sophisticated, with a focus on enhancing safety, improving efficiency, and reducing environmental impact.

What safety measures and compliance regulations govern hazardous materials transport?

The transportation of hazardous materials is subject to a complex web of safety measures and compliance regulations designed to protect public safety, worker health, and the environment. These regulations cover all aspects of hazardous materials transport, from packaging and labeling to route selection and emergency response.

Key Regulatory Bodies

United States

– Department of Transportation (DOT)

– Pipeline and Hazardous Materials Safety Administration (PHMSA)

– Federal Motor Carrier Safety Administration (FMCSA)

– Federal Railroad Administration (FRA)

– Federal Aviation Administration (FAA)

– United States Coast Guard (USCG)

International

– United Nations (UN) Committee of Experts on the Transport of Dangerous Goods

– International Maritime Organization (IMO)

– International Civil Aviation Organization (ICAO)

– International Air Transport Association (IATA)

Core Regulations

United States

– 49 CFR Parts 100-185: Hazardous Materials Regulations (HMR)

– 29 CFR 1910.120: OSHA Hazardous Waste Operations and Emergency Response (HAZWOPER)

International

– UN Recommendations on the Transport of Dangerous Goods (Orange Book)

– International Maritime Dangerous Goods (IMDG) Code

– ICAO Technical Instructions for the Safe Transport of Dangerous Goods by Air

– European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR)

Key Safety Measures

Classification and Identification

Proper classification of hazardous materials is crucial for determining appropriate handling, packaging, and transport requirements.

Packaging

Regulations specify packaging requirements based on the hazard class and quantity of the material.

Marking and Labeling

Clear and standardized markings and labels are required to communicate the nature of the hazard.

Placarding

Vehicles and containers must display appropriate placards to indicate the presence and type of hazardous materials.

Documentation

Detailed shipping papers must accompany all hazardous materials shipments, providing crucial information for handlers and emergency responders.

Training

Personnel involved in handling, preparing, or transporting hazardous materials must undergo specific training.

Security Plans

Shippers and carriers of certain high-risk materials must develop and implement security plans.

Emergency Response Information

Specific information and procedures for handling emergencies must be readily available.

Incident Reporting

Any incidents involving the release of hazardous materials must be reported to the appropriate authorities.

Mode-Specific Safety Measures

Road Transport

– Driver qualification requirements

– Route restrictions

– Vehicle inspection requirements

Rail Transport

– Tank car design standards

– Train composition rules

– Track inspection and maintenance requirements

Maritime Transport

– Vessel design requirements (e.g., double hulls for tankers)

– Stowage and segregation rules

– Marine pollutant designations

Air Transport

– Quantity limitations

– Pressure-resistant packaging requirements

– Passenger notification procedures

Compliance Requirements

Registration

Companies that transport certain types or quantities of hazardous materials must register with the DOT.

Permits

Special permits may be required for the transportation of certain high-risk materials.

Record Keeping

Detailed records of training, shipping papers, and incident reports must be maintained.

Inspections

Carriers and facilities handling hazardous materials are subject to regular inspections by regulatory agencies.

Hazard Communication

Information about the hazards of materials must be communicated to workers and emergency responders.

Future Trends in Safety and Compliance

Risk-Based Approaches

Movement towards more flexible, risk-based regulations that adapt to specific circumstances.

Technology Integration

Increased use of electronic tracking, real-time monitoring, and automated compliance systems.

Harmonization Efforts

Ongoing work to harmonize regulations across different countries and modes of transport.

Enhanced Emergency Response

Development of more sophisticated emergency response systems and technologies.

Sustainability Considerations

Growing focus on balancing safety requirements with environmental sustainability goals.

The safety measures and compliance regulations governing hazardous materials transport form a comprehensive framework designed to minimize risks associated with these potentially dangerous substances. While these regulations can be complex and demanding, they are crucial for protecting public safety, worker health, and the environment. As technology advances and our understanding of risks evolves, these regulations and safety measures continue to be refined and updated. Compliance with these regulations requires ongoing attention and commitment from all parties involved in the hazardous materials supply chain, from manufacturers and shippers to carriers and receivers.

How do different modes of transportation compare in hazardous materials handling?

The handling of hazardous materials varies significantly across different modes of transportation, each with its own strengths, limitations, and specific safety considerations. Understanding these differences is crucial for selecting the most appropriate mode for a given hazardous materials shipment.

Comparison Table: Hazardous Materials Handling by Transportation Mode

| Aspect | Road | Rail | Maritime | Air |

|---|---|---|---|---|

| Capacity | Medium | High | Very High | Low |

| Speed | Medium | Medium | Low | Very High |

| Flexibility | High | Low | Low | Medium |

| Cost | Medium | Low | Very Low | High |

| Safety Record | Good | Very Good | Good | Excellent |

| Environmental Impact | Medium | Low | Very Low | High |

| Regulatory Complexity | Medium | High | High | Very High |

Road Transportation

Strengths

– High flexibility in routing and scheduling

– Door-to-door service capability

– Suitable for small to medium shipments

Limitations

– Limited capacity compared to rail or maritime

– Higher accident rate per ton-mile

– Vulnerable to traffic congestion and weather conditions

Safety Considerations

– Driver qualifications and training

– Vehicle placarding and inspection

– Route selection and restrictions

Rail Transportation

Strengths

– High capacity for long-distance bulk shipments

– Good safety record per ton-mile

– Energy efficient for large volumes

Limitations

– Limited flexibility due to fixed rail networks

– Potential for high-impact accidents

Safety Considerations

– Tank car design and integrity

– Track maintenance and inspection

– Train composition and speed restrictions

Maritime Transportation

Strengths

– Very high capacity for international bulk shipments

– Cost-effective for long distances

– Low environmental impact per ton-mile

Limitations

– Slow transit times

– Limited to coastal and inland waterway locations

– Potential for large-scale environmental impact in case of accidents

Safety Considerations

– Vessel design (e.g., double hulls for tankers)

– Stowage and segregation of incompatible materials

– Weather and sea condition management

Air Transportation

Strengths

– Very high speed for long-distance transport

– Global reach

– High security environment

Limitations

– Very limited capacity

– High cost

– Strict limitations on types and quantities of hazardous materials

Safety Considerations

– Pressurization and temperature control

– Packaging requirements for air transport

– Quantity limitations, especially on passenger aircraft

Intermodal Considerations

Intermodal transportation, which combines two or more modes, aims to leverage the strengths of each mode while mitigating their limitations. Key considerations for intermodal hazmat transport include:

- Consistency in container design and integrity across modes

- Efficient and safe transfer procedures at intermodal points

- Coordinated documentation and tracking across the entire journey

Factors Influencing Mode Selection

Nature of the Material

The physical state, hazard class, and quantity of the material significantly influence mode selection.

Distance and Geography

Long-distance international shipments often favor maritime transport, while domestic shipments might use road or rail.

Urgency

Time-sensitive materials may require air transport despite its limitations and higher cost.

Infrastructure Availability

The presence or absence of suitable ports, airports, or rail connections can dictate mode choice.

Cost Considerations

Budget constraints may influence the choice between faster, more expensive modes and slower, more economical options.

Regulatory Requirements

Some materials may be prohibited or severely restricted on certain modes, particularly air transport.

Environmental Concerns

Increasing focus on reducing carbon footprints may favor rail or maritime transport for suitable shipments.

Safety Performance Comparison

While all modes strive for high safety standards, their performance in hazardous materials handling can vary:

Road

Generally has a higher accident rate per ton-mile, but incidents tend to be smaller in scale.

Rail

Has a lower accident rate than road, but incidents can potentially affect larger quantities of materials.

Maritime

Accidents are relatively rare but can have severe environmental consequences, especially in coastal areas.

Air

Has an excellent safety record, but the potential consequences of an air incident involving hazardous materials are severe.

Future Trends Affecting Mode Comparison

Technological Advancements

Developments in areas like autonomous vehicles, smart containers, and real-time monitoring systems may alter the safety and efficiency profiles of different modes.

Regulatory Evolution

Ongoing efforts to harmonize regulations across modes and international boundaries may reduce some of the current complexities in mode selection.

Sustainability Pressures

Increasing emphasis on reducing environmental impact may shift preferences towards more energy-efficient modes like rail and maritime for suitable shipments.

Infrastructure Development

Investments in transportation infrastructure may change the relative advantages of different modes in specific regions.

The selection of transportation mode for hazardous materials requires careful consideration of multiple factors, balancing safety, efficiency, cost, and regulatory compliance. Each mode offers distinct advantages and faces unique challenges in handling hazardous materials. As technology advances and regulations evolve, the comparative strengths and limitations of different modes may shift, necessitating ongoing reassessment of transportation strategies for hazardous materials. Ultimately, the goal remains constant: to ensure the safe, efficient, and compliant movement of these essential but potentially dangerous goods across the global supply chain.