What Are the Different Types of Shipping Trucks

What are shipping trucks and why are they important?

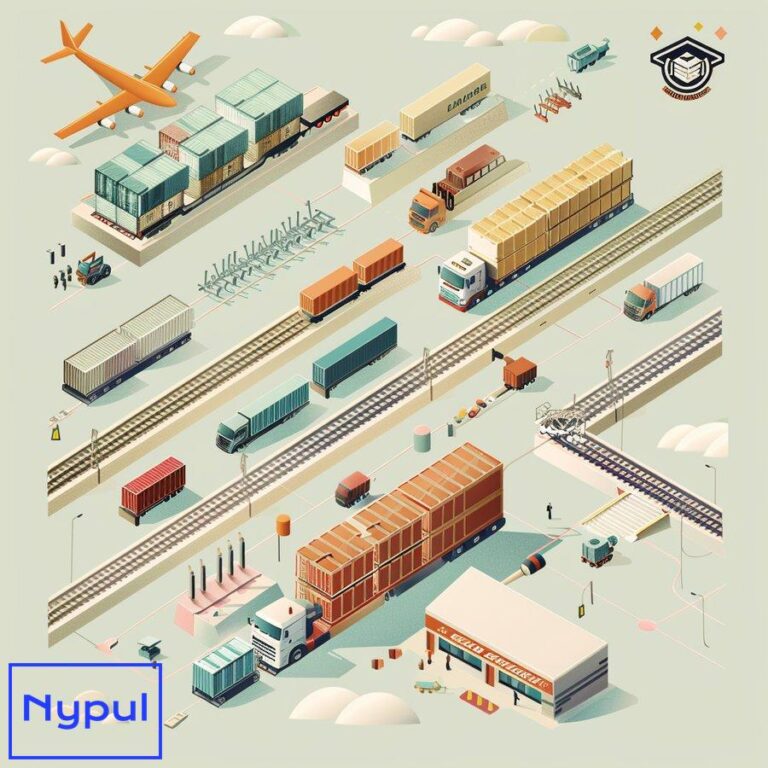

Shipping trucks form the backbone of modern logistics and supply chains. These specialized vehicles transport goods and materials across local, regional, and national networks, playing a crucial role in keeping economies moving.

At their core, shipping trucks are commercial vehicles designed to haul cargo. They come in a wide variety of types and configurations to accommodate different freight needs. From small box trucks making local deliveries to massive semi-trucks traversing highways, shipping trucks enable the efficient movement of goods from manufacturers and suppliers to distributors, retailers, and end consumers.

The importance of shipping trucks in today’s interconnected global economy cannot be overstated. They provide several key benefits:

Flexibility and accessibility

Trucks can reach virtually any destination with road access, allowing door-to-door delivery of goods. This flexibility is unmatched by other transportation modes like rail or air freight.

Cost-effectiveness

For many types of shipments, especially over short to medium distances, trucking offers the most economical transportation option. The ability to consolidate multiple shipments and make multiple stops along a route improves efficiency.

Speed

Trucks can often deliver goods faster than other modes, especially for regional shipments. They don’t require transfers between different vehicles or modes, reducing transit times.

Capacity

Modern shipping trucks can haul significant volumes and weights of cargo. A single semi-truck can transport up to 80,000 pounds of freight.

Reliability

Trucking companies can offer consistent, scheduled services to meet just-in-time delivery needs. Weather and traffic delays tend to have less impact compared to air or rail transport.

Economic impact

The trucking industry is a major employer and economic driver. In the U.S. alone, trucking provides over 7 million jobs and moves over 70% of all freight tonnage.

To illustrate the scale and impact of shipping trucks, consider these key statistics:

| Statistic | Value |

|---|---|

| Annual U.S. truck freight tonnage | 11.84 billion tons |

| Percentage of U.S. communities relying exclusively on trucks for goods | 80% |

| Number of registered large trucks in the U.S. | 13.5 million |

| Annual truck border crossings between U.S., Canada, and Mexico | 12.2 million |

| Average length of haul for U.S. trucking | 297 miles |

The versatility of shipping trucks allows them to serve diverse industries and cargo types. From transporting fresh produce to delivering industrial machinery, trucks adapt to meet specific freight requirements. This adaptability is crucial for supporting complex supply chains and the ever-growing e-commerce sector.

Environmental considerations are also driving innovation in the shipping truck industry. Manufacturers are developing more fuel-efficient engines, exploring alternative fuels like natural gas and electricity, and implementing aerodynamic designs to reduce emissions and operating costs.

As global trade continues to expand and consumer expectations for rapid delivery intensify, the role of shipping trucks in logistics networks will only grow in importance. Their ability to provide flexible, efficient, and cost-effective transportation solutions ensures that shipping trucks will remain a critical component of the global supply chain for years to come.

How do different types of shipping trucks serve various cargo needs?

The diverse landscape of shipping and logistics demands a wide array of specialized vehicles to efficiently transport different types of cargo. Each type of shipping truck is designed to address specific freight requirements, ensuring that goods are transported safely, securely, and in compliance with relevant regulations. Let’s explore the main categories of shipping trucks and how they cater to various cargo needs:

Dry van trucks

These are the workhorses of the trucking industry, featuring enclosed trailers that protect cargo from the elements. Dry vans are versatile and can transport a wide range of packaged goods, from clothing and electronics to non-perishable foods.

Key features:

– Standard dimensions: 53 feet long, 8.5 feet wide, 9 feet tall

– Capacity: Up to 45,000 pounds

– Ideal for: Palletized goods, boxed items, and general freight

Refrigerated trucks (Reefers)

Equipped with temperature-controlled trailers, reefers are essential for transporting perishable goods that require consistent temperatures during transit.

Key features:

– Temperature range: -20°F to 70°F

– Advanced climate control systems

– Ideal for: Fresh produce, dairy products, pharmaceuticals, and frozen foods

Flatbed trucks

These open-deck trucks are designed for oversized or oddly shaped cargo that doesn’t fit in enclosed trailers. They offer easy loading and unloading from the sides and top.

Key features:

– No height restrictions (except legal road limits)

– Easily accommodates tarps for weather protection

– Ideal for: Construction materials, machinery, and large industrial equipment

Tanker trucks

Specialized for transporting liquids and gases, tanker trucks come in various configurations to handle different types of fluid cargo.

Key features:

– Pressurized or non-pressurized tanks

– Multiple compartments for different liquids

– Ideal for: Fuel, chemicals, milk, and liquid food products

Lowboy trucks

Featuring a dropped deck, lowboy trucks are designed to transport tall and heavy equipment while staying within legal height restrictions.

Key features:

– Low deck height: typically 18-24 inches off the ground

– High weight capacity: up to 80,000 pounds

– Ideal for: Construction equipment, large vehicles, and industrial machinery

Container trucks

These trucks are equipped to transport standardized shipping containers, facilitating intermodal transport between ships, trains, and trucks.

Key features:

– Compatible with 20-foot and 40-foot containers

– Specialized chassis for easy loading/unloading

– Ideal for: International shipments and long-distance domestic freight

Dump trucks

Designed for easy unloading of loose materials, dump trucks feature a hydraulic lift mechanism to tilt the cargo bed.

Key features:

– Reinforced beds to withstand heavy, abrasive materials

– Various configurations (end dump, side dump, bottom dump)

– Ideal for: Construction materials, gravel, sand, and agricultural products

Livestock trucks

These specialized vehicles are designed to safely transport live animals, providing ventilation and sometimes feeding and watering systems.

Key features:

– Multiple levels for different animal sizes

– Proper ventilation and climate control

– Ideal for: Cattle, pigs, sheep, and other farm animals

Car carrier trucks

Also known as auto transporters, these trucks are specifically designed to haul multiple vehicles simultaneously.

Key features:

– Multi-level racks to maximize capacity

– Hydraulic systems for loading/unloading

– Ideal for: New and used vehicles, from dealerships to auctions

Specialty trucks

Various other specialized trucks exist to meet unique cargo needs, such as:

– Logging trucks for timber transport

– Cement mixer trucks for ready-mix concrete

– Garbage trucks for waste management

To illustrate the capacity and dimensions of common shipping truck types:

| Truck Type | Max Payload (lbs) | Typical Length (ft) | Typical Width (ft) | Typical Height (ft) |

|---|---|---|---|---|

| Dry Van | 45,000 | 53 | 8.5 | 9 |

| Reefer | 43,000 | 53 | 8.5 | 9 |

| Flatbed | 48,000 | 48-53 | 8.5 | N/A (open top) |

| Tanker | 50,000 | 42-45 | 8.5 | 11-13 |

| Lowboy | 80,000 | 29-54 | 8.5 | 11.5-12 |

The diversity of shipping truck types ensures that virtually any cargo can be transported efficiently and safely. By matching the right truck to the specific needs of the freight, shippers can optimize their logistics operations, reduce costs, and ensure the integrity of their goods throughout the transportation process.

What are the key features of specialized shipping trucks?

Specialized shipping trucks are designed with unique features to handle specific types of cargo or operate in particular environments. These features enhance efficiency, safety, and compliance with industry regulations. Let’s explore the key features of various specialized shipping trucks:

Refrigerated trucks (Reefers)

Temperature control systems:

Advanced cooling units maintain precise temperatures throughout the cargo area. These systems can typically achieve temperatures ranging from -20°F to 70°F.

Insulated walls:

High-quality insulation in the walls, floor, and ceiling helps maintain consistent temperatures and reduces energy consumption.

Air circulation:

Specialized air flow systems ensure even temperature distribution throughout the trailer, preventing hot or cold spots.

Temperature monitoring:

Real-time temperature tracking and logging systems provide documentation for quality control and regulatory compliance.

Multi-temperature zones:

Some reefers feature multiple compartments with independent temperature controls, allowing for the transport of different products with varying temperature requirements.

Tanker trucks

Tank construction:

Tanks are typically made from stainless steel, aluminum, or specialized composites to resist corrosion and withstand pressure.

Baffles:

Internal partitions reduce liquid movement during transport, improving vehicle stability and safety.

Pressure and vacuum systems:

These allow for the safe loading and unloading of pressurized or sensitive liquids and gases.

Specialized valves and fittings:

Various types of valves and connections accommodate different loading and unloading methods and ensure product integrity.

Heating systems:

Some tankers feature heating coils to maintain the temperature of certain liquids, such as asphalt or molasses.

Flatbed trucks

Tie-down points:

Numerous anchor points along the deck allow for secure fastening of cargo using chains, straps, or specialized equipment.

Removable sides and stakes:

Some flatbeds feature removable side rails or stake pockets for added versatility in load securing.

Sliding tarps:

Retractable tarp systems provide weather protection while maintaining the loading flexibility of an open deck.

Extendable trailers:

Telescoping flatbeds can extend to accommodate extra-long cargo, such as steel beams or wind turbine blades.

Lowboy trucks

Dropped deck:

The low deck height, typically 18-24 inches off the ground, allows for the transport of tall equipment while staying within legal height limits.

Hydraulic systems:

Many lowboys feature hydraulic goosenecks or removable goosenecks for easier loading and unloading of heavy equipment.

High weight capacity:

Reinforced construction allows lowboys to carry loads up to 80,000 pounds or more.

Multiple axles:

Additional axles help distribute the weight of heavy loads and comply with road weight restrictions.

Livestock trucks

Ventilation systems:

Adequate airflow is crucial for animal welfare. These trucks feature strategically placed vents and sometimes powered ventilation systems.

Non-slip flooring:

Specialized flooring materials provide traction for animals and are easy to clean and sanitize.

Watering systems:

Built-in water tanks and distribution systems allow for watering of animals during long journeys.

Adjustable decks:

Multi-level trailers with adjustable deck heights accommodate different animal sizes and species.

Car carrier trucks

Hydraulic ramps and lifts:

These systems facilitate the loading and unloading of vehicles onto multiple levels of the carrier.

Soft tie-down systems:

Specialized straps and wheel chocks secure vehicles without damaging their suspension or body.

Enclosed options:

Some car carriers feature fully enclosed trailers to protect high-value vehicles from road debris and weather.

Dump trucks

Hydraulic lift systems:

Powerful hydraulics raise the cargo bed for easy unloading of loose materials.

Tailgate designs:

Various tailgate configurations, including barn doors and spreader gates, accommodate different unloading needs.

Reinforced construction:

Heavy-duty materials and design withstand the abrasive nature of materials like gravel and the impact of loading.

Tarping systems:

Automated or manual tarps cover the load to prevent material loss during transport.

To illustrate the specialized features of different truck types:

| Truck Type | Key Specialized Features |

|---|---|

| Reefer | Temperature control, insulation, air circulation |

| Tanker | Pressure systems, specialized valves, baffles |

| Flatbed | Tie-down points, removable sides, sliding tarps |

| Lowboy | Dropped deck, hydraulic gooseneck, high weight capacity |

| Livestock | Ventilation, non-slip flooring, watering systems |

| Car Carrier | Hydraulic ramps, soft tie-downs, multi-level design |

| Dump Truck | Hydraulic lift, reinforced bed, tailgate options |

These specialized features enable shipping trucks to safely and efficiently transport a wide variety of cargo types. By understanding these features, shippers can select the most appropriate vehicle for their specific freight needs, ensuring optimal performance and compliance with industry standards and regulations.

How do cargo characteristics influence truck selection?

The characteristics of the cargo being transported play a crucial role in determining the most suitable type of shipping truck. Factors such as size, weight, fragility, temperature sensitivity, and regulatory requirements all influence the selection process. Understanding these relationships helps logistics professionals optimize their transportation strategies and ensure the safe, efficient delivery of goods.

Size and dimensions

Oversized cargo:

Large or irregularly shaped items often require flatbed trucks or lowboys. For example, construction equipment or industrial machinery may exceed the dimensions of standard enclosed trailers.

Standard palletized goods:

Dry van trucks are typically suitable for cargo that fits on standard pallets and within the dimensions of a 53-foot trailer.

Length considerations:

Extra-long items like lumber or steel beams may require extendable flatbeds or specialized trailers.

Weight

Heavy loads:

Lowboy trailers or multi-axle flatbeds are designed to distribute the weight of exceptionally heavy cargo, such as transformers or large vehicles.

Weight distribution:

The placement of cargo within a trailer is crucial for maintaining legal axle weight limits. Some specialized trailers feature adjustable axles to optimize weight distribution.

Legal weight limits:

Truck selection must consider the combined weight of the vehicle and cargo to ensure compliance with road regulations, which typically limit gross vehicle weight to 80,000 pounds in the U.S.

Fragility and value

Delicate items:

Sensitive electronics, artwork, or medical equipment may require air-ride suspension trailers to minimize vibration and shock during transport.

High-value goods:

Enclosed trailers or specialized security features may be necessary for valuable cargo to prevent theft and damage.

Stackability:

Cargo that cannot be stacked may require trucks with greater floor space to accommodate the full shipment.

Temperature sensitivity

Perishable goods:

Fresh produce, dairy products, and certain pharmaceuticals require refrigerated trucks (reefers) to maintain specific temperature ranges during transit.

Frozen products:

Deep-freeze capabilities are necessary for items like ice cream or frozen meals, requiring reefers with powerful cooling systems.

Heat-sensitive materials:

Some chemicals or food products may require temperature-controlled environments to prevent spoilage or chemical reactions.

Physical state

Liquids and gases:

Tanker trucks are essential for transporting fluids, from milk to hazardous chemicals. The specific design of the tank depends on the properties of the liquid or gas.

Loose materials:

Dump trucks are ideal for transporting and easily unloading materials like sand, gravel, or agricultural products.

Live animals:

Livestock trailers provide the necessary ventilation, secure footing, and sometimes feeding and watering systems for transporting animals.

Hazardous materials

Chemical compatibility:

Trucks transporting hazardous materials must have tanks or containers made from materials that won’t react with the cargo.

Placarding and labeling:

Vehicles carrying hazardous materials must display appropriate warning signs and comply with specific regulations.

Specialized equipment:

Some hazardous materials require trucks equipped with spill containment systems or specialized safety features.

Quantity and frequency

Full truckload (FTL):

Large quantities of goods that fill an entire trailer typically use standard dry vans or the appropriate specialized truck for the cargo type.

Less than truckload (LTL):

Smaller shipments may be consolidated with other cargo, often using dry vans with internal separations or specialized LTL trailers.

Just-in-time delivery:

Time-sensitive shipments may require trucks with GPS tracking and real-time communication systems to ensure precise scheduling.