What Is a Drage in Logistics

What is drayage in logistics?

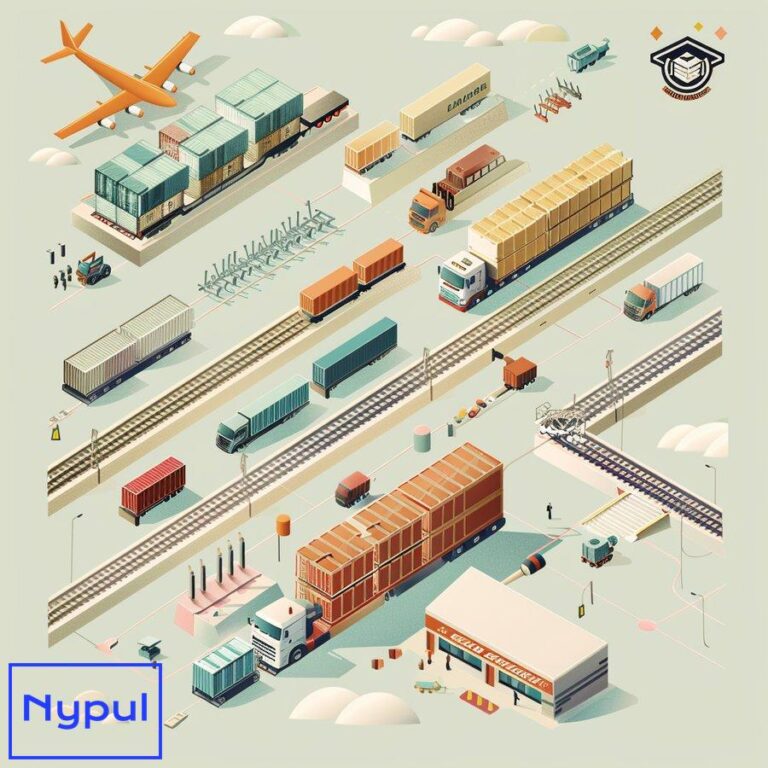

Drayage forms a critical link in the logistics and supply chain industry, serving as the short-distance transportation of goods between various points in the shipping process. This specialized service bridges the gap between long-haul transportation methods and final destinations, ensuring the seamless movement of cargo.

The term “drayage” originates from the historical use of horse-drawn carts called “drays” to transport heavy loads over short distances. While the mode of transportation has evolved, the core concept remains the same – moving freight efficiently over short distances, typically within a single metropolitan area.

In modern logistics, drayage primarily involves the transportation of containerized cargo between ports, rail terminals, warehouses, and distribution centers. This crucial service enables the transfer of goods between different modes of transportation, such as from ships to trucks or from trains to warehouses.

Key characteristics of drayage include:

Short-distance transport: Drayage typically covers distances of less than 100 miles, often within the same city or metropolitan area.

Intermodal connections: It facilitates the movement of cargo between different modes of transportation, such as sea, rail, and road.

Container handling: Drayage often involves the transportation of standardized shipping containers, allowing for efficient transfer between modes.

Time-sensitive operations: Drayage services must operate efficiently to minimize delays in the overall supply chain.

Specialized equipment: Drayage requires specific vehicles and equipment designed for short-haul transport and container handling.

To illustrate the role of drayage in the logistics process, consider the following example:

| Stage | Description | Mode of Transport |

|---|---|---|

| 1 | Goods manufactured in China | N/A |

| 2 | Transport to Shanghai port | Truck (drayage) |

| 3 | Ocean shipping to Los Angeles | Container ship |

| 4 | Transport from port to rail terminal | Truck (drayage) |

| 5 | Rail transport to Chicago | Train |

| 6 | Transport from rail terminal to warehouse | Truck (drayage) |

| 7 | Final delivery to retail store | Truck |

In this example, drayage services (highlighted in stages 2, 4, and 6) play a crucial role in connecting the various long-haul transportation modes, ensuring the smooth flow of goods from the manufacturer to the final destination.

Drayage providers must navigate complex logistics environments, including congested ports, strict regulations, and tight schedules. Their expertise in local transportation networks and ability to handle specialized equipment make them indispensable in the global supply chain.

For businesses involved in international trade or domestic shipping, understanding drayage is essential for optimizing logistics operations and reducing transportation costs. By efficiently managing the short-distance transport of goods, drayage services contribute significantly to the overall efficiency and reliability of the supply chain.

How does drayage fit into the supply chain?

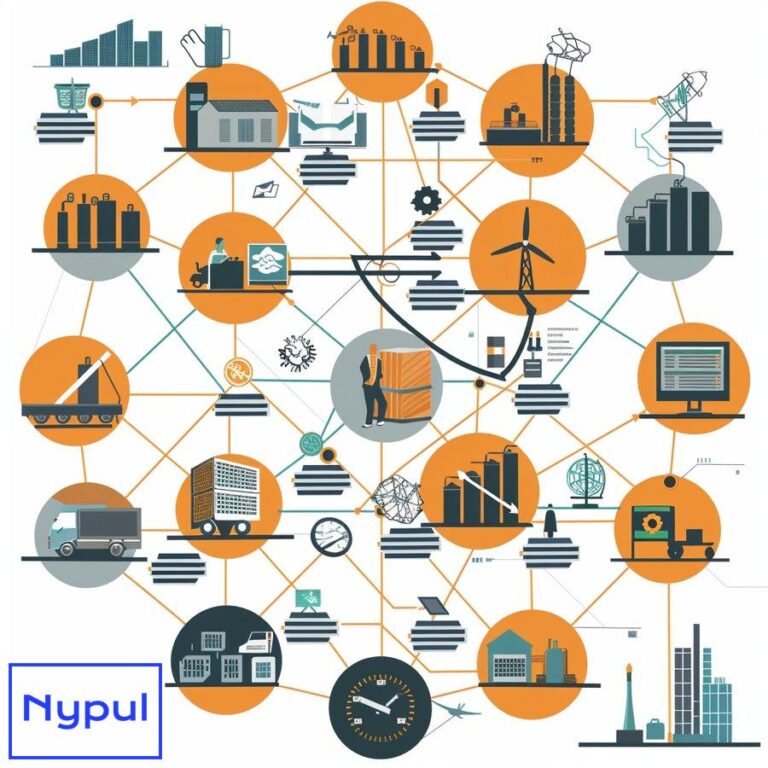

Drayage plays a pivotal role in the intricate web of modern supply chain management, serving as a crucial connector between various transportation modes and logistics hubs. Its integration into the supply chain ensures the smooth flow of goods from origin to destination, minimizing delays and optimizing overall efficiency.

Key functions of drayage in the supply chain:

Intermodal connectivity: Drayage bridges the gap between different modes of transportation, facilitating the seamless transfer of cargo between ships, trains, and long-haul trucks.

First and last-mile delivery: In many cases, drayage services handle the initial pickup from manufacturers or the final delivery to distribution centers, effectively managing the first and last miles of a shipment’s journey.

Port operations: Drayage providers play a critical role in moving containers in and out of ports, helping to alleviate congestion and ensure timely processing of incoming and outgoing shipments.

Warehouse and distribution center support: Drayage services facilitate the movement of goods between warehouses, distribution centers, and other storage facilities, supporting inventory management and order fulfillment processes.

Just-in-time logistics: By providing quick and efficient short-distance transport, drayage enables just-in-time inventory strategies, helping businesses reduce storage costs and improve cash flow.

To better understand how drayage fits into the broader supply chain, consider the following table illustrating a typical international shipping process:

| Stage | Process | Role of Drayage |

|---|---|---|

| 1 | Manufacturing | Transport finished goods from factory to local port or airport |

| 2 | Export | Move containers through customs and onto ships or planes |

| 3 | International transport | N/A (long-haul transportation) |

| 4 | Import | Transfer containers from ships/planes to customs and then to inland transportation |

| 5 | Domestic transport | Move containers between different modes of transportation (e.g., port to rail) |

| 6 | Distribution | Deliver containers to warehouses or distribution centers |

| 7 | Last-mile delivery | Transport goods from distribution centers to retail locations or end customers |

As evident from this table, drayage services are involved in multiple stages of the supply chain, ensuring the efficient movement of goods at critical transition points.

Impact of drayage on supply chain efficiency:

Reduced transit times: By efficiently managing short-distance transport, drayage helps minimize overall transit times, allowing for faster delivery of goods to end customers.

Cost optimization: Effective drayage operations can help reduce demurrage and detention fees at ports and terminals, lowering overall shipping costs.

Improved inventory management: Timely drayage services support just-in-time inventory strategies, helping businesses maintain optimal stock levels and reduce carrying costs.

Enhanced flexibility: Drayage providers offer the flexibility to adapt to changing supply chain needs, such as rerouting shipments or accommodating rush orders.

Increased visibility: Many drayage services now incorporate advanced tracking technologies, providing real-time visibility into shipment status and location.

Challenges and considerations:

While drayage is essential to supply chain efficiency, it also faces several challenges:

Port congestion: High volumes of cargo and limited port capacity can lead to delays in drayage operations, impacting the entire supply chain.

Equipment availability: Shortages of chassis, containers, or specialized equipment can hinder drayage efficiency.

Regulatory compliance: Drayage providers must navigate complex regulations, including emissions standards and driver hours-of-service rules.

Labor shortages: A shortage of qualified drivers can impact drayage capacity and reliability.

To address these challenges and maximize the benefits of drayage in the supply chain, businesses should:

Collaborate closely with drayage providers: Establish strong partnerships with reliable drayage companies to ensure consistent service and better communication.

Leverage technology: Implement advanced tracking and management systems to improve visibility and coordination across the supply chain.

Plan for contingencies: Develop backup plans and alternative routes to mitigate the impact of potential disruptions in drayage operations.

Optimize scheduling: Coordinate drayage services with other supply chain activities to minimize wait times and maximize efficiency.

Invest in sustainable practices: Work with drayage providers that prioritize environmental sustainability, such as those using low-emission vehicles or participating in green port initiatives.

By understanding the critical role of drayage and implementing strategies to optimize its integration into the supply chain, businesses can enhance their overall logistics efficiency, reduce costs, and improve customer satisfaction. As global trade continues to grow and evolve, the importance of efficient drayage operations in supporting seamless supply chain management will only increase.

What are the different types of drayage services?

Drayage services come in various forms, each tailored to meet specific logistics needs and challenges. Understanding these different types of drayage is crucial for businesses to select the most appropriate service for their supply chain requirements. Here’s a comprehensive overview of the main types of drayage services:

Inter-carrier drayage:

This type of drayage involves the movement of cargo between different carriers’ facilities. For example, transporting a container from a shipping line’s terminal to a rail yard operated by a different company.

Key features:

– Facilitates intermodal transportation

– Requires coordination between multiple carriers

– Often involves short distances within the same metropolitan area

Intra-carrier drayage:

Intra-carrier drayage refers to the movement of cargo between facilities owned or operated by the same carrier. This could include transferring containers between different terminals or depots managed by a single shipping line.

Key features:

– Streamlines operations within a carrier’s network

– Typically involves shorter distances and simpler logistics

– May offer cost advantages due to internal coordination

Expedited drayage:

This service prioritizes speed and efficiency, often used for time-sensitive shipments or to meet urgent delivery deadlines.

Key features:

– Faster transit times

– Higher cost due to prioritized handling

– Often used for perishable goods or critical components

Pier drayage:

Pier drayage specifically refers to the movement of containers between a port or pier and another nearby location, such as a rail terminal or warehouse.

Key features:

– Critical for port operations and congestion management

– Often involves navigating complex port environments

– May require specialized equipment for handling maritime containers

Shuttle drayage:

This service involves the repeated movement of cargo between two fixed points, often used to manage capacity at busy terminals or distribution centers.

Key features:

– Regular, scheduled service between two locations

– Helps manage inventory flow and terminal capacity

– Can improve overall supply chain efficiency

Door-to-door drayage:

Door-to-door drayage provides complete transportation service from the origin (e.g., a manufacturer’s facility) to the final destination (e.g., a retailer’s distribution center).

Key features:

– Offers end-to-end logistics solution

– Simplifies coordination for shippers

– May involve longer distances compared to other drayage types

Cross-town drayage:

This service involves moving cargo across a metropolitan area, often between different transportation hubs or facilities.

Key features:

– Navigates urban traffic and logistics challenges

– Typically covers distances of 50 miles or less

– Essential for connecting different modes of transportation within a city

To better understand how these different types of drayage services apply in real-world scenarios, consider the following table:

| Drayage Type | Example Scenario | Key Advantages |

|---|---|---|

| Inter-carrier | Moving a container from a shipping terminal to a rail yard operated by a different company | Enables seamless intermodal transfers |

| Intra-carrier | Transferring containers between two terminals operated by the same shipping line | Improves operational efficiency within a carrier’s network |

| Expedited | Transporting time-sensitive electronics components from an airport to a nearby manufacturing facility | Ensures rapid delivery for critical shipments |

| Pier | Moving containers from a port to a nearby distribution center | Alleviates port congestion and facilitates smooth cargo flow |

| Shuttle | Regular container transfers between a busy port and an overflow storage facility | Manages terminal capacity and improves overall port efficiency |

| Door-to-door | Transporting goods from a factory in China to a retailer’s warehouse in the United States | Provides a comprehensive logistics solution for shippers |

| Cross-town | Moving cargo from an airport freight terminal to a downtown distribution center | Connects different transportation hubs within an urban area |

When selecting the appropriate drayage service, businesses should consider several factors:

Shipment urgency: For time-sensitive cargo, expedited drayage may be necessary despite higher costs.

Distance: The required travel distance will influence the choice between local drayage services and longer-haul options.

Cargo type: Certain goods may require specialized handling or equipment, affecting the choice of drayage provider.

Volume and frequency: Regular, high-volume shipments may benefit from dedicated shuttle drayage services.

Intermodal requirements: The need to transfer between different modes of transportation will influence the type of drayage service required.

Cost considerations: Different drayage types come with varying price points, which should be balanced against service requirements.

Regulatory compliance: Some drayage services may be better equipped to handle specific regulatory requirements, such as customs clearance for international shipments.

By understanding these different types of drayage services and carefully considering their specific needs, businesses can optimize their supply chain operations, reduce costs, and improve overall logistics efficiency. The choice of drayage service can significantly impact transit times, handling efficiency, and ultimately, customer satisfaction.

As the logistics industry continues to evolve, new specialized drayage services may emerge to address specific market needs or technological advancements. Staying informed about these developments and regularly reassessing drayage strategies will help businesses maintain a competitive edge in the ever-changing landscape of global trade and transportation.

What equipment is used in drayage operations?

Drayage operations rely on a variety of specialized equipment to efficiently move containers and other cargo over short distances. The right equipment ensures safe, efficient, and compliant transportation of goods between various points in the supply chain. Here’s a comprehensive overview of the key equipment used in drayage operations:

Trucks and tractors:

The backbone of drayage operations, these vehicles are designed for short-haul transportation and container handling.

Key features:

– Powerful engines for quick acceleration and deceleration

– Reinforced frames to handle heavy container loads

– Advanced safety features for urban and port environments

– Fuel-efficient designs to reduce operational costs

Types:

– Day cabs: Shorter cab design without a sleeping compartment, ideal for local operations

– Yard trucks (hostlers): Specialized vehicles for moving trailers within terminals or warehouses

Chassis:

These are the wheeled frames designed to carry shipping containers.

Key features:

– Adjustable to accommodate different container sizes (20-foot, 40-foot, 45-foot)

– Equipped with twist locks to secure containers

– Available in various configurations for specific cargo types

Types:

– Standard chassis: For general container transport

– Extendable chassis: Adjustable length to accommodate different container sizes

– Tri-axle chassis: For heavier loads

– Specialized chassis: For refrigerated containers or oversized cargo

Containers:

While not technically drayage equipment, containers are integral to drayage operations.

Key features:

– Standardized sizes (20-foot, 40-foot, 45-foot)

– Designed for easy transfer between different modes of transportation

– Available in various types for specific cargo needs

Types:

– Dry containers: For general cargo

– Refrigerated containers (reefers): For temperature-sensitive goods

– Open-top containers: For oversized cargo

– Flat rack containers: For heavy machinery or odd-shaped items

– Tank containers: For liquid or gas cargo

Container handling equipment:

Used at terminals and warehouses to load, unload, and stack containers.

Key features:

– High lifting capacity

– Precision control for accurate positioning

– Designed for efficient operation in confined spaces

Types:

– Reach stackers: Versatile machines for stacking and moving containers

– Top loaders: Specialized for empty container handling

– Straddle carriers: For moving and stacking containers in port environments

– Gantry cranes: Large, fixed cranes for loading and unloading ships

Trailer types:

Various trailer configurations are used in drayage to accommodate different cargo types and handling requirements.

Key features:

– Designed for easy loading and unloading

– Available in different sizes and configurations

– Specialized features for specific cargo types

Types:

– Flatbed trailers: For oversized or oddly shaped cargo

– Lowboy trailers: For tall or heavy equipment

– Step deck trailers: For cargo that exceeds standard height restrictions

– Tanker trailers: For liquid or gas transportation

Auxiliary equipment:

Additional tools and equipment that support drayage operations.

Types:

– Container locks and seals: For security and cargo integrity

– Tie-down straps and chains: For securing cargo within containers or on flatbed trailers

– Dunnage: Materials used to protect and secure cargo during transport

– Portable ramps: For loading and unloading in locations without fixed docks

To better understand how these equipment types are utilized in different drayage scenarios, consider the following table:

| Drayage Scenario | Primary Equipment | Auxiliary Equipment | Key Considerations |

|---|---|---|---|

| Port to rail transfer | Day cab truck, standard chassis | Container locks, seals | Efficient terminal navigation, quick turnaround times |

| Oversized cargo transport | Flatbed or lowboy trailer | Tie-down straps, flags | Route planning for height/weight restrictions |

| Refrigerated goods delivery | Reefer container, reefer-compatible chassis | Temperature monitoring devices | Maintaining cold chain integrity |

| Cross-dock operations | Yard truck, various trailer types | Portable ramps, pallet jacks | Quick cargo transfer, space utilization |

| Heavy machinery transport | Specialized chassis, flatbed trailer | Heavy-duty tie-downs, escort vehicles | Weight distribution, road permits |

When selecting and utilizing equipment for drayage operations, several factors should be considered:

Cargo specifications: The type, size, and weight of the cargo will dictate the appropriate container and trailer choices.

Regulatory compliance: Equipment must meet local, state, and federal regulations for road use and cargo handling.

Operational efficiency: Choose equipment that allows for## What challenges do drayage logistics face?

Drayage operations face a unique set of challenges that can impact the efficiency and reliability of the overall supply chain. Understanding these challenges is crucial for businesses to develop effective strategies to mitigate risks and optimize drayage performance. Here are some of the key challenges faced by drayage logistics:

Port congestion:

One of the most significant challenges in drayage is the issue of port congestion. High volumes of cargo, limited terminal capacity, and inefficient processes can lead to significant delays in the movement of containers, causing a ripple effect throughout the supply chain.

Key factors contributing to port congestion:

– Surges in import volumes

– Chassis shortages

– Lack of coordination between stakeholders

– Outdated infrastructure and technology

Chassis availability:

The availability of chassis, the wheeled frames used to transport containers, is a critical factor in drayage operations. Shortages or imbalances in chassis supply can lead to delays and increased costs for drayage providers and shippers.

Causes of chassis shortages:

– Insufficient chassis pools

– Inefficient chassis utilization

– Lack of coordination between chassis providers and drayage operators

– Chassis damage or maintenance issues

Driver shortages and turnover:

The drayage industry faces ongoing challenges in attracting and retaining qualified drivers. High turnover rates and a limited pool of experienced drivers can impact the reliability and capacity of drayage services.

Factors contributing to driver shortages:

– Demanding work schedules and long hours

– Competitive compensation in other trucking sectors

– Strict regulations and compliance requirements

– Challenging working conditions in port and urban environments

Regulatory compliance:

Drayage operations must comply with a complex web of regulations, including emissions standards, driver hours-of-service rules, and safety requirements. Failure to comply can result in fines, delays, and reputational damage for drayage providers and their clients.

Key regulatory challenges:

– Varying emissions standards across different jurisdictions

– Strict driver hours-of-service rules that limit driving time

– Comprehensive safety regulations for commercial vehicles

– Customs and border clearance requirements for international shipments

Technology limitations:

While technology has made significant strides in improving drayage efficiency, many operations still rely on outdated systems and manual processes. Lack of investment in technology can lead to inefficiencies, data silos, and poor visibility throughout the supply chain.

Areas where technology can improve drayage:

– Real-time tracking and monitoring of containers and equipment

– Automated dispatching and routing systems

– Integrated platforms for data sharing and collaboration

– Predictive analytics for better planning and decision-making

Unpredictable demand:

Drayage operations often face unpredictable fluctuations in demand, driven by factors such as seasonal variations, economic conditions, and global events. Adapting to these changes can be challenging for drayage providers, requiring flexible capacity and agile operations.

Strategies to address unpredictable demand:

– Developing partnerships with multiple drayage providers

– Implementing dynamic pricing models to manage capacity

– Investing in flexible workforce solutions, such as temporary labor

– Leveraging data analytics to forecast demand and optimize resource allocation

To overcome these challenges and improve drayage efficiency, stakeholders across the supply chain must collaborate to develop innovative solutions. This may involve investments in infrastructure, technology, and workforce development, as well as the implementation of best practices and industry standards. By addressing these challenges proactively, businesses can enhance the reliability and resilience of their drayage operations, ultimately improving overall supply chain performance.

How can technology improve drayage efficiency?

Technology has the potential to revolutionize drayage operations, addressing many of the challenges faced by the industry and driving significant improvements in efficiency, visibility, and collaboration. By leveraging advanced technologies, drayage providers and their clients can streamline processes, reduce costs, and enhance overall supply chain performance. Here are some of the key ways technology can improve drayage efficiency:

Real-time tracking and monitoring:

One of the most significant benefits of technology in drayage is the ability to track and monitor containers and equipment in real-time. This enhanced visibility allows drayage providers to optimize routing, reduce wait times, and improve asset utilization.

Technologies enabling real-time tracking:

– GPS-enabled tracking devices on containers and chassis

– RFID tags for automated identification and location detection

– Telematics systems in trucks for driver monitoring and vehicle diagnostics

Automated dispatching and routing:

Advanced algorithms and machine learning can automate the dispatching and routing of drayage trucks, optimizing routes based on factors such as traffic conditions, driver availability, and customer requirements. This can lead to significant improvements in efficiency, reducing transit times and fuel consumption.

Key features of automated dispatching and routing systems:

– Integration with real-time traffic data and GPS

– Optimization algorithms that consider multiple variables

– Automated assignment of loads to available drivers

– Seamless communication with drivers via mobile apps or in-cab devices

Integrated platforms for collaboration:

Cloud-based platforms that enable data sharing and collaboration among supply chain stakeholders can greatly improve the efficiency of drayage operations. These platforms provide a centralized hub for information exchange, reducing data silos and improving decision-making.

Benefits of integrated collaboration platforms:

– Visibility into container status and location for all stakeholders

– Streamlined communication and coordination between drayage providers, terminals, and clients

– Automated notifications for critical events, such as container availability or delays

– Shared access to key performance metrics and analytics

Predictive analytics and AI:

By leveraging predictive analytics and artificial intelligence, drayage providers can anticipate and respond to changes in demand, optimize resource allocation, and identify potential bottlenecks before they occur. These technologies can help drayage operations become more proactive and resilient in the face of unpredictable challenges.

Applications of predictive analytics and AI in drayage:

– Forecasting demand based on historical data and market trends

– Identifying patterns and anomalies in container flow and equipment utilization

– Optimizing chassis and container pools based on anticipated needs

– Providing recommendations for improving operational efficiency and cost savings

Autonomous and electric vehicles:

While still in the early stages of adoption, autonomous and electric vehicles have the potential to significantly impact drayage operations in the future. Autonomous trucks can improve safety, reduce labor costs, and operate more efficiently, while electric vehicles can lower emissions and fuel costs.

Potential benefits of autonomous and electric vehicles in drayage:

– Improved safety through advanced sensors and collision avoidance systems

– Reduced fuel and maintenance costs with electric powertrains

– Increased efficiency and productivity through autonomous driving capabilities

– Compliance with strict emissions regulations in port and urban areas

To fully leverage the benefits of technology in drayage, stakeholders must invest in infrastructure, data integration, and workforce training. Collaboration between technology providers, drayage operators, and supply chain partners is crucial to developing and implementing effective solutions. By embracing technological innovation, the drayage industry can enhance its competitiveness, reduce costs, and contribute to the overall efficiency and sustainability of global supply chains.

What factors should be considered when selecting a drayage provider?

Selecting the right drayage provider is a critical decision for businesses looking to optimize their supply chain operations. With numerous providers offering a range of services, it’s essential to carefully evaluate potential partners based on key factors that align with your specific requirements. Here are some of the most important considerations when choosing a drayage provider:

Service quality and reliability:

One of the primary factors to consider is the provider’s track record of delivering high-quality, reliable service. Look for providers with a strong reputation for on-time performance, cargo handling expertise, and customer satisfaction.

Key indicators of service quality and reliability:

– On-time delivery rates

– Cargo damage and loss rates

– Customer reviews and references

– Certifications and industry awards

Geographic coverage and network:

Assess the provider’s geographic reach and the strength of their local network. Ideally, the drayage provider should have a presence in key logistics hubs and the ability to serve your specific origin and destination points.

Important aspects of geographic coverage and network:

– Number and location of terminals and depots

– Partnerships with local trucking companies

– Ability to provide service in your target markets

– Flexibility to adapt to changing supply chain needs

Equipment availability and maintenance:

Ensure that the drayage provider has access to a sufficient fleet of well-maintained equipment, including trucks, chassis, and specialized containers. Consider factors such as equipment age, safety features, and environmental compliance.

Key equipment considerations:

– Size and composition of the equipment fleet

– Age and condition of trucks and chassis

– Availability of specialized equipment (e.g., reefers, flatbeds)

– Maintenance and repair programs

Technology and visibility:

Evaluate the provider’s technological capabilities and the level of visibility they offer into drayage operations. Look for providers that leverage advanced tracking systems, automated dispatching, and integrated platforms for improved collaboration and decision-making.

Important technology and visibility factors:

– Real-time tracking and monitoring capabilities

– Automated dispatching and routing systems

– Integrated platforms for data sharing and collaboration

– Reporting and analytics tools for performance monitoring

Regulatory compliance and sustainability:

Assess the provider’s commitment to regulatory compliance and sustainability initiatives. Ensure that they adhere to relevant laws and industry standards, and consider their efforts to reduce environmental impact through initiatives such as emissions reduction programs or the use of alternative fuel vehicles.

Key compliance and sustainability factors:

– Compliance with emissions regulations and safety standards

– Participation in green port initiatives or sustainability programs

– Use of alternative fuel vehicles or energy-efficient equipment

– Commitment to continuous improvement in sustainability performance

Cost and pricing structure:

While cost should not be the sole deciding factor, it’s essential to understand the provider’s pricing structure and how it aligns with your budget and business objectives. Look for transparent pricing, clear invoicing, and opportunities for cost savings through volume discounts or efficiency improvements.

Pricing considerations:

– Base rates for drayage services

– Accessorial charges and fees

– Opportunities for volume discounts or long-term contracts

– Flexibility in pricing adjustments due to market conditions

Customer service and communication:

Evaluate the provider’s commitment to customer service and their ability to communicate effectively. Look for providers that are responsive to inquiries, proactive in addressing issues, and willing to collaborate on process improvements.

Key customer service and communication factors:

– Responsiveness to inquiries and issues

– Proactive communication about shipment status and delays

– Willingness to collaborate on process improvements

– Availability of dedicated account management or customer support

By carefully considering these factors and aligning them with your specific supply chain requirements, you can select a drayage provider that will contribute to the overall efficiency, reliability, and cost-effectiveness of your logistics operations. Establishing a strong partnership with a trusted drayage provider can help you navigate the complexities of the global supply chain and maintain a competitive edge in your industry.

How does drayage impact intermodal transportation?

Drayage plays a crucial role in the success of intermodal transportation, which involves the movement of cargo using two or more modes of transportation (e.g., ship and rail, rail and truck) without handling the cargo itself when changing modes. By efficiently connecting these different modes, drayage enables the seamless flow of goods throughout the supply chain, reducing costs and improving overall efficiency.

Key ways drayage impacts intermodal transportation:

Facilitates modal shifts: Drayage enables the transfer of cargo between different modes of transportation, such as from ships to trains or from trains to trucks. This flexibility allows shippers to optimize their transportation mix based on factors such as cost, speed, and environmental impact.

Improves asset utilization: By moving containers between terminals and depots, drayage helps ensure that assets such as chassis and containers are available where and when they are needed. This optimized asset utilization reduces idle time and improves overall equipment effectiveness.

Enhances visibility and coordination: Drayage providers often use advanced tracking technologies and integrated platforms to provide real-time visibility into the location and status of cargo. This enhanced visibility enables better coordination among supply chain partners, reducing delays and improving overall performance.

Supports intermodal network expansion: As intermodal transportation networks grow and evolve, drayage providers play a crucial role in connecting new terminals and depots to the broader system. This expansion allows shippers to access new markets and optimize their supply chain strategies.

Contributes to sustainability: Intermodal transportation, when combined with efficient drayage operations, can reduce the environmental impact of freight movement by shifting cargo from less fuel-efficient modes (e.g., trucks) to more sustainable options (e.g., rail, barge). This shift can lead to lower emissions, reduced fuel consumption, and improved sustainability performance.

To illustrate the impact of drayage on intermodal transportation, consider the following example:

A shipper needs to move cargo from a manufacturing facility in the Midwest to a distribution center on the East Coast. Using intermodal transportation, the cargo is first transported by truck (drayage) from the factory to a nearby rail terminal. It is then loaded onto a train for long-haul transport to an intermodal terminal near the distribution center. Finally, the cargo is moved by truck (drayage) from the terminal to the distribution center.

Without efficient drayage services, this intermodal move would be significantly more challenging and costly. Drayage providers ensure that cargo is delivered to and from the rail terminals in a timely manner, minimizing delays and demurrage fees. They also help manage the complex logistics of container and chassis availability, ensuring that equipment is ready when needed.

To maximize the benefits of drayage in intermodal transportation, shippers and transportation providers should:

Collaborate closely with drayage providers: Establish strong partnerships with reliable drayage companies to ensure consistent service and better communication.

Leverage technology: Implement advanced tracking and management systems to improve visibility and coordination across the intermodal network.

Optimize scheduling: Coordinate drayage services with other intermodal activities to minimize wait times and maximize efficiency.

Invest in infrastructure: Support the development of intermodal terminals and depots, ensuring that drayage providers have the necessary facilities to support network growth.

By recognizing the critical role of drayage in intermodal transportation and working to optimize its integration, businesses can unlock the full potential of this efficient and sustainable mode of freight movement. As global trade continues to evolve, the importance of drayage in supporting intermodal transportation will only increase, driving further innovation and collaboration across the supply chain.