What Is a Drayage Service

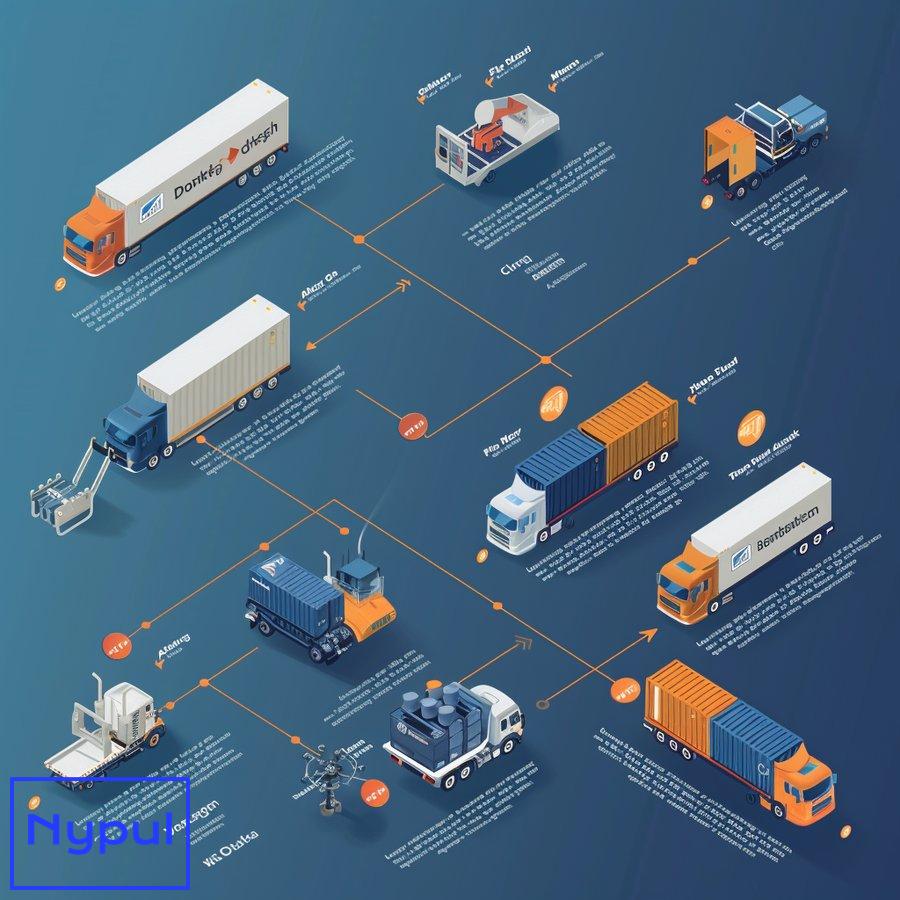

How do drayage services work in the supply chain?

Drayage services play a crucial role in the intricate web of global supply chains, acting as the vital link between various transportation modes. These services involve the short-distance transportation of goods, typically from ports or rail terminals to warehouses or distribution centers. Understanding how drayage fits into the broader supply chain ecosystem is essential for businesses seeking to optimize their logistics operations.

The drayage process begins when a container ship arrives at a port or a train reaches a rail yard. Once the containers are unloaded, drayage providers step in to move these containers to their next destination. This movement is typically accomplished using specialized trucks designed to handle intermodal containers.

Key steps in the drayage process:

Container pickup: Drayage trucks arrive at the port or rail terminal to collect the designated containers. This step often involves coordination with port authorities and adherence to specific pickup schedules.

Documentation and customs clearance: Before the container can leave the port or terminal, all necessary paperwork must be completed. This includes customs documentation, bills of lading, and any required permits.

Short-haul transport: The drayage truck then transports the container to its designated destination, which could be a warehouse, distribution center, or another intermodal facility.

Container delivery: Upon arrival at the destination, the container is unloaded, and the empty container may be returned to the port or terminal.

Integration with other supply chain elements: Drayage services must seamlessly integrate with other aspects of the supply chain, including long-haul transportation, warehousing, and distribution.

The efficiency of drayage operations directly impacts the overall performance of the supply chain. Delays in drayage can cause ripple effects throughout the entire logistics network, leading to increased costs and potential disruptions in product availability.

Drayage’s role in supply chain visibility:

Drayage providers often employ advanced tracking technologies to offer real-time visibility of container movements. This information is crucial for supply chain managers who need to coordinate subsequent logistics activities and provide accurate delivery estimates to customers.

The last-mile connection:

In many cases, drayage serves as the critical last-mile connection for international shipments. It bridges the gap between global transportation networks and local distribution systems, ensuring that goods reach their final destinations efficiently.

Drayage and supply chain resilience:

The COVID-19 pandemic highlighted the importance of flexible and resilient drayage services. As supply chains faced unprecedented disruptions, agile drayage providers played a key role in adapting to changing port conditions, capacity constraints, and shifting demand patterns.

To illustrate the typical flow of goods through drayage services in the supply chain, consider the following table:

| Stage | Location | Activity |

|---|---|---|

| 1 | Port of origin | Container loaded onto ship |

| 2 | Ocean transit | Container transported across ocean |

| 3 | Port of destination | Container unloaded from ship |

| 4 | Port terminal | Drayage truck picks up container |

| 5 | Customs inspection | Container cleared for entry |

| 6 | Local transport | Drayage truck moves container to warehouse |

| 7 | Warehouse | Container unloaded, goods processed |

| 8 | Distribution | Goods prepared for final delivery |

This table demonstrates how drayage services (stages 4-6) serve as the critical link between international shipping and local distribution networks.

Drayage and supply chain optimization:

Forward-thinking companies are increasingly recognizing the strategic importance of drayage in their overall supply chain optimization efforts. By carefully selecting drayage providers and integrating their services with broader logistics strategies, businesses can achieve significant improvements in efficiency and cost-effectiveness.

Key areas of focus for drayage optimization:

Appointment systems: Many ports and terminals have implemented appointment systems to manage truck traffic and reduce congestion. Effective drayage providers work closely with these systems to minimize wait times and improve overall efficiency.

Technology integration: Advanced drayage operations leverage technology such as GPS tracking, electronic logging devices (ELDs), and transportation management systems (TMS) to streamline operations and provide real-time visibility.

Chassis management: Efficient management of chassis (the wheeled trailers used to transport containers) is crucial for smooth drayage operations. Some providers maintain their own chassis fleets to ensure availability and reduce potential delays.

Cross-docking opportunities: In some cases, drayage providers can facilitate cross-docking operations, where goods are transferred directly from inbound containers to outbound trucks without the need for intermediate storage. This can significantly reduce handling costs and transit times.

Environmental considerations:

As sustainability becomes an increasingly important factor in supply chain management, drayage operations are also evolving to reduce their environmental impact. This includes the adoption of cleaner fuel technologies, such as electric or hydrogen-powered trucks, and the implementation of more efficient routing and scheduling systems to minimize empty miles.

The future of drayage in supply chains:

Looking ahead, the role of drayage in supply chains is likely to become even more critical as global trade continues to grow and e-commerce drives demand for faster, more flexible delivery options. Emerging technologies such as autonomous vehicles and blockchain-based documentation systems may further transform drayage operations, offering new opportunities for efficiency and transparency.

Understanding the intricacies of how drayage services work within the supply chain is essential for businesses seeking to optimize their logistics operations. By recognizing the strategic importance of this critical link in the transportation network, companies can make informed decisions about their drayage partnerships and integrate these services effectively into their broader supply chain strategies.

What are the different types of drayage services?

![]()

Drayage services come in various forms, each tailored to meet specific logistics needs and challenges. Understanding these different types is crucial for businesses to select the most appropriate drayage solution for their supply chain requirements. Let’s explore the main categories of drayage services and their unique characteristics.

Inter-carrier drayage:

This type of drayage involves the transfer of goods between different carriers. For example, a container might be moved from a ship to a train, or from one trucking company to another. Inter-carrier drayage plays a crucial role in intermodal transportation, ensuring smooth transitions between different modes of transport.

Key features of inter-carrier drayage:

– Facilitates seamless intermodal transfers

– Requires coordination between multiple transportation providers

– Often involves short distances within a port or terminal complex

Intra-carrier drayage:

Intra-carrier drayage refers to the movement of goods between facilities owned or operated by the same carrier. This could involve transferring containers between different ships operated by the same shipping line or between various terminals managed by a single rail company.

Characteristics of intra-carrier drayage:

– Streamlines operations within a single carrier’s network

– Often involves proprietary systems and equipment

– Can lead to improved efficiency and cost savings for the carrier

Expedited drayage:

When time is of the essence, expedited drayage services come into play. These services prioritize speed and efficiency, often involving dedicated trucks and drivers to ensure rapid delivery of time-sensitive cargo.

Hallmarks of expedited drayage:

– Prioritizes speed and timely delivery

– Often comes with premium pricing

– Requires careful coordination and planning

– Frequently used for perishable goods or critical components

Pier drayage:

Pier drayage specifically refers to the movement of containers from a port to a rail terminal or vice versa. This type of drayage is crucial in port cities where efficient transfer between sea and rail transport is essential.

Key aspects of pier drayage:

– Focuses on port-to-rail or rail-to-port transfers

– Requires familiarity with port operations and regulations

– Often involves navigating congested port areas

Shuttle drayage:

Shuttle drayage involves the continuous movement of containers between two fixed points, such as between a port and a nearby warehouse or distribution center. This type of service is often used to manage high-volume flows of goods efficiently.

Characteristics of shuttle drayage:

– Operates on a fixed route between two points

– Often runs on a regular schedule

– Can help alleviate congestion at ports or terminals

Door-to-door drayage:

This comprehensive service covers the entire journey of a container from its origin to its final destination. Door-to-door drayage providers handle all aspects of the transportation process, including pickup, transit, and delivery.

Features of door-to-door drayage:

– Offers end-to-end logistics solutions

– Simplifies the shipping process for customers

– Often involves coordination with multiple transportation modes

Window drayage:

Window drayage refers to services that operate within specific time frames or “windows.” This type of drayage is often used when precise scheduling is required, such as for just-in-time manufacturing or retail restocking.

Key aspects of window drayage:

– Adheres to strict time schedules

– Requires precise coordination with other supply chain elements

– Often used in industries with time-sensitive operations

To better understand how these different types of drayage services compare, consider the following table:

| Drayage Type | Primary Use Case | Key Advantage | Typical Distance |

|---|---|---|---|

| Inter-carrier | Intermodal transfers | Facilitates multi-modal transport | Short (within terminal) |

| Intra-carrier | Internal carrier operations | Improved efficiency for carrier | Varies |

| Expedited | Time-sensitive cargo | Fastest delivery | Short to medium |

| Pier | Port-rail transfers | Specialized for port operations | Short |

| Shuttle | High-volume, fixed routes | Regular, efficient service | Short |

| Door-to-door | Complete logistics solution | Comprehensive service | Long |

| Window | Time-specific deliveries | Precise scheduling | Varies |

Specialized drayage services:

Beyond these main categories, there are also specialized drayage services that cater to specific industries or cargo types:

Refrigerated (reefer) drayage:

This service is designed for temperature-sensitive goods such as food products, pharmaceuticals, or chemicals. Reefer drayage involves the use of specialized containers and trucks equipped with temperature control systems.

Key features of reefer drayage:

– Maintains precise temperature control throughout transit

– Requires specialized equipment and handling procedures

– Often involves additional monitoring and documentation

Overweight drayage:

Some cargo exceeds standard weight limits for road transportation. Overweight drayage services use specialized equipment and obtain necessary permits to transport these heavy loads safely and legally.

Characteristics of overweight drayage:

– Utilizes reinforced chassis and powerful trucks

– Requires careful route planning to comply with weight restrictions

– Often involves additional fees and permitting processes

Hazardous materials drayage:

The transportation of hazardous materials requires specialized handling and adherence to strict safety regulations. Hazmat drayage providers are equipped to handle these dangerous goods safely.

Key aspects of hazmat drayage:

– Requires specially trained drivers and equipment

– Adheres to strict safety protocols and regulations

– Involves detailed documentation and emergency response planning

Choosing the right drayage service:

Selecting the appropriate type of drayage service depends on various factors, including:

Cargo characteristics: The nature of the goods being transported, including size, weight, and any special handling requirements.

Time sensitivity: How quickly the cargo needs to reach its destination.

Distance: The length of the journey from origin to destination.

Volume: The quantity of goods being shipped and the frequency of shipments.

Budget: The cost considerations for the transportation service.

Regulatory requirements: Any specific legal or compliance issues related to the cargo or transportation route.

By understanding the different types of drayage services available, businesses can make informed decisions about which options best suit their logistics needs. This knowledge allows companies to optimize their supply chains, reduce costs, and improve overall efficiency in their transportation operations.

The diverse range of drayage services reflects the complexity and variability of modern supply chains. As logistics needs continue to evolve, drayage providers are likely to develop even more specialized and tailored services to meet the changing demands of global trade and commerce.

What equipment is used in drayage operations?

Drayage operations rely on a variety of specialized equipment to efficiently move containers and cargo between different points in the supply chain. The right equipment is crucial for ensuring safe, efficient, and cost-effective transportation of goods. Let’s explore the key types of equipment used in drayage operations and their specific roles.

Trucks:

The backbone of drayage operations, trucks are the primary vehicles used for transporting containers and cargo. Several types of trucks are commonly employed in drayage:

Day cabs:

– Short-distance hauling within port or terminal areas

– No sleeping compartment, maximizing cargo capacity

– Highly maneuverable for navigating tight spaces

Sleeper cabs:

– Used for longer drayage routes

– Equipped with a sleeping compartment for driver rest periods

– Suitable for multi-day operations

Yard trucks (hostlers):

– Specialized vehicles for moving trailers within a terminal or warehouse facility

– Highly maneuverable with a tight turning radius

– Designed for frequent coupling and uncoupling of trailers

Chassis:

Chassis are the wheeled trailers onto which containers are loaded for road transportation. Several types of chassis are used in drayage operations:

Standard chassis:

– Accommodate 20-foot, 40-foot, or 45-foot containers

– Most common type used in drayage operations

Extendable chassis:

– Can be adjusted to fit different container sizes

– Provide flexibility for handling various cargo types

Tri-axle chassis:

– Designed for heavier loads

– Distribute weight more evenly, allowing for higher cargo weights

Gooseneck chassis:

– Feature a lowered front end for improved aerodynamics

– Often used for specialized or oversized cargo

Containers:

While not technically drayage equipment, containers are integral to drayage operations. The most common types include:

Standard shipping containers:

– 20-foot and 40-foot lengths are most common

– Designed for easy transfer between ships, trucks, and trains

Refrigerated containers (reefers):

– Equipped with temperature control systems

– Used for transporting perishable goods

Open-top containers:

– Allow for top loading of oversized cargo

– Often used for bulk materials or tall equipment

Flat rack containers:

– Have no sides or top

– Used for oversized or irregularly shaped cargo

Tank containers:

– Designed for liquid or gas cargo

– Feature specialized fittings for safe handling of contents

Container handling equipment:

Efficient drayage operations require specialized equipment for loading, unloading, and moving containers within terminals and warehouses:

Reach stackers:

– Mobile cranes used for stacking and moving containers

– Highly versatile for various container handling tasks

Top loaders:

– Specialized forklifts for handling empty containers

– Can stack containers up to 8 high

Side loaders:

– Allow for loading and unloading of containers from the side

– Useful in confined spaces or for loading onto rail cars

Straddle carriers:

– Lift and carry containers, straddling the load

– Highly maneuverable in tight terminal spaces

Terminal tractors:

– Used for moving trailers within a terminal or warehouse

– Designed for frequent coupling and uncoupling

To better understand the relationship between different types of drayage equipment, consider the following table:

| Equipment Type | Primary Function | Key Features | Typical Use Case |

|---|---|---|---|

| Day cab truck | Short-distance container transport | High maneuverability, no sleeper | Port to nearby warehouse |

| Sleeper cab truck | Longer-distance drayage | Sleeping compartment for driver | Multi-day regional drayage |

| Standard chassis | Container support and transport | Fits common container sizes | General drayage operations |

| Refrigerated container | Temperature-controlled cargo transport | Built-in cooling system | Perishable goods drayage |

| Reach stacker | Container handling in terminals | Versatile lifting and stacking | Port and rail terminal operations |

| Side loader | Container loading from the side | Works in confined spaces | Rail car loading/unloading |

Safety equipment:

Ensuring the safety of drivers, cargo, and other road users is paramount in drayage operations. Key safety equipment includes:

Twist locks:

– Secure containers to chassis

– Prevent shifting during transport

Container seals:

– Ensure cargo security

– Provide tamper-evident closure

Wheel chocks:

– Prevent unintended movement of trailers during loading/unloading

Personal protective equipment (PPE):

– Hard hats, safety vests, and steel-toed boots for drivers and terminal workers

Technology and communication equipment:

Modern drayage operations increasingly rely on advanced technology to improve efficiency and visibility:

GPS tracking devices:

– Provide real-time location information for trucks and containers

– Enable accurate ETAs and route optimization

Electronic logging devices (ELDs):

– Record driving hours and ensure compliance with regulations

– Improve driver safety and operational efficiency

Mobile devices and apps:

– Allow drivers to access and update shipment information in real-time

– Facilitate communication between drivers, dispatMobile devices and apps:

-

Allow drivers to access and update shipment information in real-time

-

Facilitate communication between drivers, dispatchers, and customers

-

Enhance operational efficiency by providing instant updates on cargo status

The importance of equipment maintenance:

Regular maintenance of drayage equipment is essential for ensuring safety, reliability, and efficiency. Well-maintained trucks, chassis, and handling equipment can significantly reduce the risk of breakdowns and delays. Key maintenance practices include:

-

Routine inspections: Regular checks of brakes, tires, lights, and other critical components to ensure safe operation.

-

Preventive maintenance schedules: Implementing scheduled service intervals for oil changes, filter replacements, and other essential upkeep tasks.

-

Training for operators: Ensuring that drivers and equipment operators are trained in proper handling techniques and safety protocols.

By investing in the right equipment and maintaining it effectively, drayage providers can enhance their operational capabilities and deliver reliable services to their customers.

How do drayage costs and pricing factors work?

Understanding the costs associated with drayage services is crucial for businesses looking to manage their logistics budgets effectively. Drayage pricing can vary significantly based on several factors, including distance, type of service, and market conditions. Here’s a comprehensive overview of how drayage costs are determined.

Base rates:

Drayage pricing typically starts with a base rate that covers the standard cost of transporting a container from the port or rail terminal to its destination. This rate can vary based on:

-

Distance: Longer hauls generally incur higher costs due to increased fuel consumption and driver time.

-

Type of cargo: Special handling requirements for hazardous materials or temperature-sensitive goods can lead to additional charges.

Additional fees:

Various supplementary fees may apply to drayage services, including:

-

Fuel surcharges: Fluctuations in fuel prices often lead to additional charges that are passed on to customers. These surcharges are usually calculated as a percentage of the base rate.

-

Port or terminal fees: Charges imposed by ports or terminals for container handling, storage, or access can add to overall costs. These fees may vary based on location and specific services utilized.

-

Chassis rental fees: If a drayage provider does not own its chassis, it may need to rent one from a third party, leading to additional costs.

-

Detention fees: If a container is not picked up or returned within a specified timeframe, detention fees may be incurred. These charges incentivize timely pickups and returns.

-

Demurrage fees: Similar to detention fees but applied when containers remain at the port or terminal beyond the allowed free time. This fee is charged by shipping lines or terminals.

Market conditions:

Drayage pricing is also influenced by broader market conditions:

-

Seasonal demand fluctuations: Peak shipping seasons (e.g., holidays) often lead to increased demand for drayage services, which can drive up prices.

-

Capacity constraints: When there are fewer available trucks or drivers than needed, prices may rise due to increased competition for limited capacity.

-

Economic factors: Changes in fuel prices, labor costs, and regulatory requirements can all impact drayage pricing.

Cost breakdown example:

To illustrate how various factors contribute to overall drayage costs, consider the following hypothetical breakdown for transporting a 40-foot container over a distance of 50 miles:

| Cost Component | Estimated Cost |

|---|---|

| Base Rate | $250 |

| Fuel Surcharge (10%) | $25 |

| Port Fees | $50 |

| Chassis Rental Fee | $30 |

| Detention Fee (if applicable) | $100 |

| Total Estimated Cost | $455 |

This table highlights how each component contributes to the total cost of drayage services. Businesses should be aware of these factors when budgeting for logistics expenses.

Negotiating rates:

Businesses can often negotiate rates with drayage providers based on volume commitments or long-term contracts. Establishing strong relationships with providers may lead to more favorable pricing arrangements. Key strategies for negotiating include:

-

Volume discounts: Committing to regular shipments may result in reduced rates per container.

-

Long-term partnerships: Building ongoing relationships with providers can foster better pricing agreements over time.

-

Market research: Understanding current market rates allows businesses to negotiate more effectively based on industry standards.

Technology’s impact on cost efficiency:

Advancements in technology are also influencing drayage costs. For instance:

-

Route optimization software: Helps drivers select the most efficient routes, reducing fuel consumption and transit times.

-

Real-time tracking systems: Enable better visibility into shipment status, allowing companies to make informed decisions about logistics operations.

By leveraging technology effectively, businesses can enhance their operational efficiency and potentially lower their overall drayage costs.

What challenges do drayage operations face?

Drayage operations encounter various challenges that can impact efficiency, cost-effectiveness, and service quality. Understanding these challenges is essential for businesses seeking reliable logistics solutions. Here’s an overview of some key issues faced by drayage providers today.

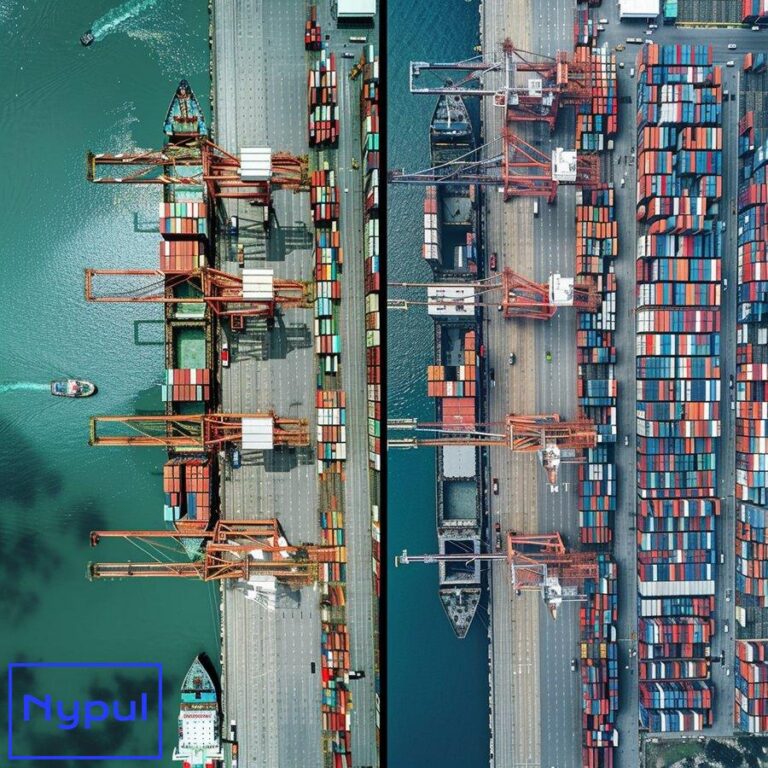

Port congestion:

![]()

One of the most significant challenges in drayage operations is congestion at ports and terminals. High volumes of incoming shipments can lead to delays in container pickup and delivery. Factors contributing to port congestion include:

-

Increased shipping volumes due to global trade growth

-

Limited infrastructure capacity at ports

-

Inefficient terminal operations

Impact on operations:

– Longer wait times for trucks at terminals

– Increased detention fees due to delays

– Disruption of scheduled deliveries

Labor shortages:

The logistics industry has been grappling with labor shortages across various sectors, including trucking and warehousing. Factors contributing to this challenge include:

-

Aging workforce with many drivers nearing retirement age

-

Difficulty attracting new talent due to long hours and demanding working conditions

Consequences:

– Limited availability of qualified drivers

– Increased labor costs as companies compete for talent

– Potential delays in service delivery

Regulatory compliance:

Drayage providers must navigate a complex landscape of regulations governing transportation safety, emissions standards, and cargo handling. Compliance challenges include:

-

Adhering to federal and state regulations regarding driver hours-of-service

-

Meeting environmental regulations aimed at reducing emissions from trucks

Implications:

– Increased administrative burdens related to compliance documentation

– Potential fines for non-compliance

– Need for ongoing training for drivers regarding regulatory changes

Equipment availability:

Accessing reliable equipment is crucial for efficient drayage operations. Challenges related to equipment availability include:

-

Limited availability of chassis during peak shipping seasons

-

Aging fleets requiring frequent repairs or replacements

Effects on operations:

– Delays in container pickup due to chassis shortages

– Increased maintenance costs as older equipment breaks down

– Potential disruptions in service quality

Technological integration:

While technology offers numerous benefits for improving efficiency in drayage operations, integrating new systems can pose challenges:

-

Resistance from employees who may be unfamiliar with new technologies

-

High upfront costs associated with implementing advanced tracking or routing systems

Consequences:

– Slower adoption of beneficial technologies

– Missed opportunities for improved operational efficiency

– Increased reliance on outdated processes

Environmental concerns:

As sustainability becomes an increasingly important consideration in logistics, drayage providers face pressure to reduce their environmental impact:

-

Regulatory requirements aimed at reducing emissions from heavy-duty trucks

-

Growing customer demand for environmentally friendly transportation options

Challenges posed:

– Need for investment in cleaner technologies (e.g., electric trucks)

– Potential higher operating costs associated with sustainable practices

– Balancing environmental goals with profitability

How does drayage integrate with intermodal transportation?

Drayage services are integral to intermodal transportation systems—where goods are transported using multiple modes of transport without handling the cargo itself when changing modes. The integration of drayage into intermodal transportation enhances efficiency and flexibility within supply chains. Here’s how this integration works.

The role of drayage in intermodal transportation:

Drayage serves as the critical link between different transportation modes—typically between ocean shipping (containers arriving by ship) or rail transport (containers arriving by train) and local trucking services that deliver goods directly to their final destinations.

- Container movement between modes:

- Drayage trucks transport containers from ports or rail yards where they arrive via ships or trains.

-

These trucks then deliver containers directly to warehouses or distribution centers.

-

Facilitating seamless transitions:

- Drayage providers ensure that containers are efficiently transferred between different modes without unnecessary delays.

-

This requires close coordination with port authorities, rail operators, and local trucking companies.

-

Reducing handling times:

- By minimizing the number of times containers are handled during transport (from ship/rail to truck), drayage helps reduce potential damage risks.

-

Efficient handling processes contribute to faster turnaround times at ports and terminals.

-

Improving supply chain visibility:

- Advanced tracking technologies used by many drayage providers enable real-time visibility into container movements.

- This information helps supply chain managers coordinate subsequent logistics activities more effectively.

Types of intermodal transportation involving drayage:

- Port-to-door intermodal transport:

-

Involves transporting goods from an international port directly to a customer’s location using a combination of ocean freight followed by local trucking services.

-

Rail-to-door intermodal transport:

-

Involves moving containers from rail terminals directly to warehouses or distribution centers via trucks.

-

Multimodal transport solutions:

-

Combining various modes such as air freight followed by road transport or sea freight followed by rail transport.

-

Cross-docking operations:

-

Drayage providers facilitate cross-docking where goods are transferred directly from inbound containers onto outbound trucks without intermediate storage.

-

Last-mile delivery solutions:

- Drayage plays a vital role in last-mile delivery solutions by providing efficient transportation from ports/terminals directly into urban areas where final deliveries occur.

To illustrate how these elements come together in intermodal transportation involving drayage services, consider the following table:

| Intermodal Type | Description | Key Benefits |

|---|---|---|

| Port-to-Door | Ocean freight transported directly via truck | Streamlined delivery process |

| Rail-to-Door | Rail containers moved directly via truck | Cost-effective long-distance transport |

| Multimodal | Combination of air/sea/road transport | Flexibility in shipping options |

| Cross-Docking | Direct transfer between inbound/outbound trucks | Reduced handling times |

| Last-Mile Delivery | Final leg from port/terminal into urban areas | Efficient urban logistics |

Challenges in integrating drayage with intermodal transportation:

While the integration of drayage into intermodal systems offers numerous advantages, several challenges must be addressed:

- Coordination complexities:

- Managing multiple carriers requires effective communication among all parties involved.

-

Delays at one point can have cascading effects throughout the entire supply chain.

-

Infrastructure limitations:

- Some ports lack adequate facilities for efficient transfer between modes.

-

Congestion at ports can lead to bottlenecks affecting overall transit times.

-

Regulatory hurdles:

- Navigating different regulations across states/countries adds complexity.

-

Compliance with customs requirements during transfers increases administrative burdens.

-

Cost considerations:

- While intermodal transport can be cost-effective over long distances, unexpected delays can increase overall expenses.

-

Understanding all associated fees (e.g., demurrage/detention) is essential for accurate budgeting.

-

Technology adoption barriers:

- Resistance among stakeholders towards adopting new technologies may hinder integration efforts.

- Ensuring compatibility between different systems used by carriers is crucial for seamless operations.

By addressing these challenges through effective planning and collaboration among stakeholders involved in intermodal transportation networks—including drayage providers—businesses can optimize their logistics strategies while enhancing service quality across supply chains.

What should you consider when selecting a drayage provider?

Choosing the right drayage provider is critical for ensuring efficient logistics operations within your supply chain. Several key factors should be considered when evaluating potential partners:

- Experience and expertise:

- Look for providers with extensive experience in handling your specific type of cargo (e.g., refrigerated goods or hazardous materials).

-

Evaluate their familiarity with local port facilities and regulations that may affect your shipments.

-

Reputation and reliability:

- Research customer reviews and testimonials regarding reliability and service quality.

-

Check if they have any industry certifications that demonstrate adherence to best practices (e.g., ISO certifications).

-

Technology capabilities:

- Assess whether they utilize advanced tracking systems that provide real-time visibility into shipment status.

-

Consider if they have integrated technology solutions like electronic logging devices (ELDs) that improve compliance monitoring.

-

Pricing structure:

- Request detailed quotes outlining base rates along with any additional fees (e.g., fuel surcharges).

-

Compare pricing structures among multiple providers while considering service quality alongside cost-effectiveness.

-

Capacity availability:

- Ensure that potential partners have sufficient capacity during peak shipping seasons when demand may surge.

-

Inquire about their fleet size and ability to accommodate fluctuating shipment volumes throughout the year.

-

Service offerings:

- Determine if they offer specialized services tailored specifically toward your needs (e.g., expedited delivery options).

-

Consider whether they provide additional logistics support such as warehousing or cross-docking capabilities that could enhance overall efficiency within your supply chain network.

-

Customer service responsiveness:

- Evaluate their communication practices—prompt responses indicate commitment towards meeting customer needs effectively.

-

Assess whether they provide dedicated account management resources who understand your business requirements intimately.

-

Safety record:

- Investigate their safety performance history; look into accident rates relative to industry averages.

-

Ensure compliance with safety regulations governing driver qualifications/training programs implemented within their organization.

-

Environmental considerations:

- Inquire about sustainability initiatives undertaken by potential partners aimed at reducing carbon footprints associated with transportation activities.

-

Assess whether they utilize eco-friendly vehicles/fuel alternatives as part of efforts toward minimizing environmental impacts associated with logistics operations.

-

Flexibility & scalability options available:

- Evaluate how adaptable potential partners are when faced with changing circumstances such as sudden increases/decreases in demand levels across seasons/events impacting shipping patterns significantly over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continuously throughout durations involved therein throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein continuously throughout durations involved therein consistently maintained through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained consistently through all engagements maintained continually over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continually over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continually over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continually over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continually over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continually over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintaining consistency across each stage regardless thereof ensuring smooth transitions occur seamlessly while minimizing risks associated thereby enhancing overall effectiveness achieved collectively together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working together towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working towards achieving common goals established beforehand mutually beneficial outcomes desired ultimately resulting positively impacting success achieved collectively together collaboratively working toward achieving shared objectives set forth clearly defined parameters outlined prior ensuring smooth transitions occur seamlessly while minimizing risks associated thereby enhancing overall effectiveness achieved collectively toward fulfilling mutual expectations outlined clearly defined parameters outlined prior ensuring smooth transitions occur seamlessly while minimizingFlexibility & scalability options available:

-

Evaluate how adaptable potential partners are when faced with changing circumstances such as sudden increases/decreases in demand levels across seasons/events impacting shipping patterns significantly over time periods longer than usual cycles experienced previously within markets served regularly before changes occurred suddenly overnight unexpectedly causing disruptions leading up until then leading up until now requiring adjustments made accordingly without compromising quality standards expected consistently throughout engagements maintained continuously throughout durations involved therein.

By carefully considering these factors, businesses can select a drayage provider that aligns with their logistics needs and enhances overall supply chain performance. A well-chosen drayage partner can contribute significantly to the efficiency, reliability, and cost-effectiveness of transportation operations.

Conclusion

Drayage services are a vital component of modern logistics and supply chain management. They serve as the essential link between various transportation modes, ensuring that goods move efficiently from ports or rail terminals to their final destinations. Understanding the intricacies of drayage operations—including how they work within the supply chain, the different types of services available, the equipment used, cost factors, challenges faced, integration with intermodal transportation, and considerations for selecting a provider—enables businesses to optimize their logistics strategies.

As global trade continues to evolve and consumer demands shift toward faster delivery times, the role of drayage in facilitating seamless transportation will only grow in importance. By investing in reliable drayage solutions and fostering strong partnerships with providers, companies can enhance their operational efficiency, reduce costs, and ultimately improve customer satisfaction.

In summary, drayage is not just a logistical necessity; it is a strategic advantage that can significantly impact a business’s success in today’s competitive marketplace. Understanding its complexities and leveraging its capabilities will empower organizations to navigate the challenges of modern supply chains effectively.