What Is GPS Tracking in Logistics

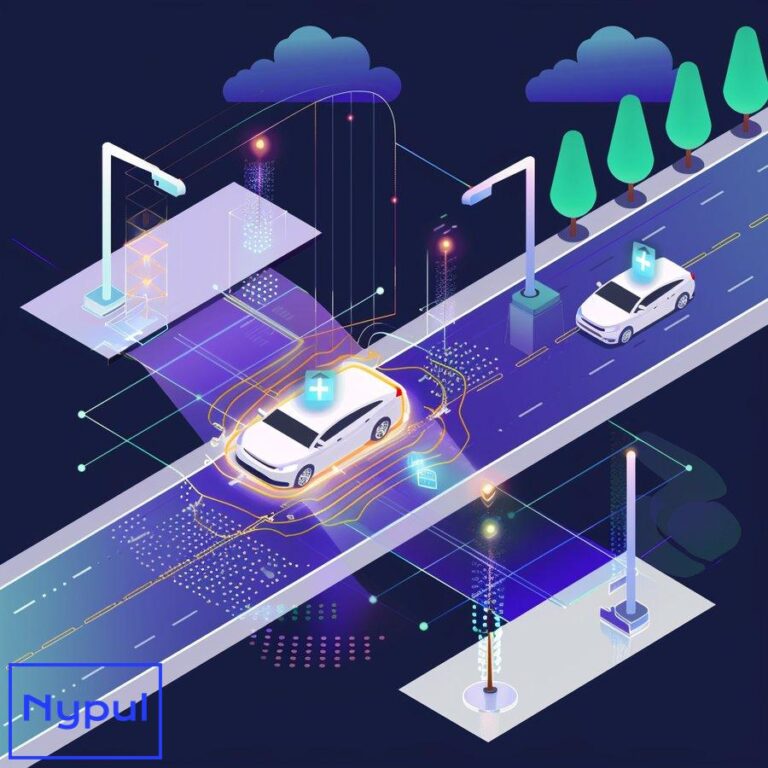

GPS tracking in logistics refers to the use of Global Positioning System technology to monitor and manage the movement of vehicles, assets, and goods throughout the supply chain. This advanced technology enables logistics companies to track the real-time location of their fleet, cargo, and other resources with remarkable precision.

The core components of GPS tracking in logistics include:

GPS Satellites: A network of satellites orbiting the Earth that transmit signals to GPS receivers.

GPS Receivers: Devices installed in vehicles or attached to assets that receive signals from GPS satellites and calculate their precise location.

Communication Networks: Systems that transmit location data from GPS receivers to central servers or monitoring stations.

Software Platforms: Applications that process, analyze, and display GPS tracking data for logistics managers and operators.

GPS tracking has revolutionized the logistics industry by providing unprecedented visibility into supply chain operations. It allows companies to optimize routes, improve efficiency, enhance security, and deliver superior customer service.

The technology works by triangulating the position of a GPS receiver using signals from multiple satellites. These signals contain information about the satellite’s location and the time the signal was sent. The receiver then uses this data to calculate its own position, typically with an accuracy of a few meters.

In logistics applications, GPS tracking goes beyond simple location reporting. Modern systems integrate with other technologies to provide a comprehensive view of logistics operations:

Telematics: Combines GPS with vehicle diagnostics to monitor not just location but also vehicle performance and driver behavior.

Internet of Things (IoT): Connects GPS trackers with sensors that can monitor environmental conditions, cargo status, and more.

Artificial Intelligence (AI): Analyzes GPS data alongside other information to predict arrival times, optimize routes, and identify potential issues before they occur.

The implementation of GPS tracking in logistics has far-reaching implications for various stakeholders:

Logistics Managers: Gain real-time visibility into fleet operations, enabling better decision-making and resource allocation.

Drivers: Benefit from optimized routes, reduced paperwork, and improved safety measures.

Customers: Enjoy more accurate delivery estimates and the ability to track their shipments in real-time.

Regulatory Bodies: Can ensure compliance with driving time regulations and verify the movement of sensitive or regulated goods.

As the logistics industry continues to evolve, GPS tracking remains a cornerstone technology, constantly adapting to meet new challenges and opportunities in the global supply chain.

How does GPS tracking benefit logistics operations?

GPS tracking offers a multitude of benefits to logistics operations, transforming the way companies manage their supply chains and deliver goods. These benefits span various aspects of logistics, from operational efficiency to customer satisfaction.

![]()

Improved Route Optimization

GPS tracking enables logistics companies to optimize their routes in real-time. By analyzing traffic patterns, road conditions, and vehicle locations, dispatchers can guide drivers to the most efficient paths. This optimization leads to:

- Reduced fuel consumption

- Decreased travel times

- Lower operational costs

- Increased number of deliveries per day

For example, a study by the American Transportation Research Institute found that eliminating just one mile from the daily route of each truck in a fleet can save up to $2,000 per truck annually.

Enhanced Asset Utilization

With GPS tracking, logistics managers gain a comprehensive view of their assets’ locations and statuses. This visibility allows for:

- Better allocation of vehicles and equipment

- Reduced idle time

- Improved maintenance scheduling

- Prevention of unauthorized use or theft

A logistics company implementing GPS tracking reported a 15% increase in asset utilization within the first six months, leading to significant cost savings and improved service capacity.

Real-Time Visibility and Transparency

GPS tracking provides real-time updates on the location and status of shipments. This transparency benefits both logistics providers and their customers:

- Accurate ETAs for deliveries

- Proactive communication about delays or issues

- Improved customer satisfaction and loyalty

- Reduced customer service inquiries

A survey by Zebra Technologies found that 89% of logistics companies believe real-time visibility is crucial for successful operations.

Increased Safety and Security

GPS tracking enhances the safety and security of drivers, vehicles, and cargo:

- Quick response to emergencies or breakdowns

- Monitoring of driver behavior (speeding, harsh braking, etc.)

- Geofencing to prevent unauthorized movement

- Tracking and recovery of stolen vehicles or cargo

Insurance companies often offer discounts for fleets equipped with GPS tracking systems, recognizing the reduced risk associated with these safety features.

Improved Regulatory Compliance

GPS tracking helps logistics companies comply with various regulations:

- Electronic logging of driver hours to meet Hours of Service (HOS) requirements

- Verification of routes for hazardous materials transport

- Documentation for customs and border crossings

- Proof of delivery for billing and dispute resolution

The Federal Motor Carrier Safety Administration (FMCSA) mandates the use of Electronic Logging Devices (ELDs), which often incorporate GPS tracking, for commercial trucks in the United States.

Data-Driven Decision Making

The wealth of data provided by GPS tracking systems enables logistics companies to make informed decisions:

- Identifying inefficiencies in operations

- Forecasting delivery times more accurately

- Optimizing fleet size and composition

- Improving customer service strategies

A report by McKinsey & Company suggests that data-driven decision making in logistics can lead to a 15-20% reduction in overall supply chain costs.

Environmental Impact Reduction

By optimizing routes and reducing idle time, GPS tracking contributes to environmental sustainability:

- Lower fuel consumption

- Reduced carbon emissions

- Decreased traffic congestion in urban areas

The World Economic Forum estimates that optimizing delivery routes through technologies like GPS tracking could reduce global CO2 emissions by 30 million tons annually.

Enhanced Customer Experience

GPS tracking allows logistics companies to offer superior customer service:

- Self-service tracking portals for customers

- Proactive notifications about shipment status

- More accurate delivery windows

- Faster resolution of delivery issues

A study by Convey found that 98% of customers consider shipping and delivery to be an important factor in their brand loyalty.

The benefits of GPS tracking in logistics are clear and quantifiable. From operational efficiencies to customer satisfaction, this technology has become an indispensable tool for modern logistics operations. As the technology continues to evolve, integrating with other advanced systems, its impact on the logistics industry is expected to grow even further.

Which types of GPS tracking devices are used in logistics?

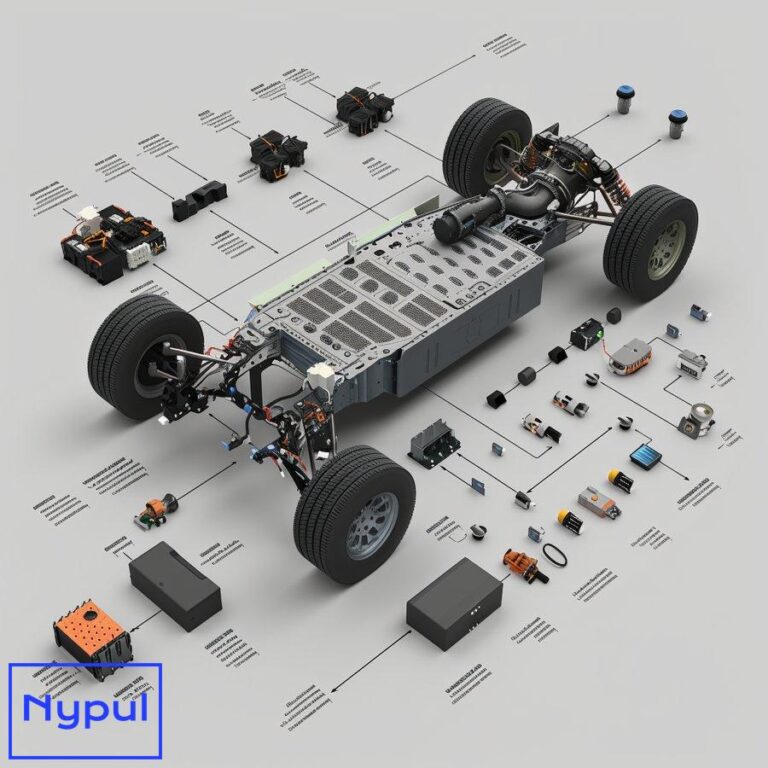

The logistics industry employs a variety of GPS tracking devices, each designed to meet specific needs within the supply chain. These devices range from simple location trackers to sophisticated units that integrate multiple sensors and communication technologies. Understanding the different types of GPS tracking devices is crucial for logistics professionals seeking to implement or upgrade their tracking systems.

Vehicle-Mounted GPS Trackers

These devices are permanently installed in trucks, vans, and other logistics vehicles. They offer continuous tracking and are typically hardwired into the vehicle’s electrical system.

Features:

– Real-time location tracking

– Integration with vehicle diagnostics

– Driver behavior monitoring

– Long battery life (often with vehicle power)

Use Case: A large trucking company uses vehicle-mounted GPS trackers to monitor its fleet of 500 semi-trucks, enabling real-time route optimization and ensuring compliance with hours-of-service regulations.

Portable GPS Trackers

These compact, battery-powered devices can be easily moved between vehicles or attached to shipments. They’re ideal for temporary tracking needs or for use with rented or subcontracted vehicles.

Features:

– Flexibility in deployment

– Battery-powered operation

– Compact and discreet design

– Often equipped with magnetic mounts

Use Case: A logistics company uses portable GPS trackers to monitor high-value shipments, attaching the devices to individual pallets or containers for end-to-end visibility.

Asset Trackers

Designed for non-powered assets such as trailers, containers, or equipment, these devices are built for long battery life and rugged conditions.

Features:

– Extended battery life (often months or years)

– Weatherproof and durable construction

– Motion sensors to conserve battery

– Periodic rather than continuous reporting

Use Case: A shipping company deploys asset trackers on its fleet of intermodal containers, allowing it to track container locations across various modes of transport and storage facilities.

Smartphone-Based Tracking Apps

These software applications turn smartphones into GPS tracking devices, leveraging the phone’s built-in GPS capabilities.

Features:

– Cost-effective implementation

– Easy deployment and updates

– Integration with other mobile apps

– Potential for driver communication features

Use Case: A last-mile delivery service uses a smartphone-based tracking app for its network of independent contractors, providing real-time location data without the need for additional hardware.

Advanced IoT-Enabled GPS Trackers

These cutting-edge devices combine GPS tracking with various sensors and IoT connectivity to provide comprehensive monitoring of assets and their environments.

Features:

– Integration with temperature, humidity, and shock sensors

– Real-time alerts for condition changes

– Cellular and satellite communication options

– Advanced data analytics capabilities

Use Case: A pharmaceutical logistics provider uses IoT-enabled GPS trackers to monitor the location and condition of temperature-sensitive medications throughout the cold chain.

To illustrate the key differences between these GPS tracking device types, consider the following comparison table:

| Feature | Vehicle-Mounted | Portable | Asset Tracker | Smartphone App | IoT-Enabled |

|---|---|---|---|---|---|

| Power Source | Vehicle Battery | Rechargeable Battery | Long-life Battery | Phone Battery | Various Options |

| Installation | Permanent | Temporary | Semi-Permanent | Software Only | Varies |

| Update Frequency | Continuous | Adjustable | Periodic | Continuous | Adjustable |

| Additional Sensors | Yes | Limited | Limited | Phone Sensors | Extensive |

| Typical Battery Life | Unlimited | Days to Weeks | Months to Years | Phone Dependent | Weeks to Months |

| Cost | High | Medium | Medium | Low | High |

| Best For | Fleet Vehicles | Flexible Tracking | Non-powered Assets | Small Operations | Complex Monitoring |

The choice of GPS tracking device depends on various factors, including:

Nature of Assets: The type of vehicle or asset being tracked (e.g., truck, trailer, container).

Tracking Duration: Whether continuous or periodic tracking is required.

Environmental Conditions: The device’s exposure to weather, temperature extremes, or rough handling.

Power Availability: Access to a constant power source or the need for battery operation.

Data Requirements: The frequency and type of data needed (location only vs. comprehensive telematics).

Budget Constraints: The initial investment and ongoing operational costs.

Regulatory Compliance: Specific requirements for electronic logging or temperature monitoring.

As logistics operations become increasingly complex and globalized, the demand for sophisticated GPS tracking devices continues to grow. Many logistics companies now employ a combination of device types to create a comprehensive tracking ecosystem that covers all aspects of their operations.

The future of GPS tracking devices in logistics points towards even greater integration with other technologies. We can expect to see:

- Increased use of AI and machine learning for predictive analytics

- Enhanced integration with blockchain for secure and transparent supply chain tracking

- Development of smaller, more energy-efficient devices with longer battery life

- Expansion of 5G and satellite internet capabilities for improved global coverage

By carefully selecting the appropriate GPS tracking devices for their specific needs, logistics companies can significantly enhance their operational efficiency, security, and customer service capabilities.

How is GPS tracking implemented in logistics systems?

Implementing GPS tracking in logistics systems is a complex process that requires careful planning, integration, and management. The successful deployment of GPS tracking can transform logistics operations, but it demands a strategic approach that considers various technical, operational, and human factors.

Planning and Assessment

The first step in implementing GPS tracking is a thorough assessment of the logistics operation’s needs and goals.

Key Considerations:

– Scope of tracking requirements (fleet size, asset types, geographical coverage)

– Existing technology infrastructure and compatibility

– Budget constraints and return on investment projections

– Regulatory compliance requirements

– Stakeholder buy-in (management, drivers, customers)

A logistics company might conduct a pilot program with a small subset of their fleet to evaluate the impact and feasibility of full-scale implementation.

Hardware Selection and Installation

Choosing the right GPS tracking devices is crucial for the success of the implementation.

Steps in Hardware Deployment:

– Select appropriate GPS devices based on asset types and tracking needs

– Develop an installation schedule that minimizes operational disruption

– Train installation technicians on proper device placement and configuration

– Establish quality control processes to ensure correct installation and functionality

For example, a trucking company might opt for hardwired GPS trackers for its owned fleet and portable devices for leased vehicles or subcontractors.

Software Integration

The GPS tracking system must be integrated with existing logistics management software to maximize its value.

Integration Points:

– Transportation Management Systems (TMS)

– Warehouse Management Systems (WMS)

– Enterprise Resource Planning (ERP) systems

– Customer Relationship Management (CRM) platforms

– Mobile applications for drivers and field personnel

A comprehensive integration might allow a dispatcher to view real-time GPS data alongside order information, inventory levels, and customer details within a single interface.

Data Management and Analytics

Effective data management is essential to derive actionable insights from GPS tracking information.

Data Handling Processes:

– Establish data collection protocols and storage systems

– Implement data cleaning and validation procedures

– Develop analytics capabilities for route optimization, performance metrics, and predictive maintenance

– Create dashboards and reporting tools for different user roles

A logistics provider might use GPS data analytics to identify patterns in delivery delays, allowing them to proactively adjust routes or schedules.

Training and Change Management

Successful implementation requires comprehensive training and change management strategies.

Training Components:

– Device operation and maintenance for drivers and field personnel

– System usage for dispatchers and logistics managers

– Data interpretation and decision-making for executives

– Customer service training for handling tracking-related inquiries

Change management efforts might include regular communication about the benefits of GPS tracking, addressing privacy concerns, and showcasing early wins to build support.

Security and Privacy Measures

Implementing robust security and privacy protocols is crucial to protect sensitive location data.

Security Considerations:

– Encryption of data in transit and at rest

– Access control and user authentication systems

– Regular security audits and vulnerability assessments

– Compliance with data protection regulations (e.g., GDPR, CCPA)

A logistics company might implement role-based access control, ensuring that employees only have access to GPS data relevant to their job functions.

Monitoring and Maintenance

Ongoing monitoring and maintenance are essential to ensure the continued effectiveness of the GPS tracking system.

Maintenance Activities:

– Regular checks of device functionality and accuracy

– Software updates and patch management

– Battery replacement for portable devices

– Calibration of integrated sensors

Establishing a dedicated team or partnering with a managed services provider can help ensure consistent system performance.

Performance Measurement and Optimization

Continuous evaluation and optimization of the GPS tracking implementation are necessary to maximize its benefits.

Key Performance Indicators (KPIs):

– Reduction in fuel consumption

– Improvement in on-time deliveries

– Decrease in unauthorized vehicle use

– Enhanced asset utilization rates

– Customer satisfaction scores related to tracking and visibility

Regular review of these KPIs can guide further refinements and expansions of the GPS tracking system.

Scalability and Future-Proofing

The implementation should be designed with scalability and future technological advancements in mind.

Scalability Considerations:

– Capacity for adding new vehicles or assets

– Ability to expand geographical coverage

– Flexibility to integrate emerging technologies (e.g., 5G, IoT)

– Adaptability to changing regulatory requirements

A forward-thinking implementation might include plans for integrating GPS tracking with emerging blockchain-based supply chain solutions.

To illustrate the typical timeline and key milestones in a GPS tracking implementation, consider the following table:

| Phase | Duration | Key Activities | Milestones |

|---|---|---|---|

| Planning | 1-3 months | Needs assessment, vendor selection, project scoping | Project charter approval |

| Pilot | 2-4 months | Small-scale deployment, testing, evaluation | Pilot results presentation |

| Hardware Deployment | 3-6 months | Device installation, testing | Full fleet equipped |

| Software Integration | 2-4 months | System integration, data flow setup | End-to-end system test |

| Training | 1-2 months | User training, documentation | Training completion certificates |

| Go-Live | 1 month | System activation, monitoring | Successful go-live |

| Optimization | Ongoing | Performance tracking, system refinement | Quarterly review meetings |

The implementation of GPS tracking in logistics systems is a transformative process that requires careful planning, execution, and ongoing management. By following a structured approach and considering all aspects of the implementation, logistics companies can harness the full potential of GPS tracking technology to drive operational excellence and competitive advantage.

As the logistics industry continues to evolve, GPS tracking implementations will likely become more sophisticated, incorporating advanced technologies such as artificial intelligence, machine learning, and predictive analytics. This evolution will enable even greater optimization of logistics operations, further enhancing efficiency, reliability, and customer satisfaction in the global supply chain.

What advanced features do GPS tracking systems offer?

Modern GPS tracking systems in logistics have evolved far beyond simple location tracking. They now offer a suite of advanced features that provide comprehensive insights## What advanced features do GPS tracking systems offer?

Modern GPS tracking systems in logistics have evolved far beyond simple location tracking. They now offer a suite of advanced features that provide comprehensive insights into fleet operations, asset utilization, and supply chain performance.

Geofencing

Geofencing allows users to create virtual boundaries around specific locations, such as warehouses, customer sites, or restricted areas. When a vehicle or asset enters or exits these zones, the system triggers alerts, enabling proactive monitoring and response.

Use Case: A logistics company sets up geofences around its warehouses to receive instant notifications when high-value shipments arrive, allowing for faster unloading and processing.

Driver Behavior Monitoring

GPS tracking systems can monitor driver behavior, including speeding, harsh braking, rapid acceleration, and idling. This data is used to identify training opportunities, improve safety, and reduce fuel consumption.

Use Case: A trucking company analyzes driver behavior data to provide targeted coaching, leading to a 20% reduction in speeding incidents and a 15% improvement in fuel efficiency.

Predictive Maintenance

By integrating GPS tracking with vehicle diagnostics, logistics companies can predict when maintenance is needed based on factors such as mileage, engine hours, and fault codes. This enables proactive maintenance scheduling, minimizing downtime and reducing repair costs.

Use Case: A fleet management company uses predictive maintenance insights to reduce unscheduled repairs by 30% and extend the average lifespan of its vehicles by two years.

Trailer Tracking

Dedicated trailer tracking devices allow logistics companies to monitor the location and status of their trailers, even when they are not attached to a tractor. This is particularly useful for intermodal operations and trailer pools.

Use Case: A logistics provider implements trailer tracking to reduce the time spent searching for trailers at its terminals by 40%, improving asset utilization and reducing the need for additional equipment.

Temperature and Environmental Monitoring

GPS tracking systems can integrate with sensors that monitor temperature, humidity, shock, and other environmental conditions. This is crucial for the transportation of perishable goods, pharmaceuticals, and other sensitive cargo.

Use Case: A food logistics company uses temperature-monitoring GPS trackers to ensure the integrity of its frozen food shipments, reducing spoilage and claims by 25%.

Cargo Monitoring

Advanced GPS trackers can detect when cargo is loaded or unloaded, providing detailed chain-of-custody information. Some systems even offer load sensors to monitor cargo weight and detect potential theft or tampering.

Use Case: A high-value goods logistics provider uses cargo monitoring GPS trackers to verify the loading and unloading of its shipments, eliminating disputes over missing items and improving customer confidence.

Integrated Dashboards and Reporting

Modern GPS tracking systems offer comprehensive dashboards and reporting tools that consolidate data from various sources, including vehicle telematics, driver behavior, maintenance records, and customer information. These tools enable logistics managers to make data-driven decisions and communicate effectively with stakeholders.

Use Case: A large logistics company develops a custom dashboard that integrates GPS tracking data with its TMS and ERP systems, providing a single pane of glass view of its operations. This dashboard helps the company identify and address inefficiencies, leading to a 10% reduction in overall supply chain costs.

Mobile Apps and Driver Engagement

Many GPS tracking systems now offer mobile apps that allow drivers to access information, communicate with dispatchers, and even perform tasks such as electronic proof of delivery. These apps help engage drivers and improve their productivity.

Use Case: A last-mile delivery company provides its drivers with a mobile app that integrates with its GPS tracking system. The app allows drivers to view their routes, receive turn-by-turn navigation, and capture electronic signatures for proof of delivery. This leads to a 15% increase in daily deliveries per driver.

Artificial Intelligence and Machine Learning

Advanced GPS tracking systems are increasingly incorporating artificial intelligence (AI) and machine learning (ML) algorithms to analyze data and provide predictive insights. These technologies can forecast arrival times, optimize routes, and identify potential issues before they occur.

Use Case: A logistics company uses AI-powered route optimization to reduce its fleet’s total mileage by 8%, leading to a corresponding decrease in fuel consumption and emissions.

As the logistics industry continues to evolve, GPS tracking systems will likely become even more sophisticated, incorporating emerging technologies such as 5G, edge computing, and blockchain. These advancements will enable real-time, end-to-end visibility and optimization across the entire supply chain.

How is data analyzed and reported in GPS logistics?

Data analysis and reporting are essential components of GPS tracking in logistics, enabling companies to derive actionable insights from the vast amounts of data generated by their tracking systems. By effectively analyzing and reporting on GPS data, logistics professionals can make informed decisions, optimize operations, and improve overall performance.

Data Collection and Storage

The first step in data analysis is ensuring that GPS tracking data is collected and stored in a structured, organized manner. This involves:

- Establishing data collection protocols and formats

- Implementing secure data storage systems, such as cloud-based databases or data lakes

- Ensuring data integrity through validation and error-checking processes

Use Case: A logistics company sets up a centralized data warehouse to store GPS tracking data, integrating it with data from its TMS, WMS, and ERP systems. This allows for comprehensive analysis and reporting across all aspects of its operations.

Data Cleaning and Normalization

Before analysis can begin, GPS tracking data must be cleaned and normalized to remove inconsistencies, errors, and outliers. This process includes:

- Identifying and addressing missing or invalid data points

- Standardizing data formats and units of measurement

- Removing duplicates and resolving data conflicts

Use Case: A logistics provider implements automated data cleaning scripts to identify and correct erroneous GPS coordinates, ensuring that its route optimization algorithms are based on accurate location data.

Descriptive Analytics

Descriptive analytics focuses on summarizing and visualizing GPS tracking data to gain insights into past and current performance. Common descriptive analytics techniques include:

- Key performance indicators (KPIs), such as on-time delivery rates, fuel efficiency, and asset utilization

- Dashboards and scorecards that provide real-time views of operational metrics

- Reports that aggregate data over specific time periods or geographic regions

Use Case: A logistics company develops a set of KPIs based on its GPS tracking data, including average delivery times, miles per gallon, and driver safety scores. These KPIs are tracked and reported on a weekly basis, enabling managers to identify trends and areas for improvement.

Diagnostic Analytics

Diagnostic analytics delves deeper into GPS tracking data to uncover the root causes of performance issues or inefficiencies. Techniques used in diagnostic analytics include:

- Root cause analysis to identify factors contributing to delays, breakdowns, or other problems

- Correlation analysis to determine relationships between variables, such as weather conditions and delivery times

- Segmentation to group data based on specific characteristics, such as vehicle type or driver performance

Use Case: A logistics provider uses diagnostic analytics to investigate a spike in fuel consumption across its fleet. By analyzing GPS data alongside vehicle diagnostics and driver behavior, the company identifies a maintenance issue with a specific vehicle model that is causing excessive idling and wasted fuel.

Predictive Analytics

Predictive analytics leverages historical GPS tracking data and machine learning algorithms to forecast future performance and identify potential risks or opportunities. Common predictive analytics techniques include:

- Forecasting models to predict arrival times, demand fluctuations, or equipment failures

- Risk assessment models to identify high-risk routes, shipments, or drivers

- Optimization models to determine the most efficient routes or resource allocations

Use Case: A logistics company uses predictive analytics to forecast delivery times based on historical GPS data, traffic patterns, and weather forecasts. This allows the company to provide customers with more accurate delivery estimates and proactively communicate any potential delays.

Prescriptive Analytics

Prescriptive analytics goes beyond forecasting to recommend specific actions or decisions based on GPS tracking data and other relevant information. Techniques used in prescriptive analytics include:

- Optimization algorithms to determine the most efficient routes or resource allocations

- Simulation models to test the impact of different scenarios or strategies

- Recommendation engines to suggest actions based on real-time data and business rules

Use Case: A logistics provider uses prescriptive analytics to optimize its fleet routing in real-time, taking into account GPS tracking data, traffic conditions, and customer priorities. The system automatically generates and recommends the most efficient routes for each driver, reducing overall mileage and fuel consumption.

Reporting and Visualization

Effective reporting and visualization are essential for communicating insights derived from GPS tracking data to various stakeholders, including managers, drivers, and customers. Common reporting and visualization techniques include:

- Dashboards and scorecards that provide at-a-glance views of key metrics

- Reports that summarize data over specific time periods or geographic regions

- Visualizations, such as maps, charts, and graphs, that highlight trends and patterns

Use Case: A logistics company develops a customer portal that allows its clients to track their shipments in real-time using GPS data. The portal includes interactive maps, delivery timelines, and performance reports, enabling customers to monitor the status of their orders and identify any potential issues.

As the volume and complexity of GPS tracking data continue to grow, the use of advanced analytics techniques, such as artificial intelligence and machine learning, will become increasingly important. By leveraging these technologies, logistics companies can gain deeper insights, make more informed decisions, and optimize their operations to stay competitive in an ever-evolving industry.

What are the privacy and legal considerations for GPS tracking in logistics?

The use of GPS tracking in logistics raises important privacy and legal considerations that must be addressed to ensure compliance and maintain trust with employees, customers, and other stakeholders. Logistics companies must balance the benefits of GPS tracking with the need to protect individual privacy and adhere to relevant regulations.

Employee Privacy

One of the primary concerns surrounding GPS tracking in logistics is the potential impact on employee privacy. Drivers and other personnel may feel that their movements and behavior are being constantly monitored, which can lead to feelings of mistrust and resentment.

To address these concerns, logistics companies should:

- Clearly communicate the purpose and benefits of GPS tracking to employees

- Establish policies and procedures that limit the use of GPS data to legitimate business purposes

- Ensure that GPS tracking is not used for excessive or unreasonable monitoring of employee activities

- Provide employees with the ability to report any misuse or abuse of GPS tracking data

Use Case: A logistics company implements a GPS tracking policy that specifies the types of data collected, the purposes for which it will be used, and the measures taken to protect employee privacy. The company also provides training to managers on the appropriate use of GPS tracking data and establishes a process for employees to raise concerns or file complaints.

Customer Privacy

GPS tracking in logistics can also raise concerns about customer privacy, particularly when it comes to the transportation of sensitive or confidential goods. Customers may be concerned about the security of their data and the potential for unauthorized access or misuse.

To address customer privacy concerns, logistics companies should:

- Clearly communicate their data privacy and security practices to customers

- Implement robust data encryption and access control measures to protect customer data

- Comply with relevant data protection regulations, such as the General Data Protection Regulation (GDPR) or the California Consumer Privacy Act (CCPA)

- Establish procedures for responding to customer inquiries or complaints about data privacy

Use Case: A logistics company that transports sensitive goods, such as medical devices or financial records, implements a comprehensive data privacy and security program. This program includes encryption of GPS tracking data, access controls based on need-to-know principles, and regular security audits. The company also provides customers with detailed information about its data privacy practices and offers a dedicated point of contact for any privacy-related concerns or inquiries.

Legal and Regulatory Compliance

The use of GPS tracking in logistics is subject to various legal and regulatory requirements, depending on the jurisdiction and the nature of the goods being transported. These requirements may include:

- Compliance with labor laws and regulations governing the monitoring of employee activities

- Adherence to transportation regulations, such as hours-of-service rules or hazardous materials handling

- Conformance with data protection and privacy laws, such as GDPR or CCPA

- Fulfillment of contractual obligations and industry standards related to cargo security and chain of custody

To ensure compliance, logistics companies should:

- Stay informed about relevant laws and regulations and monitor for changes or updates

- Consult with legal and compliance experts to develop appropriate policies and procedures

- Provide training to employees on legal and regulatory requirements related to GPS tracking

- Conduct regular audits and assessments to identify and address any compliance gaps

Use Case: A logistics company that transports hazardous materials implements a GPS tracking system that meets all relevant regulatory requirements, including the ability to generate electronic shipping papers and provide real-time location updates to emergency responders in the event of an incident. The company also ensures that its GPS tracking policies and procedures are reviewed and approved by legal and compliance experts to minimize the risk of non-compliance.

Ethical Considerations

Beyond legal and regulatory requirements, logistics companies should also consider the ethical implications of GPS tracking. This includes:

- Ensuring that the use of GPS tracking is proportionate to the legitimate business needs and does not infringe on individual rights or freedoms

- Considering the potential impact of GPS tracking on vulnerable populations, such as migrant workers or independent contractors

- Promoting transparency and accountability in the use of GPS tracking data, including clear communication of data collection and usage practices

Use Case: A logistics company that employs a significant number of independent contractors establishes an ethics committee to oversee the use of GPS tracking. The committee develops guidelines for the ethical use of GPS data, including measures to protect the privacy and autonomy of contractors. The company also provides contractors with the ability to access their own GPS data and offers training on how to interpret and use this information to improve their own performance and safety.

By proactively addressing privacy and legal considerations, logistics companies can harness the power of GPS tracking while maintaining the trust and confidence of their employees, customers, and other stakeholders. As the use of GPS tracking continues to evolve, ongoing dialogue and collaboration between industry, policymakers, and civil society will be essential to ensure that the benefits of this technology are realized in a responsible and ethical manner.

How do you choose the right GPS tracking solution for your logistics needs?

Choosing the right GPS tracking solution for your logistics needs is a critical decision that can have far-reaching implications for your operations, efficiency, and bottom line. With a wide range of GPS tracking providers and solutions available, it’s essential to carefully evaluate your options and select a system that aligns with your specific requirements and goals.

Assess Your Needs

The first step in choosing a GPS tracking solution is to conduct a thorough assessment of your logistics operation’s needs and goals. Consider factors such as:

- Fleet size and composition (e.g., trucks, trailers, containers)

- Geographic coverage and operating areas

- Types of goods transported (e.g., perishable, hazardous, high-value)

- Current challenges and pain points (e.g., route optimization, asset utilization, driver safety)

- Future growth and expansion plans

Use Case: A logistics company operating a fleet of 200 trucks across the United States identifies the need for a GPS tracking solution that can provide real-time visibility, optimize routes, and monitor driver behavior to improve safety and efficiency.

Evaluate Provider Capabilities

Once you have a clear understanding of your needs, research and evaluate potential GPS tracking providers. Consider factors such as:

- Breadth and depth of features (e.g., geofencing, driver behavior monitoring, predictive maintenance)

- Integration capabilities with existing systems (e.g., TMS, WMS, ERP)

- Data security and privacy measures

- Scalability and future-proofing

- Customer support and training resources

Use Case: A logistics company evaluates several GPS tracking providers and selects a solution that offers advanced features such as AI-powered route optimization, integrated dashboards, and mobile apps for driver engagement. The provider also demonstrates a strong commitment to data security and offers comprehensive training and support resources.

Assess Hardware and Installation

In addition to the software capabilities, consider the hardware requirements and installation process. Key factors to evaluate include:

- Types of GPS tracking devices available (e.g., vehicle-mounted, portable, asset trackers)

- Installation requirements and compatibility with existing vehicles and assets

- Ongoing maintenance and replacement needs

- Ease of installation and impact on operations

Use Case: A logistics company chooses a GPS tracking solution that offers a range of device types, including hardwired units for its owned fleet and portable trackers for leased vehicles and subcontractors. The provider offers a streamlined installation process that minimizes operational disruption and provides ongoing support for device maintenance and replacement.

Analyze Costs and ROI

GPS tracking solutions can vary significantly in terms of cost, so it’s essential to carefully analyze the total cost of ownership and potential return on investment. Consider factors such as:

- Initial hardware and software costs

- Ongoing subscription or usage fees

- Installation and training expenses

- Potential cost savings from improved efficiency, safety, and customer service

Use Case: A logistics company calculates the potential ROI of its GPS tracking investment based on factors such as reduced fuel consumption, improved asset utilization, and decreased insurance premiums. The company determines that the solution will pay for itself within 12-18 months and continue to generate significant cost savings in the long term.

Evaluate Vendor Support and Partnerships

The quality of the vendor’s support and partnerships can also be a critical factor in the success of your GPS tracking implementation. Consider factors such as:

- Responsiveness and expertise of the vendor’s support team

- Availability of training resources and user documentation

- Partnerships with complementary technology providers (e.g., ELD manufacturers, telemEvaluate Vendor Support and Partnerships

The quality of the vendor’s support and partnerships can also be a critical factor in the success of your GPS tracking implementation. Consider factors such as:

- Responsiveness and expertise of the vendor’s support team

- Availability of training resources and user documentation

- Partnerships with complementary technology providers (e.g., ELD manufacturers, telematics solutions)

- Community or user groups for sharing best practices and troubleshooting

Use Case: A logistics company selects a GPS tracking provider known for its exceptional customer support, including 24/7 assistance and extensive online resources. The vendor also has partnerships with leading telematics providers, allowing for seamless integration with other systems.

Request Demos and Trials

Before making a final decision, request demonstrations or trial periods from potential GPS tracking vendors. This hands-on experience will allow you to evaluate the user interface, functionality, and overall performance of the system in real-world scenarios.

Use Case: A logistics manager arranges for trial access to multiple GPS tracking systems, allowing the team to test features such as route optimization, geofencing alerts, and driver behavior monitoring. Feedback from drivers and dispatchers during the trial helps inform the final selection.

Consider Long-Term Scalability

As your logistics operation grows and evolves, your GPS tracking solution should be able to scale with you. Consider whether the system can accommodate:

- An increasing number of vehicles or assets

- Expansion into new geographic regions

- Additional features or integrations as technology advances

Use Case: A rapidly growing logistics startup selects a GPS tracking solution that offers modular features, allowing them to add capabilities such as IoT sensors or advanced analytics as their business scales.

Review Customer Feedback and Case Studies

Research customer feedback and case studies related to potential GPS tracking providers. This information can provide valuable insights into the experiences of other logistics companies and help you gauge the effectiveness of the solution in real-world applications.

Use Case: A logistics company reviews case studies from similar businesses that successfully implemented a particular GPS tracking solution. Positive feedback regarding improved efficiency and customer satisfaction influences their decision-making process.

Make an Informed Decision

After thoroughly evaluating your options based on the criteria outlined above, make an informed decision regarding your GPS tracking solution. Ensure that all stakeholders are aligned with the choice and that there is a clear plan for implementation.

Use Case: Following extensive research and evaluation, a logistics company selects a GPS tracking provider that meets its operational needs, aligns with its budget, and offers strong support. The decision is communicated to all employees involved in the implementation process to ensure buy-in and cooperation.

Choosing the right GPS tracking solution for your logistics needs is a multi-faceted process that requires careful consideration of various factors. By conducting thorough assessments, evaluating provider capabilities, analyzing costs, and seeking input from stakeholders, logistics companies can select a system that enhances operational efficiency, improves safety, and ultimately drives customer satisfaction.

As technology continues to advance, staying informed about new developments in GPS tracking will be essential for maintaining a competitive edge in the logistics industry. Embracing innovation while aligning with business goals will ensure that your organization remains agile and responsive to changing market demands.