What Is Dwell Time in Supply Chain Management

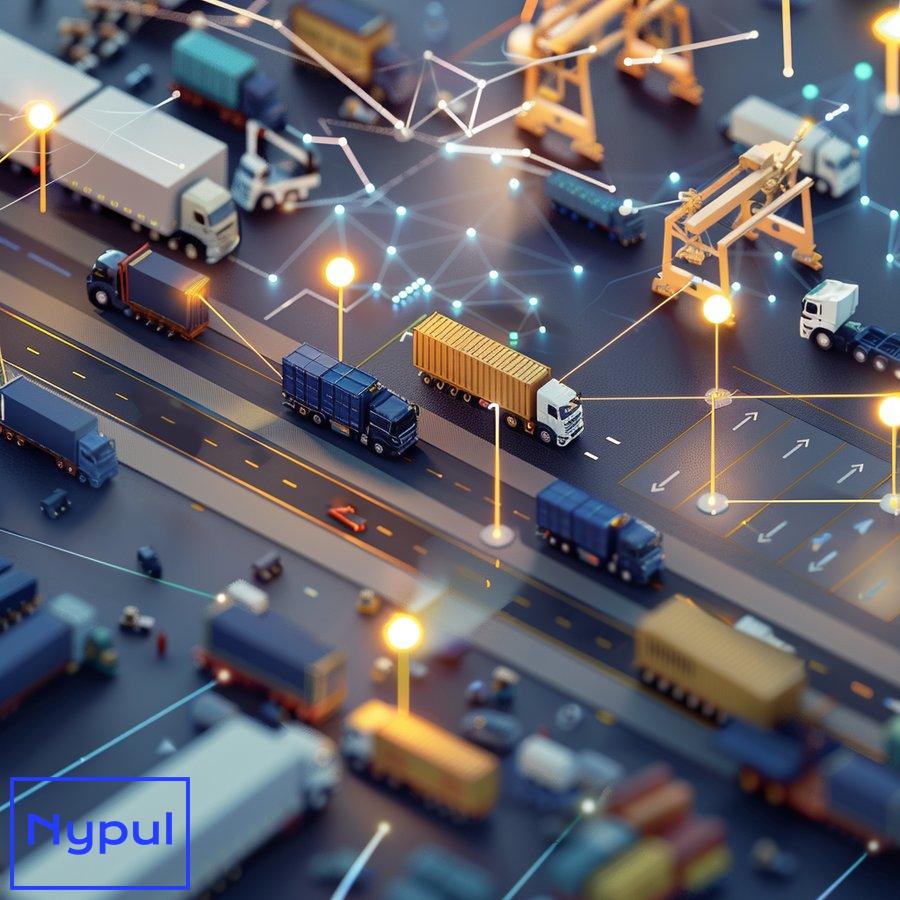

Dwell time is a critical metric in supply chain management, representing the duration that cargo, vehicles, or equipment remain stationary at a particular point in the logistics process. This can occur at various locations, including ports, terminals, warehouses, and distribution centers. Understanding dwell time is essential for improving operational efficiency and reducing costs across the supply chain.

Dwell time begins when a shipment arrives at a facility and ends when it departs for its next destination. It can be categorized into several types:

-

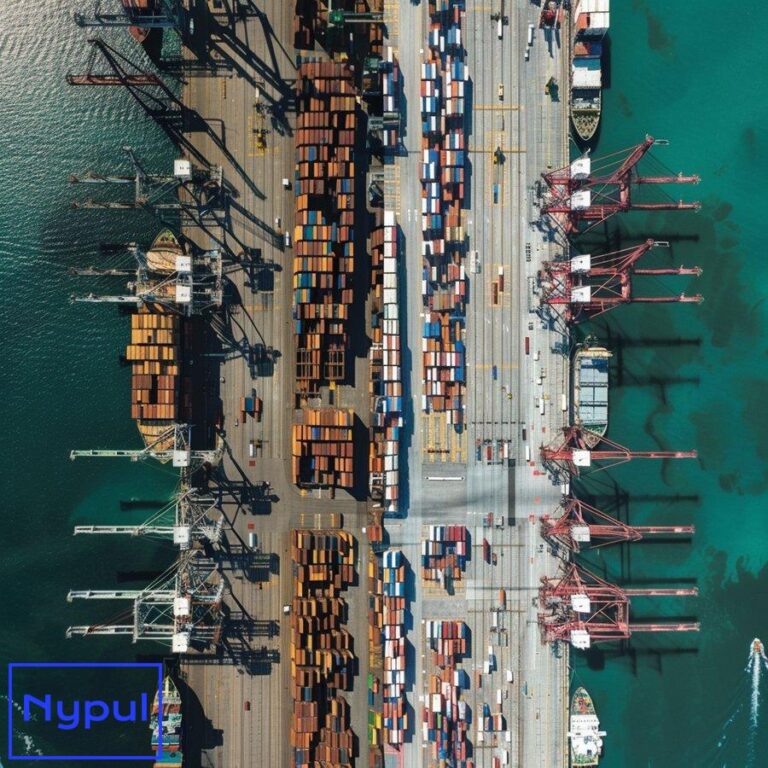

Vessel Dwell Time: The time an ocean vessel spends at port while unloading and loading cargo. High vessel dwell times can lead to congestion and operational inefficiencies.

-

Terminal Dwell Time: The duration that a container or piece of equipment waits at a terminal before moving to the next transport phase. Low terminal dwell times indicate efficient operations.

-

Container Street Dwell Time: The time that containers spend between leaving the terminal and returning. Extended street dwell times may signal inefficiencies in delivery processes.

-

Free Time: The period during which cargo can remain at a location without incurring storage fees. Once this period expires, additional charges may apply.

Understanding these distinctions is vital for stakeholders in the supply chain, as each type of dwell time can significantly impact overall logistics performance.

Why is dwell time important for logistics efficiency?

Dwell time plays a crucial role in logistics efficiency for several reasons:

-

Impact on Costs: Extended dwell times can lead to increased operational costs due to storage fees, detention charges, and lost productivity. For instance, if trucks are delayed at loading docks, drivers may incur detention fees, affecting their profitability.

-

Effect on Delivery Schedules: Longer dwell times disrupt delivery schedules, leading to delays that ripple through the supply chain. This can result in missed customer deadlines and dissatisfied clients.

-

Resource Utilization: High dwell times tie up valuable resources such as trucks and drivers that could be utilized elsewhere. This inefficiency reduces the overall capacity of the transportation network.

-

Supply Chain Visibility: Monitoring dwell time provides insights into operational bottlenecks and inefficiencies. By analyzing this data, companies can identify areas for improvement and streamline their processes.

To illustrate the importance of managing dwell time effectively, consider the following table that summarizes its impact on logistics efficiency:

| Impact Area | Effect of High Dwell Time | Benefits of Low Dwell Time |

|---|---|---|

| Costs | Increased storage and detention fees | Reduced operational costs |

| Delivery Schedules | Delayed deliveries leading to customer dissatisfaction | Timely deliveries enhancing customer satisfaction |

| Resource Utilization | Inefficient use of trucks and drivers | Improved asset utilization |

| Supply Chain Visibility | Difficulty identifying bottlenecks | Enhanced process optimization |

By recognizing the implications of dwell time on these critical areas, organizations can prioritize its management as part of their logistics strategy.

How do different types of dwell time affect supply chains?

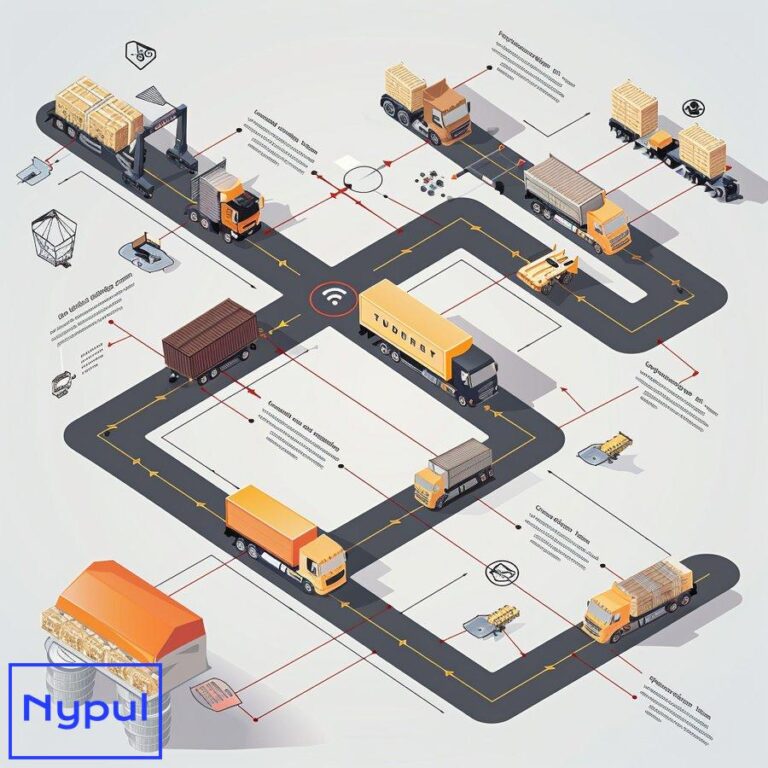

Different types of dwell time impact supply chains in unique ways:

-

Vessel Dwell Time: When vessels remain docked longer than necessary, it leads to congestion at ports. This not only delays subsequent shipments but also increases costs associated with port operations and demurrage fees.

-

Terminal Dwell Time: High terminal dwell times indicate inefficiencies in cargo handling processes. This can stem from inadequate staffing, poor scheduling practices, or insufficient infrastructure. Such delays hinder the flow of goods through the supply chain.

-

Container Street Dwell Time: Prolonged street dwell times suggest issues with last-mile delivery operations. If containers are not picked up promptly after leaving terminals, it can lead to increased inventory carrying costs and potential penalties for exceeding free time limits.

-

Free Time: The management of free time is crucial; if shipments exceed this period without being picked up or delivered, companies face additional charges that can erode profit margins.

The following table summarizes how each type of dwell time affects supply chain dynamics:

| Type of Dwell Time | Impact on Supply Chain |

|---|---|

| Vessel Dwell Time | Congestion at ports; increased demurrage fees |

| Terminal Dwell Time | Inefficiencies in cargo handling; delays in goods flow |

| Container Street Dwell Time | Increased carrying costs; penalties for late pickups |

| Free Time | Additional charges; potential inventory management issues |

Understanding these effects allows supply chain managers to implement targeted strategies to mitigate delays associated with each type of dwell time.

What are the primary causes of extended dwell time?

Extended dwell times can arise from various factors within the logistics ecosystem:

-

Inefficient On-Site Processes: Slow document processing or cumbersome check-in procedures can significantly prolong loading and unloading times. Poor communication among staff also exacerbates these delays.

-

Customs Clearance Delays: Regulatory compliance checks often lead to extended waits at ports or terminals. Delays in customs clearance can cause significant backlogs and affect overall supply chain performance.

-

Equipment Availability: A lack of available transportation or handling equipment can lead to bottlenecks. For example, if trucks are not readily available for loading or unloading, it results in increased wait times.

-

Unplanned Disruptions: Unexpected events such as equipment failures or adverse weather conditions can disrupt schedules and extend dwell times. These disruptions often create cascading effects throughout the supply chain.

The following table outlines common causes of extended dwell time:

| Cause | Description |

|---|---|

| Inefficient On-Site Processes | Slow procedures leading to longer wait times |

| Customs Clearance Delays | Regulatory checks causing significant delays |

| Equipment Availability | Lack of transportation leading to bottlenecks |

| Unplanned Disruptions | Unexpected events causing operational interruptions |

By identifying these root causes, organizations can develop strategies to address them effectively.

How does dwell time impact supply chain costs and performance?

Dwell time has a direct correlation with both costs and performance metrics within the supply chain:

-

Cost Implications: Extended dwell times result in increased storage fees, detention charges for carriers, and potential penalties for shippers due to missed delivery windows. These costs accumulate quickly and impact profitability across all stakeholders involved in the logistics process.

-

Performance Metrics: Key performance indicators (KPIs) such as on-time delivery rates and customer satisfaction scores are adversely affected by high dwell times. Delays in shipments lead to unmet expectations from customers, which can harm relationships and brand reputation.

To quantify these impacts further, consider the following statistics:

-

A study found that every additional hour a truck spends waiting leads to an average cost increase of $66 per truck due to lost productivity.

-

According to industry reports, companies experience an average increase of 20% in logistics costs when average dwell times exceed 24 hours at ports or terminals.

The following table summarizes how extended dwell times affect costs and performance:

| Area | Impact of Extended Dwell Times |

|---|---|

| Costs | Increased storage fees; detention charges |

| Performance Metrics | Lower on-time delivery rates; decreased customer satisfaction |

Understanding these implications allows organizations to prioritize strategies aimed at reducing dwell time as part of their broader cost management efforts.

What methods are used to measure and analyze dwell time?

Measuring and analyzing dwell time involves several methodologies that provide insights into operational efficiency:

-

Data Tracking Systems: Many facilities utilize advanced tracking systems that log arrival and departure times for shipments. This data helps calculate average dwell times over specific periods or for particular routes.

-

Performance Dashboards: Real-time dashboards aggregate data from various sources within the supply chain to provide visibility into current operations. These dashboards allow stakeholders to monitor key metrics related to dwell time continuously.

-

Root Cause Analysis: By analyzing patterns in dwelling data alongside other performance metrics (such as delays), organizations can identify root causes contributing to extended wait times. This analysis helps prioritize areas for improvement.

The following table illustrates common methods used for measuring and analyzing dwell time:

| Method | Description |

|---|---|

| Data Tracking Systems | Logs arrival/departure times for accurate calculations |

| Performance Dashboards | Aggregates data for real-time visibility |

| Root Cause Analysis | Identifies underlying issues contributing to delays |

Implementing these measurement methods enables organizations to gain actionable insights into their operations regarding dwelling metrics.

How can technology improve dwell time management?

Technology plays a pivotal role in enhancing the management of dwell time by providing tools that streamline processes:

-

Real-Time Tracking Systems: These systems enable stakeholders to monitor shipments continuously throughout their journey. By providing visibility into where delays occur, companies can quickly address issues before they escalate into significant problems.

-

Automated Scheduling Tools: Advanced scheduling software helps optimize loading dock appointments based on real-time data regarding shipment arrivals and departures. This minimizes wait times by ensuring that resources are allocated efficiently during peak periods.

-

Data Analytics Platforms: Utilizing analytics tools allows companies to analyze historical data related to dwelling patterns. Insights derived from this analysis help identify trends over time, enabling proactive decision-making regarding resource allocation and process improvements.

The following table summarizes how various technologies contribute to improved dwelling management:

| Technology | Contribution |

|---|---|

| Real-Time Tracking Systems | Continuous monitoring enhances visibility |

| Automated Scheduling Tools | Optimizes dock appointments based on real-time data |

| Data Analytics Platforms | Analyzes trends for proactive decision-making |

By leveraging these technologies effectively, organizations can significantly reduce average dwelling times across their operations.

What strategies can reduce dwell time in supply chains?

Reducing dwelling times requires a multifaceted approach involving various strategies tailored to specific operational contexts:

-

Improved Coordination Among Partners: Enhancing communication between shippers, carriers, and receivers fosters better collaboration throughout the logistics process. Establishing clear expectations regarding schedules helps minimize misunderstandings that lead to delays.

-

Streamlined Customs Processes: Investing in technology solutions that expedite customs clearance procedures reduces wait times significantly at ports. Automation tools help manage documentation more efficiently while ensuring compliance with regulations.

-

Optimized Resource Allocation: Analyzing historical data allows organizations to allocate resources more effectively during peak periods or high-demand seasons. This proactive approach minimizes bottlenecks caused by uneven workloads across facilities.

The following table outlines effective strategies for reducing dwelling times:

| Strategy | Description |

|---|---|

| Improved Coordination | Enhances communication between all parties involved |

| Streamlined Customs Processes | Expedites clearance through automation |

| Optimized Resource Allocation | Allocates resources based on historical demand patterns |

Implementing these strategies collectively contributes towards minimizing dwelling durations within supply chains while improving overall efficiency across logistics operations.

In conclusion, understanding and managing dwell time is crucial for optimizing logistics operations within today’s complex supply chains. By addressing its causes through technology adoption and strategic planning efforts—companies not only enhance their operational efficiencies but also improve customer satisfaction levels while reducing associated costs over time.