What Is Inter-Carrier Drayage

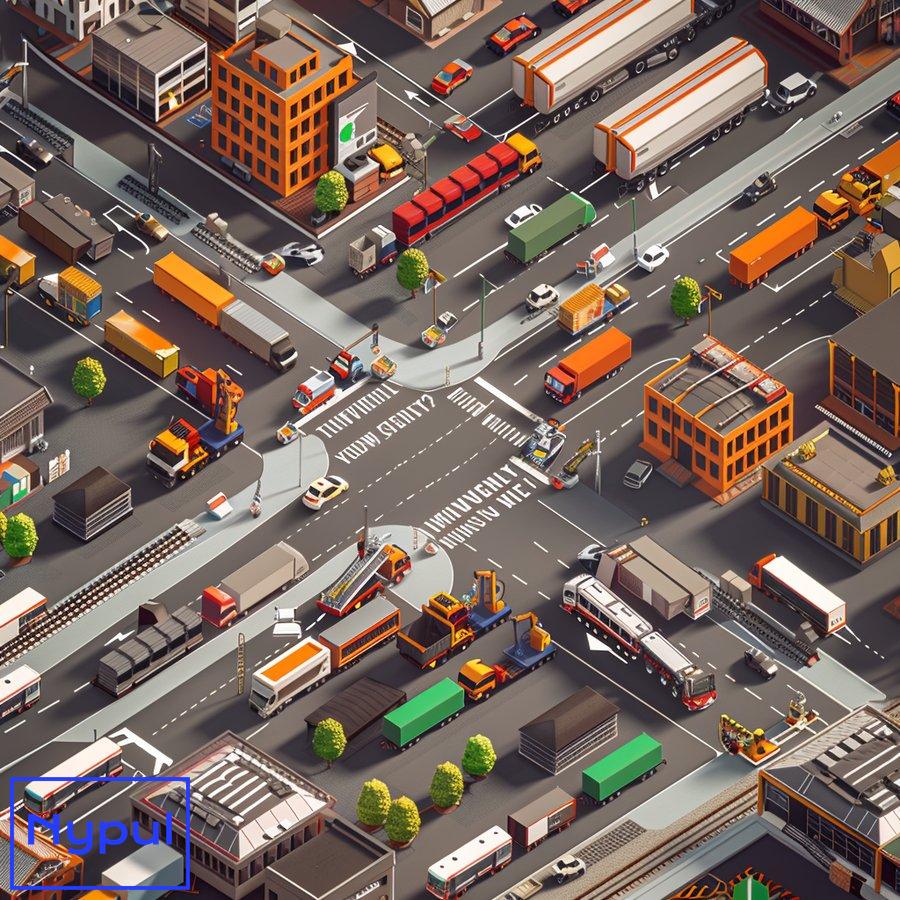

Inter-carrier drayage is a specialized logistics service that involves the transportation of shipping containers or cargo between different carriers or modes of transportation. This crucial component of the supply chain facilitates the seamless movement of goods from one carrier to another, typically over short distances within a localized area.

The term “inter-carrier” specifically refers to the transfer between different transportation providers or modes. For example, inter-carrier drayage might involve moving a container from a rail yard to a shipping port, or from one trucking company’s terminal to another’s. The “drayage” part of the term comes from the historical use of horse-drawn carts called “drays” for short-distance freight transport.

Inter-carrier drayage serves as a vital link in the intermodal transportation network, enabling efficient cargo transfers and ensuring the continuous flow of goods through various stages of the supply chain. This service is particularly important in today’s globalized economy, where products often travel across multiple modes of transportation and through various carriers before reaching their final destination.

Key aspects of inter-carrier drayage include:

Short-distance transport: Inter-carrier drayage typically covers relatively short distances, usually within a metropolitan area or between nearby logistics hubs.

Intermodal connectivity: This service bridges gaps between different transportation modes, such as rail, sea, and road, facilitating smooth transitions in the intermodal supply chain.

Carrier coordination: Inter-carrier drayage providers must coordinate closely with multiple carriers to ensure timely and efficient transfers of cargo.

Specialized equipment: Drayage operations often require specialized trucks and trailers capable of handling various types of containers and cargo.

Regulatory compliance: Drayage providers must adhere to local, national, and international regulations governing the transportation of goods, including customs and security requirements.

Understanding inter-carrier drayage is essential for logistics professionals, supply chain managers, and businesses involved in international trade. This service plays a critical role in optimizing the movement of goods, reducing transportation costs, and improving overall supply chain efficiency.

How does inter-carrier drayage differ from other types of drayage?

Inter-carrier drayage is one of several types of drayage services within the logistics industry. To fully appreciate its unique characteristics, it’s important to compare it with other drayage categories. Each type of drayage serves a specific purpose in the supply chain, and understanding these differences can help logistics professionals choose the most appropriate service for their needs.

Inter-carrier drayage vs. Pier drayage

Inter-carrier drayage involves the movement of cargo between different carriers or modes of transportation. In contrast, pier drayage specifically refers to the transport of containers from a port to another location, typically a rail terminal or a warehouse. While both services involve short-distance transportation, pier drayage is more focused on port operations and the initial movement of imported goods.

Key differences:

– Inter-carrier drayage: Transfers between various carriers and modes

– Pier drayage: Primarily moves containers from ports to inland locations

Inter-carrier drayage vs. Intra-carrier drayage

Intra-carrier drayage involves the movement of goods within a single carrier’s network. For example, this might include transferring containers between different terminals operated by the same shipping line. Inter-carrier drayage, on the other hand, involves transfers between different carriers or transportation providers.

Key differences:

– Inter-carrier drayage: Involves multiple carriers or transportation providers

– Intra-carrier drayage: Operates within a single carrier’s network

Inter-carrier drayage vs. Shuttle drayage

Shuttle drayage refers to the continuous movement of containers between two points, often within a port or terminal complex. This service is used to manage high-volume cargo flows and reduce congestion. Inter-carrier drayage, while it may involve similar short-distance movements, is not limited to a fixed route between two points and typically involves transfers between different carriers.

Key differences:

– Inter-carrier drayage: Flexible routing between various carriers and locations

– Shuttle drayage: Fixed route between two points, often within a single facility

Inter-carrier drayage vs. Expedited drayage

Expedited drayage is a time-sensitive service that prioritizes speed in moving containers or cargo. While inter-carrier drayage can be expedited when necessary, it is not inherently focused on rapid delivery. The primary goal of inter-carrier drayage is to facilitate efficient transfers between carriers, which may or may not require expedited service.

Key differences:

– Inter-carrier drayage: Focuses on efficient transfers between carriers

– Expedited drayage: Prioritizes speed and time-sensitive deliveries

Inter-carrier drayage vs. Door-to-door drayage

Door-to-door drayage involves the transport of goods directly from the shipper’s location to the final recipient. This service often includes the entire journey, from pickup to delivery. Inter-carrier drayage, in contrast, typically focuses on a specific segment of the transportation process, facilitating transfers between carriers rather than covering the entire shipment journey.

Key differences:

– Inter-carrier drayage: Focuses on transfers between carriers in the supply chain

– Door-to-door drayage: Covers the entire shipment journey from origin to destination

To illustrate these differences more clearly, consider the following table comparing inter-carrier drayage with other drayage types:

| Drayage Type | Primary Focus | Typical Distance | Number of Carriers Involved | Main Objective |

|---|---|---|---|---|

| Inter-carrier | Transfers between carriers/modes | Short to medium | Multiple | Facilitate efficient carrier transitions |

| Pier | Port to inland location | Short | Single or multiple | Move containers from ports to inland destinations |

| Intra-carrier | Within a single carrier’s network | Short | Single | Optimize a carrier’s internal operations |

| Shuttle | Fixed route between two points | Very short | Single | Manage high-volume cargo flows |

| Expedited | Time-sensitive deliveries | Varies | Single or multiple | Prioritize speed of delivery |

| Door-to-door | Entire shipment journey | Long | Single or multiple | Provide comprehensive shipping solution |

Understanding these distinctions is crucial for logistics professionals and businesses involved in the supply chain. Each type of drayage service offers unique benefits and is suited to specific operational needs. Inter-carrier drayage, with its focus on facilitating transfers between different carriers and transportation modes, plays a vital role in ensuring the smooth flow of goods through complex, multi-modal supply chains.

By choosing the appropriate drayage service for each situation, companies can optimize their logistics operations, reduce costs, and improve overall supply chain efficiency. Inter-carrier drayage, in particular, offers the flexibility and coordination necessary to navigate the increasingly complex world of global logistics and intermodal transportation.

What role does inter-carrier drayage play in the logistics supply chain?

Inter-carrier drayage plays a crucial role in the logistics supply chain, serving as a vital link that connects different transportation modes and carriers. This service is essential for ensuring the smooth and efficient flow of goods through complex, global supply networks. To fully appreciate the significance of inter-carrier drayage, it’s important to examine its various roles and impacts on the overall logistics ecosystem.

Facilitating intermodal transportation

One of the primary roles of inter-carrier drayage is to enable seamless intermodal transportation. In today’s global supply chains, goods often travel via multiple modes of transport – such as ships, trains, and trucks – before reaching their final destination. Inter-carrier drayage bridges the gaps between these different modes, ensuring that cargo can transition smoothly from one carrier to another.

For example, when a shipping container arrives at a port, inter-carrier drayage might be used to transport it to a nearby rail yard. From there, the container can continue its journey by train to an inland distribution center. Without efficient inter-carrier drayage, these transitions would be more complicated and time-consuming, potentially leading to delays and increased costs.

Optimizing supply chain efficiency

Inter-carrier drayage contributes significantly to overall supply chain efficiency. By specializing in short-distance transportation between carriers, drayage providers can optimize routes, reduce transit times, and minimize the risk of delays or disruptions. This efficiency translates into several benefits for the supply chain:

Reduced costs: Efficient inter-carrier drayage can help lower overall transportation costs by minimizing idle time and maximizing the utilization of transportation assets.

Improved speed: Quick and seamless transfers between carriers can significantly reduce the total transit time for shipments, allowing for faster delivery to end customers.

Enhanced flexibility: Inter-carrier drayage provides the flexibility to adapt to changing transportation needs and route cargo through the most efficient channels.

Supporting just-in-time inventory management

Many modern businesses rely on just-in-time (JIT) inventory management to reduce storage costs and improve cash flow. Inter-carrier drayage plays a crucial role in supporting JIT strategies by ensuring that goods can be moved quickly and reliably between different stages of the supply chain. This capability allows companies to maintain lean inventories while still meeting customer demand.

Enhancing supply chain visibility

Inter-carrier drayage providers often employ advanced tracking and communication technologies to monitor the movement of cargo. This enhanced visibility benefits the entire supply chain by:

Improving coordination: Real-time tracking allows for better coordination between different carriers and logistics providers.

Enabling proactive problem-solving: Early detection of potential delays or issues allows for quick interventions to keep shipments on schedule.

Enhancing customer service: Improved visibility enables more accurate delivery estimates and better communication with end customers.

Facilitating global trade

In the context of international trade, inter-carrier drayage plays a critical role in moving goods through customs and between different countries’ transportation networks. This service helps navigate the complex regulations and documentation requirements associated with cross-border shipments, facilitating smoother international trade flows.

Managing peak season demands

During peak shipping seasons, such as the holiday rush, inter-carrier drayage becomes even more critical. Drayage providers help manage increased volumes by efficiently moving cargo between carriers, preventing bottlenecks and ensuring that goods reach their destinations on time despite heightened demand.

Supporting sustainability initiatives

As the logistics industry increasingly focuses on sustainability, inter-carrier drayage can contribute to reducing the environmental impact of transportation. By optimizing routes and ensuring efficient transfers between carriers, drayage services can help minimize fuel consumption and reduce overall carbon emissions in the supply chain.

Addressing port congestion

Major ports often face congestion issues, which can lead to delays and increased costs. Inter-carrier drayage helps alleviate this problem by quickly moving containers out of port areas to inland terminals or distribution centers. This rapid movement helps keep port operations flowing smoothly and prevents backups that could affect the entire supply chain.

To illustrate the multifaceted role of inter-carrier drayage in the logistics supply chain, consider the following table:

| Supply Chain Function | Role of Inter-Carrier Drayage | Impact on Overall Logistics |

|---|---|---|

| Intermodal Connectivity | Bridges gaps between transportation modes | Enables seamless global shipping |

| Efficiency Optimization | Minimizes transfer times and idle periods | Reduces overall transportation costs |

| Just-in-Time Support | Ensures timely movement of goods | Facilitates lean inventory management |

| Visibility Enhancement | Provides real-time tracking and updates | Improves coordination and problem-solving |

| Global Trade Facilitation | Navigates customs and cross-border requirements | Streamlines international shipments |

| Peak Season Management | Helps manage increased volumes efficiently | Prevents bottlenecks during high-demand periods |

| Sustainability Promotion | Optimizes routes to reduce fuel consumption | Contributes to lowering carbon emissions |

| Port Congestion Mitigation | Quickly moves containers out of port areas | Helps maintain smooth port operations |

In conclusion, inter-carrier drayage serves as a critical component of the modern logistics supply chain. Its role extends far beyond simple transportation, encompassing aspects of efficiency optimization, global trade facilitation, and even environmental sustainability. By enabling smooth transitions between different carriers and transportation modes, inter-carrier drayage helps create a more integrated, responsive, and efficient global supply network. As supply chains continue to evolve and become more complex, the importance of effective inter-carrier drayage is likely to grow, making it an essential consideration for logistics professionals and businesses aiming to optimize their supply chain operations.

How does the inter-carrier drayage process work?

The inter-carrier drayage process involves a series of coordinated steps to ensure the smooth transfer of cargo between different carriers or modes of transportation. Understanding this process is crucial for logistics professionals and businesses involved in supply chain management. Let’s break down the typical inter-carrier drayage process into its key components and examine how they work together to facilitate efficient cargo movement.

Planning and coordination

The inter-carrier drayage process begins with careful planning and coordination. This initial stage involves several key activities:

Shipment assessment: The drayage provider evaluates the cargo’s characteristics, including size, weight, and any special handling requirements.

Route planning: Optimal routes are determined based on the origin and destination points, taking into account factors such as traffic patterns, road conditions, and any restrictions on cargo movement.

Scheduling: The drayage provider coordinates with both the origin and destination carriers to establish pickup and delivery times that align with their respective schedules.

Equipment allocation: Appropriate vehicles and equipment are assigned based on the cargo’s specifications and the planned route.

Documentation preparation

Proper documentation is crucial for smooth inter-carrier transfers. This step involves:

Bill of lading: This document serves as a receipt for the cargo and outlines the terms of transportation.

Customs documentation: For international shipments, necessary customs paperwork is prepared to ensure compliance with import/export regulations.

Carrier-specific forms: Any additional documentation required by the involved carriers is completed and verified.

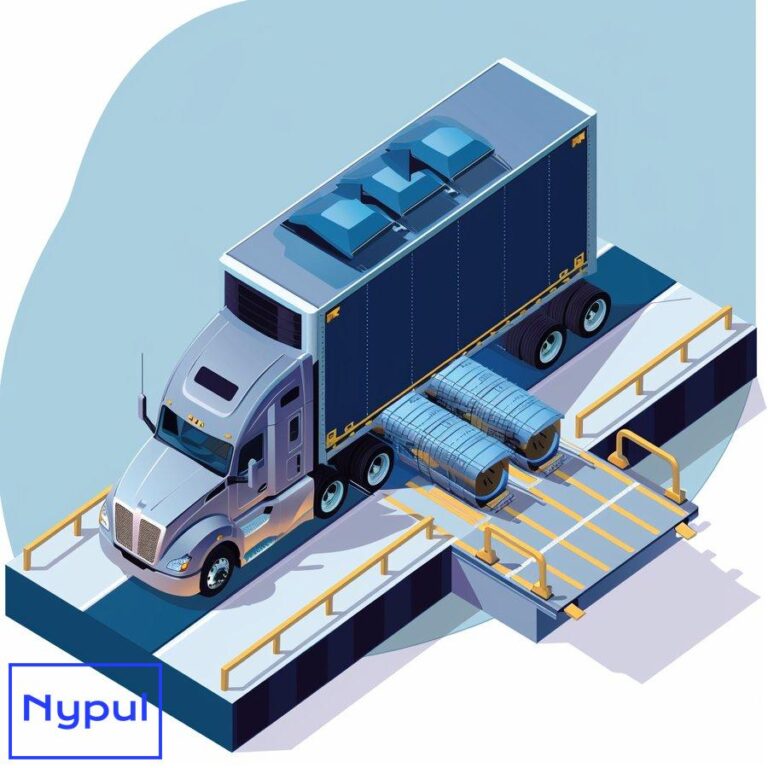

Pickup and loading

Once planning and documentation are complete, the actual physical movement of cargo begins:

Arrival at origin: The drayage truck arrives at the designated pickup location, which could be a port, rail yard, or another carrier’s terminal.

Cargo inspection: The driver inspects the cargo to ensure it matches the description in the documentation and is in proper condition for transport.

Loading: The cargo is carefully loaded onto the drayage vehicle, following proper securing procedures to prevent damage during transit.

Transportation

The core of the inter-carrier drayage process is the actual movement of cargo:

Short-distance transport: The drayage truck transports the cargo over a relatively short distance, typically within a metropolitan area or between nearby logistics hubs.

Real-time tracking: Many drayage providers offer GPS tracking, allowing all parties to monitor the cargo’s progress in real-time.

Traffic management: Drivers navigate local traffic conditions, choosing alternate routes if necessary to avoid delays.

Transfer and unloading

Upon reaching the destination, the transfer process begins:

Arrival at destination: The drayage truck arrives at the designated transfer point, such as another carrier’s terminal or a different mode of transportation hub.

Cargo verification: The receiving party inspects the cargo to ensure it matches the documentation and is in good condition.

Unloading: The cargo is carefully unloaded from the drayage vehicle and transferred to the next carrier or mode of transportation.

Documentation exchange

As the cargo changes hands, proper documentation transfer is essential:

Proof of delivery: The drayage provider obtains confirmation that the cargo has been successfully transferred to the receiving carrier.

Information update: All relevant parties are notified of the completed transfer, and tracking systems are updated accordingly.

Customs clearance (if applicable)

For international shipments, the inter-carrier drayage process may include facilitating customs clearance:

Documentation submission: Required customs documents are submitted to the appropriate authorities.

Inspection coordination: If customs inspections are necessary, the drayage provider may coordinate this process to ensure minimal disruption to the cargo’s journey.

Clearance confirmation: Once customs clearance is obtained, the cargo is released for continued transport.

Billing and reconciliation

The final stage of the inter-carrier drayage process involves financial settlement:

Invoice generation: The drayage provider generates an invoice based on the agreed-upon rates and any additional services provided.

Payment processing: The client processes the payment according to the established terms.

Performance review: Many companies conduct regular performance reviews to assess the efficiency and reliability of their drayage providers.

To illustrate the inter-carrier drayage process more clearly, consider the following table outlining the key steps and their associated activities:

| Process Step | Key Activities | Responsible Parties |

|---|---|---|

| Planning and Coordination | Shipment assessment, route planning, scheduling, equipment allocation | Drayage provider, origin carrier, destination carrier |

| Documentation Preparation | Bill of lading, customs paperwork, carrier-specific forms | Drayage provider, shippers |

| Pickup and Loading | Cargo inspection, secure loading | Drayage driver, origin carrier |

| Transportation | Short-distance transport, real-time tracking | Drayage provider |

| Transfer and Unloading | Cargo verification, careful unloading | Drayage driver, destination carrier |

| Documentation Exchange | Proof of delivery, information update | Drayage provider, destination carrier |

| Customs Clearance (if applicable) | Document submission, inspection coordination | Drayage provider, customs authorities |

| Billing and Reconciliation | Invoice generation | Process Step |

| ————– | —————- | ——————— |

| Billing and Reconciliation | Invoice generation, payment processing, performance review | Drayage provider, client |

By following these steps, inter-carrier drayage ensures that cargo is transferred efficiently and effectively between different carriers and modes of transportation. Each phase of the process is crucial for maintaining the integrity of the shipment and ensuring timely delivery.

What are the main types of inter-carrier drayage services?

Inter-carrier drayage services can be categorized into several types, each tailored to meet specific logistical needs and operational requirements. Understanding these different types is essential for businesses looking to optimize their supply chain and choose the most suitable drayage service for their operations.

Port drayage

Port drayage is a specialized service that involves transporting containers between ports and nearby logistics facilities. This type of inter-carrier drayage is critical for managing the flow of goods in and out of ports, ensuring that containers are efficiently moved to their next destination.

- Key features:

- Focuses on short-distance transport from ports to rail yards, warehouses, or distribution centers.

- Often involves coordination with multiple shipping lines and logistics providers.

- Plays a vital role in reducing port congestion by quickly moving containers away from busy terminals.

Rail drayage

Rail drayage refers to the movement of containers between rail terminals and other transportation hubs, such as ports or warehouses. This service is essential for facilitating intermodal transportation by connecting rail networks with other modes of transport.

- Key features:

- Involves transporting cargo to and from rail yards, often requiring specialized equipment for loading and unloading containers.

- Enhances the efficiency of rail transport by ensuring timely transfers between different carriers.

- Supports businesses that rely on rail for long-haul transportation while managing local deliveries.

Container drayage

Container drayage specifically focuses on the movement of shipping containers between various points within a logistics network. This service can include transporting containers from a port to a warehouse or between different terminals operated by the same carrier.

- Key features:

- Emphasizes the handling of shipping containers, which may require specialized equipment for loading and unloading.

- Provides flexibility in managing container movements within a supply chain.

- Helps optimize inventory management by ensuring that containers are delivered to the right locations when needed.

Expedited drayage

Expedited drayage services prioritize speed and time-sensitive deliveries. This type of inter-carrier drayage is crucial for businesses with urgent shipping needs or those operating in industries where timely delivery is essential.

- Key features:

- Offers faster transit times compared to standard drayage services.

- May involve dedicated vehicles and drivers to ensure prompt delivery.

- Supports industries such as e-commerce, automotive, and healthcare, where delays can have significant consequences.

Shuttle drayage

Shuttle drayage involves the continuous movement of containers between two fixed points, often within a port or terminal complex. This service is designed to manage high-volume cargo flows efficiently.

- Key features:

- Focuses on short-distance transport between designated locations, such as between a port and an inland terminal.

- Helps reduce congestion within busy logistics hubs by optimizing container movements.

- Often used during peak shipping seasons when demand for cargo movement increases significantly.

Dedicated drayage

Dedicated drayage services provide exclusive transportation solutions tailored to specific clients or industries. This type of service is ideal for businesses with unique logistical requirements or those seeking greater control over their supply chain operations.

- Key features:

- Offers customized solutions based on client needs, including dedicated vehicles, drivers, and routes.

- Enhances reliability by providing consistent service tailored to specific operational demands.

- Suitable for industries with specialized cargo handling requirements or unique delivery schedules.

To summarize the main types of inter-carrier drayage services, consider the following table:

| Drayage Service Type | Description | Key Features |

|---|---|---|

| Port Drayage | Transporting containers between ports and nearby logistics facilities | Reduces port congestion; coordinates with multiple carriers |

| Rail Drayage | Movement of containers between rail terminals and other transportation hubs | Connects rail networks; enhances efficiency |

| Container Drayage | Focused on moving shipping containers within a logistics network | Flexibility in container management; supports inventory optimization |

| Expedited Drayage | Prioritizes speed for time-sensitive deliveries | Faster transit times; dedicated vehicles for urgent needs |

| Shuttle Drayage | Continuous movement between two fixed points within a terminal complex | Optimizes high-volume cargo flows; reduces congestion |

| Dedicated Drayage | Customized transportation solutions for specific clients or industries | Tailored service; enhances reliability |

By understanding these various types of inter-carrier drayage services, businesses can make informed decisions about which solutions best meet their logistical needs. Each type offers unique advantages that can enhance supply chain efficiency, reduce costs, and improve overall operational performance.

What challenges are commonly faced in inter-carrier drayage operations?

While inter-carrier drayage plays a vital role in facilitating efficient cargo transfers within the logistics supply chain, it also presents several challenges that can impact operations. Understanding these challenges is crucial for businesses looking to optimize their logistics processes and mitigate potential disruptions. Here are some common challenges faced in inter-carrier drayage operations:

Port congestion

Port congestion is one of the most significant challenges affecting inter-carrier drayage operations. High volumes of incoming and outgoing shipments can lead to delays in loading and unloading containers at ports. Congestion can result from various factors:

- Increased shipping demand during peak seasons

- Limited terminal capacity

- Inefficient coordination among multiple carriers

The consequences of port congestion include longer wait times for trucks, increased transportation costs, and potential disruptions in the overall supply chain.

Regulatory compliance

Inter-carrier drayage operations must adhere to various local, national, and international regulations governing the transportation of goods. Compliance challenges may arise due to:

- Complex customs requirements for international shipments

- Varying regulations across different jurisdictions

- Changes in laws or regulations that impact transportation practices

Failure to comply with regulatory requirements can lead to delays, fines, or even confiscation of cargo.

Equipment availability

The availability of suitable equipment is another challenge faced by inter-carrier drayage providers. This issue can stem from several factors:

- Fluctuations in demand leading to shortages of trucks or trailers

- Maintenance issues affecting vehicle availability

- Limited access to specialized equipment needed for certain types of cargo

Equipment shortages can result in delays in cargo movement and increased costs due to last-minute arrangements.

Driver shortages

The logistics industry has been experiencing a shortage of qualified truck drivers, which poses significant challenges for inter-carrier drayage operations. Contributing factors include:

- Aging workforce with many drivers nearing retirement

- Increased demand for freight transport leading to higher competition for drivers

- Working conditions that may deter new entrants into the profession

Driver shortages can lead to delays in pickups and deliveries, impacting overall supply chain efficiency.

Communication breakdowns

Effective communication among all parties involved in inter-carrier drayage is essential for smooth operations. However, communication breakdowns can occur due to:

- Lack of coordination between different carriers

- Inadequate information sharing regarding shipment status

- Misunderstandings related to scheduling or documentation

These breakdowns can result in delays, increased costs, and potential damage to relationships among carriers and clients.

Technology integration

As technology plays an increasingly important role in logistics operations, integrating new systems into existing processes can present challenges. Issues may include:

- Resistance to change from employees accustomed to traditional methods

- Compatibility problems between different technology platforms

- The need for training staff on new systems

Successful technology integration is crucial for enhancing visibility, tracking capabilities, and overall operational efficiency.

To summarize these common challenges faced in inter-carrier drayage operations, consider the following table:

| Challenge | Description | Potential Consequences |

|---|---|---|

| Port Congestion | High volumes leading to delays at ports | Longer wait times; increased costs |

| Regulatory Compliance | Adherence to complex regulations | Delays; fines; confiscation |

| Equipment Availability | Shortages of suitable trucks or trailers | Delays; last-minute arrangements |

| Driver Shortages | Lack of qualified drivers | Delays in pickups/deliveries |

| Communication Breakdowns | Ineffective coordination among parties | Delays; increased costs |

| Technology Integration | Challenges integrating new systems | Resistance; compatibility issues |

Addressing these challenges requires proactive strategies from logistics professionals. By identifying potential issues early on and implementing effective solutions—such as investing in technology upgrades or improving communication protocols—businesses can enhance their inter-carrier drayage operations and ensure smoother cargo transfers within their supply chains.

How is pricing determined for inter-carrier drayage services?

Pricing for inter-carrier drayage services can vary significantly based on several factors. Understanding how these pricing structures work is essential for businesses looking to manage their logistics costs effectively. Here are some key elements that influence pricing in inter-carrier drayage:

Distance traveled

The distance between pickup and delivery points plays a significant role in determining pricing. Generally speaking:

- Longer distances typically incur higher costs due to increased fuel consumption and driver time.

- Shorter distances may result in lower rates but could still be affected by other factors like congestion or waiting times at terminals.

Pricing structures often reflect this relationship between distance traveled and overall cost.

Cargo characteristics

The nature of the cargo being transported also impacts pricing. Factors include:

- Weight: Heavier loads may require specialized equipment or additional handling procedures that increase costs.

- Size: Oversized or irregularly shaped cargo might necessitate special permits or equipment adjustments.

- Hazardous materials: Transporting hazardous goods often involves additional regulatory compliance measures that can raise prices.

Understanding these characteristics helps providers accurately assess costs associated with specific shipments.

Service level required

Different levels of service come with varying price points. For example:

- Standard inter-carrier drayage services typically offer more economical rates but may involve longer transit times.

- Expedited services prioritize speed but come at a premium price due to dedicated resources focused on urgent deliveries.

Businesses should evaluate their specific needs when selecting a service level that aligns with their budget constraints.

Market conditions

Pricing can fluctuate based on market conditions such as demand levels within the logistics industry. Factors influencing market dynamics include:

- Seasonal variations: Peak shipping seasons often lead to higher prices due to increased demand.

- Economic trends: Changes in economic conditions can impact overall freight rates across various modes of transport.

Logistics providers must stay informed about market trends when determining pricing strategies.

Accessorial charges

Additional fees may apply depending on specific circumstances surrounding each shipment. Common accessorial charges include:

-

Fuel surcharges: Fluctuating fuel prices often lead providers to implement fuel surcharges as part of their pricing structure.

-

Waiting time fees: If trucks must wait at pickup or drop-off locations beyond an agreed-upon timeframe due to delays caused by others (e.g., port congestion), additional fees may apply.

Understanding these potential extra charges helps businesses anticipate total costs associated with their shipments more accurately.

To summarize how pricing is determined for inter-carrier drayage services consider this table outlining key factors influencing pricing structures:

| Pricing Factor | Description | Impact on Costs |

|---|---|---|

| Distance Traveled | Length between pickup/delivery points | Longer distances generally incur higher costs |

| Cargo Characteristics | Weight/size/hazardous materials | Heavier/oversized/hazardous loads may increase prices |

| Service Level Required | Standard vs expedited services | Expedited services come at a premium |

| Market Conditions | Demand levels/economic trends | Seasonal variations may lead to price fluctuations |

| Accessorial Charges | Additional fees (fuel surcharges/waiting time) | Extra charges can increase total shipment costs |

By understanding these factors influencing pricing structures within inter-carrier drayage services—businesses gain valuable insights into managing logistics expenses effectively while optimizing their supply chain operations accordingly.

What factors should be considered when choosing an inter-carrier drayage provider?

Selecting the right inter-carrier drayage provider is critical for ensuring efficient cargo transfers within your logistics network. Several factors should be considered during this decision-making process to identify a provider that aligns with your operational needs and goals effectively. Here are some key considerations when choosing an inter-carrier drayage provider:

Experience and reputation

A provider’s experience within the industry significantly impacts its ability to deliver reliable services consistently. Look for providers who have established reputations based on positive customer feedback over time:

-

Industry experience: Providers with extensive experience are more likely familiar with common challenges associated with inter-carrier transfers while possessing effective solutions.

-

Customer reviews: Research online reviews/testimonials from previous clients regarding service quality/timeliness helps gauge provider reliability.

Choosing an experienced provider enhances confidence in their ability not only meet but exceed expectations throughout your partnership together.

Service offerings

Different providers offer varying levels/types of service tailored toward specific client needs/preferences:

- Range of services: Evaluate whether potential providers offer comprehensive solutions encompassing all aspects related specifically toward your logistical requirements (e.g., expedited delivery options).

Assessing available service offerings ensures you select a partner capable addressing diverse situations arising throughout your supply chain journey.

Technology integration capabilities

In today’s fast-paced logistics environment—technology plays an increasingly vital role enhancing visibility/tracking capabilities throughout transportation processes:

When evaluating potential partners—consider whether they utilize advanced technologies such as GPS tracking systems/real-time monitoring tools enabling seamless communication regarding shipment status updates throughout transit phases.

Cost structure

Understanding how each provider determines pricing structures helps identify which options align best budgetary constraints while still meeting quality standards expected during partnerships established together moving forward:

When assessing cost structures—consider factors including distance traveled/cargo characteristics/service levels required/accessorial charges associated with specific shipments.

This comprehensive approach ensures clarity surrounding total expenses incurred throughout partnerships established together moving forward.

Geographic coverage

Evaluate whether prospective partners operate effectively across regions relevant toward your business operations/needs:

Choosing partners capable providing coverage across all necessary locations ensures seamless transitions occur consistently without interruptions arising due unforeseen circumstances.

Consider geographic coverage when selecting partners capable meeting demands across multiple locations efficiently while maintaining high standards expected throughout partnerships established together moving forward.

Conclusion

Inter-carrier drayage serves as an integral component within modern supply chains—enabling efficient transfers between various carriers/modes while enhancing overall operational efficiencies throughout processes involved transporting goods globally today.

By understanding its importance/differences compared against other types/driving forces behind successful implementations—businesses gain valuable insights necessary optimizing logistical strategies effectively addressing diverse situations arising throughout journeys taken together moving forward!