How Do You Organize Employee Shifts

Why is shift organization crucial in logistics and drayage?

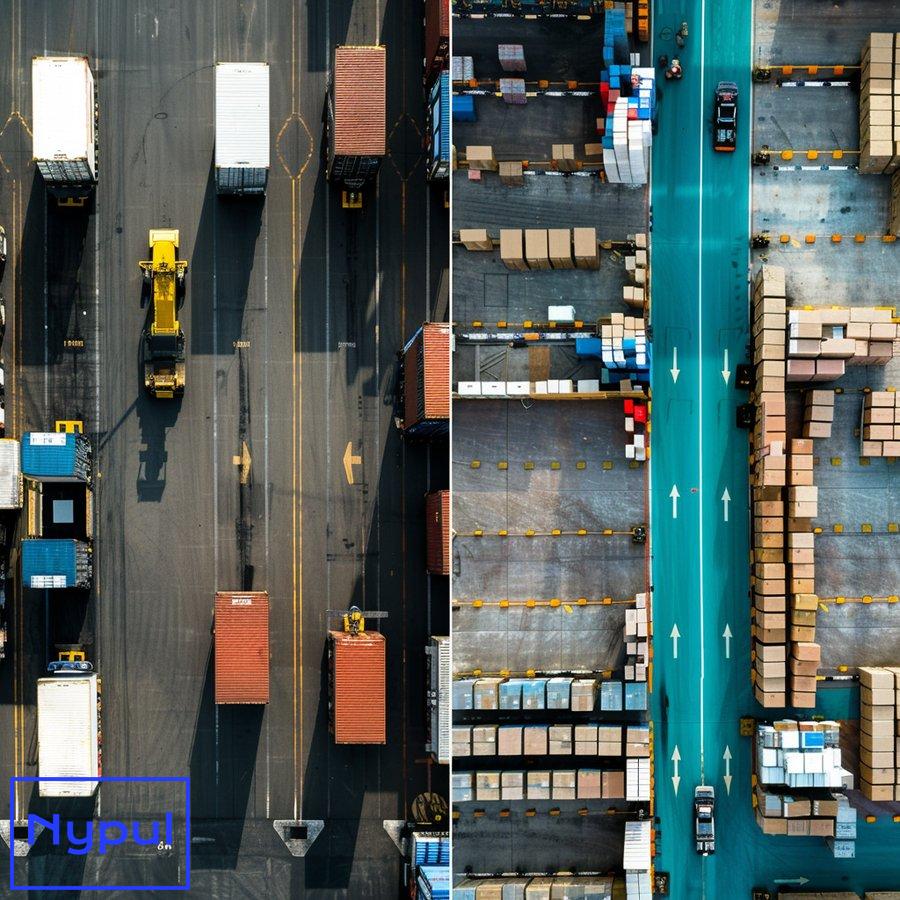

Shift organization forms the backbone of efficient logistics and drayage operations. The seamless movement of goods from ports to distribution centers relies heavily on well-coordinated employee schedules. Properly organized shifts ensure continuous operations, maximize resource utilization, and maintain high service levels in the fast-paced world of supply chain management.

Continuous Operations

Logistics and drayage companies often operate around the clock to meet tight delivery deadlines. Organized shifts allow for uninterrupted service, preventing bottlenecks and delays in the supply chain. For instance, a 24/7 operation at a busy port requires carefully planned shifts to ensure constant coverage for loading, unloading, and transporting containers.

Resource Optimization

Effective shift organization optimizes the use of human resources and equipment. By aligning employee schedules with peak operational periods, companies can ensure they have the right number of workers available when demand is highest. This approach minimizes idle time and reduces unnecessary labor costs.

Customer Satisfaction

In the logistics industry, meeting delivery timelines is paramount. Well-organized shifts contribute directly to customer satisfaction by ensuring timely pickups and deliveries. When shifts are properly structured, there’s always a team ready to handle incoming shipments or respond to customer inquiries, regardless of the time of day.

Employee Well-being

Organized shifts also play a crucial role in maintaining employee health and job satisfaction. Predictable schedules allow workers to plan their personal lives, reducing stress and improving work-life balance. This, in turn, leads to higher retention rates and increased productivity.

Regulatory Compliance

The logistics and drayage sectors are subject to various regulations, including hours of service rules for drivers. Proper shift organization ensures compliance with these regulations, avoiding potential fines and legal issues that could disrupt operations.

Adaptability to Market Demands

The logistics industry experiences fluctuations in demand due to seasonal changes, economic factors, and unforeseen events. A well-structured shift system provides the flexibility to scale operations up or down as needed, allowing companies to remain responsive to market conditions.

Cost Management

Efficient shift organization contributes significantly to cost management. By avoiding overstaffing during slow periods and understaffing during peak times, companies can optimize their labor costs while maintaining operational efficiency.

Safety and Risk Mitigation

Organized shifts help mitigate safety risks associated with fatigue and overwork. By ensuring adequate rest periods between shifts and managing workload distribution, companies can reduce the likelihood of accidents and errors that could compromise safety and operational integrity.

The importance of shift organization in logistics and drayage cannot be overstated. It serves as the foundation for operational efficiency, customer satisfaction, regulatory compliance, and employee well-being. Companies that prioritize effective shift management are better positioned to navigate the complexities of the modern supply chain landscape and maintain a competitive edge in the industry.

How do you assess operational needs for shift planning?

Assessing operational needs is a critical step in developing an effective shift planning strategy for logistics and drayage operations. This process involves a comprehensive analysis of various factors that influence workload, resource requirements, and overall operational efficiency. By conducting a thorough assessment, companies can create shift plans that align with their specific needs and optimize their workforce utilization.

Analyze Historical Data

Examining past operational data provides valuable insights into workload patterns and resource utilization. This analysis should include:

- Shipment volumes by day, week, and month

- Peak operational hours

- Seasonal fluctuations in demand

- Equipment usage rates

- Employee productivity metrics

By identifying trends and patterns in historical data, planners can anticipate future needs and allocate resources accordingly.

Evaluate Current Workforce

A detailed assessment of the current workforce is essential for effective shift planning. This evaluation should consider:

- Number of employees by role and skill level

- Employee availability and preferences

- Overtime patterns and costs

- Absenteeism rates

- Training and certification requirements

Understanding the capabilities and constraints of the existing workforce helps in creating realistic and efficient shift schedules.

Assess Equipment and Infrastructure

The availability and capacity of equipment and infrastructure play a crucial role in determining operational needs. Consider:

- Number and types of vehicles in the fleet

- Warehouse or distribution center capacity

- Loading dock availability

- Maintenance schedules for equipment

- Technological infrastructure (e.g., tracking systems, communication tools)

Aligning shift plans with equipment availability ensures maximum utilization of resources and prevents bottlenecks in operations.

Review Customer Requirements

Customer needs and service level agreements (SLAs) significantly impact shift planning. Assess:

- Delivery time windows

- Pickup and drop-off locations

- Special handling requirements

- Customer communication preferences

- Service level expectations

Tailoring shift plans to meet customer requirements helps maintain high service quality and customer satisfaction.

Analyze Regulatory Environment

Compliance with industry regulations is crucial in logistics and drayage. Consider:

- Hours of service regulations for drivers

- Labor laws regarding work hours and breaks

- Safety regulations and required rest periods

- Environmental regulations affecting operations

Ensuring shift plans adhere to regulatory requirements prevents legal issues and maintains operational integrity.

Conduct Stakeholder Interviews

Gathering input from key stakeholders provides valuable insights into operational needs. Interview:

- Operations managers

- Shift supervisors

- Drivers and warehouse staff

- Customer service representatives

- HR personnel

These interviews can reveal pain points, inefficiencies, and opportunities for improvement that may not be apparent from data analysis alone.

Perform Workload Forecasting

Utilizing forecasting techniques helps anticipate future operational needs. Consider:

- Market trends and economic indicators

- Planned business expansions or contractions

- Upcoming customer contracts or projects

- Technological advancements that may impact operations

Accurate forecasting allows for proactive shift planning to meet future demands.

Evaluate Competitive Landscape

Understanding industry benchmarks and competitor practices can inform shift planning strategies. Assess:

- Industry standards for shift structures

- Competitor staffing models

- Best practices in workforce management

This evaluation helps ensure that shift plans remain competitive and aligned with industry norms.

Conduct Cost-Benefit Analysis

Assessing the financial implications of different shift structures is crucial. Analyze:

- Labor costs for various shift patterns

- Overtime expenses

- Productivity gains or losses associated with different schedules

- Potential cost savings from optimized resource allocation

This analysis helps in selecting shift structures that balance operational efficiency with cost-effectiveness.

Use Technology for Data Collection and Analysis

Leveraging technology streamlines the assessment process. Utilize:

- Workforce management software

- Business intelligence tools

- Predictive analytics platforms

- Time and attendance systems

These tools can provide real-time insights and automate much of the data collection and analysis process.

By thoroughly assessing these operational needs, logistics and drayage companies can develop shift plans that optimize resource utilization, meet customer demands, and maintain regulatory compliance. This comprehensive approach ensures that shift planning aligns with the organization’s strategic goals and operational realities, setting the foundation for efficient and effective workforce management.

What are the most effective shift structures for logistics operations?

Selecting the most effective shift structures for logistics operations is crucial for maintaining operational efficiency, employee satisfaction, and regulatory compliance. The ideal shift structure varies depending on the specific needs of the organization, the nature of the operations, and the workforce characteristics. Here are some of the most effective shift structures commonly used in logistics operations, along with their advantages and considerations:

24/7 Continuous Operations Model

This model ensures round-the-clock coverage, which is essential for many logistics operations, especially those involving international shipments or time-sensitive deliveries.

Structure:

– Four teams working 12-hour shifts

– Two day shifts (e.g., 6 AM to 6 PM) and two night shifts (e.g., 6 PM to 6 AM)

– Teams rotate between day and night shifts on a weekly or bi-weekly basis

Advantages:

– Provides continuous coverage

– Reduces handover frequency

– Allows for longer rest periods between shifts

Considerations:

– Requires careful management of fatigue and work-life balance

– May require higher staffing levels to cover all shifts

Traditional 8-Hour Shift Model

This model is suitable for operations that align with standard business hours or have predictable peak periods.

Structure:

– Three shifts per day: morning (e.g., 6 AM to 2 PM), afternoon (e.g., 2 PM to 10 PM), and night (e.g., 10 PM to 6 AM)

– Employees typically work five 8-hour shifts per week

Advantages:

– Aligns with traditional work patterns

– Easier to manage overtime and breaks

– Provides flexibility for employees with family commitments

Considerations:

– Requires more frequent shift changes and handovers

– May result in higher staffing costs due to overlap during shift changes

4/10 Compressed Workweek Model

This model compresses the standard 40-hour workweek into four 10-hour days, providing an extra day off for employees.

Structure:

– Employees work four 10-hour shifts per week

– Shifts can be staggered to provide coverage throughout the week

Advantages:

– Reduces commuting time for employees

– Can improve work-life balance

– Provides extended daily coverage without overtime

Considerations:

– Longer workdays may lead to fatigue

– May require adjustments to break schedules and meal periods

Rotating Shift Model

This model involves employees rotating through different shift times on a regular basis, ensuring fair distribution of less desirable shifts.

Structure:

– Employees rotate between morning, afternoon, and night shifts on a weekly or monthly basis

– Can be combined with other models like the 12-hour or 8-hour shift structures

Advantages:

– Distributes less desirable shifts fairly among all employees

– Provides variety in work schedules

– Can help in cross-training employees across different operational periods

Considerations:

– Requires careful planning to ensure adequate rest between shift changes

– May be disruptive to employees’ sleep patterns and personal lives

Split Shift Model

This model divides the workday into two or more parts with a significant break in between, useful for operations with distinct peak periods.

Structure:

– Employees work two separate periods within a day (e.g., 6 AM to 10 AM and 3 PM to 7 PM)

– Total hours worked typically equal a standard shift

Advantages:

– Allows for coverage during peak operational periods

– Can reduce overtime costs by aligning staffing with demand

Considerations:

– May be unpopular with employees due to the split nature of the workday

– Requires careful scheduling to ensure compliance with labor laws regarding split shifts

Flexible Shift Model

This model allows for variations in start and end times, providing flexibility for both the organization and employees.

Structure:

– Core hours where all employees must be present (e.g., 10 AM to 3 PM)

– Flexible start and end times within a specified range (e.g., start between 6 AM and 10 AM, end between 3 PM and 7 PM)

Advantages:

– Improves employee satisfaction and work-life balance

– Can help in managing traffic congestion and commuting issues

– Allows for extended operational hours without overtime

Considerations:

– Requires robust time-tracking systems

– May complicate scheduling and coordination of team activities

On-Call Shift Model

This model is useful for handling unexpected surges in demand or emergency situations.

Structure:

– Employees are scheduled for regular shifts but are also on-call during specific periods

– On-call employees must be available to work on short notice if needed

Advantages:

– Provides flexibility to handle unexpected workload increases

– Ensures coverage for emergencies without overstaffing during normal periods

Considerations:

– May impact employee work-life balance

– Requires clear policies on compensation for on-call time and minimum notice periods

When selecting the most effective shift structure for logistics operations, consider the following factors:

- Operational demands and peak periods

- Employee preferences and work-life balance

- Regulatory requirements and labor laws

- Cost implications, including overtime and shift differentials

- Impact on productivity and service quality

- Equipment utilization and maintenance schedules

- Customer service requirements and time zone considerations

The most effective shift structure often involves a combination of these models, tailored to the specific needs of the organization. Regular review and adjustment of shift structures are essential to ensure they continue to meet operational needs and employee expectations in the dynamic logistics environment.

How can you create a fair and balanced scheduling system?

Creating a fair and balanced scheduling system is crucial for maintaining employee satisfaction, operational efficiency, and compliance with labor regulations in logistics and drayage operations. A well-designed scheduling system promotes equity, transparency, and flexibility while meeting the organization’s operational needs. Here are key strategies and considerations for developing a fair and balanced scheduling system:

Establish Clear Scheduling Policies

Develop and communicate clear scheduling policies that outline:

- Shift assignment procedures

- Time-off request processes

- Overtime allocation methods

- Shift swapping rules

- On-call expectations

Transparent policies ensure all employees understand the scheduling process and reduce perceptions of favoritism or unfairness.

Implement a Rotating Shift System

A rotating shift system helps distribute less desirable shifts (e.g., nights, weekends) equitably among all employees. Consider:

- Rotating shifts on a weekly or monthly basis

- Balancing the number of weekend and holiday shifts for each employee

- Allowing employees to provide input on rotation preferences

This approach ensures that no single group of employees is consistently assigned to less favorable shifts.

Use Seniority-Based Scheduling with Flexibility

Incorporate seniority into the scheduling process while maintaining flexibility:

- Allow senior employees first choice of shifts or days off

- Implement a bidding system for preferred shifts based on seniority

- Balance seniority considerations with operational needs and junior employee development

This approach recognizes employee tenure while still providing opportunities for newer staff.

Incorporate Employee Preferences

Collect and consider employee preferences when creating schedules:

- Use surveys or preference forms to gather input on shift preferences

- Allow employees to specify preferred days off or shift times

- Consider personal circumstances (e.g., childcare needs, educational commitments)

Accommodating preferences where possible increases job satisfaction and reduces absenteeism.

Ensure Adequate Rest Periods

Design schedules that provide sufficient rest between shifts:

- Adhere to legal requirements for minimum rest periods

- Avoid back-to-back shifts or quick turnarounds

- Consider the impact of shift patterns on circadian rhythms and fatigue management

Proper rest periods are essential for employee well-being and operational safety.

Balance Workload Distribution

Distribute workload evenly across shifts and employees:

- Analyze historical data to identify peak periods and staff accordingly

- Ensure a mix of experienced and newer employees on each shift

- Rotate high-demand or high-stress tasks among qualified staff

Balanced workload distribution prevents burnout and promotes skill development across the team.

Implement Advanced Notice for Schedules

Provide schedules well in advance to allow employees to plan their personal lives:

- Aim for at least two weeks’ notice for regular schedules

- Communicate any changes as early as possible

- Use a reliable system for notifying employees of their schedules (e.g., mobile apps, email)

Advanced notice helps employees maintain work-life balance and reduces last-minute conflicts.

Establish a Fair Process for Time-Off Requests

Create a transparent and equitable system for handling time-off requests:

- Implement a first-come, first-served policy for non-emergency requests

- Set clear deadlines for submitting requests for popular times (e.g., holidays)

- Develop a fair system for resolving conflicts when multiple employees request the same time off

A fair time-off request process reduces conflicts and ensures equitable access to desired time off.

Use Technology for Scheduling

Leverage scheduling software to enhance fairness and efficiency:

- Utilize algorithms that consider multiple factors (e.g., employee preferences, skills, labor laws)

- Implement self-service portals for shift swaps and time-off requests

- Use data analytics to identify and address scheduling patterns that may be unfair

Technology can help remove bias and ensure consistent application of scheduling rules.

Regularly Review and Adjust the System

Continuously evaluate and improve the scheduling system:

- Solicit feedback from employees and managers

- Analyze key metrics (e.g., overtime rates, absenteeism, employee satisfaction)

- Stay informed about industry best practices and emerging trends in scheduling

Regular reviews ensure the system remains fair and effective as organizational needs evolve.

Provide Training on Scheduling Practices

Educate managers and employees on fair scheduling practices:

- Train scheduling managers on the importance of fairness and how to apply scheduling policies consistently

- Provide employees with information on their rights and responsibilities regarding scheduling

- Offer guidance on how to use scheduling tools and systems effectively

Well-informed managers and employees contribute to a more transparent and fair scheduling process.

Implement an Open Door Policy for Scheduling Concerns

Establish channels for employees to voice scheduling concerns:

- Designate a point of contact for scheduling issues

- Create a formal process for addressing scheduling grievances

- Encourage open dialogue between employees and managers about scheduling challenges

An open door policy helps identify and resolve scheduling issues promptly.

Consider Compressed Work Weeks orConsider Compressed Work Weeks or Flexible Schedules**

Explore the option of compressed work weeks or flexible schedules to enhance employee satisfaction:

- Offer four-day work weeks with longer shifts, allowing for extended time off

- Implement flexible start and end times to accommodate personal commitments

- Allow employees to choose between traditional and flexible scheduling options

These alternatives can lead to improved morale and retention while still meeting operational needs.

Which technologies can streamline shift management?

In the logistics and drayage sectors, leveraging technology for shift management is essential for enhancing efficiency, accuracy, and employee satisfaction. Various tools and software solutions can streamline scheduling processes, facilitate communication, and optimize workforce utilization. Here are key technologies that can significantly improve shift management:

Workforce Management Software

Workforce management (WFM) software provides comprehensive solutions for scheduling, time tracking, and labor forecasting. Key features include:

- Automated scheduling based on employee availability, preferences, and operational needs

- Real-time tracking of employee hours worked and attendance

- Reporting tools to analyze labor costs and productivity metrics

By automating routine tasks, WFM software reduces administrative burdens and allows managers to focus on strategic planning.

Employee Self-Service Portals

Self-service portals empower employees to manage their schedules more effectively. Features may include:

- Access to personal schedules and shift assignments

- Options for requesting time off or swapping shifts with colleagues

- Notifications for schedule changes or upcoming shifts

Such portals enhance transparency and give employees greater control over their work-life balance.

Mobile Applications

Mobile applications facilitate communication and scheduling on-the-go. Key benefits include:

- Instant notifications about schedule changes or important announcements

- Ability for employees to check their schedules from anywhere

- Options for submitting time-off requests or shift swaps via mobile devices

Mobile apps improve engagement and ensure that employees remain informed about their schedules.

Cloud-Based Scheduling Solutions

Cloud-based scheduling platforms enable real-time collaboration among team members and managers. Advantages include:

- Centralized access to scheduling information from any location

- Easy updates and adjustments to schedules without the need for physical paperwork

- Integration with other systems (e.g., payroll, HR) for streamlined operations

Cloud solutions enhance flexibility and accessibility in managing shift schedules.

Time and Attendance Systems

Automated time and attendance systems help track employee hours accurately. Key features include:

- Biometric scanning or mobile check-in options to prevent buddy punching

- Integration with payroll systems for accurate compensation calculations

- Reporting capabilities to analyze attendance patterns and identify issues

Accurate time tracking reduces payroll discrepancies and enhances compliance with labor regulations.

Communication Tools

Effective communication is crucial in logistics operations. Consider using tools such as:

- Instant messaging platforms for quick communication between team members

- Project management software that includes task assignments related to shifts

- Video conferencing tools for remote meetings or training sessions

Robust communication tools foster collaboration and ensure everyone is aligned on operational goals.

Predictive Analytics Tools

Predictive analytics can enhance shift planning by forecasting demand based on historical data. Key applications include:

- Analyzing trends in shipment volumes or peak operational periods

- Identifying patterns in employee absenteeism or turnover rates

- Providing insights into optimal staffing levels needed during specific times

These tools allow logistics companies to proactively adjust their staffing strategies based on anticipated needs.

Integration with GPS Tracking Systems

For drayage operations, integrating scheduling systems with GPS tracking enhances efficiency. Benefits include:

- Real-time visibility into vehicle locations and estimated arrival times

- Coordination of driver schedules with delivery windows

- Optimization of routes based on traffic conditions

This integration helps ensure timely deliveries while maximizing resource utilization.

Training Management Systems

Training management systems play a crucial role in ensuring that employees are adequately trained for their roles. Features may include:

- Tracking employee certifications and training completion status

- Scheduling training sessions based on operational needs

- Providing online training modules accessible at any time

By ensuring that employees are well-trained, logistics companies can maintain high safety standards and operational efficiency.

Feedback Mechanisms

Implementing feedback mechanisms within scheduling software allows employees to voice concerns or suggestions regarding their shifts. This can include:

- Anonymous surveys about scheduling fairness and preferences

- Tools for reporting issues related to workload or shift assignments

- Regular check-ins between managers and staff regarding scheduling challenges

Feedback mechanisms promote a culture of open communication and continuous improvement in shift management practices.

By leveraging these technologies, logistics companies can streamline shift management processes, enhance employee satisfaction, and improve overall operational efficiency. The integration of advanced tools not only simplifies scheduling but also fosters a more engaged workforce capable of adapting to the dynamic demands of the logistics industry.

What strategies optimize shift handovers in logistics?

Effective shift handovers are critical in logistics operations to ensure continuity, maintain productivity, and minimize errors during transitions between shifts. A well-organized handover process enhances communication between outgoing and incoming teams, ensuring that critical information is shared efficiently. Here are several strategies to optimize shift handovers in logistics:

Standardized Handover Procedures

Establishing standardized procedures for handovers ensures consistency across shifts. Key components should include:

- A checklist of essential information to be communicated (e.g., pending tasks, equipment status)

- Designated locations for handover meetings (e.g., break rooms or designated areas)

- Clear guidelines on who is responsible for leading the handover process

Standardization reduces confusion during transitions and ensures all necessary details are covered.

Use Handover Logs

Implementing handover logs provides a written record of key information exchanged during shifts. Elements to include in the log are:

- Summary of completed tasks during the previous shift

- Outstanding issues or concerns that need attention

- Updates on equipment status or maintenance requirements

Handover logs serve as a reference point for incoming staff, promoting accountability and continuity.

Encourage Face-to-Face Communication

Whenever possible, encourage face-to-face communication during handovers. Benefits include:

- Immediate clarification of questions or concerns between outgoing and incoming staff

- Enhanced relationship-building among team members across shifts

- Opportunities for informal knowledge sharing about best practices or challenges faced

Face-to-face interactions help build trust among team members while ensuring critical information is conveyed accurately.

Designate Shift Leaders

Assigning designated shift leaders can streamline the handover process. Responsibilities may include:

- Leading the handover meeting between shifts

- Ensuring all relevant information is communicated effectively

- Addressing any immediate concerns raised by incoming staff

Having a dedicated leader helps maintain focus during handovers while ensuring accountability.

Utilize Technology for Handover Documentation

Leveraging technology can enhance the efficiency of handovers. Consider using:

- Digital platforms where outgoing staff can input updates before leaving their shift (e.g., shared documents)

- Mobile applications that facilitate real-time communication about ongoing tasks or issues

- Centralized dashboards displaying key performance indicators (KPIs) relevant to both shifts

Technology streamlines documentation processes while providing real-time visibility into operations.

Conduct Handover Training Sessions

Providing training sessions focused on effective handover practices ensures all employees understand expectations. Training topics may include:

- Importance of thorough communication during transitions

- Techniques for documenting critical information

- Strategies for addressing common challenges faced during handovers

Regular training reinforces best practices while promoting a culture of continuous improvement.

Implement Shift Overlap Periods

Introducing overlap periods between shifts allows outgoing staff to brief incoming staff directly. Benefits include:

- Additional time for discussing outstanding tasks or issues

- Opportunities for outgoing staff to provide context about specific situations

- Enhanced teamwork through collaborative problem-solving

Overlapping shifts promote smoother transitions while ensuring all critical information is shared effectively.

Encourage Feedback on Handover Processes

Soliciting feedback from employees regarding the handover process encourages continuous improvement. Strategies may involve:

- Conducting regular surveys about the effectiveness of current procedures

- Holding debrief sessions after particularly challenging transitions

- Creating an open-door policy where employees feel comfortable discussing concerns

Feedback mechanisms empower employees to contribute ideas that enhance the overall effectiveness of handovers.

Monitor Performance Metrics Related to Handovers

Tracking performance metrics related to shift transitions can identify areas for improvement. Key metrics may include:

- Error rates associated with miscommunication during handovers

- Time taken for incoming staff to become fully operational after a transition

- Employee satisfaction ratings regarding the handover process

Monitoring these metrics provides valuable insights into the effectiveness of current practices while guiding future improvements.

By implementing these strategies, logistics companies can optimize shift handovers, ensuring seamless transitions between teams while maintaining high levels of productivity and service quality. A focus on effective communication, documentation, training, and continuous improvement fosters a culture where every team member feels empowered during these critical moments.

How do you manage overtime and maintain flexibility in shifts?

Managing overtime effectively while maintaining flexibility in shifts is essential in logistics operations where demand fluctuations are common. Striking this balance ensures that companies meet operational needs without overburdening employees or incurring excessive labor costs. Here are several strategies for managing overtime while maintaining flexibility in scheduling:

Establish Clear Overtime Policies

Develop clear policies regarding overtime expectations, including:

- Criteria for when overtime will be required (e.g., peak seasons, unexpected demand)

- Approval processes for overtime requests from supervisors

- Compensation structures (e.g., time-and-a-half pay)

Transparent policies help set clear expectations around overtime work while ensuring compliance with labor regulations.

Monitor Workload Trends Regularly

Regularly analyzing workload trends enables proactive planning around staffing needs:

- Review historical data on shipment volumes during peak periods

- Identify patterns related to seasonal fluctuations in demand

- Utilize predictive analytics tools to forecast future workload requirements

By understanding workload trends, companies can anticipate staffing needs without relying heavily on last-minute overtime requests.

Cross-train Employees

Cross-training employees across different roles enhances flexibility within the workforce:

- Equip workers with skills needed for various tasks (e.g., driving different types of vehicles)

- Create a versatile workforce capable of stepping into different roles as needed

- Foster collaboration among teams by encouraging knowledge sharing

Cross-trained employees increase organizational agility while reducing reliance on overtime when demand surges unexpectedly.

Implement Flexible Scheduling Options

Offering flexible scheduling options allows employees greater control over their work hours without compromising operational efficiency:

- Provide opportunities for staggered start times based on individual preferences

- Allow part-time employees access to additional hours when available

- Introduce compressed workweeks as an alternative arrangement

Flexibility promotes job satisfaction while enabling organizations to adapt quickly when demand fluctuates.

Utilize On-call Staffing Models

Implementing an on-call staffing model allows organizations to respond rapidly when additional labor is needed without committing long-term resources:

- Maintain a pool of qualified workers who can be called upon during peak periods

- Clearly communicate expectations regarding availability among on-call staff

- Compensate appropriately for being on-call even if not activated

On-call models provide flexibility while minimizing unnecessary overtime costs associated with overstaffing during slower periods.

Encourage Shift Swapping Among Employees

Allowing employees the option to swap shifts promotes flexibility within the workforce while reducing reliance on overtime:

- Implement self-service portals where employees can request swaps easily

- Establish guidelines around how swaps should be managed (e.g., supervisor approval)

- Encourage open communication among team members about availability

Shift swapping empowers employees by giving them control over their schedules while ensuring coverage remains intact.

Track Overtime Hours Closely

Monitoring overtime hours closely helps identify trends that may indicate underlying issues:

- Analyze data related to which departments consistently require overtime support

- Assess whether specific roles experience higher burnout rates due to excessive hours worked

- Identify opportunities for workload redistribution across teams

Tracking overtime provides insights necessary for making informed decisions about staffing adjustments needed moving forward.

Engage Employees in Scheduling Decisions

Involving employees in scheduling decisions fosters buy-in regarding overtime expectations:

- Solicit input from staff regarding preferred working hours or availability constraints

- Conduct regular check-ins with teams about workload pressures they face

- Create opportunities where workers feel comfortable discussing concerns around excessive hours worked

Engaging employees creates an environment where they feel valued while enhancing overall morale within operations.

Review Staffing Levels Regularly

Regularly reviewing staffing levels against operational demands helps ensure adequate coverage without relying heavily upon overtime:

- Assess whether current headcounts align with workload requirements

- Adjust hiring strategies based on anticipated changes in business volume

- Consider temporary staffing solutions during peak seasons instead of relying solely upon existing personnel

Proactive reviews allow organizations greater control over labor costs associated with unplanned overtime scenarios arising unexpectedly throughout operations.

By implementing these strategies effectively within logistics operations—companies can manage both overtime requirements efficiently while maintaining flexibility across their workforce—resulting ultimately in improved productivity levels alongside enhanced employee satisfaction rates overall!

What legal considerations are essential for shift organization?

Understanding legal considerations surrounding shift organization is crucial in logistics operations where compliance with labor laws protects both employers’ interests as well as workers’ rights within various jurisdictions involved throughout supply chains globally! Here are key legal aspects organizations must consider when organizing employee shifts effectively:

Labor Laws Governing Work Hours

Adhering strictly adhering labor laws governing maximum allowable working hours ensures compliance:

- Familiarize yourself thoroughly local regulations concerning standard workweek limits—typically 40 hours/week unless otherwise specified

2 . Understand rules governing mandatory rest periods between consecutive shifts—particularly important given nature physically demanding roles often found within logistics

Compliance minimizes risks associated potential fines arising non-compliance situations encountered frequently across industries!

Overtime Regulations Compliance

Understanding regulations surrounding payment requirements associated overtime work is vital:

1 . Ensure familiarity applicable laws mandating payment rates exceeding standard hourly wages—often requiring time-and-a-half compensation minimums

2 . Monitor total hours worked regularly track instances where additional payments become necessary due increased workloads encountered periodically

Compliance prevents potential litigation arising unpaid wages claims filed by disgruntled workers seeking redress through legal channels!

Meal Break Requirements Compliance

Many jurisdictions mandate minimum meal break provisions which must be adhered:

1 . Familiarize yourself thoroughly local laws dictating duration frequency breaks required throughout daily work schedule

2 . Implement policies guaranteeing compliance ensuring workers receive adequate rest periods necessary maintain productivity levels high

Failure comply could lead serious consequences including penalties imposed regulatory agencies overseeing enforcement labor standards!

Shift Length Regulations Compliance

Certain jurisdictions impose restrictions upon maximum allowable lengths individual shifts worked consecutively:

1 . Understand local regulations governing maximum durations permitted before mandatory rest periods must be provided

2 . Develop policies ensuring compliance preventing potential violations arising excessive fatigue experienced by workers due long hours without adequate breaks

Compliance safeguards against liability claims stemming from workplace accidents resulting fatigue-related incidents occurring frequently within physically demanding environments!

Anti-discrimination Laws Compliance

Ensuring fair treatment all employees regardless race gender age disability status paramount importance:

1 . Familiarize yourself thoroughly anti-discrimination laws applicable your jurisdiction prohibiting bias hiring promotions scheduling practices

2 . Implement policies fostering inclusivity diversity throughout workforce promoting equal opportunities regardless background

Compliance safeguards against potential lawsuits arising discriminatory practices leading reputational damage financial liabilities incurred through legal proceedings initiated affected parties!

Union Agreements Compliance (if applicable)

For organizations operating under union agreements—compliance collective bargaining agreements essential:

1 . Understand terms conditions outlined within agreements governing wages benefits working conditions including those specifically related scheduling practices

2 . Engage regularly union representatives maintain open lines communication addressing concerns raised by members promptly

Failure adhere could result significant repercussions including strikes disruptions operations leading financial losses incurred due halted activities!

How can you monitor and improve shift performance?

Monitoring and improving shift performance is essential in optimizing productivity levels within logistics operations where efficiency directly impacts overall success! Organizations must implement strategies enabling them track performance metrics effectively identify areas requiring enhancement continuously adapting processes accordingly! Here are several approaches organizations can take monitor improve shift performance effectively:

Define Key Performance Indicators (KPIs)

Establish clear KPIs aligned organizational goals enable effective monitoring performance across various dimensions:

1 . Identify relevant KPIs such as productivity rates error rates absenteeism turnover costs associated each metric tracked periodically

2 . Ensure KPIs measurable allowing comparison against established benchmarks identifying trends emerging over time

Defining KPIs provides actionable insights guiding decision-making processes aimed enhancing overall performance!

Utilize Real-Time Data Analytics Tools

Leveraging real-time data analytics tools enables organizations track performance metrics instantly providing timely insights necessary adjust operations accordingly:

1 . Implement dashboards displaying key metrics allowing managers view progress towards targets at-a-glance facilitating quicker responses needed address issues arise

2 . Utilize predictive analytics forecast future performance trends based historical data enabling proactive adjustments made ahead potential problems encountered regularly

Real-time analytics empower organizations make informed decisions enhancing overall effectiveness throughout operations!

Conduct Regular Performance Reviews

Regularly scheduled performance reviews facilitate constructive feedback discussions between managers employees fostering continuous improvement culture within workforce environment:

1 . Schedule one-on-one meetings discussing individual contributions highlighting successes areas needing development providing actionable feedback

2 . Encourage open dialogue where employees feel comfortable discussing challenges faced seeking guidance support from leadership teams involved!

Performance reviews promote accountability engagement ultimately driving better outcomes achieved collectively!

Implement Continuous Training Programs

Ongoing training programs equip workers necessary skills knowledge required excel their roles improving overall efficiency productivity levels achieved consistently across all shifts operated!

1 . Identify skill gaps existing current workforce develop targeted training initiatives addressing those areas needing enhancement

2 . Encourage participation workshops seminars online courses enhancing professional development opportunities available individuals seeking growth advancement!

Continuous training empowers workforce adapt changing demands evolving landscape logistics industry remain competitive long-term!

Solicit Employee Feedback Regularly

Engaging directly with frontline workers soliciting feedback regarding processes procedures enables organizations identify bottlenecks inefficiencies affecting overall performance negatively!

1 . Conduct regular surveys focus group discussions gathering input suggestions improvements desired by team members involved day-to-day activities performed

2 . Create anonymous channels reporting issues raised encouraging candidness openness fostering trust relationships built between management staff involved!

Soliciting feedback cultivates culture transparency accountability ultimately driving better outcomes achieved collectively!

By implementing these strategies effectively monitoring improving shift performance organizations enhance productivity levels achieved ultimately contributing success long-term sustainability efforts undertaken throughout entire supply chain operation!