What Is a Just-in-Time Delivery Schedule

A just-in-time (JIT) delivery schedule is a logistics strategy that aims to receive goods only as they are needed in the production process. This approach minimizes inventory costs and improves efficiency by coordinating deliveries to arrive precisely when materials are required for manufacturing or assembly.

The core principle of JIT delivery is to have the right materials, at the right time, in the right quantity. This contrasts with traditional inventory management methods that maintain large safety stocks. JIT delivery schedules rely on accurate demand forecasting, reliable suppliers, and streamlined logistics to function effectively.

Key characteristics of a JIT delivery schedule include:

Frequent small deliveries: Rather than receiving large shipments infrequently, JIT systems typically involve more frequent deliveries of smaller quantities. This reduces storage requirements and allows for greater flexibility.

Precise timing: Deliveries are timed to coincide with production needs, often down to the hour or even minute. This requires close coordination between suppliers, logistics providers, and manufacturers.

Minimal inventory: JIT aims to keep inventory levels as low as possible without risking stockouts. This frees up capital and reduces carrying costs.

Strong supplier relationships: Successful JIT implementation depends on reliable, responsive suppliers who can consistently meet tight delivery schedules.

Continuous flow: The goal is to create a smooth, uninterrupted flow of materials through the production process, minimizing waste and idle time.

To illustrate how JIT delivery schedules work in practice, consider this example from the automotive industry:

| Time | Action |

|---|---|

| 8:00 AM | Production line starts assembling vehicles |

| 8:30 AM | Delivery of seats arrives, just before they’re needed |

| 9:15 AM | Shipment of dashboard components delivered |

| 10:00 AM | Tire delivery arrives for vehicles nearing completion |

| 11:30 AM | Engine parts delivered for afternoon assembly |

This schedule demonstrates how materials arrive throughout the day, closely aligned with the production sequence. Each delivery is timed to provide components shortly before they’re required, minimizing storage needs and ensuring a continuous workflow.

JIT delivery schedules offer several potential benefits:

Reduced inventory costs: By minimizing stored inventory, companies can significantly reduce warehousing expenses and free up capital.

Improved quality control: With smaller, more frequent deliveries, it’s easier to identify and address quality issues quickly.

Enhanced flexibility: JIT systems allow manufacturers to respond more rapidly to changes in demand or product specifications.

Increased efficiency: By eliminating excess inventory and streamlining processes, JIT can lead to improved overall operational efficiency.

However, implementing a JIT delivery schedule also presents challenges:

Supply chain vulnerability: Any disruptions in the supply chain can quickly halt production, as there’s little buffer inventory.

Complex coordination: JIT requires precise synchronization between suppliers, logistics providers, and manufacturers.

Potential for increased transportation costs: More frequent deliveries may result in higher transportation expenses.

Demand forecasting pressure: Accurate demand forecasting becomes crucial to avoid stockouts or excess inventory.

For businesses considering JIT delivery schedules, it’s essential to weigh these potential benefits and challenges carefully. Success with JIT often depends on factors such as industry characteristics, supply chain reliability, and the company’s ability to forecast demand accurately.

In the following sections, we’ll explore how JIT delivery differs from traditional methods, examine its key components, and delve into the reasons companies choose to implement this approach. We’ll also look at real-world examples of successful JIT implementation and discuss the technologies that support effective JIT delivery systems.

How does JIT delivery differ from traditional methods?

Just-in-time (JIT) delivery represents a significant departure from traditional inventory management and supply chain practices. Understanding these differences is crucial for businesses considering a shift to JIT methods. Let’s examine the key distinctions between JIT delivery and conventional approaches:

Inventory levels

JIT delivery: Maintains minimal inventory levels, often described as “zero inventory.” Materials arrive just before they’re needed in production.

Traditional methods: Keep large safety stocks to buffer against supply chain disruptions and demand fluctuations.

Order frequency and size

JIT delivery: Frequent orders of smaller quantities, closely matched to immediate production needs.

Traditional methods: Less frequent orders of larger quantities to take advantage of bulk discounts and reduce ordering costs.

Supplier relationships

JIT delivery: Requires close, collaborative partnerships with a smaller number of highly reliable suppliers.

Traditional methods: Often involves a larger supplier base with less emphasis on long-term, strategic relationships.

Production approach

JIT delivery: Pull-based system where production is driven by actual customer orders.

Traditional methods: Push-based system where production is based on forecasted demand.

Focus on waste reduction

JIT delivery: Emphasizes eliminating all forms of waste, including excess inventory, overproduction, and unnecessary movement.

Traditional methods: Less emphasis on waste reduction, with a focus on economies of scale and buffer stocks.

Supply chain complexity

JIT delivery: Requires a highly coordinated, often more complex supply chain with precise timing.

Traditional methods: Generally simpler supply chain management with more room for error and delays.

Risk management

JIT delivery: Higher risk of production disruptions due to supply chain issues, but lower risk of obsolete inventory.

Traditional methods: Lower risk of production stoppages, but higher risk of holding excess or obsolete inventory.

Cash flow impact

JIT delivery: Improves cash flow by reducing inventory investment and associated carrying costs.

Traditional methods: Ties up more capital in inventory, potentially impacting cash flow negatively.

Quality control

JIT delivery: Facilitates quicker identification and resolution of quality issues due to smaller batch sizes.

Traditional methods: Quality issues may affect larger batches before detection, potentially leading to more waste.

Flexibility and responsiveness

JIT delivery: Enables rapid adaptation to changes in demand or product specifications.

Traditional methods: Less flexible due to larger inventory commitments and longer production cycles.

To illustrate these differences more concretely, let’s compare JIT and traditional approaches in a manufacturing context:

| Aspect | JIT Delivery | Traditional Methods |

|---|---|---|

| Inventory turnover | 20-30 times per year | 3-4 times per year |

| Safety stock | Minimal or none | 2-3 months’ supply |

| Order frequency | Daily or weekly | Monthly or quarterly |

| Supplier base | 2-3 key suppliers per component | 5-10 suppliers per component |

| Production lot sizes | Small, matched to daily demand | Large, based on monthly forecasts |

| Setup times | Minimized, multiple daily changeovers | Longer setups, less frequent changeovers |

| Quality inspection | 100% inspection, immediate feedback | Sampling inspection, delayed feedback |

This comparison highlights how JIT delivery fundamentally alters the approach to inventory management, production planning, and supplier relationships. While JIT offers significant potential benefits in terms of efficiency and cost reduction, it also requires a more sophisticated and tightly controlled supply chain.

The choice between JIT and traditional methods often depends on factors such as:

Industry characteristics: JIT is particularly well-suited to industries with predictable demand and standardized products.

Supply chain reliability: Companies with stable, reliable supply chains are better positioned to implement JIT successfully.

Competitive environment: In markets where rapid response to changing customer demands is crucial, JIT can provide a competitive advantage.

Organizational culture: JIT requires a commitment to continuous improvement and waste reduction throughout the organization.

Technological capabilities: Advanced inventory management and supply chain visibility tools are often necessary for effective JIT implementation.

For businesses considering a shift to JIT delivery, it’s essential to carefully evaluate these factors and potentially implement JIT principles gradually. Many companies find success in adopting a hybrid approach, applying JIT methods to certain product lines or components while maintaining traditional inventory practices for others.

As we delve deeper into the key components of JIT delivery systems in the next section, we’ll explore how these principles are put into practice and the infrastructure required to support successful JIT implementation.

What are the key components of a JIT delivery system?

A successful just-in-time (JIT) delivery system relies on several interconnected components working in harmony. Understanding these key elements is crucial for businesses looking to implement or optimize their JIT processes. Let’s explore the essential components that form the foundation of an effective JIT delivery system:

Demand forecasting

Accurate demand forecasting is the cornerstone of JIT delivery. It involves:

- Advanced analytics to predict customer demand

- Real-time data integration from sales, market trends, and historical patterns

- Continuous refinement of forecasting models

Precise forecasting enables companies to align production schedules with expected demand, minimizing excess inventory while avoiding stockouts.

Supplier relationships

Strong, collaborative partnerships with suppliers are critical for JIT success. This component includes:

- Rigorous supplier selection based on reliability and quality

- Long-term contracts with performance incentives

- Open communication channels for sharing forecasts and production schedules

- Collaborative problem-solving and continuous improvement initiatives

These partnerships ensure that suppliers can meet the stringent timing and quality requirements of JIT delivery.

Production scheduling

Efficient production scheduling is essential to synchronize manufacturing with material deliveries. Key aspects include:

- Flexible production lines capable of quick changeovers

- Balanced workloads to maintain consistent output

- Real-time adjustments based on actual demand and material availability

- Integration with supplier delivery schedules

Well-executed production scheduling minimizes downtime and ensures smooth material flow through the manufacturing process.

Inventory management

While JIT aims to minimize inventory, effective management of existing stock is crucial. This involves:

- Real-time inventory tracking systems

- Clear labeling and organization of materials

- First-in, first-out (FIFO) inventory rotation

- Kanban systems to signal replenishment needs

Proper inventory management prevents stockouts and ensures that the right materials are available when needed.

Transportation and logistics

Reliable transportation is vital for timely material delivery. Key elements include:

- Optimized routing and scheduling

- Real-time tracking of shipments

- Contingency planning for potential disruptions

- Multi-modal transportation options for flexibility

Efficient logistics ensure that materials arrive precisely when needed, supporting the JIT production flow.

Quality control

Maintaining high quality standards is essential in a JIT system. This component encompasses:

- Stringent quality checks at supplier facilities

- Incoming material inspection processes

- Statistical process control in manufacturing

- Rapid problem identification and resolution

Robust quality control prevents defective materials from disrupting production and ensures consistent product quality.

Information systems

Advanced information technology forms the backbone of JIT delivery systems. Key features include:

- Enterprise Resource Planning (ERP) systems for integrated data management

- Real-time communication tools for coordination with suppliers

- Advanced analytics for demand forecasting and performance monitoring

- Automated reordering systems

These systems provide the visibility and coordination necessary for JIT operations.

Continuous improvement processes

JIT delivery systems require ongoing refinement and optimization. This component involves:

- Regular performance reviews and benchmarking

- Kaizen events for process improvement

- Cross-functional teams for problem-solving

- Employee training and skill development

Continuous improvement ensures that the JIT system evolves to meet changing business needs and market conditions.

To illustrate how these components work together in a JIT delivery system, consider the following example of a typical JIT process flow:

| Stage | Action | Key Components Involved |

|---|---|---|

| 1 | Sales data analyzed to forecast demand | Demand forecasting, Information systems |

| 2 | Production schedule created based on forecast | Production scheduling, Information systems |

| 3 | Material requirements communicated to suppliers | Supplier relationships, Information systems |

| 4 | Suppliers prepare and ship materials | Supplier relationships, Transportation and logistics |

| 5 | Materials received and quality-checked | Quality control, Inventory management |

| 6 | Materials moved to production line as needed | Inventory management, Production scheduling |

| 7 | Production begins, consuming materials | Production scheduling, Quality control |

| 8 | Finished products shipped to customers | Transportation and logistics |

| 9 | Process performance reviewed and optimized | Continuous improvement processes |

This example demonstrates how each component plays a crucial role in the smooth operation of a JIT delivery system. The interconnected nature of these elements underscores the importance of a holistic approach to JIT implementation.

For businesses considering or refining their JIT delivery systems, it’s essential to evaluate each of these components carefully. Strengths and weaknesses in any area can significantly impact the overall effectiveness of the JIT approach. Often, companies find that gradual implementation, focusing on one component at a time, allows for smoother adoption and optimization of JIT principles.

As we move forward, we’ll explore the motivations behind companies’ decisions to implement JIT delivery schedules and the challenges they may face in doing so. Understanding these factors can help businesses make informed decisions about whether and how to adopt JIT practices in their operations.

Why do companies implement JIT delivery schedules?

Companies implement just-in-time (JIT) delivery schedules for various strategic reasons, all aimed at improving operational efficiency, reducing costs, and enhancing competitiveness. Let’s explore the primary motivations driving businesses to adopt JIT practices:

Cost reduction

JIT delivery schedules significantly reduce inventory holding costs. By minimizing the amount of stock on hand, companies can:

- Decrease warehouse space requirements

- Lower insurance costs for stored inventory

- Reduce the risk of obsolescence and spoilage

- Minimize capital tied up in inventory

These cost savings can have a substantial impact on a company’s bottom line, freeing up resources for other strategic initiatives.

Improved cash flow

With less capital invested in inventory, companies can improve their cash flow position. This enhanced liquidity allows businesses to:

- Invest in growth opportunities

- Pay down debt more quickly

- Increase dividends or share buybacks

- Respond more flexibly to market changes

Improved cash flow can provide a significant competitive advantage, especially in capital-intensive industries.

Enhanced quality control

JIT delivery facilitates better quality management through:

- Smaller batch sizes, making defects easier to detect and isolate

- Quicker feedback loops between production and suppliers

- Reduced risk of damage or deterioration during storage

- Increased focus on process quality to prevent disruptions

Higher quality products lead to increased customer satisfaction and potentially lower warranty costs.

Increased flexibility

JIT systems enable companies to respond more rapidly to changes in:

- Customer demand

- Product specifications

- Market trends

This agility allows businesses to:

- Introduce new products more quickly

- Customize offerings to meet specific customer needs

- Adjust production volumes without excessive inventory buildup

Flexibility can be a key differentiator in fast-moving markets.

Waste reduction

JIT principles align closely with lean manufacturing concepts, focusing on eliminating various forms of waste:

- Overproduction

- Excess inventory

- Unnecessary transportation

- Waiting time

- Defective products

By reducing waste, companies can improve overall efficiency and sustainability.

Improved supplier relationships

Implementing JIT often leads to closer, more collaborative relationships with suppliers. This can result in:

- Better communication and coordination

- Shared cost savings

- Joint problem-solving and innovation

- Increased reliability and quality from suppliers

Strong supplier partnerships can become a source of competitive advantage.

Streamlined operations

JIT delivery schedules force companies to optimize their entire supply chain and production processes. This leads to:

- Simplified material handling

- Reduced paperwork and administrative overhead

- More efficient use of labor and equipment

- Clearer visibility into the entire production process

Streamlined operations contribute to overall organizational effectiveness.

To illustrate the potential impact of JIT implementation, consider the following comparison of key performance indicators before and after JIT adoption:

| Metric | Before JIT | After JIT | Improvement |

|---|---|---|---|

| Inventory turnover | 4 times/year | 20 times/year | 400% increase |

| Average inventory value | $10 million | $2 million | 80% reduction |

| Lead time | 4 weeks | 1 week | 75% reduction |

| Defect rate | 3% | 0.5% | 83% reduction |

| On-time delivery | 85% | 98% | 15% increase |

| Cash conversion cycle | 60 days | 30 days | 50% reduction |

These improvements demonstrate the potential for significant operational and financial benefits from JIT implementation.

Companies in various industries have reported substantial gains from adopting JIT practices:

Automotive manufacturing: Toyota, the pioneer of JIT, reduced its inventory carrying costs by 50% and improved productivity by 100% over traditional mass production methods.

Electronics: Dell Computer achieved a negative cash conversion cycle by implementing JIT, allowing it to receive payment for products before paying suppliers.

Retail: Walmart’s use of JIT principles in its cross-docking system has contributed to its position as a cost leader in the retail industry.

Fast food: McDonald’s applies JIT concepts to food preparation, reducing waste and ensuring freshness.

While the benefits of JIT can be substantial, it’s important to note that successful implementation requires careful planning and execution. Companies must consider their specific industry characteristics, supply chain reliability, and organizational readiness before committing to a JIT approach.

Factors that may influence a company’s decision to implement JIT include:

Industry volatility: IndustriesIndustry volatility: Industries with fluctuating demand or rapid product changes may find JIT more challenging to implement effectively. Companies in such sectors must invest in robust forecasting and flexible supply chains.

Supply chain reliability: Businesses with stable, dependable suppliers are better positioned to adopt JIT practices. Unreliable suppliers can disrupt production schedules and lead to stockouts, undermining the benefits of JIT.

Organizational culture: A culture that embraces continuous improvement, teamwork, and problem-solving is essential for successful JIT implementation. Companies must foster an environment where employees are encouraged to identify inefficiencies and suggest improvements.

Technological capabilities: Advanced information systems and real-time data analytics are critical for effective JIT delivery. Companies need the right technology to track inventory levels, monitor supplier performance, and respond quickly to changes in demand.

In summary, companies implement JIT delivery schedules to achieve cost reductions, improve cash flow, enhance quality control, increase flexibility, reduce waste, strengthen supplier relationships, and streamline operations. While the potential benefits are significant, businesses must carefully evaluate their readiness and capacity to implement JIT successfully.

As we continue our exploration of JIT delivery schedules, the next section will address the challenges businesses face when adopting this approach. Understanding these challenges is crucial for companies looking to navigate the complexities of JIT implementation effectively.

What challenges do businesses face with JIT delivery?

While just-in-time (JIT) delivery offers numerous advantages, businesses also encounter several challenges when implementing this approach. Recognizing these obstacles is essential for developing strategies to mitigate risks and ensure successful adoption of JIT practices. Here are some of the key challenges companies face:

Supply chain disruptions

JIT systems rely on a seamless flow of materials from suppliers to manufacturers. Any disruption—such as natural disasters, political instability, or transportation issues—can halt production lines. To address this challenge:

- Companies should develop contingency plans that include alternative suppliers and logistics options.

- Building buffer stock for critical components may be necessary in industries prone to disruptions.

Demand variability

Accurate demand forecasting is crucial for JIT success. However, fluctuations in customer demand can lead to stockouts or excess inventory. Companies can mitigate this risk by:

- Utilizing advanced analytics and machine learning algorithms for better demand predictions.

- Implementing flexible production systems that can quickly adapt to changing demand patterns.

Supplier reliability

JIT delivery requires strong partnerships with reliable suppliers who can meet tight deadlines consistently. Challenges include:

- Supplier failures can lead to production stoppages.

- Companies should conduct thorough supplier evaluations and establish long-term relationships based on performance metrics.

To further strengthen supplier relationships:

- Regular communication and collaboration on forecasts can help align expectations.

- Joint problem-solving initiatives can enhance trust and responsiveness.

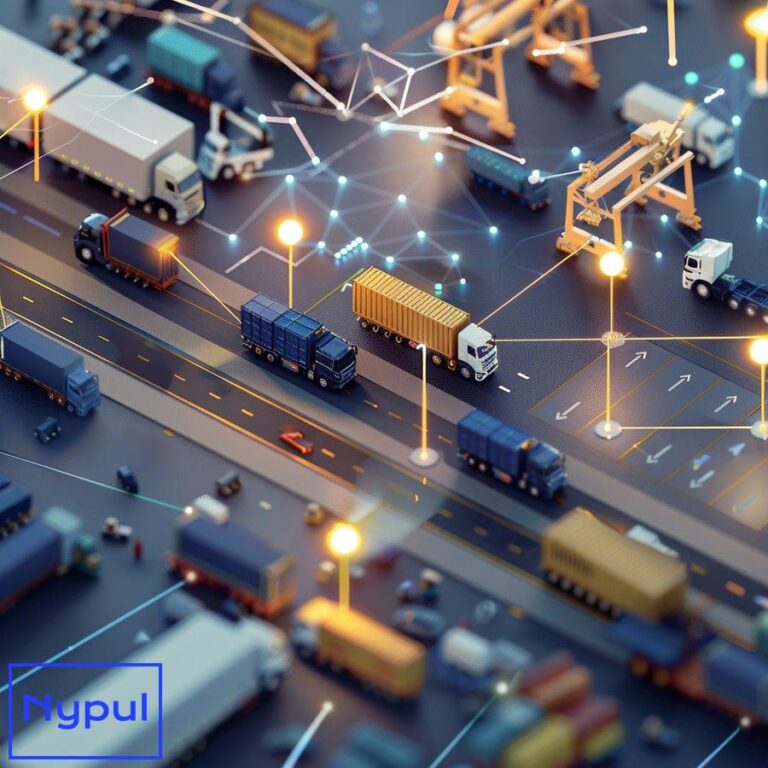

Complex logistics management

Managing logistics in a JIT environment is inherently more complex due to the need for precise timing and coordination. Challenges include:

- Increased transportation costs associated with more frequent deliveries.

- The need for real-time tracking systems to monitor shipments closely.

Companies can address these logistics challenges by:

- Investing in advanced transportation management systems (TMS) that optimize routing and scheduling.

- Collaborating with logistics providers who understand the intricacies of JIT operations.

Quality control issues

Maintaining high-quality standards is crucial in a JIT system. Challenges arise from:

- The potential for defects in smaller batch sizes leading to production delays.

- The need for rigorous incoming quality inspections without slowing down the supply chain.

To ensure quality control in a JIT environment:

- Implementing statistical process control (SPC) techniques can help identify defects early.

- Establishing strong quality assurance protocols with suppliers ensures that materials meet specifications before arrival.

Employee training and engagement

Successful JIT implementation requires a workforce that understands the principles of lean manufacturing and continuous improvement. Challenges include:

- Resistance to change from employees accustomed to traditional inventory practices.

- The need for ongoing training programs that emphasize teamwork and problem-solving skills.

To foster employee engagement:

- Involve staff in the planning process and solicit their feedback on potential improvements.

- Provide training on lean principles and encourage participation in continuous improvement initiatives.

Technology integration

Effective JIT delivery relies on advanced technology for real-time data sharing and inventory tracking. Challenges include:

- Integration of various information systems across different departments or locations.

- Ensuring that employees are adequately trained to use new technologies effectively.

To overcome technology integration challenges:

- Choose scalable solutions that can grow with the business.

- Invest in comprehensive training programs that empower employees to leverage technology effectively.

In summary, businesses face several challenges when implementing JIT delivery schedules, including supply chain disruptions, demand variability, supplier reliability issues, complex logistics management, quality control concerns, employee training needs, and technology integration hurdles. By proactively addressing these challenges through strategic planning and investment in resources, companies can enhance their chances of successful JIT adoption.

Next, we will explore which industries benefit most from adopting JIT delivery schedules. Understanding these industry-specific applications will provide valuable insights into the versatility of JIT practices across different sectors.

Which industries benefit most from JIT delivery?

Just-in-time (JIT) delivery schedules offer significant advantages across various industries by enhancing efficiency, reducing costs, and improving responsiveness to customer demands. However, certain sectors are particularly well-suited for implementing JIT principles due to their operational characteristics and market dynamics. Here are some industries that benefit most from adopting JIT delivery schedules:

Automotive manufacturing

The automotive industry was one of the pioneers of JIT practices, largely popularized by Toyota’s production system. Key benefits include:

- Reduced inventory costs through minimal stock levels at assembly plants.

- Improved quality control by receiving components just before they are needed.

- Enhanced flexibility in responding to changes in consumer preferences or production schedules.

The automotive sector’s complex supply chains require precise coordination between multiple suppliers, making JIT an effective strategy for optimizing operations.

Electronics manufacturing

Electronics manufacturers face rapid technological advancements and shifting consumer demands. Benefits of JIT in this industry include:

- Faster response times to market changes by minimizing lead times between component procurement and production.

- Reduced risk of obsolescence for components due to shorter inventory holding periods.

- Improved collaboration with suppliers who provide just-in-time components like circuit boards or semiconductors.

By leveraging JIT principles, electronics manufacturers can maintain competitive advantages in a fast-paced market.

Retail

Retailers increasingly adopt JIT practices to optimize inventory levels while meeting customer demands efficiently. Benefits include:

- Reduced carrying costs associated with excess inventory on shelves.

- Improved cash flow by aligning product availability with actual sales trends.

- Enhanced responsiveness through real-time data analysis of consumer purchasing patterns.

For instance, Walmart employs sophisticated supply chain management techniques that incorporate JIT principles to maintain low prices while ensuring product availability.

Aerospace

The aerospace industry benefits from JIT delivery schedules through enhanced operational efficiency and reduced lead times for critical components. Key advantages include:

- Streamlined production processes that minimize downtime during assembly.

- Improved supplier collaboration for timely deliveries of specialized parts such as engines or avionics systems.

- Enhanced quality assurance measures through rigorous inspection protocols at each stage of production.

Given the complexity of aerospace manufacturing processes, effective implementation of JIT can lead to significant cost savings and improved project timelines.

Food service

The food service industry relies heavily on freshness and quality; therefore, adopting JIT practices is beneficial. Advantages include:

- Reduced waste from perishable goods by aligning deliveries closely with demand patterns.

- Improved menu flexibility based on seasonal ingredients or changing consumer preferences.

- Enhanced supplier relationships through collaborative forecasting efforts.

Restaurants that implement JIT principles can adapt quickly while maintaining high standards of food quality.

Pharmaceuticals

In pharmaceuticals, where compliance with regulations is paramount, adopting a JIT approach helps streamline operations while ensuring product availability. Key benefits include:

- Reduced inventory holding costs while maintaining compliance with strict regulatory requirements.

- Enhanced responsiveness to changes in patient needs or market demand fluctuations.

- Improved collaboration with suppliers who provide active pharmaceutical ingredients (APIs) just-in-time for production runs.

Pharmaceutical companies leveraging JIT principles can enhance their agility while adhering to stringent industry regulations.

To summarize, industries such as automotive manufacturing, electronics manufacturing, retail, aerospace, food service, and pharmaceuticals benefit significantly from implementing just-in-time delivery schedules. By optimizing inventory levels and enhancing operational efficiency through close collaboration with suppliers and real-time data analysis, these sectors can achieve substantial competitive advantages in their respective markets.

As we continue our discussion on implementing successful JIT delivery schedules, we will explore practical strategies companies can employ to adopt this approach effectively while addressing potential pitfalls along the way.

How can companies implement a JIT delivery schedule?

Implementing a just-in-time (JIT) delivery schedule requires careful planning and execution across various aspects of an organization’s operations. By following a structured approach tailored to their specific needs and industry requirements, companies can successfully adopt JIT principles while minimizing disruptions. Here are key steps organizations should consider when implementing a JIT delivery schedule:

1. Assess current processes

Before transitioning to a JIT system, companies should conduct a thorough assessment of their existing processes. This includes:

- Evaluating current inventory levels against actual consumption rates.

| Metric | Current Level | Ideal Level | Difference |

|---|---|---|---|

| Inventory turnover | 4 times/year | 20 times/year | -16 times |

| Average lead time | 4 weeks | 1 week | -3 weeks |

-

Identifying bottlenecks or inefficiencies within the supply chain.

-

Analyzing order fulfillment times

- Reviewing communication channels between departments

This assessment provides valuable insights into areas requiring improvement before implementing a new system.

2. Establish clear goals

Setting clear objectives is crucial for guiding the implementation process effectively. Companies should define specific goals related to their desired outcomes from adopting a JIT system such as:

-

Reducing inventory carrying costs by X%

-

Example: Aim for a 30% reduction within one year

-

Improving on-time deliveries from suppliers

-

Example: Increase on-time performance from 85% to 95%

These goals serve as benchmarks against which progress can be measured throughout the implementation process.

3. Build strong supplier relationships

Successful implementation of a JIT system relies heavily on collaboration with reliable suppliers who understand your business needs. Steps include:

- Selecting key suppliers based on performance metrics such as reliability and quality

| Supplier Name | Reliability Rating | Quality Rating |

|---|---|---|

| Supplier A | 95% | 98% |

| Supplier B | 90% | 97% |

-

Establishing long-term contracts that incentivize performance improvements

-

Include clauses related to penalties or bonuses based on adherence to delivery schedules

Regular communication regarding forecasts allows both parties to align expectations effectively while fostering trust over time through joint problem-solving initiatives when issues arise during production cycles.

4. Optimize production scheduling

Efficient production scheduling ensures alignment between material deliveries and manufacturing activities within your organization’s operations:

-

Utilize flexible manufacturing systems capable of quick changeovers between products

-

Implement Kanban systems that signal replenishment needs based on actual consumption rates rather than forecasts

This optimization minimizes downtime during transitions while ensuring materials arrive precisely when needed throughout each stage of production processes without excess delays caused by waiting times or misaligned inventories.

5. Invest in technology

Advanced technology plays an essential role in supporting effective implementation strategies associated with just-in-time delivery systems:

-

Implement Enterprise Resource Planning (ERP) software capable of integrating data across departments

-

Utilize real-time tracking tools enabling visibility into shipments at every stage

-

Leverage analytics platforms capable of generating actionable insights based on historical trends

Investing appropriately ensures organizations have access not only necessary information but also tools facilitating seamless communication among stakeholders involved throughout various stages within supply chains leading up until final product deliveries occur successfully without hiccups along routes taken during transit periods involved therein!

6. Train employees

Employee engagement is critical during any transition towards new operational methodologies like those inherent within just-in-time frameworks:

-

Provide comprehensive training programs focused specifically around lean manufacturing principles

-

Encourage cross-functional teams responsible for identifying areas needing improvement while fostering collaboration among departments

Empowering employees equips them better handle challenges encountered along way ensuring smooth transitions occur without unnecessary disruptions stemming from lack understanding regarding new processes introduced into workflows established previously prior implementations taking place overall!

7. Monitor performance metrics

Establishing key performance indicators (KPIs) allows organizations track progress towards achieving set goals throughout implementation phases:

| Metric | Target Value | Current Value |

|---|---|---|

| Inventory turnover | 20 times/year | TBD |

| On-time deliveries | 95% | TBD |

| Lead time | <1 week | TBD |

Regularly reviewing these metrics provides insights into areas needing further refinement while celebrating successes achieved thus far!

In conclusion, implementing a just-in-time delivery schedule involves assessing current processes thoroughly; establishing clear goals; building strong supplier relationships; optimizing production scheduling; investing appropriately into technology solutions available today; providing necessary training programs aimed at engaging employees fully within organizations’ missions towards achieving operational excellence overall! By following these steps diligently over time—companies position themselves favorably towards maximizing benefits derived from adopting innovative methodologies like those found within frameworks associated directly related back toward successful implementations achieved via utilizing concepts inherent behind just-in-time strategies employed effectively across various sectors!

Next up will be exploring how technologies support effective just-in-time delivery systems—shedding light upon advancements shaping future landscapes surrounding logistics management practices being utilized today!

What technologies support effective JIT delivery?

The successful implementation of just-in-time (JIT) delivery schedules hinges significantly upon leveraging advanced technologies that facilitate real-time data sharing across supply chains while optimizing operational efficiencies throughout various stages involved therein! Here’s an overview outlining key technologies supporting effective execution strategies associated directly back toward achieving desired outcomes linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied across diverse sectors today!

1. Enterprise Resource Planning (ERP) Systems

ERP systems integrate all facets related back toward business operations—from finance through procurement alongside sales—into one cohesive platform enabling seamless communication among departments involved throughout organizational workflows! Key features include:

-

Centralized data repository allowing stakeholders access relevant information quickly whenever needed

-

Automated reporting capabilities generating insights based upon historical trends observed over time

-

Real-time visibility into inventory levels ensuring timely replenishment orders placed accordingly based upon actual consumption rates observed regularly!

2. Inventory Management Software

Inventory management software plays an essential role supporting effective execution strategies linked back toward achieving desired outcomes associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied across diverse sectors today! Key functionalities encompass:

-

Real-time tracking capabilities ensuring accurate visibility regarding stock levels maintained across warehouses

-

Automated alerts notifying stakeholders whenever predefined thresholds reached prompting timely replenishment orders placed accordingly

-

Analytics tools generating actionable insights helping organizations identify trends impacting overall performance metrics observed regularly!

3. Transportation Management Systems (TMS)

TMS solutions optimize logistics operations facilitating efficient routing alongside scheduling activities required during transit periods involved therein! Key features comprise:

-

Route optimization algorithms minimizing transportation costs associated with delivering goods timely without unnecessary delays incurred along routes taken

-

Real-time tracking capabilities enabling stakeholders monitor shipments at every stage ensuring transparency throughout entire supply chains

-

Performance analytics assessing carrier effectiveness helping organizations make informed decisions regarding partnerships established moving forward!

4. Advanced Analytics & Machine Learning Tools

Advanced analytics coupled alongside machine learning tools empower organizations harness vast amounts data generated daily transforming raw information into actionable insights driving decision-making processes forward! Key applications involve:

-

Predictive analytics forecasting future demand patterns based upon historical sales data observed over time enabling proactive adjustments made proactively rather than reactively later down line!

-

Machine learning algorithms identifying inefficiencies present within existing workflows allowing organizations refine processes continuously improving overall performance metrics achieved over time!

5. Internet of Things (IoT)

IoT devices facilitate real-time monitoring conditions affecting products during transit periods involved therein! Key applications encompass:

-

Sensors embedded within shipping containers providing visibility temperature humidity levels ensuring perishable goods remain fresh throughout entire journey taken until final destination reached!

-

RFID tags attached products enabling accurate tracking movement items throughout entire supply chains ensuring timely deliveries occur without unnecessary delays incurred along routes taken!

6. Cloud Computing Solutions

Cloud computing solutions facilitate secure storage access vast amounts data generated daily allowing stakeholders collaborate seamlessly regardless geographic locations occupied! Key benefits involve:

-

Enhanced scalability accommodating growing demands placed upon businesses operating within dynamic markets requiring flexibility adapt quickly whenever necessary!

-

Improved collaboration enabling teams work together efficiently sharing critical information needed make informed decisions promptly whenever required!

7. Robotics & Automation Technologies

Robotics automation technologies streamline repetitive tasks enhancing productivity levels achieved during various stages involved throughout organizational workflows! Key applications encompass:

-

Automated guided vehicles transporting materials across warehouses reducing manual labor required completing tasks efficiently!

-

Robotic process automation handling administrative functions freeing up employees focus higher-value activities contributing overall success achieved moving forward!

In summary—leveraging advanced technologies supports effective execution strategies linked back toward achieving desired outcomes associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied across diverse sectors today! By investing appropriately into these technological solutions—companies position themselves favorably towards maximizing benefits derived from adopting innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today!

As we conclude our exploration surrounding technologies supporting effective just-in-time delivery systems—it’s important also shed light upon real-world examples demonstrating how companies utilize these principles successfully driving operational efficiencies forward achieving remarkable results overall!

How do real-world companies use JIT delivery successfully?

Numerous companies worldwide have successfully implemented just-in-time (JIT) delivery strategies resulting in substantial operational efficiencies alongside cost savings achieved over time! Here’s an overview highlighting notable examples showcasing how various organizations leverage these principles driving remarkable results forward effectively navigating complexities associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today!

1. Toyota Motor Corporation

As one of the pioneers behind developing lean manufacturing techniques—including foundational concepts underpinning modern-day approaches surrounding just-in-time logistics—Toyota has continually refined its processes leading industry standards globally! Key achievements encompass:

-

Reduction inventory carrying costs significantly through optimized supply chain management practices resulting higher profitability margins achieved consistently over several decades now!

-

Enhanced flexibility allowing rapid adaptation changing consumer preferences reflected through diversified product offerings available meeting diverse customer needs efficiently without excess delays incurred along routes taken during transit periods involved therein!

2. Dell Technologies

Dell revolutionized personal computer sales utilizing direct-to-consumer models incorporating elements inherent behind successful implementations surrounding just-in-time methodologies driving remarkable results forward effectively navigating complexities associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today! Key achievements encompass:

-

Achieving negative cash conversion cycles enabling receipt payments customers before paying suppliers resulting improved cash flow positions allowing reinvestment growth opportunities consistently over time!

-

Streamlining assembly processes minimizing lead times delivering customized products customers efficiently without excess delays incurred along routes taken during transit periods involved therein!

3. Walmart Inc.

Walmart employs sophisticated supply chain management techniques incorporating elements inherent behind successful implementations surrounding just-in-time methodologies driving remarkable results forward effectively navigating complexities associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today! Key achievements encompass:

-

Maintaining low prices while ensuring product availability through optimized inventory levels aligned closely actual sales trends observed regularly!

-

Leveraging advanced technology solutions facilitating seamless communication### 3. Walmart Inc.

Walmart employs sophisticated supply chain management techniques incorporating elements inherent behind successful implementations surrounding just-in-time methodologies driving remarkable results forward effectively navigating complexities associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today! Key achievements encompass:

-

Maintaining low prices while ensuring product availability through optimized inventory levels aligned closely actual sales trends observed regularly!

-

Leveraging advanced technology solutions facilitating seamless communication among stakeholders involved throughout various stages within supply chains leading up until final product deliveries occur successfully without hiccups along routes taken during transit periods involved therein!

4. Zara (Inditex)

Zara, the flagship brand of Spanish retail group Inditex, has pioneered fast fashion by implementing just-in-time delivery strategies enabling rapid response to evolving consumer preferences! Key achievements encompass:

-

Reducing lead times from design to store shelf significantly allowing introduction of new products quickly meeting demands efficiently without excess delays incurred along routes taken during transit periods involved therein!

-

Maintaining lean inventory levels minimizing markdowns required clearing seasonal merchandise while ensuring availability popular items consistently over time!

5. Procter & Gamble

Procter & Gamble, a leading consumer goods manufacturer, has successfully implemented just-in-time delivery strategies across various product categories driving operational efficiencies forward effectively navigating complexities associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today! Key achievements encompass:

-

Reducing inventory carrying costs significantly through optimized supply chain management practices resulting higher profitability margins achieved consistently over several decades now!

-

Enhancing collaboration with retail partners ensuring on-time deliveries meeting consumer demands efficiently without excess delays incurred along routes taken during transit periods involved therein!

In conclusion, real-world examples demonstrate how companies across diverse sectors have successfully implemented just-in-time delivery strategies driving remarkable results forward effectively navigating complexities associated directly linked back toward utilizing innovative methodologies like those found within frameworks surrounding just-in-time concepts applied effectively across diverse sectors today! By investing appropriately into advanced technologies alongside fostering strong supplier relationships—organizations position themselves favorably towards maximizing benefits derived from adopting these principles consistently over time!