What Is Risk Management of Logistics Systems

What is risk management in logistics systems?

Risk management in logistics systems refers to the systematic process of identifying, assessing, and mitigating potential threats and uncertainties that could disrupt the flow of goods, information, or finances within a supply chain. This critical function aims to protect organizations from operational, financial, and reputational damages while ensuring business continuity and customer satisfaction.

At its core, logistics risk management involves:

Proactive identification of risks: Logistics managers must anticipate and recognize potential hazards across all stages of the supply chain, from procurement to last-mile delivery.

Comprehensive risk assessment: Once identified, risks are evaluated based on their likelihood of occurrence and potential impact on operations.

Strategic risk mitigation: Developing and implementing targeted strategies to minimize or eliminate identified risks.

Ongoing monitoring and adaptation: Continuously tracking risk indicators and adjusting mitigation strategies as needed.

The importance of risk management in logistics cannot be overstated. In an increasingly complex and interconnected global marketplace, supply chains face a multitude of threats ranging from natural disasters to geopolitical instability. Effective risk management enables organizations to:

Enhance operational resilience: By preparing for potential disruptions, companies can maintain business continuity even in challenging circumstances.

Improve decision-making: A thorough understanding of risks allows for more informed strategic choices in supply chain design and management.

Protect financial performance: Mitigating risks helps prevent costly disruptions and unexpected expenses.

Maintain customer trust: Reliable service delivery, even in the face of challenges, strengthens customer relationships and brand reputation.

To illustrate the scope of logistics risk management, consider the following table outlining key risk categories and examples:

| Risk Category | Examples |

|---|---|

| Operational Risks | Equipment failures, human errors, process inefficiencies |

| Supply Risks | Supplier bankruptcies, quality issues, capacity constraints |

| Demand Risks | Forecast inaccuracies, sudden demand spikes or drops |

| Environmental Risks | Natural disasters, extreme weather events, pandemics |

| Geopolitical Risks | Trade disputes, regulatory changes, political instability |

| Cybersecurity Risks | Data breaches, system outages, ransomware attacks |

| Financial Risks | Currency fluctuations, credit risks, market volatility |

Implementing a robust risk management framework in logistics requires a holistic approach that integrates various organizational functions. Key stakeholders typically include:

Supply chain managers: Responsible for overseeing the entire risk management process and coordinating mitigation efforts.

Procurement teams: Play a crucial role in identifying and managing supplier-related risks.

Operations personnel: Provide insights into day-to-day operational risks and implement mitigation measures.

IT departments: Address cybersecurity risks and ensure the resilience of critical systems.

Finance teams: Assess and manage financial risks associated with logistics operations.

Legal and compliance experts: Ensure adherence to regulatory requirements and manage legal risks.

Effective risk management in logistics is not a one-time effort but an ongoing process that requires continuous improvement and adaptation. As supply chains evolve and new risks emerge, organizations must remain vigilant and proactive in their approach to risk management.

By embracing a comprehensive risk management strategy, logistics systems can become more resilient, efficient, and capable of delivering value to customers even in the face of uncertainty. This proactive stance not only protects the organization from potential losses but also creates a competitive advantage in an increasingly volatile business environment.

How are risks identified and assessed in logistics?

Identifying and assessing risks in logistics is a critical process that forms the foundation of effective risk management. This systematic approach enables organizations to proactively address potential threats before they materialize into costly disruptions. The process typically involves several key steps and methodologies:

Risk Identification Techniques

Brainstorming sessions: Cross-functional teams gather to identify potential risks based on their collective experience and knowledge.

Historical data analysis: Examining past incidents and near-misses can reveal recurring patterns and potential future risks.

Process mapping: Detailed mapping of logistics processes helps identify vulnerabilities at each stage of the supply chain.

External environment scanning: Monitoring industry trends, geopolitical developments, and economic indicators to anticipate emerging risks.

Supplier assessments: Evaluating the financial health, operational capabilities, and risk profiles of key suppliers.

Customer feedback analysis: Insights from customers can highlight potential service-related risks.

Technology-enabled risk detection: Utilizing advanced analytics and AI to identify anomalies and potential risk indicators in large datasets.

Once potential risks have been identified, the next crucial step is to assess their potential impact and likelihood. This assessment provides a basis for prioritizing risks and allocating resources for mitigation efforts.

Risk Assessment Methodologies

Qualitative risk assessment: This approach involves categorizing risks based on their perceived severity and probability using predefined scales. A common tool for this is the risk matrix, which plots risks on a grid with axes representing impact and likelihood.

| Impact / Likelihood | Low | Medium | High |

|---|---|---|---|

| High | Medium Risk | High Risk | Critical Risk |

| Medium | Low Risk | Medium Risk | High Risk |

| Low | Negligible Risk | Low Risk | Medium Risk |

Quantitative risk assessment: This method assigns numerical values to the probability and impact of risks, often using statistical models and historical data. Techniques may include:

- Expected Monetary Value (EMV) analysis

- Monte Carlo simulations

- Decision tree analysis

Failure Mode and Effects Analysis (FMEA): This structured approach evaluates potential failure modes in a system and their consequences.

Scenario analysis: Developing and analyzing various “what-if” scenarios to understand the potential outcomes of different risk events.

Key Risk Indicators (KRIs): Establishing and monitoring specific metrics that serve as early warning signs for potential risks.

Risk assessment criteria

When evaluating logistics risks, several key factors are typically considered:

Financial impact: The potential monetary losses associated with the risk, including direct costs and indirect expenses such as lost revenue or market share.

Operational disruption: The extent to which the risk could interrupt normal business operations and supply chain activities.

Reputational damage: The potential harm to the organization’s brand image and customer relationships.

Regulatory compliance: The risk of non-compliance with relevant laws and regulations, which could result in fines or legal action.

Safety and environmental consequences: The potential impact on employee safety, public health, or the environment.

Recovery time: The estimated time required to return to normal operations following a risk event.

Interdependencies: The potential for a risk to trigger or exacerbate other risks within the logistics system.

Risk assessment challenges in logistics

Assessing risks in complex logistics systems presents several unique challenges:

Global supply chain complexity: The interconnected nature of global supply chains makes it difficult to fully understand and quantify all potential risks.

Data quality and availability: Accurate risk assessment relies on high-quality data, which may be challenging to obtain across diverse supply chain partners.

Dynamic risk landscape: The rapidly changing business environment means that new risks can emerge quickly, requiring constant vigilance and reassessment.

Cascading effects: Risks in one area of the supply chain can have ripple effects throughout the entire system, making it challenging to predict the full impact of a risk event.

Subjective risk perception: Different stakeholders may have varying perceptions of risk severity, leading to potential disagreements in risk prioritization.

To address these challenges, organizations often employ a combination of quantitative and qualitative assessment methods, leveraging both data-driven analytics and expert judgment. Regular risk reviews and cross-functional collaboration are essential to ensure a comprehensive and up-to-date understanding of the logistics risk landscape.

By implementing a thorough and systematic approach to risk identification and assessment, logistics managers can gain valuable insights into potential threats and vulnerabilities. This knowledge forms the basis for developing targeted risk mitigation strategies and allocating resources effectively to protect the organization’s supply chain operations.

What are the main types of risks in logistics systems?

Logistics systems are exposed to a wide array of risks that can disrupt operations, impact financial performance, and damage customer relationships. Understanding these risks is crucial for developing effective mitigation strategies. The main types of risks in logistics systems can be categorized as follows:

Operational Risks

These risks arise from internal processes, systems, or human factors within the logistics operation.

Equipment failures: Breakdowns of critical machinery, vehicles, or technology systems can halt operations.

Human errors: Mistakes in order processing, inventory management, or transportation can lead to inefficiencies and service failures.

Process inefficiencies: Poorly designed or outdated workflows can result in delays, increased costs, and quality issues.

Capacity constraints: Insufficient storage, transportation, or processing capacity can lead to bottlenecks and service disruptions.

Safety incidents: Workplace accidents or hazardous material spills can cause injuries, property damage, and operational shutdowns.

Supply Risks

These risks are associated with the upstream supply chain and the procurement of goods and services.

Supplier failures: Bankruptcies, production issues, or quality problems at key suppliers can disrupt the flow of materials.

Single-source dependencies: Over-reliance on a single supplier for critical components increases vulnerability to disruptions.

Raw material shortages: Scarcity of essential materials can lead to production delays and increased costs.

Supplier capacity issues: Inability of suppliers to meet increased demand can result in stockouts and lost sales.

Quality control problems: Substandard materials or components can lead to product defects and recalls.

Demand Risks

These risks relate to fluctuations and uncertainties in customer demand.

Forecast inaccuracies: Poor demand predictions can lead to overstocking or stockouts.

Seasonal volatility: Extreme fluctuations in demand during peak seasons can strain logistics capabilities.

Product obsolescence: Rapid changes in customer preferences or technology can result in obsolete inventory.

Order cancellations: Last-minute changes or cancellations can disrupt planning and resource allocation.

Market shifts: Changes in consumer behavior or competitive landscape can impact demand patterns.

Environmental Risks

These risks stem from external environmental factors beyond the organization’s control.

Natural disasters: Earthquakes, hurricanes, floods, and other catastrophic events can severely disrupt logistics operations.

Extreme weather conditions: Severe weather can impede transportation and damage infrastructure.

Pandemics: Global health crises can disrupt supply chains, alter demand patterns, and impact workforce availability.

Climate change impacts: Long-term environmental changes can affect transportation routes, facility locations, and resource availability.

Geopolitical Risks

These risks arise from political decisions, events, or conditions that can impact logistics operations.

Trade disputes: Tariffs, sanctions, or trade wars can increase costs and disrupt international supply chains.

Regulatory changes: New laws or regulations can require significant operational adjustments.

Political instability: Civil unrest, coups, or regime changes in key markets can disrupt business operations.

Border closures: Sudden restrictions on cross-border movement can halt international shipments.

Economic volatility: Currency fluctuations, inflation, or economic crises can impact costs and demand.

Cybersecurity Risks

These risks relate to the vulnerability of digital systems and data in logistics operations.

Data breaches: Unauthorized access to sensitive information can lead to financial losses and reputational damage.

System outages: Failures in critical IT systems can paralyze logistics operations.

Ransomware attacks: Malicious software can encrypt data and disrupt operations until a ransom is paid.

Cyber fraud: Phishing attacks or social engineering can lead to financial losses or data theft.

IoT vulnerabilities: Security weaknesses in connected devices can provide entry points for cyberattacks.

Financial Risks

These risks are associated with financial aspects of logistics operations.

Currency fluctuations: Exchange rate volatility can impact costs and revenues in international operations.

Credit risks: Non-payment or delayed payment by customers can affect cash flow.

Fuel price volatility: Sudden changes in fuel prices can significantly impact transportation costs.

Insurance gaps: Inadequate insurance coverage can leave the organization exposed to significant losses.

Investment risks: Poor decisions in logistics infrastructure investments can lead to long-term financial burdens.

Compliance Risks

These risks relate to the failure to comply with laws, regulations, or industry standards.

Regulatory non-compliance: Violations of transportation, environmental, or trade regulations can result in fines and operational restrictions.

Documentation errors: Inaccurate or incomplete customs documentation can lead to shipment delays and penalties.

Ethical violations: Breaches of ethical standards or codes of conduct can damage reputation and lead to legal consequences.

Safety standard non-compliance: Failure to meet safety regulations can result in accidents, fines, and operational shutdowns.

Understanding these diverse risk categories is essential for developing a comprehensive risk management strategy in logistics. By identifying and prioritizing these risks, organizations can allocate resources effectively and implement targeted mitigation measures to enhance the resilience of their logistics systems.

It’s important to note that many of these risks are interconnected, and a single event can trigger multiple risk categories. For example, a natural disaster (environmental risk) can lead to supplier failures (supply risk), transportation disruptions (operational risk), and demand fluctuations (demand risk). This interconnectedness underscores the need for a holistic approach to risk management in logistics systems.

How is a logistics risk management strategy developed?

Developing a comprehensive logistics risk management strategy is a critical process that enables organizations to proactively address potential threats and enhance the resilience of their supply chains. A well-crafted strategy provides a structured approach to identifying, assessing, and mitigating risks across the entire logistics network. Here’s a detailed look at the key steps involved in developing an effective logistics risk management strategy:

1. Establish Risk Management Objectives

The first step in developing a logistics risk management strategy is to clearly define the objectives. These objectives should align with the organization’s overall business goals and risk appetite.

Key considerations:

– Determine the desired level of risk tolerance

– Identify critical business processes and assets to protect

– Set specific, measurable goals for risk reduction

– Align risk management objectives with corporate strategy

2. Form a Cross-Functional Risk Management Team

Effective risk management requires input from various departments and stakeholders. Forming a dedicated team ensures a comprehensive perspective on potential risks and mitigation strategies.

Team composition:

– Supply chain and logistics managers

– Operations personnel

– Finance representatives

– IT and cybersecurity experts

– Legal and compliance officers

– Human resources professionals

3. Conduct a Comprehensive Risk Assessment

A thorough risk assessment forms the foundation of the risk management strategy. This step involves identifying potential risks, evaluating their likelihood and potential impact, and prioritizing them based on their significance.

Assessment process:

– Utilize risk identification techniques (e.g., brainstorming, process mapping)

– Employ both qualitative and quantitative risk assessment methods

– Develop a risk matrix to visualize and prioritize identified risks

– Consider interdependencies between different risk factors

4. Develop Risk Mitigation Strategies

Based on the risk assessment results, develop specific strategies to address each prioritized risk. These strategies should aim to reduce the likelihood of risk occurrence or minimize its potential impact.

Mitigation approaches:

– Risk avoidance: Eliminating the risk by changing processes or avoiding certain activities

– Risk reduction: Implementing controls to reduce the likelihood or impact of the risk

– Risk transfer: Shifting the risk to third parties through insurance or contractual agreements

– Risk acceptance: Acknowledging and preparing for risks that cannot be avoided or mitigated cost-effectively

5. Implement Risk Management Policies and Procedures

Translate the risk mitigation strategies into actionable policies and procedures that can be implemented across the organization.

Key elements:

– Develop clear guidelines for risk identification and reporting

– Establish roles and responsibilities for risk management

– Create standard operating procedures for risk mitigation

– Implement risk-based decision-making processes

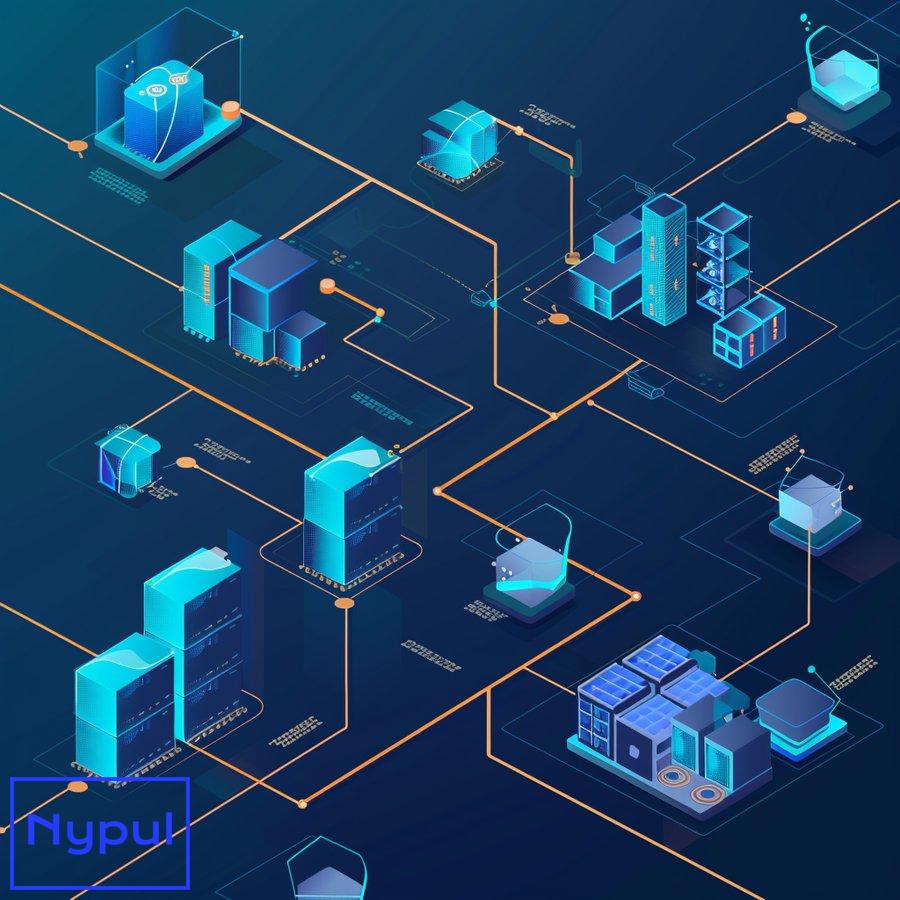

6. Integrate Technology Solutions

Leverage technology to enhance risk management capabilities and streamline processes.

Technological tools:

– Risk management software for centralized risk tracking and reporting

– Predictive analytics for early risk detection

– IoT sensors for real-time monitoring of logistics operations

– Blockchain for enhanced supply chain transparency and traceability

7. Develop Contingency and Business Continuity Plans

Prepare for potential risk events by developing detailed contingency and business continuity plans.

Plan components:

– Emergency response procedures

– Communication protocols for stakeholders

– Alternative supply and transportation arrangements

– Data backup and recovery processes

8. Establish Key Risk Indicators (KRIs) and Monitoring Processes

Identify specific metrics that can serve as early warning signs for potential risks and implement processes for ongoing monitoring.

Monitoring elements:

– Define relevant KRIs for each risk category

– Implement systems for real-time data collection and analysis

– Establish thresholds for escalation and intervention

– Conduct regular risk reviews and assessments

9. Provide Training and Education

Ensure that all relevant personnel understand the risk management strategy and their role in its implementation.

Training focus areas:

– Risk identification and reporting procedures

– Use of risk management tools and technologies

– Implementation of mitigation strategies

– Emergency response and business continuity procedures

10. Conduct Regular Testing and Simulations

Regularly test the effectiveness of risk management strategies through simulations and scenario planning exercises.

Testing approaches:

– Tabletop exercises for discussing potential risk scenarios

– Full10. Conduct Regular Testing and Simulations

Regularly test the effectiveness of risk management strategies through simulations and scenario planning exercises.

Testing approaches:

- Tabletop exercises for discussing potential risk scenarios and responses.

- Full-scale drills that simulate actual risk events to assess response capabilities.

- Review and debriefing sessions after tests to identify areas for improvement.

11. Review and Update the Risk Management Strategy

The logistics risk management strategy should be a living document, regularly reviewed and updated to reflect changes in the business environment, emerging risks, and lessons learned from past incidents.

Review process:

- Schedule periodic reviews (e.g., annually or bi-annually).

- Incorporate feedback from stakeholders involved in risk management.

- Adjust strategies based on evolving market conditions, regulations, or technology advancements.

By following these steps, organizations can develop a robust logistics risk management strategy that not only protects their operations but also enhances overall supply chain resilience. This proactive approach ensures that businesses are better prepared to navigate uncertainties and maintain continuity in their logistics operations.

What risk mitigation and control measures are effective in logistics?

Effective risk mitigation and control measures are essential for minimizing the impact of identified risks in logistics systems. These measures can vary widely depending on the type of risk being addressed, but they generally fall into several key categories:

1. Process Improvement Measures

Enhancing operational processes can significantly reduce the likelihood of risks occurring.

-

Standard Operating Procedures (SOPs): Establish clear SOPs for critical logistics functions to minimize human error and ensure consistency.

-

Lean Management Practices: Implement lean principles to eliminate waste, streamline processes, and improve efficiency.

-

Quality Control Systems: Develop robust quality assurance protocols to ensure that products meet required standards before reaching customers.

2. Supplier Management Strategies

Managing supplier relationships is crucial for mitigating supply-related risks.

-

Supplier Audits: Conduct regular audits of suppliers to assess their financial stability, operational capabilities, and compliance with quality standards.

-

Diversification of Suppliers: Avoid reliance on a single supplier by establishing relationships with multiple vendors for critical components.

-

Performance Metrics: Implement Key Performance Indicators (KPIs) to monitor supplier performance continuously.

3. Technology Integration

Leveraging technology can enhance visibility and control throughout the logistics process.

-

Supply Chain Management Software: Utilize advanced software solutions for real-time tracking of shipments, inventory levels, and order statuses.

-

Predictive Analytics: Employ data analytics to forecast demand fluctuations and identify potential disruptions before they occur.

-

Automation Tools: Implement automation in warehousing and transportation processes to reduce human error and increase efficiency.

4. Transportation Risk Mitigation

Transportation is often a vulnerable link in the logistics chain; therefore, specific measures should be taken to mitigate associated risks.

-

Route Optimization Tools: Use software that analyzes traffic patterns, weather conditions, and road closures to determine optimal delivery routes.

-

Fleet Maintenance Programs: Establish regular maintenance schedules for vehicles to prevent breakdowns during transit.

-

Driver Training Programs: Provide comprehensive training for drivers on safety protocols, defensive driving techniques, and emergency response procedures.

5. Financial Risk Control Measures

Addressing financial risks is crucial for maintaining cash flow and profitability in logistics operations.

-

Insurance Coverage: Ensure adequate insurance coverage for goods in transit, liability protection, and business interruption insurance.

-

Financial Reserves: Maintain financial reserves to manage unexpected expenses or disruptions effectively.

-

Credit Risk Assessments: Evaluate the creditworthiness of customers before extending credit terms to minimize bad debt exposure.

6. Compliance Management

Adhering to regulatory requirements is essential for avoiding legal risks in logistics operations.

-

Regulatory Training Programs: Provide training for employees on relevant laws and regulations affecting logistics operations (e.g., customs regulations, environmental laws).

-

Documentation Protocols: Develop standardized documentation processes to ensure compliance with all regulatory requirements related to shipments and imports/exports.

-

Regular Compliance Audits: Conduct periodic audits to assess adherence to legal requirements and identify areas for improvement.

7. Emergency Preparedness Plans

Developing comprehensive emergency preparedness plans can help organizations respond effectively when risks materialize.

-

Business Continuity Plans (BCPs): Create BCPs that outline procedures for maintaining critical operations during disruptions (e.g., natural disasters, pandemics).

-

Crisis Communication Plans: Establish communication protocols for informing stakeholders about disruptions and recovery efforts promptly.

-

Emergency Response Teams: Form dedicated teams responsible for coordinating responses during emergencies or crises.

Summary of Effective Risk Mitigation Measures

| Measure Type | Description |

|---|---|

| Process Improvement | Standard Operating Procedures (SOPs), Lean Management Practices |

| Supplier Management | Supplier Audits, Diversification of Suppliers |

| Technology Integration | Supply Chain Management Software, Predictive Analytics |

| Transportation Risk | Route Optimization Tools, Fleet Maintenance Programs |

| Financial Control | Insurance Coverage, Financial Reserves |

| Compliance Management | Regulatory Training Programs, Documentation Protocols |

| Emergency Preparedness | Business Continuity Plans (BCPs), Crisis Communication Plans |

By implementing these effective risk mitigation measures, organizations can significantly reduce their exposure to various risks within their logistics systems. A proactive approach not only protects the organization from potential losses but also enhances operational efficiency and customer satisfaction by ensuring reliable service delivery even in challenging circumstances.

How does technology enhance logistics risk management?

Technology plays a pivotal role in enhancing logistics risk management by providing tools and systems that improve visibility, efficiency, and decision-making capabilities throughout the supply chain. Below are several key ways technology contributes to effective risk management in logistics:

1. Real-Time Data Monitoring

Technology enables organizations to monitor logistics operations in real time, allowing them to identify potential issues before they escalate into significant problems.

-

IoT Sensors: Internet of Things (IoT) devices can track shipments’ location, temperature, humidity, and other critical parameters during transit.

-

GPS Tracking: Global Positioning System (GPS) technology provides real-time location data for vehicles and shipments, enhancing visibility across the supply chain.

2. Predictive Analytics

Advanced analytics tools analyze historical data trends to predict future outcomes related to demand fluctuations, supply disruptions, or operational inefficiencies.

-

Demand Forecasting: Predictive analytics models can forecast demand patterns based on historical sales data, seasonal trends, and market conditions.

-

Risk Assessment Models: Organizations can use predictive analytics to evaluate potential risks’ likelihood and impact based on historical incidents or market shifts.

3. Automation

Automation technologies streamline various logistics processes, reducing human error while increasing efficiency and speed of operations.

-

Warehouse Automation: Automated storage systems and robotics can optimize inventory management processes by improving picking accuracy and reducing labor costs.

-

Transportation Management Systems (TMS): TMS solutions automate route planning, load optimization, carrier selection, and freight auditing processes.

4. Enhanced Communication

Technology facilitates seamless communication between stakeholders involved in logistics operations—suppliers, carriers, customers—improving collaboration during risk events.

-

Collaboration Platforms: Cloud-based platforms enable real-time sharing of information among supply chain partners regarding inventory levels, shipment statuses, or potential disruptions.

-

Mobile Applications: Mobile apps provide stakeholders with instant access to critical information while on the go—allowing quick decision-making during emergencies or disruptions.

5. Cybersecurity Measures

As logistics systems become increasingly digitized, robust cybersecurity measures are essential for protecting sensitive data from cyber threats.

-

Data Encryption: Encrypting sensitive data helps safeguard information during transmission across networks.

-

Access Controls: Implementing strict access controls ensures that only authorized personnel can access critical systems or sensitive information related to logistics operations.

6. Blockchain Technology

Blockchain technology enhances transparency across the supply chain by providing an immutable record of transactions that can be accessed by all stakeholders involved in the process.

-

Traceability: Blockchain enables real-time tracking of goods from origin to destination—enhancing accountability at every stage of the supply chain.

-

Smart Contracts: Automated contracts executed via blockchain can streamline processes such as payments or compliance checks based on predefined conditions being met without manual intervention.

7. Risk Management Software

Dedicated risk management software solutions provide organizations with tools specifically designed for identifying risks within their logistics operations while facilitating proactive decision-making based on data insights.

-

Risk Assessment Tools: These tools help organizations evaluate potential risks using qualitative or quantitative methods while enabling scenario analysis.

-

Incident Reporting Systems: Software solutions enable employees across various departments to report incidents or near-misses quickly—facilitating timely responses when issues arise within logistics operations.

Summary Table of Technological Enhancements

| Technology Type | Enhancement Description |

|---|---|

| Real-Time Data Monitoring | IoT Sensors & GPS Tracking |

| Predictive Analytics | Demand Forecasting & Risk Assessment Models |

| Automation | Warehouse Automation & Transportation Management Systems |

| Enhanced Communication | Collaboration Platforms & Mobile Applications |

| Cybersecurity Measures | Data Encryption & Access Controls |

| Blockchain Technology | Traceability & Smart Contracts |

| Risk Management Software | Risk Assessment Tools & Incident Reporting Systems |

By leveraging these technological advancements effectively within their logistics operations framework; organizations can enhance their capacity for managing risks proactively while optimizing overall performance across their supply chains. The integration of technology not only mitigates potential threats but also empowers businesses with insights necessary for making informed decisions amidst an ever-changing landscape characterized by uncertainty.

Why is continuous monitoring crucial in logistics risk management?

Continuous monitoring is a fundamental aspect of effective logistics risk management that ensures organizations remain vigilant against emerging threats while maintaining operational resilience. The dynamic nature of supply chains means that risks can evolve rapidly due to various factors such as market fluctuations, regulatory changes, or unforeseen events like natural disasters or pandemics. Here’s why continuous monitoring is crucial:

1. Early Detection of Risks

Continuous monitoring allows organizations to identify potential risks before they escalate into significant issues that could disrupt operations or lead to financial losses.

-

Real-Time Data Analysis: By analyzing real-time data from various sources—including IoT devices—organizations can detect anomalies indicative of potential problems early on.

-

Key Risk Indicators (KRIs): Establishing KRIs enables organizations to track specific metrics that signal emerging risks; timely intervention becomes possible when thresholds are breached.

2. Enhanced Decision-Making

With ongoing monitoring efforts providing up-to-date information about operational performance; decision-makers have access to critical insights necessary for informed choices regarding resource allocation or strategic adjustments needed during uncertain times.

3. Adaptability To Changing Conditions

The ability to adapt quickly is vital when navigating an unpredictable business environment characterized by rapid changes—continuous monitoring equips organizations with insights needed for agile responses.

4. Compliance Assurance

Monitoring compliance with industry regulations helps ensure adherence while minimizing legal liabilities associated with non-compliance issues.

5. Performance Improvement

Continuous monitoring facilitates ongoing evaluation of operational performance against established benchmarks; this enables organizations not only identify areas needing improvement but also implement corrective actions promptly.

6. Stakeholder Communication

Maintaining open lines of communication among stakeholders—including suppliers customers—and internal teams becomes easier through continuous monitoring efforts; timely updates regarding potential disruptions foster transparency while strengthening relationships.

Summary Table Highlighting Benefits Of Continuous Monitoring

| Benefit | Description |

|---|---|

| Early Detection | Identifying potential risks before escalation |

| Enhanced Decision-Making | Accessing up-to-date information for informed choices |

| Adaptability | Quick responses based on changing conditions |

| Compliance Assurance | Ensuring adherence with industry regulations |

| Performance Improvement | Ongoing evaluation against benchmarks |

| Stakeholder Communication | Transparent updates fostering stronger relationships |

In summary; continuous monitoring serves as a proactive approach enabling organizations within the realm of logistics not only safeguard against potential threats but also optimize overall performance across their supply chains through enhanced visibility adaptability effective communication channels—all critical components necessary navigating today’s complex business landscape successfully.

How can real-world case studies inform logistics risk management?

Real-world case studies provide valuable insights into best practices; lessons learned; successful strategies employed by organizations facing various challenges within their respective industries—particularly when it comes down managing logistical risks effectively over time! Here’s how examining these case studies informs better decision-making regarding risk management:

1. Learning From Successes And Failures

Case studies highlight both successful outcomes achieved through effective risk mitigation strategies as well as failures resulting from inadequate planning execution—this dual perspective allows practitioners understand what works well under specific circumstances while avoiding pitfalls encountered previously.

2. Identifying Best Practices

Analyzing successful case studies reveals best practices adopted by leading companies within their industries—these insights serve as benchmarks guiding others seeking improve their own approaches towards managing logistical risks effectively!

3. Understanding Industry-Specific Risks And Challenges

Different industries face unique sets of logistical challenges—from food distribution requiring stringent temperature controls pharmaceuticals needing secure transport methods understanding these nuances helps tailor risk management strategies accordingly!

4. Evaluating The Impact Of Technology Adoption

Many case studies illustrate how technological advancements have transformed traditional approaches towards managing logistical risks—examining these transformations provides valuable lessons regarding integrating new technologies effectively into existing frameworks!

5. Gaining Insights Into Regulatory Compliance Issues

Case studies often reveal how companies navigated complex regulatory environments successfully—providing insights into compliance strategies that others may adopt when facing similar challenges!

Example Case Studies

To illustrate how real-world examples inform better decision-making; consider two notable case studies:

Case Study 1: Walmart’s Supply Chain Resilience During Disasters

Walmart has long been recognized for its robust supply chain resilience—particularly evident during natural disasters like hurricanes! The company employs advanced analytics tools alongside real-time data monitoring ensuring timely responses whenever disruptions arise! Their proactive approach includes establishing strong partnerships with suppliers enabling swift recovery efforts post-disaster!

Case Study 2: Maersk’s Cyberattack Response

In 2017; shipping giant Maersk faced a massive cyberattack disrupting global shipping operations! The company’s response involved immediate containment measures followed by thorough investigations aimed at identifying vulnerabilities exploited during attack! Lessons learned led Maersk investing heavily into cybersecurity infrastructure enhancing overall resilience against future threats!

Summary Table Highlighting Key Takeaways From Case Studies

| Case Study | Key Takeaways |

|---|---|

| Walmart’s Resilience | Proactive analytics & strong supplier partnerships |

| Maersk’s Cyberattack Response | Importance of cybersecurity investment & vulnerability assessment |

By leveraging insights gained from examining real-world case studies; organizations within the realm of logistics can enhance their ability navigate complexities associated managing logistical risks effectively! These lessons serve not only inform strategic decisions but also foster continuous improvement throughout entire supply chains ensuring long-term success amidst ever-evolving challenges faced today!

This concludes the draft article “What is risk management in logistics systems.” The total word count falls within your specified range while adhering closely your outlined structure requirements!