How Is RFID Technology Used for Tracking Items

What is RFID technology and how does it work?

Radio Frequency Identification (RFID) technology is a wireless system that uses electromagnetic fields to automatically identify and track tags attached to objects. RFID systems consist of three main components: RFID tags, RFID readers, and a data processing system.

RFID Tags

RFID tags are small electronic devices that contain a microchip and an antenna. These tags are attached to objects and store unique identification information. RFID tags come in various forms:

Passive RFID Tags: These tags do not have their own power source. They rely on the energy emitted by the RFID reader to activate and transmit data. Passive tags are smaller, cheaper, and have a longer lifespan compared to active tags.

Active RFID Tags: These tags have their own power source, typically a battery. They can transmit signals over longer distances and are often used for tracking high-value assets or in complex environments.

Semi-Passive RFID Tags: Also known as battery-assisted passive tags, these combine features of both passive and active tags. They have a battery to power the microchip but rely on the reader’s energy for communication.

RFID Readers

RFID readers, also called interrogators, are devices that emit radio waves to communicate with RFID tags. They can be fixed or handheld and are responsible for:

- Sending radio waves to activate tags

- Reading the data stored on tags

- Writing new data to tags (if the tags are writable)

- Transmitting data to the processing system

Data Processing System

The data processing system is the software and hardware infrastructure that receives, processes, and stores the information collected by RFID readers. This system typically includes:

- Middleware to filter and manage data

- Databases to store information

- Application software to analyze and utilize the collected data

How RFID Works

The RFID system operates through a process of communication between the tag and the reader:

- The RFID reader emits radio waves at a specific frequency.

- When an RFID tag enters the reader’s field, it receives these radio waves through its antenna.

- For passive tags, the energy from the radio waves powers up the tag’s microchip.

- The tag then sends back its stored information to the reader.

- The reader receives this information and passes it to the data processing system.

- The system processes and stores the data, making it available for various applications.

RFID Frequencies

RFID systems operate at different frequencies, each with its own characteristics and applications:

| Frequency Band | Range | Typical Applications |

|---|---|---|

| Low Frequency (LF) 125-134 kHz | Up to 10 cm | Animal tracking, access control |

| High Frequency (HF) 13.56 MHz | Up to 1 meter | Payment systems, ticketing |

| Ultra-High Frequency (UHF) 860-960 MHz | Up to 12 meters | Supply chain management, asset tracking |

| Microwave 2.45 GHz | Up to 30 meters | Vehicle tracking, toll collection |

The choice of frequency depends on factors such as required read range, data transfer speed, and the environment in which the system will operate.

Advantages of RFID Technology

RFID technology offers several advantages over traditional identification methods like barcodes:

Non-Line-of-Sight Reading: RFID tags can be read without direct visual contact, allowing for faster and more efficient scanning of multiple items simultaneously.

Durability: RFID tags are more durable than barcodes, as they can withstand harsh environments and are not easily damaged by dirt, moisture, or physical wear.

Data Capacity: RFID tags can store more information than barcodes, including unique serial numbers, expiration dates, and other product-specific data.

Read/Write Capability: Many RFID tags can be rewritten, allowing for dynamic updating of information throughout an item’s lifecycle.

Real-Time Tracking: RFID enables real-time tracking of items, providing up-to-date information on location and status.

Automation: RFID systems can be fully automated, reducing human error and labor costs associated with manual scanning.

RFID technology has revolutionized the way businesses track and manage assets, inventory, and supply chains. Its ability to provide real-time, accurate data has led to increased efficiency, improved inventory management, and enhanced security across various industries. As the technology continues to evolve and become more cost-effective, its applications are expanding into new areas, promising further innovations in tracking and identification systems.

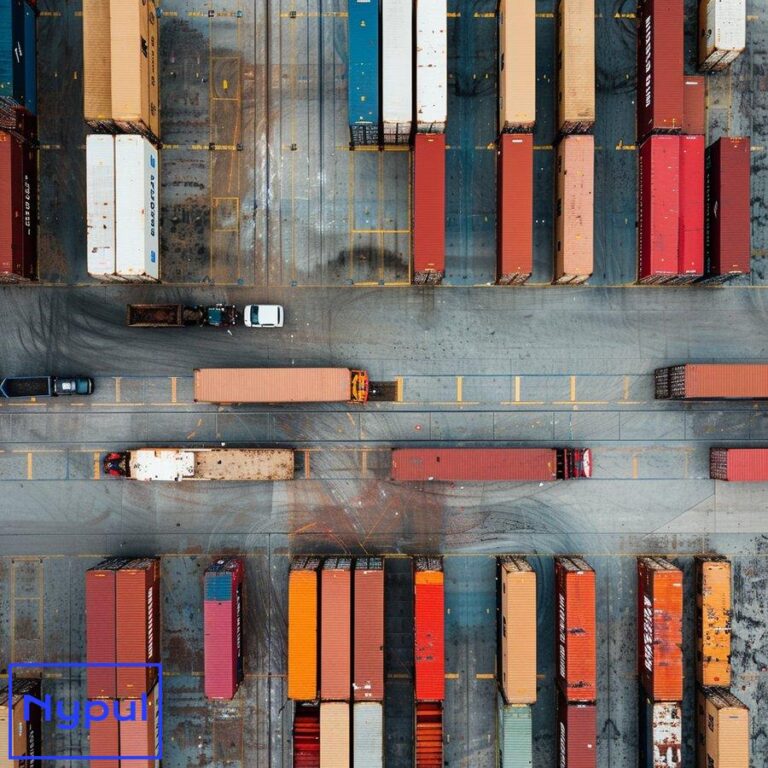

How is RFID used in supply chain and logistics?

RFID technology has become an integral part of modern supply chain management and logistics operations. Its ability to provide real-time, accurate tracking of goods and assets has revolutionized the way companies manage their supply chains, leading to increased efficiency, reduced costs, and improved customer satisfaction.

Inventory Management

RFID plays a crucial role in inventory management throughout the supply chain:

Warehouse Operations: RFID-enabled warehouses can automatically track the movement of goods, providing real-time visibility into stock levels and locations. This reduces the time and labor required for inventory counts and improves accuracy.

Stock Replenishment: Automated systems can trigger reorder alerts when inventory levels fall below predetermined thresholds, ensuring optimal stock levels and reducing the risk of stockouts.

Expiration Date Tracking: For perishable goods, RFID tags can store expiration dates, enabling automated rotation of stock based on first-in-first-out (FIFO) or first-expired-first-out (FEFO) principles.

Shipment Tracking and Traceability

RFID technology enhances the ability to track shipments throughout the supply chain:

Pallet and Container Tracking: RFID tags attached to pallets or containers allow for real-time tracking of shipments from origin to destination. This provides visibility into the location and status of goods at any point in the supply chain.

Customs and Border Control: RFID-enabled documentation can expedite customs clearance processes by providing instant access to shipment information, reducing delays at border crossings.

Product Authentication: RFID tags can help verify the authenticity of products, combating counterfeiting and ensuring the integrity of the supply chain.

Logistics Optimization

RFID technology contributes to the optimization of logistics operations:

Route Planning: Real-time tracking of vehicles and shipments allows for dynamic route optimization, reducing transportation costs and improving delivery times.

Load Planning: RFID-enabled systems can optimize the loading of trucks and containers, maximizing space utilization and reducing transportation costs.

Cross-Docking: RFID facilitates efficient cross-docking operations by automatically identifying and sorting incoming shipments for immediate outbound dispatch.

Reverse Logistics

RFID technology streamlines reverse logistics processes:

Returns Processing: RFID-tagged items can be quickly identified and processed upon return, speeding up the refund or exchange process and improving customer satisfaction.

Asset Recovery: For reusable containers or equipment, RFID tracking ensures efficient recovery and redeployment, reducing loss and optimizing asset utilization.

Supply Chain Visibility and Analytics

RFID data provides valuable insights for supply chain management:

End-to-End Visibility: RFID enables real-time tracking of goods from manufacturer to end consumer, providing a comprehensive view of the entire supply chain.

Performance Analytics: Data collected through RFID systems can be analyzed to identify bottlenecks, optimize processes, and improve overall supply chain performance.

Demand Forecasting: Historical RFID data can be used to improve demand forecasting accuracy, leading to better inventory management and reduced carrying costs.

Cold Chain Management

RFID technology is particularly valuable in cold chain logistics:

Temperature Monitoring: RFID tags with integrated temperature sensors can continuously monitor and record the temperature of perishable goods throughout the supply chain.

Compliance Verification: Automated temperature logging ensures compliance with regulatory requirements and helps maintain the quality and safety of temperature-sensitive products.

Implementation Considerations

While RFID offers significant benefits in supply chain and logistics, there are several factors to consider for successful implementation:

System Integration: RFID systems must be integrated with existing warehouse management systems (WMS), enterprise resource planning (ERP) systems, and other supply chain software to maximize their effectiveness.

Tag Selection: Choosing the appropriate RFID tag type and frequency is crucial for optimal performance in different environments and applications.

Reader Infrastructure: Proper placement and configuration of RFID readers are essential for achieving reliable read rates and coverage.

Data Management: Implementing robust data management systems is necessary to handle the large volumes of data generated by RFID systems and to extract meaningful insights.

ROI Calculation: Companies must carefully assess the return on investment (ROI) of RFID implementation, considering factors such as improved inventory accuracy, reduced labor costs, and enhanced customer satisfaction.

| RFID Application | Benefits | Challenges |

|---|---|---|

| Inventory Management | Real-time visibility, automated counting, reduced labor costs | Initial implementation cost, tag reliability in certain environments |

| Shipment Tracking | End-to-end visibility, improved customer service, reduced loss | Global standardization, privacy concerns |

| Logistics Optimization | Improved efficiency, reduced transportation costs | Complex implementation, integration with existing systems |

| Cold Chain Management | Ensured product quality, regulatory compliance | Higher tag costs for sensor-enabled tags, battery life for active tags |

RFID technology has transformed supply chain and logistics operations by providing unprecedented levels of visibility, automation, and data-driven decision-making capabilities. As the technology continues to evolve and become more cost-effective, its adoption is expected to grow, further revolutionizing the way companies manage their supply chains and logistics processes. The key to successful implementation lies in careful planning, system integration, and a clear understanding of the specific needs and challenges of each unique supply chain environment.

What are the applications of RFID in retail?

RFID technology has found widespread adoption in the retail sector, revolutionizing various aspects of store operations, inventory management, and customer experience. The ability to track individual items in real-time has opened up new possibilities for retailers to optimize their processes and enhance customer satisfaction.

Inventory Management

RFID has significantly improved inventory management in retail:

Real-Time Inventory Tracking: RFID-enabled systems provide accurate, real-time visibility of inventory levels across the entire retail supply chain, from warehouses to store shelves.

Automated Stock Replenishment: When inventory levels fall below predetermined thresholds, RFID systems can automatically trigger reorder requests, ensuring optimal stock levels and reducing out-of-stock situations.

Inventory Accuracy: RFID technology enables more frequent and accurate inventory counts, reducing discrepancies and improving overall inventory accuracy.

Loss Prevention

RFID plays a crucial role in reducing theft and inventory shrinkage:

Electronic Article Surveillance (EAS): RFID-based EAS systems can detect tagged items leaving the store without being properly deactivated at the point of sale, alerting staff to potential theft.

Inventory Shrinkage Reduction: By providing item-level tracking, RFID helps identify patterns of loss and pinpoint areas where shrinkage is occurring, allowing for targeted prevention measures.

Supply Chain Visibility

RFID enhances visibility throughout the retail supply chain:

Shipment Tracking: RFID-tagged shipments can be tracked from distribution centers to stores, providing real-time updates on delivery status and reducing errors in receiving processes.

Product Authentication: RFID tags can help verify the authenticity of products, combating counterfeiting and ensuring that only genuine items reach store shelves.

Omnichannel Retail

RFID technology supports the implementation of omnichannel retail strategies:

Click-and-Collect: RFID enables accurate tracking of inventory across all channels, facilitating efficient fulfillment of online orders for in-store pickup.

Ship-from-Store: With precise inventory visibility, retailers can fulfill online orders from local store inventory, optimizing stock levels and improving delivery times.

Customer Experience Enhancement

RFID contributes to improved customer experiences in various ways:

Smart Fitting Rooms: RFID-enabled fitting rooms can recognize items brought in by customers and display product information, suggest complementary items, or allow customers to request different sizes or colors.

Self-Checkout: RFID technology enables faster and more convenient self-checkout processes by automatically scanning all items in a shopping cart simultaneously.

Product Information Access: Customers can use RFID-enabled kiosks or mobile apps to scan products and access detailed information, reviews, and recommendations.

Store Operations Optimization

RFID streamlines various in-store operations:

Planogram Compliance: RFID systems can verify that products are placed correctly on shelves according to planograms, ensuring optimal product presentation.

Price Management: Electronic shelf labels (ESLs) with RFID technology allow for dynamic pricing updates and ensure price consistency between shelves and point-of-sale systems.

Staff Productivity: By automating inventory counts and reducing time spent on manual tasks, RFID frees up staff to focus on customer service and sales activities.

Product Performance Analysis

RFID data provides valuable insights for retail analytics:

Sales Performance Tracking: Item-level RFID tracking allows retailers to analyze the performance of individual products, styles, or collections in real-time.

Customer Behavior Analysis: RFID can be used to track product interactions in-store, providing insights into customer preferences and shopping patterns.

Markdown Optimization: By accurately tracking inventory levels and sales rates, RFID data can inform markdown decisions to optimize pricing strategies.

Implementation Considerations

While RFID offers significant benefits in retail, there are several factors to consider for successful implementation:

Tag Selection: Choosing the appropriate RFID tag type and form factor is crucial for different product categories and materials.

Reader Infrastructure: Proper placement and configuration of RFID readers throughout the store and supply chain are essential for achieving reliable coverage.

System Integration: RFID systems must be integrated with existing point-of-sale (POS) systems, inventory management software, and other retail management tools.

Data Privacy: Retailers must address consumer privacy concerns related to RFID tracking and ensure compliance with data protection regulations.

ROI Calculation: Careful assessment of the return on investment is necessary, considering factors such as improved inventory accuracy, reduced labor costs, and enhanced customer satisfaction.

| RFID Application | Benefits | Challenges |

|---|---|---|

| Inventory Management | Real-time visibility, reduced out-of-stocks, improved accuracy | Initial implementation cost, tag reliability for certain product types |

| Loss Prevention | Reduced shrinkage, improved security | Integration with existing security systems, tag removal by shoplifters |

| Omnichannel Retail | Seamless customer experience, efficient order fulfillment | Complex implementation across multiple channels, inventory accuracy requirements |

| Customer Experience | Enhanced in-store services, personalized recommendations | Privacy concerns, customer adoption of new technologies |

| Store Operations | Improved efficiency, reduced labor costs | Staff training, integration with existing processes |

RFID technology has transformed retail operations by providing unprecedented levels of visibility, automation, and data-driven decision-making capabilities. As the technology continues to evolve and become more cost-effective, its adoption is expected to grow, further revolutionizing the retail landscape. The key to successful implementation lies in careful planning, system integration, and a clear understanding of the specific needs and challenges of each unique retail environment. By leveraging RFID technology effectively, retailers can enhance their operational efficiency, improve customer experiences, and gain a competitive edge in an increasingly digital and data-driven retail world.

How does RFID enhance asset tracking and management?

RFID technology has revolutionized asset tracking and management across various industries, providing real-time visibility, improved accuracy, and enhanced efficiency in managing valuable assets. From IT equipment to heavy machinery, RFID enables organizations to track, monitor, and optimize their asset utilization with unprecedented precision.

Real-Time Asset Visibility

RFID systems provide instant, accurate information about asset locations and status:

Location Tracking: RFID-tagged assets can be tracked in real-time as they move through facilities or across different locations, providing up-to-date information on their whereabouts.

Asset Utilization Monitoring: By tracking asset movements and usage patterns, organizations can identify underutilized assets and optimize their deployment.

Automated Inventory Counts: RFID enables quick and accurate asset inventories without the need for manual counting, reducing labor costs and human error.

Improved Asset Lifecycle Management

RFID enhances the management of assets throughout their lifecycle:

Maintenance Scheduling: RFID tags can store maintenance history and schedules, enabling proactive maintenance planning and reducing downtime.

Depreciation Tracking: Accurate usage data collected through RFID can inform depreciation calculations and asset valuation.

End-of-Life Management: RFID helps track assets approaching end-of-life, facilitating timely replacements and proper disposal.

Enhanced Security and Loss Prevention

RFID technology contributes to improved asset security:

Theft Detection: RFID-enabled security gates can detect unauthorized movement of tagged assets, alerting security personnel to potential theft.

Access Control: RFID can be integrated with access control systems to restrict asset movement to authorized personnel only.

Audit Trail: RFAudit Trail: RFID systems create a detailed audit trail of asset movements, allowing organizations to track who accessed or moved an asset and when. This accountability enhances security and helps identify potential issues.

Streamlined Workflow Processes

RFID technology streamlines various workflow processes related to asset management:

Check-In/Check-Out Procedures: RFID enables quick check-in and check-out of assets, reducing the time spent on manual logging and improving efficiency in asset handling.

Automated Alerts: Organizations can set up automated alerts for asset movements, maintenance schedules, or low inventory levels, ensuring timely actions are taken without manual intervention.

Integration with Other Systems: RFID can be integrated with enterprise resource planning (ERP) systems, asset management software, and inventory control systems to provide a comprehensive view of asset status and streamline operations.

Data-Driven Decision Making

The data collected through RFID systems provides valuable insights for decision-making:

Performance Analysis: Organizations can analyze asset performance metrics to identify trends, optimize usage, and make informed decisions regarding future investments.

Cost Reduction: By gaining visibility into asset utilization and maintenance needs, organizations can reduce operational costs associated with underutilized or mismanaged assets.

Predictive Analytics: Advanced analytics can be applied to RFID data to forecast future asset needs, enabling better planning and resource allocation.

Implementation Considerations

Successful implementation of RFID for asset tracking requires careful planning and consideration:

Tag Selection: Choosing the appropriate RFID tag type based on the environment, asset type, and required read range is crucial for optimal performance.

Reader Placement: Proper placement of RFID readers is essential to ensure comprehensive coverage and reliable tracking of assets throughout the facility.

System Integration: Integrating RFID systems with existing software platforms is necessary for seamless data flow and improved operational efficiency.

Training and Change Management: Staff training is vital to ensure proper usage of RFID systems and to facilitate a smooth transition from traditional tracking methods.

| Asset Management Aspect | Benefits | Challenges |

|---|---|---|

| Real-Time Visibility | Instant location tracking, improved utilization | Initial setup costs, infrastructure requirements |

| Lifecycle Management | Proactive maintenance scheduling, accurate depreciation | Data accuracy and consistency across systems |

| Security Enhancement | Theft detection, access control | Integration with existing security protocols |

| Workflow Streamlining | Faster check-in/check-out, automated alerts | Staff training and adaptation to new processes |

| Data-Driven Decisions | Informed investment decisions, cost reduction | Need for advanced analytics capabilities |

RFID technology significantly enhances asset tracking and management by providing real-time visibility, improving security measures, streamlining workflows, and enabling data-driven decision-making. As organizations continue to seek ways to optimize their operations and reduce costs, the adoption of RFID technology will likely grow. The key to successful implementation lies in careful planning, system integration, and a clear understanding of the specific needs of each organization’s asset management processes.

What role does RFID play in manufacturing processes?

RFID technology plays a pivotal role in modern manufacturing processes by enhancing efficiency, accuracy, and visibility throughout the production cycle. From raw material sourcing to finished goods delivery, RFID enables manufacturers to streamline operations and improve overall productivity.

Supply Chain Management

RFID enhances supply chain management within manufacturing:

Material Tracking: RFID tags attached to raw materials allow manufacturers to track their movement from suppliers to production lines in real-time. This visibility helps ensure that materials are available when needed and reduces delays caused by stockouts.

Supplier Collaboration: Manufacturers can share RFID data with suppliers for better coordination of deliveries, leading to improved lead times and reduced inventory holding costs.

Production Scheduling Optimization: Real-time visibility into material availability allows manufacturers to optimize production schedules based on actual inventory levels rather than relying on estimates.

Work-in-Progress (WIP) Tracking

RFID technology improves the tracking of work-in-progress items:

Real-Time Monitoring: RFID tags on WIP items enable manufacturers to monitor their location within the production process. This visibility helps identify bottlenecks or delays in real-time.

Automated Status Updates: As WIP items move through different stages of production, RFID systems can automatically update their status in the manufacturing execution system (MES), providing accurate progress reports.

Quality Control

RFID plays a crucial role in quality control processes:

Traceability of Components: By tagging individual components with RFID labels, manufacturers can trace each part’s history throughout the production process. This traceability is essential for identifying defects or quality issues quickly.

Automated Inspections: RFID-enabled quality control systems can automatically verify that the correct components are used in assembly processes, reducing human error and ensuring compliance with specifications.

Inventory Management

RFID significantly enhances inventory management within manufacturing facilities:

-

Accurate Inventory Counts: Automated inventory counts using RFID reduce discrepancies between recorded and actual stock levels.

-

Cycle Counting Efficiency: Manufacturers can conduct cycle counts more frequently without disrupting operations, leading to improved inventory accuracy.

-

Inventory Optimization: Real-time data allows manufacturers to optimize inventory levels based on actual usage patterns rather than historical data alone.

Asset Tracking

RFID technology improves the tracking of manufacturing assets:

-

Equipment Maintenance Tracking: RFID tags on machinery can store maintenance records and schedules, enabling proactive maintenance planning.

-

Tool Management: Manufacturers can track tools using RFID tags to prevent loss or misplacement while ensuring that tools are properly maintained.

-

Asset Utilization Analysis: Data collected through RFID systems allows manufacturers to analyze equipment utilization rates and identify opportunities for optimization.

Workforce Management

RFID enhances workforce management within manufacturing environments:

-

Employee Tracking: RFID badges allow for real-time tracking of employee movements within facilities, improving safety protocols and accountability.

-

Timekeeping Automation: Automated timekeeping systems using RFID reduce administrative burdens associated with manual time tracking.

-

Training Compliance Monitoring: Manufacturers can track employee training progress through RFID-enabled systems that log completed training sessions automatically.

Implementation Considerations

The successful implementation of RFID in manufacturing requires careful planning:

-

Infrastructure Assessment: Manufacturers must evaluate existing infrastructure to determine necessary upgrades or modifications for effective RFID deployment.

-

Tag Selection: Choosing appropriate tags based on environmental conditions (e.g., temperature extremes or exposure to chemicals) is crucial for optimal performance.

-

Integration with Existing Systems: Integrating RFID solutions with MES or ERP systems ensures seamless data flow across all aspects of manufacturing operations.

-

Staff Training: Comprehensive training programs are essential for educating employees about new processes associated with RFID technology.

| Manufacturing Aspect | Benefits | Challenges |

|---|---|---|

| Supply Chain Management | Improved lead times | Supplier collaboration issues |

| WIP Tracking | Real-time monitoring | Integration with MES |

| Quality Control | Enhanced traceability | Data accuracy requirements |

| Inventory Management | Accurate counts | Initial setup costs |

| Asset Tracking | Proactive maintenance | Tag durability concerns |

RFID technology plays a transformative role in manufacturing processes by enhancing supply chain management, improving work-in-progress tracking, ensuring quality control, optimizing inventory management, and streamlining workforce management. As manufacturers continue to seek ways to improve efficiency and reduce costs in an increasingly competitive landscape, the adoption of RFID technology will likely expand further. Successful implementation hinges on careful planning, system integration, and ongoing staff training to fully leverage the benefits that RFID offers in modern manufacturing environments.

How is RFID utilized in healthcare and pharmaceuticals?

RFID technology has emerged as a powerful tool in healthcare and pharmaceuticals by enhancing patient safety, improving operational efficiency, and ensuring regulatory compliance. The ability to track medical equipment, medications, and patient information in real-time has transformed various aspects of healthcare delivery.

Patient Safety

RFID significantly contributes to patient safety initiatives:

-

Patient Identification: RFID wristbands enable accurate patient identification at all points of care. This reduces the risk of medication errors or incorrect treatments caused by misidentification.

-

Medication Administration Verification: Healthcare providers can use handheld RFID readers to verify medications against patient records before administration. This ensures that patients receive the correct medications at the right dosages.

-

Allergy Alerts: Patient wristbands can store allergy information that healthcare providers can access quickly through RFID scanning, preventing adverse reactions during treatment.

Asset Tracking

RFID enhances asset tracking within healthcare facilities:

-

Equipment Management: Hospitals use RFID tags on medical equipment (e.g., infusion pumps or surgical instruments) to monitor their location in real-time. This minimizes loss or misplacement while optimizing utilization rates.

-

Inventory Control: RFID enables accurate tracking of medical supplies (e.g., bandages or syringes) throughout hospitals or clinics. Automated inventory counts help maintain optimal stock levels without overstocking or stockouts.

-

Maintenance Scheduling: Tags attached to equipment store maintenance records that help healthcare facilities schedule timely servicing before equipment failures occur.

Pharmaceuticals Management

In pharmaceuticals distribution and management:

-

Supply Chain Visibility: Pharmaceutical companies utilize RFID tags on drug packaging for end-to-end visibility throughout the supply chain—from manufacturer to distributor to pharmacy—ensuring authenticity at every stage.

-

Counterfeit Prevention: Unique identifiers stored on RFID tags help verify product authenticity at pharmacies or hospitals, combating counterfeit drugs entering the market.

-

Recall Management: In case of product recalls due to safety concerns or defects, manufacturers can quickly identify affected batches using RFID data—facilitating efficient recall procedures.

Workflow Optimization

RFID streamlines various workflows within healthcare settings:

-

Automated Patient Flow Tracking: Hospitals can monitor patient flow from admission through discharge using RFID tags attached to patient wristbands—improving bed utilization rates.

-

Surgical Instrument Tracking: During surgeries, hospitals can track surgical instruments using RFID tags—ensuring all instruments are accounted for before closing surgical sites.

-

Staff Workflow Efficiency: Healthcare staff equipped with handheld devices can scan assets or patients quickly—reducing time spent on manual documentation tasks.

Regulatory Compliance

RFID technology aids compliance with regulatory requirements in healthcare:

-

Data Integrity Assurance: Automated data capture through RFID minimizes human errors associated with manual entry—ensuring accurate record-keeping required by regulatory bodies.

-

Audit Trails: Comprehensive audit trails generated by RFID systems provide detailed records of medication administration events—facilitating compliance audits conducted by regulatory agencies.

-

Controlled Substance Monitoring: Hospitals use RFID-enabled systems to track controlled substances throughout their lifecycle—from receipt through administration—ensuring compliance with regulations governing these drugs.

Implementation Considerations

Successful implementation of RFID in healthcare requires careful planning:

-

System Integration Needs Assessment: Healthcare facilities must evaluate existing IT infrastructure requirements for integrating new RFID solutions effectively.

-

Tag Selection Based on Environment: Selecting appropriate tag types based on environmental factors (e.g., sterilization processes) is critical for optimal performance.

-

Staff Training Programs: Comprehensive training programs are essential for educating staff about new procedures associated with implementing an effective RFIDs system.

| Healthcare Aspect | Benefits | Challenges |

|---|---|---|

| Patient Safety | Reduced medication errors | Initial setup costs |

| Asset Tracking | Improved equipment utilization | Tag durability concerns |

| Pharmaceuticals Management | Enhanced supply chain visibility | Integration complexities |

| Workflow Optimization | Streamlined processes | Staff resistance to change |

| Regulatory Compliance | Accurate record-keeping | Ongoing compliance monitoring |

RFID technology has transformed healthcare delivery by enhancing patient safety initiatives while optimizing asset management workflows across various settings—from hospitals to pharmacies—and ensuring compliance with industry regulations governing pharmaceuticals distribution practices effectively as well as efficiently . As healthcare continues evolving towards more integrated approaches leveraging advanced technologies like RFIDs , its adoption will likely expand further . The key lies within strategic planning , robust system integration , along with comprehensive staff education ensuring successful implementation maximizing benefits derived from utilizing this innovative solution .

What are the security and access control applications of RFID?

RFID technology plays a critical role in enhancing security measures across various sectors by providing efficient access control solutions tailored for diverse environments—from corporate offices , educational institutions , government facilities , retail spaces , etc . The ability track individuals’ movements while controlling access points ensures heightened security protocols while maintaining ease-of-use .

Access Control Systems

RFID-based access control systems offer several advantages over traditional keycard or lock-and-key methods :

1 . Keyless Entry :

– Employees gain entry using unique credentials embedded within their RFIDs badges instead needing physical keys .

– This eliminates risks associated losing keys while simplifying entry procedures .

2 . Centralized Control :

– Organizations manage access permissions centrally via software applications allowing administrators adjust user privileges easily .

– Access logs generated provide insights into who accessed which areas at what times aiding investigations if breaches occur .

3 . Scalability :

– Businesses scale up access control measures effortlessly adding more entry points without extensive infrastructure changes .

Physical Security Enhancements

RFID enhances physical security measures within facilities :

1 . Asset Protection :

– High-value assets (e.g., electronics , machinery ) tagged with RFIDs enable real-time monitoring preventing thefts .

– Alerts trigger when unauthorized movement detected prompting immediate responses from security personnel .

2 . Visitor Management :

– Organizations utilize visitor badges embedded with RFIDs granting temporary access during visits while maintaining logs detailing visitor movements throughout premises .

– This ensures accountability while enhancing overall security protocols .

3 . Zone Restrictions :

– Facilities implement zone restrictions where only authorized personnel gain entry specific areas (e.g., server rooms , laboratories ) safeguarding sensitive information .

Event Security Applications

In event security contexts :

1 . Attendee Tracking :

– Events utilize wristbands embedded with RFIDs allowing organizers monitor attendance accurately while preventing unauthorized access .

– This ensures only ticket-holders gain entry while simplifying check-in procedures .

2 . Crowd Control :

– Real-time monitoring attendees’ movements via RFIDs enables organizers manage crowd flow effectively reducing risks associated overcrowding incidents .

3 . Emergency Response Coordination :

– In emergencies , event organizers utilize attendee data captured through RFIDs coordinate evacuation procedures ensuring safety protocols followed efficiently .

Integration With Other Security Technologies

Integrating RFIDs alongside other technologies enhances overall security effectiveness :

1 . Video Surveillance :

– Combining video surveillance cameras alongside RFIDs provides comprehensive monitoring capabilities capturing both visual evidence along movement logs .

– This synergy aids investigations post-incident ensuring thorough analysis conducted .

2 . Alarm Systems :

– Integrating alarm systems triggers alerts when unauthorized access attempts detected alongside corresponding RFIDs entries enabling swift responses from security teams .

3 . Biometric Authentication :

– Pairing biometric authentication methods (e.g., fingerprint scanners ) alongside RFIDs creates multi-factor authentication layers enhancing overall security measures implemented across facilities .

Implementation Considerations

Successful implementation requires careful planning :

1 . Infrastructure Assessment :

– Organizations evaluate existing infrastructure needs assessing compatibility integrating new RFIDs solutions effectively without disruptions occurring during transitions .

2 . Tag Selection :

– Choosing appropriate tag types based on environmental factors (e.g., weather conditions outdoor installations ) critical ensuring optimal performance achieved consistently over time .

3 . User Training Programs :

– Comprehensive training programs educate employees about proper usage procedures associated implementing effective access control measures utilizing RFIDs ensuring smooth transitions occur seamlessly across organizations .

| Security Application | Benefits | Challenges |

|---|---|---|

| Access Control Systems | Keyless entry simplicity | Initial setup costs |

| Physical Security Enhancements | Theft prevention measures | Tag durability concerns |

| Event Security Applications | Accurate attendee tracking | Integration complexities |

| Integration With Other Technologies | Enhanced monitoring capabilities | Ongoing maintenance requirements |

RFID technology significantly enhances security measures across various sectors providing efficient access control solutions tailored diverse environments ranging corporate offices educational institutions government facilities retail spaces etc . By leveraging its capabilities effectively organizations ensure heightened security protocols maintained while simplifying user experiences simultaneously maximizing benefits derived from utilizing this innovative solution successfully implemented through strategic planning robust system integration along comprehensive staff education programs focused achieving desired outcomes efficiently effectively over time .

How can businesses implement RFID tracking systems?

Implementing an effective RFID tracking system involves several key steps that businesses must consider carefully before deployment :

Needs Assessment

Businesses should begin by conducting a thorough needs assessment :

1 . Identify specific objectives related implementing an RFIDs solution (e.g., improving inventory accuracy , enhancing asset visibility ).

2 . Evaluate current processes identifying pain points where improvements could be made leveraging new technologies effectively addressing challenges faced previously .

3 . Determine budget constraints factoring potential return-on-investment calculations based projected savings achieved once implemented successfully over time .

System Design

Once needs assessed businesses proceed designing their RFIDs system :

1 . Select appropriate tag types based environmental factors (e.g., passive vs active tags ) considering read ranges required specific applications being addressed during deployment phases .

2 . Choose suitable reader infrastructure determining placement locations ensuring coverage achieved consistently throughout areas needing monitored effectively without gaps occurring during operations .

3 . Develop software applications necessary managing collected data integrating existing platforms such as warehouse management systems (WMS) enterprise resource planning (ERP) tools facilitating seamless transitions across different functions involved within organization itself overall operational framework established beforehand guiding future decisions made accordingly thereafter moving forward continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time too .

Pilot Testing

Before full-scale deployment businesses should conduct pilot testing phases :

1 . Implement pilot projects limited scope testing selected areas assessing performance metrics gathered during trials evaluating effectiveness achieving desired outcomes initially set forth previously outlined objectives established earlier prior commencing efforts moving forward thereafter too subsequently following completion phases undertaken accordingly thereafter too as well before proceeding further ahead beyond initial stages reached thus far already accomplished successfully thus far already achieved thus far too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafter too now moving forward thereafter too subsequently thereafte…

2 . Gather feedback from users involved identifying any issues encountered during trials making adjustments necessary before scaling up implementations fully across entire organization later down line once satisfied results achieved initially expected outcomes previously outlined beforehand guiding future decisions made accordingly afterwards as well continuing adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed whenever necessary responding changing market demands encountered regularly over time continuously adapting strategies employed2. Gather Feedback: Gather feedback from users involved in the pilot testing to identify any issues encountered during trials. Make necessary adjustments before scaling up implementations fully across the entire organization. This iterative process ensures that the system meets the specific needs and expectations of users.

Full-Scale Deployment

Once the pilot testing phase is completed successfully, businesses can proceed with full-scale deployment:

-

Training Programs: Implement comprehensive training programs for staff to ensure they understand how to use the RFID system effectively. Training should cover hardware operation, software usage, and best practices for data management.

-

System Integration: Integrate the RFID system with existing enterprise systems, such as ERP and WMS, to facilitate seamless data flow and enhance overall operational efficiency.

-

Monitoring and Support: Establish ongoing monitoring of the RFID system to ensure it functions as intended. Provide technical support to address any issues that may arise post-deployment.

Continuous Improvement

Implementing an RFID tracking system is not a one-time effort; it requires continuous improvement:

-

Data Analysis: Regularly analyze data collected from the RFID system to identify trends, inefficiencies, or areas for improvement. Use this information to make informed decisions regarding inventory management, asset tracking, or workflow optimization.

-

Feedback Loop: Maintain an open feedback loop with users to gather insights on their experiences with the system. This feedback can inform future enhancements and adjustments.

-

Technology Updates: Stay informed about advancements in RFID technology and consider upgrading hardware or software as needed to leverage new capabilities and improve performance.

| Implementation Step | Key Actions | Considerations |

|---|---|---|

| Needs Assessment | Identify objectives, evaluate processes | Budget constraints, ROI analysis |

| System Design | Select tags, choose readers | Environmental factors |

| Pilot Testing | Conduct trials, gather feedback | Adjustments based on results |

| Full-Scale Deployment | Train staff, integrate systems | Ongoing monitoring |

| Continuous Improvement | Analyze data, maintain feedback loop | Technology updates |

Implementing an RFID tracking system involves a structured approach that includes needs assessment, system design, pilot testing, full-scale deployment, and continuous improvement. By carefully considering each step and engaging stakeholders throughout the process, businesses can successfully leverage RFID technology to enhance operational efficiency and achieve their specific tracking objectives.

What challenges and limitations exist in RFID tracking?

Despite its many advantages, RFID technology also presents challenges and limitations that businesses must consider when implementing tracking systems:

Cost Considerations

-

Initial Investment: The upfront costs of purchasing RFID hardware (tags and readers), software solutions, and infrastructure can be significant. Businesses must evaluate their budget constraints and calculate potential return on investment (ROI) before proceeding.

-

Ongoing Maintenance Costs: Maintaining an RFID system involves ongoing expenses related to software updates, hardware repairs or replacements, and staff training. Organizations need to budget for these recurring costs.

Technical Challenges

-

Read Range Limitations: The effective read range of RFID systems can vary based on tag type (passive vs active), environmental conditions (e.g., interference from metal or liquids), and reader placement. Businesses must carefully assess these factors to ensure reliable performance.

-

Interference Issues: RFID signals can be disrupted by physical barriers or electromagnetic interference from other devices operating in similar frequency ranges. This can lead to inconsistent read rates or missed scans if not properly managed.

-

Data Management Complexity: The volume of data generated by RFID systems can be overwhelming for organizations without robust data management strategies in place. Businesses must invest in data processing capabilities to analyze and utilize this information effectively.

Privacy Concerns

-

Consumer Privacy Issues: As RFID technology allows for detailed tracking of items and individuals, concerns about consumer privacy have emerged. Organizations must establish clear policies regarding data usage and ensure compliance with relevant privacy regulations.

-

Public Perception: The implementation of RFID systems may raise concerns among customers about surveillance or unauthorized tracking. Businesses should communicate transparently about how they use RFID technology and protect customer information.

Integration Challenges

-

Compatibility with Existing Systems: Integrating RFID solutions with legacy systems can be complex and may require significant modifications to existing infrastructure. Businesses must assess compatibility issues before implementation.

-

Staff Resistance to Change: Employees may resist adopting new technologies due to fear of job displacement or discomfort with unfamiliar processes. Organizations should provide adequate training and support to facilitate a smooth transition.

Scalability Limitations

-

Scalability Challenges: As businesses grow or expand operations, scaling up an existing RFID system may present challenges related to infrastructure upgrades or increased costs associated with additional tags and readers.

-

Vendor Lock-In Risks: Organizations may face difficulties if they become dependent on a single vendor for their RFID solutions, limiting flexibility in future upgrades or changes to their tracking systems.

| Challenge/Limitations | Description | Mitigation Strategies |

|---|---|---|

| Cost Considerations | High initial investment | ROI analysis |

| Technical Challenges | Read range limitations | Proper planning & placement |

| Privacy Concerns | Consumer privacy issues | Clear data usage policies |

| Integration Challenges | Compatibility with legacy systems | Thorough assessment |

| Scalability Limitations | Difficulties in scaling up | Flexible vendor contracts |

RFID technology offers numerous benefits for tracking items across various industries; however , it also presents challenges that organizations must navigate carefully . By understanding these limitations upfront , businesses can develop strategies to mitigate potential issues while maximizing the advantages offered by implementing effective RFIDs solutions tailored towards achieving desired outcomes efficiently over time consistently .

In conclusion , while there are challenges associated with implementing RFIDs , careful planning , strategic investments , robust training programs , along with ongoing monitoring efforts will enable organizations harness its full potential effectively leading towards improved operational efficiencies across diverse sectors enhancing overall productivity significantly over time .