What Is Predictive Analytics in Transportation Industry

What is predictive analytics in the transportation industry?

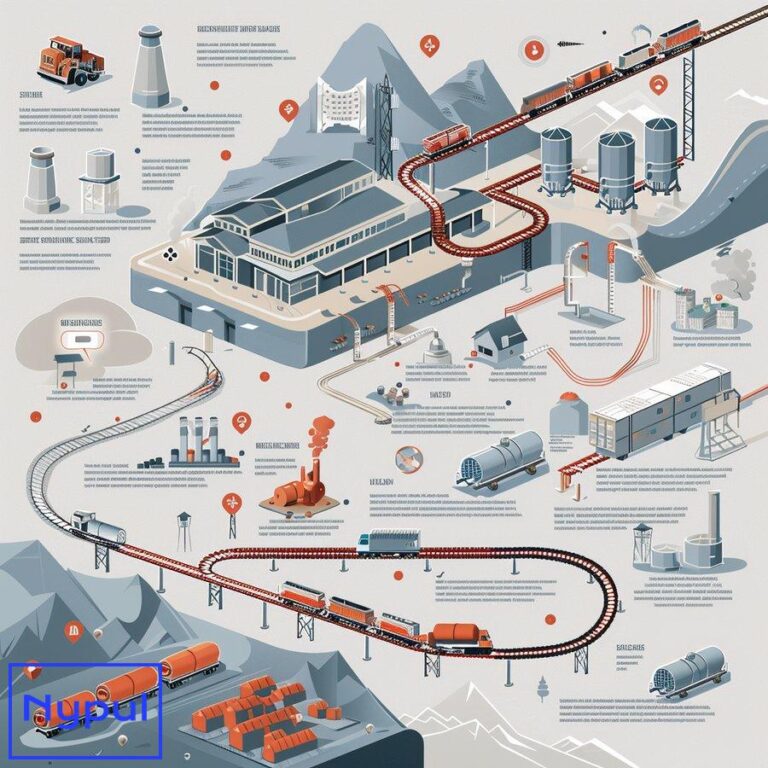

Predictive analytics in the transportation industry represents a powerful tool that leverages historical data, statistical algorithms, and machine learning techniques to forecast future events and trends. This advanced analytical approach enables transportation companies to make data-driven decisions, optimize operations, and enhance overall efficiency.

At its core, predictive analytics in transportation involves the systematic analysis of vast amounts of data collected from various sources within the industry. These sources may include GPS tracking systems, weather reports, traffic patterns, fuel consumption records, and customer feedback. By processing and interpreting this data, predictive analytics can provide valuable insights into potential outcomes, allowing companies to anticipate challenges and opportunities before they arise.

The application of predictive analytics in transportation extends across multiple facets of the industry:

Route Optimization: Predictive models can analyze historical traffic patterns, weather conditions, and other relevant factors to suggest the most efficient routes for vehicles. This optimization can lead to significant reductions in fuel consumption and delivery times.

Maintenance Scheduling: By analyzing data from vehicle sensors and maintenance records, predictive analytics can forecast when a vehicle is likely to require maintenance. This proactive approach helps prevent unexpected breakdowns and minimizes downtime.

Demand Forecasting: Predictive analytics can analyze historical shipping data, economic indicators, and seasonal trends to predict future demand for transportation services. This information allows companies to allocate resources more effectively and adjust their capacity accordingly.

Risk Management: By analyzing data on accidents, weather conditions, and driver behavior, predictive analytics can identify potential safety risks and suggest preventive measures.

Customer Behavior Analysis: Predictive models can analyze customer data to forecast future shipping needs, allowing transportation companies to tailor their services and improve customer satisfaction.

The implementation of predictive analytics in transportation requires a combination of advanced technologies, including big data infrastructure, machine learning algorithms, and data visualization tools. These technologies work together to process large volumes of data, identify patterns, and present actionable insights to decision-makers.

One of the key strengths of predictive analytics in transportation is its ability to continuously learn and improve over time. As more data is collected and analyzed, the predictive models become increasingly accurate and refined, leading to better forecasts and more informed decision-making.

However, it’s crucial to note that predictive analytics is not a crystal ball. While it can provide valuable insights and probabilities, it cannot guarantee specific outcomes. The effectiveness of predictive analytics relies heavily on the quality and quantity of data available, as well as the expertise of data scientists and analysts in interpreting the results.

As the transportation industry continues to evolve and face new challenges, predictive analytics is becoming an increasingly essential tool for companies looking to stay competitive. By harnessing the power of data and advanced analytics, transportation companies can improve their operational efficiency, reduce costs, enhance safety, and ultimately provide better service to their customers.

How has predictive analytics evolved in logistics?

The evolution of predictive analytics in logistics has been a transformative journey, marked by significant technological advancements and shifting industry needs. This progression has fundamentally changed how logistics companies operate, make decisions, and plan for the future.

Early Stages: The roots of predictive analytics in logistics can be traced back to the 1960s and 1970s when companies began using basic statistical methods to forecast demand and inventory needs. These early efforts were limited by the computational power available at the time and relied heavily on historical data and simple trend analysis.

1980s and 1990s: The advent of personal computers and more sophisticated software in the 1980s and 1990s marked a significant leap forward. Logistics companies started using more complex forecasting models, such as time series analysis and regression models. This period also saw the introduction of Enterprise Resource Planning (ERP) systems, which provided a more integrated approach to data collection and analysis.

Early 2000s: The early 2000s brought about the concept of supply chain optimization. Predictive analytics began to be applied not just to individual components of the logistics process, but to the entire supply chain. This holistic approach allowed companies to identify inefficiencies and optimize their operations on a broader scale.

Mid to Late 2000s: The rise of big data and cloud computing in the mid to late 2000s revolutionized predictive analytics in logistics. These technologies enabled companies to collect, store, and analyze vast amounts of data from multiple sources. This led to more accurate predictions and the ability to consider a wider range of variables in forecasting models.

2010s: The 2010s saw the integration of machine learning and artificial intelligence into predictive analytics. These technologies allowed for more sophisticated pattern recognition and the ability to handle unstructured data, such as text from customer reviews or social media posts. This period also saw the rise of real-time analytics, enabling logistics companies to make decisions based on up-to-the-minute data.

Present Day: Today, predictive analytics in logistics has evolved into a sophisticated, multi-faceted discipline. It incorporates advanced technologies such as:

Internet of Things (IoT): IoT devices provide real-time data on everything from vehicle location to cargo conditions, enabling more accurate and timely predictions.

Artificial Intelligence and Machine Learning: These technologies allow for more complex pattern recognition and can even make autonomous decisions based on predictive models.

Blockchain: While still in its early stages of adoption in logistics, blockchain technology promises to enhance data security and transparency in predictive analytics.

Advanced Visualization Tools: These tools make complex data more accessible and understandable to decision-makers, facilitating quicker and more informed decisions.

The evolution of predictive analytics in logistics can be summarized in the following table:

| Era | Key Technologies | Focus Areas |

|---|---|---|

| 1960s-1970s | Basic statistical methods | Simple demand forecasting |

| 1980s-1990s | Personal computers, ERP systems | More complex forecasting models, integrated data analysis |

| Early 2000s | Supply chain management software | Supply chain optimization |

| Mid to Late 2000s | Big data, cloud computing | Multi-source data analysis, improved accuracy |

| 2010s | Machine learning, AI, real-time analytics | Sophisticated pattern recognition, real-time decision making |

| Present Day | IoT, advanced AI, blockchain, visualization tools | Comprehensive, real-time, and autonomous predictive capabilities |

This evolution has not only improved the accuracy and scope of predictions but has also changed the very nature of decision-making in logistics. Companies can now make proactive, data-driven decisions rather than reactive ones based on intuition or limited information.

The future of predictive analytics in logistics promises even more exciting developments. As technologies like quantum computing and 5G networks become more prevalent, we can expect to see even more sophisticated predictive models that can process larger amounts of data faster and with greater accuracy.

However, this evolution also brings challenges. As predictive analytics becomes more complex, there’s an increasing need for skilled professionals who can develop, implement, and interpret these models. There’s also the ongoing challenge of data quality and integration, as well as ethical considerations around data privacy and the use of AI in decision-making.

Despite these challenges, the evolution of predictive analytics in logistics has undoubtedly transformed the industry. It has enabled companies to operate more efficiently, respond more quickly to changes in the market, and provide better service to their customers. As this technology continues to evolve, it will undoubtedly play an even more crucial role in shaping the future of logistics.

What are the core components of predictive analytics?

Predictive analytics is a complex field that relies on several core components working together to generate accurate forecasts and insights. Understanding these components is crucial for anyone looking to implement or improve predictive analytics in their organization. Let’s delve into each of these core components:

Data Collection: The foundation of any predictive analytics system is data. This component involves gathering relevant information from various sources, which may include:

- Internal databases (e.g., sales records, customer information)

- External sources (e.g., market trends, economic indicators)

- IoT devices (e.g., GPS trackers, sensors)

- Social media and web data

The key to effective data collection is ensuring that the data is comprehensive, accurate, and relevant to the predictions you want to make.

Data Preprocessing: Raw data is often messy and inconsistent. The preprocessing stage involves cleaning and preparing the data for analysis. This includes:

- Removing duplicates and irrelevant data

- Handling missing values

- Normalizing data (bringing all variables to a common scale)

- Encoding categorical variables

Effective preprocessing is crucial for ensuring the accuracy and reliability of predictive models.

Feature Selection and Engineering: This component involves identifying the most relevant variables (features) for your predictive model and creating new features that might improve prediction accuracy. It includes:

- Selecting the most informative features from the available data

- Creating new features by combining or transforming existing ones

- Reducing the dimensionality of the data to improve model performance

Model Selection: Choosing the right predictive model is crucial for accurate forecasting. Different types of models are suited to different types of problems and data. Common types of predictive models include:

- Linear regression

- Logistic regression

- Decision trees

- Random forests

- Neural networks

- Support Vector Machines (SVM)

The choice of model depends on factors such as the nature of the problem, the type of data available, and the desired outcome.

Model Training: Once a model is selected, it needs to be trained on historical data. This process involves:

- Splitting the data into training and testing sets

- Feeding the training data into the model

- Adjusting the model’s parameters to minimize prediction errors

The goal of model training is to create a model that can accurately predict outcomes for new, unseen data.

Model Evaluation: After training, the model needs to be evaluated to ensure it’s performing well. This involves:

- Testing the model on the held-out test data

- Using various metrics to assess performance (e.g., accuracy, precision, recall, F1 score)

- Comparing the model’s performance to baseline models or industry standards

Model Deployment: Once a model has been trained and evaluated, it needs to be deployed in a production environment where it can make real-time predictions. This involves:

- Integrating the model with existing systems

- Ensuring the model can handle the required volume of data

- Setting up monitoring systems to track the model’s performance

Continuous Monitoring and Updating: Predictive models need to be continuously monitored and updated to ensure they remain accurate over time. This involves:

- Regularly retraining the model with new data

- Monitoring for concept drift (changes in the underlying patterns the model is trying to predict)

- Adjusting the model as needed based on its performance

Interpretation and Visualization: The insights generated by predictive models need to be interpreted and communicated effectively. This component involves:

- Creating visualizations to represent the model’s predictions

- Interpreting the model’s results in the context of the business problem

- Communicating insights to stakeholders in an understandable way

Here’s a table summarizing these core components and their key aspects:

| Component | Key Aspects |

|---|---|

| Data Collection | Gathering relevant data from various sources |

| Data Preprocessing | Cleaning, normalizing, and preparing data for analysis |

| Feature Selection and Engineering | Identifying relevant variables and creating new features |

| Model Selection | Choosing the appropriate predictive model for the problem |

| Model Training | Adjusting model parameters using historical data |

| Model Evaluation | Assessing model performance using various metrics |

| Model Deployment | Integrating the model into production systems |

| Continuous Monitoring and Updating | Ensuring ongoing model accuracy and relevance |

| Interpretation and Visualization | Communicating insights effectively to stakeholders |

Each of these components plays a crucial role in the predictive analytics process. The effectiveness of a predictive analytics system depends on how well each of these components is implemented and how seamlessly they work together.

It’s important to note that while these components form the core of predictive analytics, the specific implementation can vary depending on the industry, the nature of the problem being addressed, and the available resources. In the transportation industry, for example, data collection might heavily rely on GPS and IoT devices, while the models might focus on route optimization or demand forecasting.

Understanding these core components is essential for anyone looking to implement or improve predictive analytics in their organization. By mastering each of these components, companies can build robust predictive analytics systems that provide valuable insights and drive better decision-making.

How is predictive analytics applied in transportation?

Predictive analytics has found numerous applications in the transportation industry, revolutionizing how companies plan, operate, and make decisions. These applications span across various aspects of transportation, from route planning to maintenance scheduling. Let’s explore some of the key areas where predictive analytics is making a significant impact:

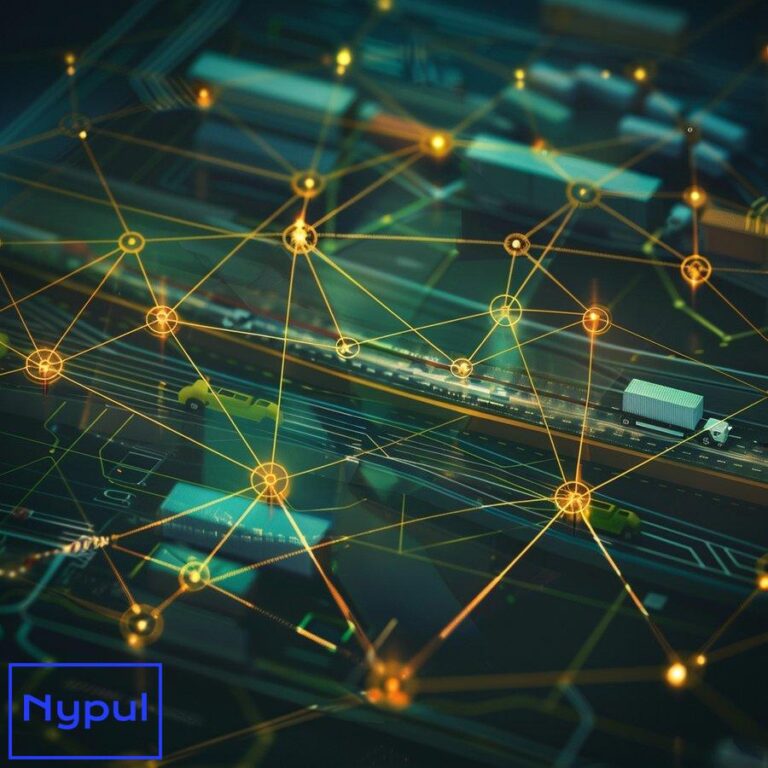

Route Optimization: One of the most prominent applications of predictive analytics in transportation is route optimization. This involves:

- Analyzing historical traffic patterns, weather conditions, and road conditions

- Predicting potential delays or disruptions

- Suggesting optimal routes that minimize travel time and fuel consumption

For example, a delivery company might use predictive analytics to forecast traffic congestion at different times of the day and adjust their delivery routes accordingly. This not only reduces fuel costs but also improves delivery times and customer satisfaction.

Demand Forecasting: Predictive analytics plays a crucial role in anticipating transportation demand. This application involves:

- Analyzing historical shipping data

- Considering external factors like economic indicators and seasonal trends

- Predicting future demand for transportation services

Airlines, for instance, use predictive analytics to forecast passenger demand on different routes, allowing them to adjust their schedules and pricing strategies accordingly.

Fleet Management: Predictive analytics enhances fleet management in several ways:

- Predicting vehicle maintenance needs based on usage patterns and sensor data

- Optimizing fleet size and composition based on predicted demand

- Improving vehicle utilization by predicting idle times and opportunities for shared use

A trucking company might use predictive analytics to forecast which trucks are likely to need maintenance soon, allowing them to schedule repairs proactively and minimize unexpected breakdowns.

Risk Management and Safety: Predictive analytics contributes significantly to improving safety in transportation:

- Analyzing data on past accidents and near-misses

- Identifying high-risk areas or conditions

- Predicting potential safety issues and suggesting preventive measures

For example, a railway company might use predictive analytics to identify sections of track that are at higher risk of failure based on factors like age, usage, and environmental conditions.

Fuel Consumption Optimization: Predictive analytics helps in reducing fuel consumption:

- Analyzing factors affecting fuel efficiency (e.g., driving behavior, vehicle condition, route characteristics)

- Predicting fuel consumption under different scenarios

- Suggesting strategies to minimize fuel use

A shipping company might use predictive analytics to forecast fuel consumption for different route options, helping them choose the most fuel-efficient routes.

Customer Behavior Analysis: Predictive analytics helps transportation companies understand and anticipate customer behavior:

- Analyzing historical customer data

- Predicting future customer needs and preferences

- Enabling personalized service offerings

An urban transit authority might use predictive analytics to forecast passenger volumes at different times and adjust their service frequency accordingly.

Supply Chain Optimization: In logistics, predictive analytics plays a crucial role in optimizing the entire supply chain:

- Predicting potential disruptions in the supply chain

- Optimizing inventory levels based on predicted demand

- Improving coordination between different parts of the supply chain

A large retailer might use predictive analytics to forecast demand for different products and optimize their distribution network accordingly.

Pricing Optimization: Predictive analytics helps transportation companies optimize their pricing strategies:

- Analyzing historical pricing data and customer responses

- Predicting demand at different price points

- Suggesting optimal pricing strategies to maximize revenue

Airlines frequently use predictive analytics for dynamic pricing, adjusting ticket prices based on predicted demand.

Here’s a table summarizing these applications and their key benefits:

| Application | Key Benefits |

|---|---|

| Route Optimization | Reduced travel time, lower fuel costs, improved delivery times |

| Demand Forecasting | Better resource allocation, improved service planning |

| Fleet Management | Reduced maintenance costs, improved vehicle utilization |

| Risk Management and Safety | Fewer accidents, lower insurance costs |

| Fuel Consumption Optimization | Lower fuel costs, reduced environmental impact |

| Customer Behavior Analysis | Improved customer satisfaction, personalized services |

| Supply Chain Optimization | Reduced inventory costs, improved coordination |

| Pricing Optimization | Increased revenue, better market competitiveness |

The application of predictive analytics in transportation is not without challenges. These include:

Data Quality and Integration: Transportation companies often deal with data from multiple sources, which can be of varying quality and format. Ensuring data quality and integrating data from different systems can be challenging.

Real-time Processing: Many transportation applications require real-time or near-real-time predictions, which can be computationally intensive.

Privacy Concerns: The use of customer data for predictive analytics can raise privacy concerns, especially in passenger transportation.

Model Accuracy: The accuracy of predictive models can be affected by unexpected events or changes in patterns, requiring constant monitoring and updating.

Despite these challenges, the benefits of predictive analytics in transportation are substantial. By leveraging predictive analytics, transportation companies can improve their operational efficiency, reduce costs, enhance safety, and provide better service to their customers.

As technology continues to advance, we can expect to see even more sophisticated applications of predictive analytics in transportation. Emerging technologies like 5G networks and edge computing are likely to enable more real-time and localized predictive analytics, further enhancing its impact on the transportation industry.

What benefits does predictive analytics offer to logistics companies?

Predictive analytics offers a wide array of benefits to logistics companies, transforming their operations and decision-making## What benefits does predictive analytics offer to logistics companies?

Predictive analytics offers a wide array of benefits to logistics companies, transforming their operations and decision-making processes. By harnessing data-driven insights, these companies can enhance efficiency, reduce costs, and improve customer satisfaction. Here are some of the key benefits:

Improved Operational Efficiency:

Predictive analytics enables logistics companies to streamline their operations by anticipating demand and optimizing processes. This includes:

-

Route Optimization: By analyzing historical traffic patterns and other variables, logistics companies can identify the most efficient routes for deliveries, reducing travel time and fuel consumption.

-

Resource Allocation: Predictive models help in forecasting demand, allowing companies to allocate resources effectively. This ensures that they have the right amount of vehicles and personnel available when needed.

Cost Reduction:

Implementing predictive analytics can lead to significant cost savings in various areas:

-

Maintenance Costs: Predictive maintenance models can forecast when vehicles are likely to require servicing, allowing companies to perform maintenance proactively rather than reactively. This reduces unexpected breakdowns and associated costs.

-

Fuel Efficiency: By optimizing routes and analyzing driving behavior, logistics companies can minimize fuel consumption, leading to lower operational costs.

Enhanced Customer Satisfaction:

Predictive analytics allows logistics companies to better understand and meet customer needs:

-

Timely Deliveries: By predicting potential delays and optimizing routes, companies can improve delivery times, enhancing customer satisfaction.

-

Personalized Services: Analyzing customer data helps logistics providers tailor their services to individual preferences, leading to improved customer experiences.

Risk Management:

Predictive analytics plays a crucial role in identifying and mitigating risks in logistics operations:

-

Safety Improvements: By analyzing historical accident data and driver behavior, predictive models can identify high-risk situations and suggest preventive measures, improving overall safety.

-

Supply Chain Resilience: Predictive analytics helps companies anticipate disruptions in the supply chain, allowing them to develop contingency plans and maintain service continuity.

Data-Driven Decision Making:

With predictive analytics, logistics companies can make more informed decisions based on data rather than intuition:

-

Informed Strategy Development: Predictive insights enable companies to develop strategies that align with market trends and customer demands.

-

Performance Monitoring: Continuous monitoring of predictive models allows for real-time adjustments to operations based on changing conditions.

Here is a table summarizing the key benefits of predictive analytics in logistics:

| Benefit | Description |

|---|---|

| Improved Operational Efficiency | Streamlined processes through demand anticipation and route optimization |

| Cost Reduction | Lower maintenance and fuel costs through proactive management |

| Enhanced Customer Satisfaction | Timely deliveries and personalized services based on customer data |

| Risk Management | Improved safety measures and supply chain resilience |

| Data-Driven Decision Making | Informed strategies and real-time performance monitoring |

The implementation of predictive analytics is not without challenges. Companies must ensure they have access to high-quality data, invest in the necessary technology infrastructure, and develop the analytical capabilities required to interpret the results effectively. However, the potential rewards far outweigh these challenges.

As the logistics industry continues to evolve with advancements in technology, the role of predictive analytics will become increasingly critical. Companies that leverage these insights will be better positioned to navigate the complexities of modern logistics, stay competitive in a rapidly changing market, and ultimately deliver greater value to their customers.

What challenges do companies face when implementing predictive analytics?

While predictive analytics offers significant advantages for logistics companies, its implementation is not without challenges. Understanding these obstacles is essential for organizations looking to adopt predictive analytics effectively. The following are some common challenges faced during implementation:

Data Quality Issues:

The effectiveness of predictive analytics relies heavily on the quality of data used. Common issues include:

-

Inaccurate Data: Poorly recorded or outdated information can lead to misleading predictions.

-

Incomplete Data Sets: Missing data points can skew analysis results and reduce model accuracy.

To address these issues, organizations must invest in robust data governance practices that ensure data accuracy and completeness.

Integration of Data Sources:

Logistics companies often rely on diverse data sources (e.g., GPS systems, ERP software, customer databases). Integrating these disparate systems poses several challenges:

-

Compatibility Issues: Different systems may use incompatible formats or standards.

-

Data Silos: Information may be isolated within departments or systems, making it difficult to access comprehensive datasets for analysis.

To overcome these challenges, organizations should prioritize establishing a unified data architecture that facilitates seamless integration across platforms.

Skill Gaps in Data Analytics:

The successful implementation of predictive analytics requires skilled personnel who can develop models, interpret results, and communicate insights effectively. Challenges include:

-

Shortage of Qualified Analysts: There is often a lack of professionals with expertise in data science and machine learning within the logistics sector.

-

Training Needs: Existing staff may require training to adapt to new analytical tools and methodologies.

Organizations should consider investing in training programs or partnering with educational institutions to build a pipeline of skilled talent.

Model Complexity and Maintenance:

Developing effective predictive models can be complex due to various factors:

-

Choosing the Right Model: Selecting an appropriate model for specific business problems requires expertise.

-

Ongoing Maintenance Needs: Predictive models need regular updates based on new data or changes in underlying patterns (concept drift).

Companies should establish processes for continuous monitoring and updating of models to maintain their accuracy over time.

Change Management Resistance:

Implementing predictive analytics often requires changes in organizational processes and culture. Challenges include:

-

Resistance from Employees: Staff may be hesitant to adopt new technologies or change established workflows.

-

Leadership Buy-In: Gaining support from leadership is crucial for successful implementation but may be challenging if decision-makers are skeptical about the value of predictive analytics.

To address these concerns, organizations should focus on change management strategies that promote buy-in from all stakeholders through effective communication about the benefits of predictive analytics.

Here’s a summary table outlining these challenges:

| Challenge | Description |

|---|---|

| Data Quality Issues | Inaccurate or incomplete data affecting model reliability |

| Integration of Data Sources | Compatibility issues between disparate systems leading to data silos |

| Skill Gaps in Data Analytics | Shortage of qualified analysts requiring training initiatives |

| Model Complexity and Maintenance | Difficulty selecting appropriate models and maintaining accuracy over time |

| Change Management Resistance | Employee reluctance towards new technologies impacting adoption |

Despite these challenges, many logistics companies are successfully implementing predictive analytics by adopting best practices such as investing in training programs, prioritizing data governance initiatives, fostering a culture of collaboration across departments, and ensuring strong leadership support throughout the process.

By addressing these challenges head-on, organizations can unlock the full potential of predictive analytics, leading to improved operational efficiency, cost savings, enhanced customer satisfaction, and a competitive edge in the market.

What are some real-world examples of predictive analytics in action?

Real-world applications of predictive analytics showcase its transformative impact across various sectors within transportation and logistics. Here are several notable examples that illustrate how organizations leverage predictive analytics effectively:

UPS

United Parcel Service (UPS) has integrated predictive analytics into its operations through its ORION (On-Road Integrated Optimization and Navigation) system. This sophisticated tool analyzes vast amounts of historical delivery data along with real-time traffic information. Key outcomes include:

-

Route Optimization: ORION helps drivers determine the most efficient delivery routes by predicting traffic conditions.

-

Fuel Savings: The system has reportedly saved UPS over 10 million gallons of fuel annually by reducing unnecessary miles driven.

DHL

DHL employs predictive analytics for demand forecasting within its supply chain operations. By analyzing historical shipping trends alongside external factors such as economic indicators or seasonal fluctuations, DHL achieves several benefits:

-

Resource Allocation: The company can optimize staffing levels at distribution centers based on predicted demand spikes during peak seasons.

-

Inventory Management: Predictive insights enable better inventory planning across global warehouses, reducing excess stock while ensuring timely product availability.

FedEx

FedEx utilizes predictive maintenance strategies for its fleet management through advanced sensor technology integrated into its vehicles. The key features include:

-

Maintenance Predictions: By analyzing vehicle performance data in real-time, FedEx can predict when maintenance is required before breakdowns occur.

-

Cost Reduction: This proactive approach minimizes downtime costs associated with unexpected repairs while extending vehicle lifespan through timely servicing.

American Airlines

American Airlines employs predictive analytics for flight scheduling optimization. By analyzing historical flight performance metrics along with factors like weather patterns or airport congestion levels:

-

Flight Delay Predictions: The airline can forecast potential delays before they occur.

-

Customer Communication: Passengers receive timely notifications regarding flight changes or delays based on accurate predictions derived from real-time data analysis.

Walmart

Walmart leverages predictive analytics extensively within its supply chain management processes. The retail giant analyzes sales data alongside external factors such as weather forecasts or local events:

-

Inventory Optimization: Predictive models help forecast product demand accurately across different store locations.

-

Supply Chain Efficiency: This enables Walmart to maintain optimal inventory levels while reducing stockouts during peak shopping periods like holidays or promotions.

Here’s a summary table highlighting these examples:

| Company | Application Area | Key Outcomes |

|---|---|---|

| UPS | Route Optimization | Fuel savings; improved delivery efficiency |

| DHL | Demand Forecasting | Optimized resource allocation; better inventory management |

| FedEx | Predictive Maintenance | Reduced downtime; extended vehicle lifespan |

| American Airlines | Flight Scheduling | Accurate delay predictions; enhanced customer communication |

| Walmart | Supply Chain Management | Improved inventory optimization; reduced stockouts |

These examples illustrate how diverse organizations across transportation sectors harness the power of predictive analytics to drive operational improvements. As technology continues evolving alongside analytical capabilities expanding further into areas like artificial intelligence (AI) integration into existing systems—more innovative applications will likely emerge across industries seeking competitive advantages through enhanced decision-making processes driven by actionable insights from vast datasets available today.

How do data quality and integration impact predictive analytics?

Data quality and integration are critical factors influencing the effectiveness of predictive analytics initiatives within transportation and logistics sectors. High-quality data combined with seamless integration across various sources leads to more accurate predictions while enhancing decision-making capabilities. Here’s an exploration into how each factor impacts predictive analytics outcomes:

Data Quality

The quality of data used in predictive modeling directly affects model reliability. Key aspects include:

Accuracy

Data must accurately represent reality; inaccuracies can lead to misleading predictions. For instance:

- If historical delivery times are incorrectly recorded due to human error or system glitches—predictions regarding future delivery times will also be flawed.

Completeness

Incomplete datasets hinder comprehensive analysis by omitting crucial information needed for accurate forecasting. Missing values may arise from various sources such as sensor malfunctions or inconsistent reporting practices among different departments within an organization.

Consistency

Data consistency ensures uniformity across datasets collected from multiple sources. Discrepancies between datasets (e.g., different formats for recording customer addresses) complicate analysis efforts—leading analysts down paths that yield inaccurate conclusions about trends over time.

Timeliness

Data must be up-to-date; outdated information diminishes relevance when making predictions about future events—such as anticipating demand spikes during holiday seasons without considering recent sales trends reflecting changing consumer preferences over time.

Integration

Effective integration involves consolidating diverse datasets from various sources into a cohesive framework that enables comprehensive analysis. Challenges include:

Compatibility Issues

Different systems may utilize varying formats (e.g., CSV files versus relational databases), complicating efforts toward seamless integration—leading organizations toward manual reconciliation processes that consume valuable time while increasing error potential along the way.

Data Silos

Isolated datasets residing within departmental boundaries create barriers hindering holistic analyses necessary for accurate predictions—resulting in missed opportunities for cross-functional collaboration where insights could drive improvements across multiple areas simultaneously (e.g., aligning marketing campaigns with inventory levels).

Real-Time Access

For many applications—especially those requiring immediate responses (e.g., route optimization)—real-time access becomes paramount; however achieving this requires robust infrastructure capable of processing incoming streams efficiently without latency hindering responsiveness during critical moments when decisions must be made swiftly based on current conditions observed at any given moment throughout operations daily cycles.

Here’s a summary table highlighting how data quality and integration impact predictive analytics outcomes:

| Factor | Impact on Predictive Analytics |

|---|---|

| Data Quality | Affects accuracy; completeness; consistency; timeliness |

| Integration | Ensures seamless access; resolves compatibility issues; eliminates silos |

Investing resources into enhancing both aspects—data quality improvement initiatives alongside developing effective strategies for integrating disparate datasets—will ultimately yield significant returns through increased accuracy within predictions generated by analytic models deployed throughout transportation/logistics operations today while fostering greater agility needed amidst ever-evolving market dynamics faced regularly by businesses operating within this sector moving forward into future landscapes ahead!