Are There Electric Commercial Trucks

What types of electric commercial trucks are currently available?

Yes, there are several types of electric commercial trucks available today, ranging from light-duty delivery vans to heavy-duty semi-trucks. The electric truck market has expanded rapidly in recent years as manufacturers work to meet growing demand for zero-emission vehicles.

Light-duty electric trucks

At the smaller end of the spectrum, light-duty electric trucks and vans are becoming increasingly common for last-mile deliveries and urban logistics. Some popular models include:

Ford E-Transit: An all-electric version of Ford’s popular Transit cargo van, with up to 126 miles of range.

Rivian Electric Delivery Van: Purpose-built electric vans developed in partnership with Amazon, featuring 150-200 miles of range.

BrightDrop Zevo 600: General Motors’ electric delivery van with 250 miles of range.

These vehicles are well-suited for predictable urban routes where daily mileage is limited and charging can occur overnight at depots.

Medium-duty electric trucks

Moving up in size and capability, medium-duty electric trucks are emerging for regional haul and urban distribution applications:

Freightliner eM2: An electric box truck with up to 230 miles of range.

Volvo VNR Electric: A Class 7 electric truck offering 275 miles of range.

Lion Electric Lion6: A versatile Class 6 electric truck with modular battery options.

These trucks can handle heavier loads and longer routes than light-duty vans while still benefiting from electric powertrains.

Heavy-duty electric trucks

At the top end of the market, manufacturers are developing long-haul electric semi-trucks:

Tesla Semi: Promises up to 500 miles of range and ultra-fast charging.

Freightliner eCascadia: An electric version of the popular Cascadia semi with 230 miles of range.

Volvo VNR Electric (Class 8): The largest version offers up to 275 miles of range.

While still emerging, these trucks aim to electrify even long-distance freight transport.

The table below summarizes the key specifications of some popular electric truck models:

| Model | Class | Range (miles) | Payload Capacity (lbs) |

|---|---|---|---|

| Ford E-Transit | 2 | 126 | 3,880 |

| Rivian EDV | 2 | 150-200 | 2,200 |

| Freightliner eM2 | 6-7 | 230 | 12,000 |

| Volvo VNR Electric | 7-8 | 275 | 37,000 |

| Tesla Semi | 8 | 300-500 | 80,000 |

As battery technology improves and charging infrastructure expands, we can expect to see continued growth in the variety and capabilities of electric commercial trucks. Fleet operators now have options across multiple vehicle classes to begin electrifying their operations.

How do electric trucks compare to traditional diesel trucks in performance?

Electric trucks offer several performance advantages over traditional diesel trucks, though they also face some limitations. Let’s examine how they compare across key performance metrics:

Acceleration and torque

Electric trucks generally accelerate faster than diesel trucks due to the instant torque delivery of electric motors. This quick acceleration can be particularly beneficial in urban environments with frequent stops and starts.

Top speed

Most electric trucks have lower top speeds than diesel trucks to maximize efficiency and range. While diesel semi-trucks can often reach speeds of 75-80 mph, electric models are typically limited to 60-65 mph.

Range

Diesel trucks still hold a significant advantage in range. A typical diesel semi-truck can travel 600-1000 miles on a single tank, while most electric trucks are limited to 200-300 miles per charge. However, advancements in battery technology are steadily improving electric truck range.

Payload capacity

The heavy weight of batteries can reduce the payload capacity of electric trucks compared to diesel models. However, this gap is narrowing as battery energy density improves. Some electric trucks now offer payload capacities comparable to their diesel counterparts.

Reliability and maintenance

Electric trucks have fewer moving parts than diesel trucks, which can lead to improved reliability and reduced maintenance needs. There’s no need for oil changes, and regenerative braking reduces wear on brake components.

Performance in extreme conditions

Diesel trucks generally perform better in extreme cold, as battery performance can degrade in low temperatures. However, electric trucks produce less heat and perform well in hot conditions.

Noise levels

Electric trucks operate much more quietly than diesel trucks, which can be advantageous for urban deliveries and night operations.

The table below summarizes these performance comparisons:

| Performance Metric | Electric Trucks | Diesel Trucks |

|---|---|---|

| Acceleration | Faster | Slower |

| Top Speed | Lower (60-65 mph) | Higher (75-80 mph) |

| Range | 200-300 miles | 600-1000 miles |

| Payload Capacity | Slightly lower | Higher |

| Maintenance Needs | Lower | Higher |

| Cold Weather Performance | Reduced | Better |

| Noise Levels | Very low | Higher |

While electric trucks excel in some areas like acceleration and low maintenance needs, they still face challenges in range and extreme weather performance. As technology advances, we can expect these gaps to narrow further, making electric trucks increasingly competitive with diesel models across all performance metrics.

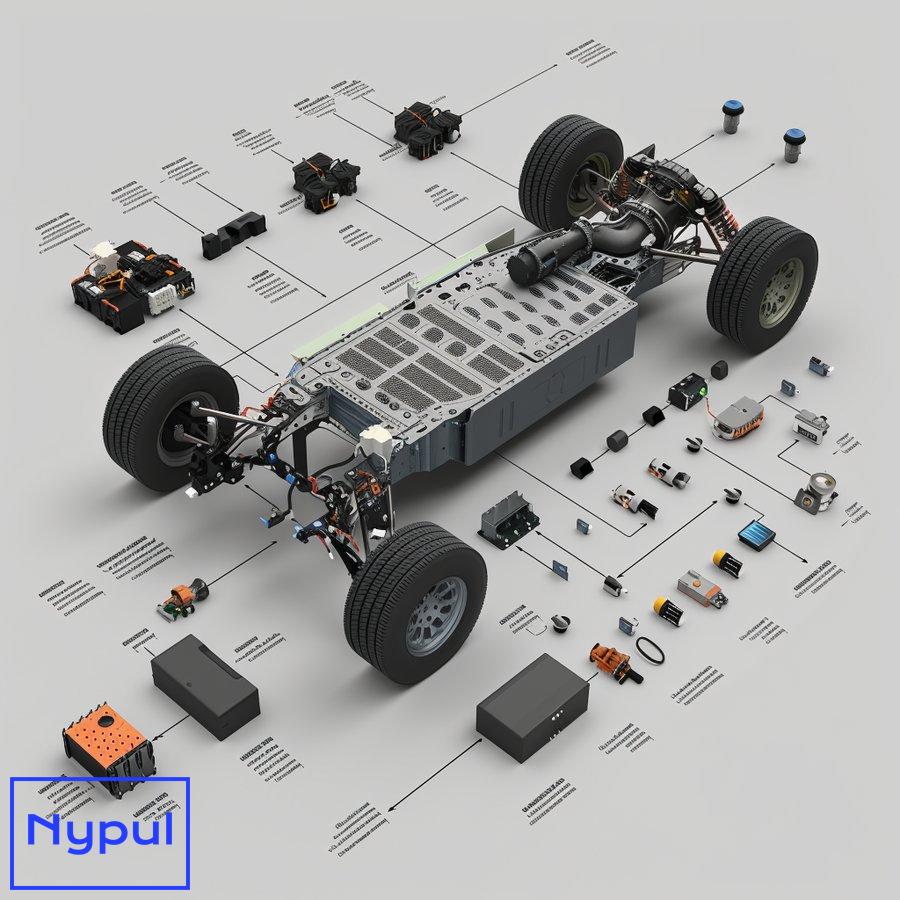

What are the key technological components of electric commercial trucks?

Electric commercial trucks rely on several key technological components that differentiate them from traditional diesel trucks. Understanding these components is crucial for fleet managers and operators considering the transition to electric vehicles.

Electric motors

The heart of any electric truck is its electric motor(s). Unlike internal combustion engines, electric motors provide instant torque and high efficiency. Most electric trucks use permanent magnet synchronous motors or induction motors. Some designs feature a single motor, while others employ multiple motors for increased power and redundancy.

Battery packs

Large lithium-ion battery packs store the energy needed to power electric trucks. These batteries are typically modular, allowing for different capacity options. Current electric truck batteries often use nickel-manganese-cobalt (NMC) or lithium iron phosphate (LFP) chemistries. Battery capacity is measured in kilowatt-hours (kWh) and directly impacts the truck’s range.

Battery management system (BMS)

The BMS monitors and controls the battery pack, ensuring optimal performance and longevity. It manages charging and discharging processes, balances cell voltages, and provides critical data to the truck’s central computer.

Power electronics

Inverters and converters are essential components that manage the flow of electricity between the battery, motor, and other vehicle systems. The inverter converts DC power from the battery to AC power for the motor, while converters provide appropriate voltage levels for various vehicle systems.

Thermal management system

Maintaining optimal temperature for batteries and other components is crucial for performance and longevity. Electric trucks employ sophisticated cooling systems, often using liquid coolant, to regulate temperatures across the powertrain.

Regenerative braking system

This system captures kinetic energy during braking and converts it back into electrical energy, storing it in the battery. It significantly improves overall efficiency and extends the truck’s range, especially in urban environments with frequent stops.

Charging system

On-board charging systems allow the truck to connect to external power sources. Most electric trucks support both AC and DC charging, with DC fast charging capabilities becoming increasingly common for rapid recharging during route breaks.

Telematics and fleet management software

Advanced telematics systems provide real-time data on battery status, energy consumption, and vehicle performance. This information is crucial for optimizing routes, managing charging schedules, and maximizing the efficiency of electric truck fleets.

The table below summarizes these key components and their functions:

| Component | Function |

|---|---|

| Electric Motor(s) | Provide propulsion power |

| Battery Pack | Store electrical energy |

| Battery Management System | Monitor and control battery performance |

| Power Electronics | Manage electricity flow between components |

| Thermal Management System | Regulate component temperatures |

| Regenerative Braking | Recover energy during deceleration |

| Charging System | Enable connection to external power sources |

| Telematics | Provide real-time vehicle data and analytics |

These technological components work together to create a highly efficient and capable electric powertrain. As these technologies continue to advance, we can expect to see improvements in range, charging speed, and overall performance of electric commercial trucks.

What economic advantages do electric trucks offer fleet operators?

Electric trucks present several economic advantages for fleet operators, potentially leading to significant cost savings over the vehicle’s lifetime. While the initial purchase price of electric trucks is typically higher than that of diesel trucks, the long-term operational savings can make them a financially attractive option.

Lower fuel costs

Electricity is generally cheaper than diesel fuel on a per-mile basis. The exact savings depend on local electricity rates and diesel prices, but many fleet operators report 50-70% lower fuel costs with electric trucks. This advantage is particularly pronounced in regions with low electricity rates or where fleets can charge during off-peak hours.

Reduced maintenance costs

Electric trucks have fewer moving parts and fluids compared to diesel trucks, leading to lower maintenance costs. There’s no need for oil changes, and brake wear is reduced due to regenerative braking. Studies suggest maintenance costs for electric trucks can be 30-50% lower than for diesel trucks over their lifetime.

Longer vehicle lifespan

Electric powertrains typically have a longer lifespan than diesel engines due to reduced wear and tear. This can lead to extended vehicle service life, spreading the initial investment over more years of operation.

Government incentives

Many governments offer incentives for the purchase and operation of electric trucks, including tax credits, grants, and rebates. These incentives can significantly offset the higher upfront costs of electric trucks.

Lower emissions compliance costs

As emissions regulations become stricter, diesel trucks may require expensive aftertreatment systems or face operational restrictions. Electric trucks, with zero tailpipe emissions, avoid these costs and potential limitations.

Improved operational efficiency

Electric trucks can operate more efficiently in urban environments due to their quick acceleration and regenerative braking. This can lead to faster delivery times and increased productivity.

Potential for lower insurance costs

Some insurance companies offer lower rates for electric vehicles due to their advanced safety features and lower fire risk compared to diesel vehicles.

The table below provides a simplified comparison of costs between electric and diesel trucks over a 5-year period:

| Cost Category | Electric Truck | Diesel Truck |

|---|---|---|

| Initial Purchase Price | $300,000 | $150,000 |

| Fuel Costs (5 years) | $50,000 | $150,000 |

| Maintenance Costs (5 years) | $30,000 | $60,000 |

| Potential Government Incentives | -$50,000 | $0 |

| Total 5-Year Cost | $330,000 | $360,000 |

Note: These figures are illustrative and will vary based on specific models, usage patterns, and local conditions.

While the upfront cost of electric trucks is higher, the long-term savings in fuel and maintenance can lead to a lower total cost of ownership. As battery prices continue to decrease and electric truck production scales up, we can expect the initial price gap to narrow, making the economic case for electric trucks even stronger.

Fleet operators should conduct thorough total cost of ownership analyses based on their specific operational needs and local conditions to determine the economic viability of electric trucks for their fleet.

How are charging infrastructure challenges being addressed for electric trucks?

The development of adequate charging infrastructure is crucial for the widespread adoption of electric trucks. Several strategies are being employed to address this challenge:

Public-private partnerships

Government agencies are collaborating with private companies to build out charging networks. For example, the U.S. Department of Energy’s National Electric Vehicle Infrastructure (NEVI) program is providing $5 billion in funding to states for EV charging infrastructure along major highways.

Utility company involvement

Electric utilities are playing a key role in upgrading grid infrastructure to support high-power charging stations. Many are offering special rate plans for commercial EV charging and providing assistance with site planning and installation.

Dedicated truck charging depots

Companies like WattEV and TeraWatt Infrastructure are developing large-scale charging depots specifically for commercial trucks. These facilities offer multiple high-power chargers and are strategically located near major freight corridors.

Megawatt charging system (MCS) development

A new standard for ultra-high-power charging, capable of delivering up to 3.75 megawatts, is being developed. This will enable much faster charging for long-haul electric trucks, reducing downtime.

On-route charging strategies

Some companies are exploring dynamic charging technologies, such as in-road charging strips, that would allow trucks to charge while driving on certain highway sections.

Hydrogen fuel cell integration

To address range limitations, some manufacturers are developing trucks that combine battery-electric powertrains with hydrogen fuel cells as range extenders.

Smart charging solutions

Advanced software systems are being developed to optimize charging schedules, balancing grid load and minimizing costs for fleet operators.

Battery swapping stations

Some companies are exploring battery swapping as a rapid “refueling” option for electric trucks, though this approach faces standardization challenges.

The table below summarizes key charging infrastructure initiatives:

| Initiative | Description | Key Players |

|---|---|---|

| NEVI Program | $5 billion federal funding for highway charging | U.S. Department of Energy, State DOTs |

| Utility Programs | Special EV rates, infrastructure support | Local electric utilities |

| Truck Charging Depots | Large-scale facilities for multiple trucks | WattEV, TeraWatt Infrastructure |

| Megawatt Charging System | Ultra-high-power charging standard | CharIN, truck manufacturers |

| Dynamic Charging | In-road charging technology | Electreon, road authorities |

| Smart Charging Software | Optimized charging management | ChargeLab, Amply Power |

These initiatives are helping to build the robust charging ecosystem necessary for widespread electric truck adoption. As these solutions continue to develop and deploy, range anxiety and charging logistics will become less of a barrier for fleet operators considering the switch to electric trucks.

However, challenges remain, particularly in coordinating the rollout of charging infrastructure with the production and adoption of electric trucks. Ensuring interoperability between different charging systems and managing the increased load on the electrical grid are ongoing concerns that require continued attention and investment.

What operational constraints do electric trucks face in commercial use?

While electric trucks offer many advantages, they also face several operational constraints that fleet managers must consider:

Limited range

Most current electric trucks have a range of 200-300 miles on a single charge, significantly less than diesel trucks. This limits their use for long-haul operations without careful route planning and charging stops.

Charging time

Even with fast-charging technology, electric trucks require more time to “refuel” than diesel trucks. A 30-80% charge typically takes 60-90 minutes, which can impact scheduling and driver hours of service.

Payload reduction

The weight of battery packs can reduce the available payload capacity of electric trucks, though this is becoming less of an issue as battery technology improves.

Weather sensitivity

Extreme temperatures, particularly cold, can reduce battery performance and range. This requires additional planning in regions with harsh climates.

Infrastructure availability

The limited availability of high-power charging stations along some routes can constrain operational flexibility.

Route planning complexity

Fleet managers must carefully plan routes to ensure trucks can complete their journeys with available charging options, adding complexity to logistics operations.

Driver training

Operators need to train drivers on the nuances of electric truck operation, including optimal driving techniques for range maximization and proper charging procedures.

Longer dwell times

The need for charging can increase dwell times at depots or distribution centers, potentially impacting overall fleet efficiency.

Initial cost

The higher upfront cost of electric trucks can constrain fleet electrification efforts, especially for smaller operators with limited capital.

Grid capacity

In some areas, the local electrical grid may not have sufficient capacity to support charging multiple trucks simultaneously, requiring coordination with utilities.

The table below summarizes these constraints and potential mitigation strategies:

| Constraint | Impact | Mitigation Strategy |

|---|---|---|

| Limited Range | Restricted long-haul use | Route optimization, strategic charging stops |

| Charging Time | Scheduling challenges | Off-peak charging, battery swapping |

| Payload Reduction | Reduced cargo capacity | Lightweight materials, improved battery density |

| Weather Sensitivity | Reduced performance in extreme temps | Thermal management systems, route adjustments |

| Infrastructure Availability | Operational limitations | Investment in depot charging, partnerships with charge point operators |

| Route Planning Complexity | Increased logistics overhead | Advanced fleet management software |

| Driver Training | Initial productivity dip | Comprehensive training programs, driver incentives |

| Longer Dwell Times | Reduced asset utilization | Optimized charging schedules, opportunity charging |

| Initial Cost | Slower fleet electrification | Leasing options, government incentives |

| Grid Capacity | Charging limitations | On-site energy storage## How have electric trucks performed in real-world applications? |

The performance of electric trucks in real-world applications has been promising, with numerous fleets reporting positive results across various sectors. These case studies illustrate the potential of electric trucks to meet operational needs while delivering environmental benefits.

Urban delivery services

Many urban delivery fleets have adopted electric trucks to reduce emissions and noise pollution. For instance, UPS has rolled out electric delivery vans in several cities, reporting lower operating costs and improved sustainability metrics. The company aims to have 10,000 electric vehicles in its fleet by 2025.

Long-haul freight

Tesla’s Semi is being tested by several companies for long-haul operations. PepsiCo has committed to using Tesla Semis for its freight operations, citing the truck’s potential for cost savings and reduced emissions. Early reports indicate that the Tesla Semi can handle typical freight loads while providing substantial energy savings compared to diesel counterparts.

Public transportation

Electric buses have seen widespread adoption in public transportation systems, paving the way for electric trucks. Cities like Los Angeles and Seattle have integrated electric buses into their fleets, demonstrating that electric vehicles can meet rigorous operational demands. The success of electric buses has encouraged transit agencies to explore electric trucks for goods movement.

Construction and waste management

Companies in construction and waste management are also testing electric trucks. Daimler’s eCascadia is being used by waste management companies like Republic Services, which report lower operational costs and reduced emissions. The quiet operation of electric trucks is particularly advantageous in residential areas during early morning hours.

Telematics and data analytics

Fleets utilizing telematics systems report improved efficiency with electric trucks. Data analytics helps optimize routes, monitor battery usage, and schedule charging times effectively. This capability enhances overall fleet performance and reduces operational costs.

The table below summarizes key real-world applications of electric trucks:

| Application Area | Example Company | Key Benefits |

|---|---|---|

| Urban Delivery | UPS | Lower operating costs, reduced emissions |

| Long-Haul Freight | PepsiCo (Tesla Semi) | Energy savings, sustainability |

| Public Transportation | Los Angeles Metro | Rigorous operational demands met |

| Construction/Waste Management | Republic Services (eCascadia) | Reduced emissions, quiet operation |

| Telematics Integration | Various Fleets | Improved efficiency, optimized routing |

These case studies highlight the versatility and adaptability of electric trucks across various sectors. As more companies adopt electric vehicles, the collective experience will contribute to refining operational strategies and enhancing the overall performance of electric trucks.

What strategies can fleet managers use to transition to electric trucks?

Transitioning to electric trucks requires careful planning and strategic implementation. Fleet managers can adopt several strategies to facilitate a smooth transition:

Conduct a total cost of ownership analysis

Before making the switch, fleet managers should conduct a thorough total cost of ownership (TCO) analysis comparing electric and diesel options. This analysis should consider purchase price, fuel costs, maintenance expenses, and potential incentives.

Evaluate operational suitability

Fleet managers must assess their specific operational needs to determine if electric trucks are a viable option. Key factors include daily mileage, route characteristics, charging infrastructure availability, and payload requirements.

Start with pilot programs

Implementing pilot programs allows fleets to test electric trucks in real-world conditions without committing fully upfront. This approach provides valuable data on performance and operational challenges.

Invest in charging infrastructure

Developing adequate charging infrastructure is critical for successful integration. Fleet managers should consider installing on-site charging stations at depots or partnering with charging networks to ensure reliable access.

Train drivers and staff

Training programs are essential for educating drivers about operating electric trucks efficiently. Staff should also be trained on maintenance procedures specific to electric vehicles.

Leverage government incentives

Fleet managers should explore available government incentives for purchasing electric vehicles or installing charging infrastructure. These incentives can significantly offset initial costs.

Optimize routes for efficiency

Using telematics systems can help fleet managers optimize routes for electric trucks based on range and charging availability. This optimization minimizes downtime and maximizes productivity.

Monitor performance metrics

Establishing key performance indicators (KPIs) allows fleet managers to track the performance of electric trucks over time. Metrics such as energy consumption, range efficiency, and maintenance costs provide insights into operational effectiveness.

Engage with manufacturers

Building relationships with manufacturers can provide valuable support during the transition process. Manufacturers often offer training resources, maintenance support, and insights into best practices for operating their vehicles.

The table below outlines these strategies along with their benefits:

| Strategy | Benefits |

|---|---|

| Total Cost of Ownership Analysis | Informed decision-making |

| Operational Suitability Evaluation | Tailored solutions |

| Pilot Programs | Real-world testing |

| Charging Infrastructure Investment | Reliable access to power |

| Driver Training Programs | Improved efficiency |

| Government Incentives Exploration | Cost savings |

| Route Optimization | Increased productivity |

| Performance Monitoring | Continuous improvement |

| Manufacturer Engagement | Ongoing support |

By implementing these strategies, fleet managers can navigate the complexities of transitioning to electric trucks effectively. A well-planned approach will help maximize the benefits of electrification while minimizing potential disruptions.

How do current and future regulations impact electric truck adoption?

Regulatory frameworks play a significant role in shaping the adoption of electric trucks. Both current regulations and anticipated future policies influence fleet operators’ decisions regarding electrification.

Current emissions regulations

Many regions have implemented stringent emissions regulations aimed at reducing greenhouse gas emissions from commercial vehicles. These regulations create a financial incentive for fleet operators to transition from diesel to zero-emission alternatives like electric trucks.

For example, California’s Advanced Clean Trucks (ACT) regulation mandates that a percentage of new truck sales be zero-emission vehicles starting in 2024. Similar initiatives are being adopted by other states aiming for ambitious climate goals.

Incentives for electrification

Governments at various levels offer incentives such as tax credits, grants, or rebates for purchasing electric vehicles or installing charging infrastructure. These incentives help offset the higher upfront costs associated with electric trucks.

For instance, the federal government provides a tax credit of up to $7,500 for qualifying electric vehicle purchases under the Inflation Reduction Act, which incentivizes fleet operators to invest in electrification.

Future regulations on carbon emissions

As governments worldwide commit to achieving net-zero emissions by mid-century, stricter regulations on carbon emissions are expected to be introduced across industries. These future policies will likely accelerate the shift toward electrification as companies seek compliance with new standards.

The European Union has proposed legislation targeting a significant reduction in CO2 emissions from heavy-duty vehicles by 2030. Such regulations will push manufacturers to develop more efficient zero-emission options.

Infrastructure funding initiatives

Government funding initiatives aimed at expanding charging infrastructure will also facilitate greater adoption of electric trucks. Programs like the U.S. Department of Transportation’s Charging and Fueling Infrastructure Discretionary Grant Program provide financial support for developing EV charging networks along major freight corridors.

The table below summarizes key regulatory impacts on electric truck adoption:

| Regulatory Aspect | Impact on Adoption |

|---|---|

| Emissions Regulations | Financial incentive to switch |

| Purchase Incentives | Offset initial costs |

| Future Carbon Regulations | Accelerated electrification efforts |

| Infrastructure Funding Initiatives | Enhanced charging availability |

Regulatory frameworks are essential drivers of change within the commercial trucking industry. As regulations become more stringent and supportive policies emerge, fleet operators will increasingly view electrification as not only beneficial but necessary for compliance and competitiveness in an evolving market landscape.

Conclusion

The landscape of commercial trucking is undergoing a significant transformation as electric trucks gain traction across various sectors. With advancements in technology leading to improved range, performance, and affordability, these vehicles present compelling advantages over traditional diesel options.

Fleet operators are recognizing the economic benefits associated with lower fuel costs and reduced maintenance expenses while contributing to environmental sustainability goals through decreased emissions. As charging infrastructure continues to expand through public-private partnerships and government initiatives, many barriers that once hindered adoption are being addressed effectively.

While challenges remain—such as limited range compared to diesel counterparts—strategies exist that enable successful transitions to electrification within fleets. By leveraging pilot programs, optimizing routes for efficiency, investing in training resources, and engaging with manufacturers for ongoing support, fleet managers can navigate this shift successfully.

As regulatory pressures mount globally demanding cleaner transportation solutions alongside growing public awareness regarding climate change impacts, it is evident that the future belongs increasingly to electrified commercial trucking solutions—an evolution poised not only for success but also essentiality within our modern logistics ecosystem.