How Do You Handle Project Cargo

What is project cargo?

Project cargo refers to the transportation of large, complex, or high-value equipment and materials that require specialized handling, planning, and execution. This type of cargo often involves oversized or heavy items that cannot be accommodated in standard shipping containers or through regular freight services.

Project cargo typically includes:

Industrial equipment: Large machinery, turbines, generators, and manufacturing equipment fall under this category. These items often require disassembly for transport and reassembly at the destination.

Construction materials: Structural steel, pre-fabricated building components, and heavy construction equipment are common project cargo items. Their size and weight necessitate careful planning and specialized transport solutions.

Energy sector components: Wind turbine blades, solar panels, oil and gas drilling equipment, and power plant components frequently require project cargo logistics due to their dimensions and fragility.

Aerospace and defense equipment: Aircraft parts, satellites, military vehicles, and other sensitive defense-related cargo often demand project cargo expertise for secure and precise handling.

Mining and agricultural machinery: Excavators, combines, and other large-scale equipment used in these industries often require project cargo solutions for transport to remote locations.

The defining characteristics of project cargo include:

Non-standard dimensions: Project cargo often exceeds the size limits of standard shipping containers or trailers, requiring specialized transport equipment and handling procedures.

Heavy weight: Many project cargo items weigh several tons, necessitating heavy-lift equipment and reinforced transport vehicles.

High value: The cargo often represents significant financial investments, making proper handling and risk management crucial.

Time-sensitive nature: Project cargo is frequently tied to specific project timelines, making punctual delivery essential for avoiding costly delays.

Complex logistics: The transportation of project cargo often involves multiple modes of transport, intricate route planning, and coordination among various stakeholders.

To illustrate the scale and complexity of project cargo, consider the following comparison table:

| Characteristic | Standard Cargo | Project Cargo |

|---|---|---|

| Dimensions | Fits in standard 20′ or 40′ containers | Often exceeds standard container dimensions |

| Weight | Typically under 25 tons per container | Can range from 25 to over 1000 tons |

| Handling | Standard forklifts and cranes | Specialized heavy-lift equipment required |

| Planning | Routine logistics procedures | Extensive pre-planning and route surveys |

| Documentation | Standard shipping documents | Additional permits and specialized documentation |

| Transport modes | Usually single mode (sea, air, or land) | Often multimodal, requiring careful coordination |

Project cargo logistics demands expertise in various areas, including engineering, risk management, and international trade regulations. Logistics providers specializing in project cargo must possess in-depth knowledge of handling oversized and heavy loads, route planning for abnormal transports, and navigating complex customs procedures.

The successful execution of project cargo transportation requires a holistic approach that considers every aspect of the journey, from the initial planning stages to the final delivery at the project site. This comprehensive process ensures that even the most challenging cargo reaches its destination safely, on time, and within budget.

How do you plan for project cargo transportation?

Planning for project cargo transportation is a complex process that requires meticulous attention to detail and extensive coordination among various stakeholders. The success of a project cargo shipment hinges on thorough preparation and strategic planning. Here’s a comprehensive guide to planning project cargo transportation:

Cargo assessment

The first step in planning project cargo transportation is a thorough assessment of the cargo itself. This involves:

Dimensional analysis: Precise measurements of the cargo’s length, width, height, and weight are crucial. These dimensions will determine the type of transport equipment needed and any potential route restrictions.

Fragility evaluation: Assess the cargo’s sensitivity to movement, vibration, or environmental factors. This information guides packaging and handling requirements.

Special handling requirements: Identify any specific needs, such as temperature control, pressurization, or particular orientation during transport.

Route planning and survey

Once the cargo details are established, the next step is to plan the transportation route:

Origin and destination analysis: Evaluate the infrastructure at both the pickup and delivery locations. Consider factors like road conditions, bridge clearances, and port capabilities.

Route survey: Conduct a detailed survey of the entire transportation route. This may involve physical inspections, satellite imagery analysis, and consultation with local authorities.

Obstacle identification: Identify potential obstacles such as low bridges, narrow roads, or weight-restricted areas. Develop strategies to overcome these challenges, which may include route alterations or temporary infrastructure modifications.

Permits and documentation

Project cargo often requires special permits and documentation:

Transportation permits: Obtain necessary permits for oversized or overweight loads from relevant authorities along the entire route.

Customs documentation: Prepare all required customs documents, including detailed cargo descriptions, valuations, and country of origin certificates.

Insurance certificates: Secure appropriate insurance coverage for the cargo and provide necessary documentation.

Equipment and resources allocation

Selecting the right equipment and resources is critical for project cargo transportation:

Transport equipment: Choose appropriate vehicles, such as specialized trailers for road transport or heavy-lift vessels for sea freight.

Handling equipment: Arrange for necessary cranes, forklifts, or other specialized handling equipment at loading and unloading points.

Personnel: Assign experienced staff, including project managers, engineers, and specialized operators, to oversee the transportation process.

Risk assessment and mitigation

Identifying potential risks and developing mitigation strategies is crucial:

Risk identification: Conduct a comprehensive risk assessment, considering factors such as weather conditions, political instability, or potential equipment failures.

Contingency planning: Develop backup plans for various scenarios, including alternative routes or transport modes.

Safety protocols: Establish clear safety procedures for all stages of the transportation process.

Stakeholder coordination

Effective communication and coordination among all involved parties is essential:

Shipper coordination: Work closely with the cargo owner to understand project timelines and specific requirements.

Subcontractor management: If using subcontractors for any part of the transportation, ensure clear communication of expectations and responsibilities.

Authority liaison: Maintain open lines of communication with relevant authorities, including port officials, customs agents, and local governments.

Timeline development

Create a detailed timeline for the entire transportation process:

Milestone identification: Establish key milestones for each stage of the transportation process.

Buffer allocation: Include buffer time in the schedule to account for potential delays or unforeseen circumstances.

Critical path analysis: Identify the critical path of activities and focus resources on ensuring these tasks are completed on time.

Cost estimation and budgeting

Develop a comprehensive budget for the project:

Cost breakdown: Itemize all expected costs, including transportation, handling, permits, and potential contingencies.

Budget approval: Obtain necessary approvals for the budget from relevant stakeholders.

Financial tracking: Implement a system to track expenses throughout the project and manage any budget variances.

To illustrate the complexity of project cargo planning, consider the following comparison table of planning elements for standard cargo versus project cargo:

| Planning Element | Standard Cargo | Project Cargo |

|---|---|---|

| Route planning | Standard shipping lanes | Custom route survey and analysis |

| Equipment needs | Standard containers and vehicles | Specialized trailers, cranes, and vessels |

| Permits | Routine shipping documents | Multiple special permits and authorizations |

| Risk assessment | General transportation risks | Comprehensive risk analysis and mitigation strategies |

| Timeline | Predictable shipping schedules | Custom timeline with multiple coordinated stages |

| Stakeholder involvement | Limited coordination required | Extensive coordination among numerous parties |

| Cost estimation | Standardized pricing models | Custom quotations for each aspect of transport |

Effective planning for project cargo transportation requires a blend of technical expertise, logistical acumen, and strategic thinking. By meticulously addressing each aspect of the planning process, logistics professionals can ensure the successful execution of even the most challenging project cargo shipments.

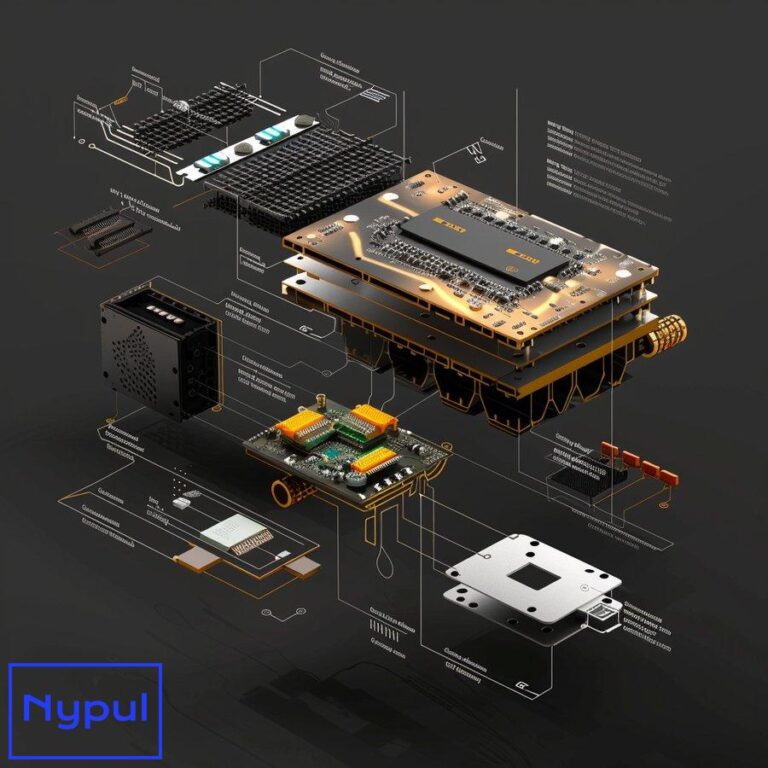

Which specialized equipment is needed for handling project cargo?

Handling project cargo requires a diverse array of specialized equipment designed to manage oversized, heavy, and complex loads safely and efficiently. The selection of appropriate equipment is crucial for ensuring the integrity of the cargo and the safety of personnel involved in the transportation process. Here’s an overview of the specialized equipment commonly used in project cargo handling:

Heavy-lift cranes

Heavy-lift cranes are essential for loading and unloading large project cargo components:

Mobile harbor cranes: These versatile cranes can handle loads up to 300 tons and are commonly used in ports for loading and unloading project cargo from vessels.

Crawler cranes: With their ability to move while carrying loads, crawler cranes are ideal for construction sites and areas with uneven terrain. They can handle weights up to 3,000 tons.

Tower cranes: Used in construction projects, tower cranes can lift heavy loads to great heights, making them crucial for assembling large structures.

Gantry cranes: These cranes span over the cargo area and can lift extremely heavy loads, sometimes exceeding 1,000 tons. They are often used in shipyards and heavy manufacturing facilities.

Specialized trailers

Various types of trailers are designed to transport project cargo by road:

Low-bed trailers: These trailers have a low deck height, allowing for the transport of tall cargo while staying within legal height limits. They can typically handle loads up to 80 tons.

Multi-axle trailers: With multiple axles to distribute weight, these trailers can transport extremely heavy loads, sometimes exceeding 300 tons.

Extendable trailers: These trailers can be lengthened to accommodate oversized cargo, with some models extending up to 100 feet.

Self-propelled modular transporters (SPMTs)

SPMTs are highly versatile vehicles used for moving extremely heavy and large project cargo:

Modular design: SPMTs consist of multiple axle lines that can be combined to create platforms capable of carrying thousands of tons.

Maneuverability: With independent steering of each axle, SPMTs can move in any direction, making them ideal for navigating tight spaces.

Load distribution: Advanced hydraulic systems ensure even weight distribution, protecting both the cargo and the transport surface.

Specialized vessels

Several types of vessels are designed specifically for project cargo transport:

Heavy-lift vessels: These ships are equipped with cranes capable of lifting hundreds of tons, allowing them to load and unload project cargo without relying on port facilities.

Roll-on/roll-off (RoRo) vessels: With ramps that allow wheeled cargo to be driven on and off, RoRo vessels are ideal for transporting large vehicles and machinery.

Semi-submersible vessels: These ships can partially submerge, allowing floating cargo to be loaded directly onto the deck. They are often used for transporting offshore platforms and other massive structures.

Handling and securing equipment

Various specialized tools and equipment are used to secure and manipulate project cargo:

Spreader beams: These beams distribute the weight of the load across multiple lifting points, ensuring stable and safe lifting of large cargo.

Lifting slings: High-strength slings made of synthetic materials or steel wire are used to lift and secure cargo during transport.

Hydraulic jacking systems: These systems allow for precise lifting and positioning of heavy loads in confined spaces.

Cargo securing systems: Specialized lashing equipment, including chains, turnbuckles, and custom-designed brackets, is used to secure cargo during transport.

Specialized containers and platforms

Modified containers and platforms are used to accommodate non-standard project cargo:

Flat rack containers: These containerized platforms have collapsible sides, allowing for the transport of oversized cargo within the container shipping system.

Open-top containers: With removable roofs, these containers can accommodate tall cargo while still providing some protection from the elements.

Platforms: Custom-built platforms are designed to securely hold specific pieces of project cargo during transport.

To illustrate the capabilities of various specialized equipment used in project cargo handling, consider the following comparison table:

| Equipment Type | Maximum Capacity | Key Features | Typical Applications |

|---|---|---|---|

| Mobile harbor crane | Up to 300 tons | Versatility, mobility | Port operations |

| Crawler crane | Up to 3,000 tons | All-terrain capability | Construction sites |

| Low-bed trailer | Up to 80 tons | Low deck height | Road transport of tall cargo |

| SPMT | Over 10,000 tons (combined) | Extreme maneuverability | Moving massive structures |

| Heavy-lift vessel | Up to 14,000 tons (crane capacity) | Self-sufficient cargo handling | Ocean transport of large equipment |

| Spreader beam | Varies (up to several hundred tons) | Even load distribution | Lifting oversized cargo |

The selection of appropriate specialized equipment for handling project cargo depends on various factors, including the cargo’s dimensions and weight, the transportation route, and the specific requirements of the project. Logistics professionals must carefully evaluate these factors to choose the most suitable equipment for each stage of the project cargo transportation process.

By utilizing the right combination of specialized equipment, project cargo handlers can ensure the safe, efficient, and timely delivery of even the most challenging loads. This expertise in equipment selection and utilization is a key differentiator in the project cargo logistics industry, enabling the successful execution of complex transportation projects.

What are the key transportation modes for project cargo?

Project cargo transportation often involves a combination of different modes to move oversized or heavy items from origin to destination. Each mode offers unique advantages and challenges, and the selection depends on factors such as cargo characteristics, route constraints, and project timelines. Here’s an in-depth look at the key transportation modes for project cargo:

Ocean freight

Ocean transportation is the most common mode for long-distance project cargo shipments:

Breakbulk shipping: This traditional method involves loading individual pieces of cargo directly onto a vessel. It’s ideal for oversized items that don’t fit into containers.

Heavy-lift vessels: Specialized ships equipped with powerful onboard cranes can handle extremely heavy and large cargo pieces.

Roll-on/Roll-off (RoRo) vessels: These ships are designed to accommodate wheeled cargo, making them suitable for transporting large vehicles and machinery.

Container ships: While not typically associated with project cargo, container ships can transport smaller project components using flat racks or open-top containers.

Advantages of ocean freight for project cargo:

– Cost-effective for long-distance transport

– Ability to handle extremely large and heavy items

– Established global network of ports and shipping lanes

Challenges:

– Longer transit times compared to air freight

– Susceptibility to weather-related delays

– Potential for cargo damage due to sea conditions

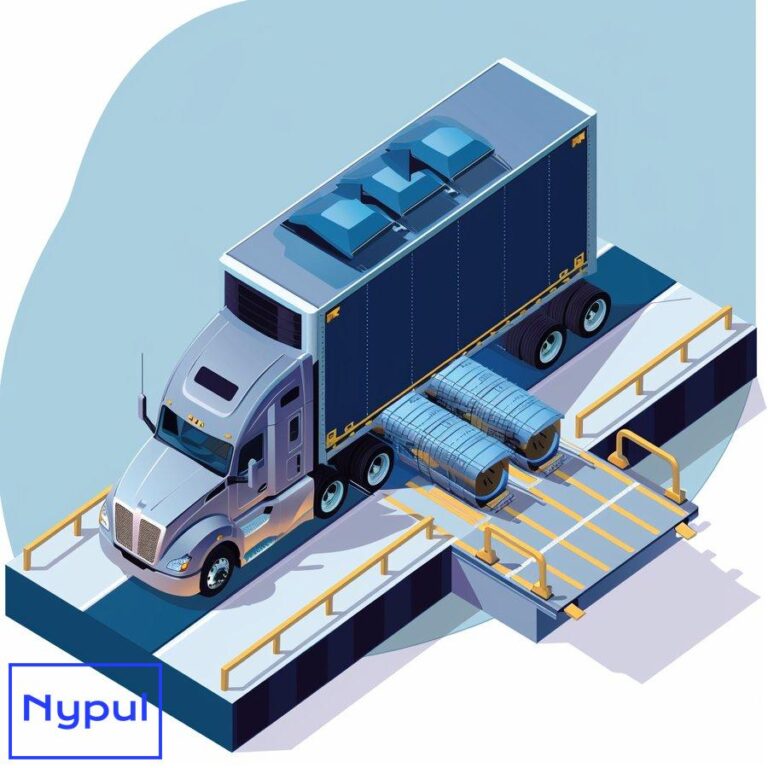

Road transport

Road transportation is crucial for the first and last mile of most project cargo shipments:

Heavy haul trucking: Specialized trucks and trailers are used to transport oversized and overweight loads on highways and local roads.

Self-propelled modular transporters (SPMTs): These highly maneuverable vehicles are used for short-distance transport of extremely heavy loads, often within industrial sites or ports.

Advantages of road transport for project cargo:

– Flexibility in routing and scheduling

– Door-to-door delivery capability

– Ability to reach remote locations

Challenges:

– Weight and dimension restrictions on public roads

– Need for special permits and escorts

– Potential for traffic-related delays

Rail transport

Rail transportation can be an efficient option for long-distance overland project cargo shipments:

Heavy haul rail cars: Specialized rail cars are designed to carry extremely heavy loads, sometimes exceeding 400 tons per car.

Depressed center flatcars: These cars have a lowered deck to accommodate tall cargo while staying within clearance limits.

Advantages of rail transport for project cargo:

– Cost-effective for long-distance inland transport

– Ability to move very heavy loads

– Reduced impact of traffic congestion compared to road transport

Challenges:

– Limited flexibility in routing

– Potential clearance issues with tunnels and bridges

– Dependence on existing rail infrastructure

Air freight

While less common due to size and weight limitations, air transport can be crucial for time-sensitive project cargo:

Charter flights: Entire aircraft are chartered to transport project cargo, allowing for customized loading and handling procedures.

Specialized cargo aircraft: Some aircraft, like the Antonov An-225, are designed specifically for transporting oversized and heavy cargo.

Advantages of air freight for project cargo:

– Fastest transportation mode for long distances

– Reduced risk of cargo damage due to shorter transit times

– Ability to reach remote locations quickly

Challenges:

– High cost compared to other modes

– Significant size and weight limitations

– Limited availability of specialized aircraft

Inland waterways

Rivers and canals can provide efficient transportation options for project cargo in certain regions:

Barges: These flat-bottomed vessels can transport large and heavy cargo pieces along rivers and canals.

Push-tow systems: Multiple barges are connected and pushed by a tugboat, allowing for the transport of substantial volumes of project cargo.

Advantages of inland waterway transport for project cargo:

– Cost-effective for bulk transport

– Ability to handle oversized cargo

– Reduced impact on road congestion

Challenges:

– Limited to areas with navigable waterways

– Potential for seasonal variations in water levels

– Slower transit times compared to road or rail

Multimodal transport

Most project cargo shipments involve a combination of transportation modes:

Intermodal solutions:Multimodal transport

Most project cargo shipments involve a combination of transportation modes:

Intermodal solutions: This approach integrates multiple modes of transport, such as road, rail, and ocean freight, to optimize efficiency and reduce costs. For example, a project cargo shipment might travel by truck to a port, then by ship to a destination country, and finally by rail or truck to the final site.

Coordinated logistics: Effective multimodal transport requires careful planning and coordination among various carriers and logistics providers to ensure seamless transitions between modes. This includes managing schedules, documentation, and handling requirements.

Advantages of multimodal transport for project cargo:

– Flexibility in choosing the most efficient routes and modes

– Cost savings by leveraging the strengths of each mode

– Enhanced reliability through coordinated logistics

Challenges:

– Increased complexity in planning and execution

– Potential for delays at transfer points

– Need for comprehensive documentation across different modes

In summary, selecting the right transportation mode for project cargo is critical to ensuring timely delivery while managing costs and risks. Each mode has its unique advantages and challenges, and logistics professionals must carefully evaluate the specific needs of each shipment to determine the optimal combination of transportation methods.

How do you navigate customs and documentation for project cargo?

Navigating customs and documentation for project cargo is a critical aspect of the logistics process. Given the complex nature of project cargo, proper documentation is essential for ensuring compliance with international trade regulations and avoiding delays at borders. Here’s a detailed guide on how to effectively manage customs and documentation for project cargo:

Understanding customs regulations

Each country has its own customs regulations that govern the import and export of goods. Understanding these regulations is crucial for successful project cargo transportation:

Tariff classifications: Determine the correct tariff classification for your cargo. This classification affects duty rates and import/export restrictions.

Import/export permits: Identify any specific permits required for your cargo type. Certain goods may require additional approvals from government agencies.

Restricted items: Be aware of any restrictions or prohibitions on specific items in the destination country. This includes items that may be subject to export controls or trade sanctions.

Documentation requirements

Proper documentation is essential for smooth customs clearance. Key documents typically required for project cargo include:

Bill of Lading (BOL): A legal document issued by the carrier that serves as a receipt for the cargo and outlines the terms of transport.

Commercial Invoice: This document provides details about the transaction, including descriptions of the goods, their value, and payment terms.

Packing List: A detailed list that outlines all items included in the shipment, including dimensions, weights, and packaging details.

Certificate of Origin: This document certifies where the goods were manufactured or produced, which may affect duty rates.

Customs Declaration Form: A form submitted to customs authorities detailing the contents of the shipment, its value, and other relevant information.

Insurance Certificates: Proof of insurance coverage for the cargo during transit is often required by customs authorities.

To illustrate the importance of proper documentation in project cargo logistics, consider this comparison table:

| Document Type | Purpose | Importance |

|---|---|---|

| Bill of Lading | Receipt for cargo; outlines transport terms | Legal protection during transit |

| Commercial Invoice | Details transaction; includes value | Determines duty rates |

| Packing List | Lists all items; provides dimensions/weights | Essential for customs clearance |

| Certificate of Origin | Certifies manufacturing location | Affects duty rates |

| Customs Declaration Form | Details shipment contents | Required for customs clearance |

| Insurance Certificates | Proof of coverage | Protects against loss/damage |

Customs clearance process

The customs clearance process can be intricate, especially for project cargo:

-

Pre-arrival preparations: Submit all required documentation to customs authorities before arrival at the port or border crossing. This helps expedite clearance upon arrival.

-

Customs broker engagement: Consider hiring a licensed customs broker who specializes in project cargo. They can help navigate complex regulations and ensure compliance with all requirements.

-

Duty payments: Be prepared to pay any applicable duties or taxes upon clearance. Understanding duty rates in advance can help manage costs effectively.

-

Inspection readiness: Some shipments may be subject to inspection by customs officials. Ensure that all documentation is accurate and readily available to facilitate this process.

-

Post-clearance compliance: After clearance, maintain records of all documentation related to the shipment for future reference or audits by customs authorities.

What are the main challenges in project cargo logistics?

Project cargo logistics presents unique challenges that require specialized knowledge and expertise to navigate effectively. Understanding these challenges is essential for successful planning and execution. Here are some of the main challenges faced in project cargo logistics:

Complexity of operations

Project cargo often involves multiple stakeholders, including shippers, carriers, port authorities, customs officials, and end-users:

-

Coordination difficulties: Managing communication among various parties can be challenging due to differing priorities and timelines.

-

Scheduling conflicts: Aligning schedules across multiple transport modes can lead to delays if not managed effectively.

-

Resource allocation: Ensuring that adequate resources are available at each stage of transport requires careful planning.

Regulatory compliance

Navigating international trade regulations can be daunting:

-

Customs regulations variability: Different countries have varying customs requirements that must be adhered to.

-

Documentation accuracy: Inaccurate or incomplete documentation can lead to delays or fines during customs clearance.

-

Permit acquisition delays: Obtaining necessary permits for oversized loads can be time-consuming due to bureaucratic processes.

Logistical constraints

Project cargo often faces logistical hurdles due to its size and weight:

-

Route limitations: Many roads have weight restrictions or low bridges that prevent oversized loads from passing through.

-

Infrastructure inadequacies: Ports or terminals may lack facilities capable of handling large equipment efficiently.

-

Transport equipment availability: Specialized equipment may not always be readily available when needed.

To illustrate these challenges further, consider this comparison table highlighting operational complexities versus standard freight operations:

| Challenge Type | Project Cargo Logistics | Standard Freight Operations |

|---|---|---|

| Coordination | Multiple stakeholders with varied interests | Fewer parties involved |

| Regulatory Compliance | Complex international regulations | More straightforward regulations |

| Logistical Constraints | Route limitations due to size/weight | Standard routes available |

| Resource Allocation | Requires specialized equipment/resources | Generally standard resources |

How can technology improve project cargo handling?

Technology plays a pivotal role in enhancing efficiency, safety, and transparency in project cargo handling. The integration of advanced technologies into logistics processes can significantly mitigate challenges associated with transporting oversized or heavy loads. Here are several ways technology improves project cargo handling:

Digital tracking systems

Real-time tracking solutions allow stakeholders to monitor shipments throughout their journey:

-

GPS tracking devices provide precise location data for vehicles transporting project cargo.

-

IoT sensors, when applied to containers or equipment, can monitor conditions such as temperature or humidity during transport.

Benefits:

– Enhanced visibility into shipment status

– Improved communication among stakeholders

– Ability to proactively address potential delays

Automated documentation management

Digital platforms streamline documentation processes:

-

Electronic Data Interchange (EDI) allows for seamless sharing of documents between parties involved in the transportation process.

-

Automated systems can generate required documents based on predefined templates, reducing errors associated with manual entry.

Benefits:

– Faster processing times for documentation

– Reduced risk of inaccuracies

– Improved compliance with regulatory requirements

Advanced route planning software

Sophisticated software tools assist in optimizing routes for project cargo:

-

These tools analyze various factors such as road conditions, traffic patterns, weight restrictions, and infrastructure capabilities.

-

AI-driven algorithms can suggest alternative routes based on real-time data inputs.

Benefits:

– More efficient routing leads to reduced transit times

– Enhanced ability to avoid obstacles or restrictions

– Improved overall cost-effectiveness

To illustrate how technology enhances efficiency in project cargo handling further, consider this comparison table:

| Technology Type | Functionality | Benefits |

|---|---|---|

| GPS Tracking | Real-time location monitoring | Increased visibility |

| IoT Sensors | Condition monitoring during transit | Enhanced safety |

| EDI | Streamlined document sharing | Faster processing |

| Automated Systems | Document generation | Reduced errors |

| Route Planning Software | Optimized routing analysis | Cost-effective transportation |

What factors influence project cargo costs?

Understanding the factors that influence costs associated with project cargo is crucial for effective budgeting and financial planning. Several elements contribute to overall expenses in transporting oversized or heavy loads:

Cargo characteristics

The dimensions and weight of the cargo significantly impact costs:

-

Size limitations: Larger items often require specialized equipment or additional permits that increase expenses.

-

Weight considerations: Heavier loads may necessitate more robust transport vehicles or additional escorts during transit.

Costs associated with these factors can vary widely based on specific requirements related to size and weight.

Transportation mode selection

The choice of transportation mode directly affects overall costs:

-

Ocean freight vs air freight: Air freight is typically more expensive than ocean freight but offers faster transit times.

-

Multimodal solutions: Combining different modes may lead to cost savings but requires careful coordination among carriers.

Understanding how each mode impacts pricing helps logistics professionals make informed decisions about transportation strategies.

To illustrate how different factors influence costs further, consider this comparison table highlighting key cost drivers in project cargo logistics:

| Cost Factor | Description | Impact on Costs |

|---|---|---|

| Cargo Characteristics | Size/weight affecting equipment needs | Higher costs for larger/heavier items |

| Transportation Mode | Choice between ocean/air/road/rail | Varies significantly based on mode |

| Route Complexity | Permits needed due to route restrictions | Additional fees may apply |

| Handling Requirements | Specialized equipment/personnel needed | Increased labor/equipment costs |

By understanding these cost drivers, stakeholders involved in project cargo logistics can develop more accurate budgets while identifying opportunities for cost savings through strategic planning and execution.

In conclusion, effective management of project cargo requires a multifaceted approach that addresses unique challenges while leveraging technology advancements. By understanding key elements such as transportation modes, regulatory compliance needs, logistical constraints, cost factors, and technological improvements—logistics professionals can ensure successful execution while minimizing risks associated with transporting complex loads.