How Do You Mitigate Port Congestion

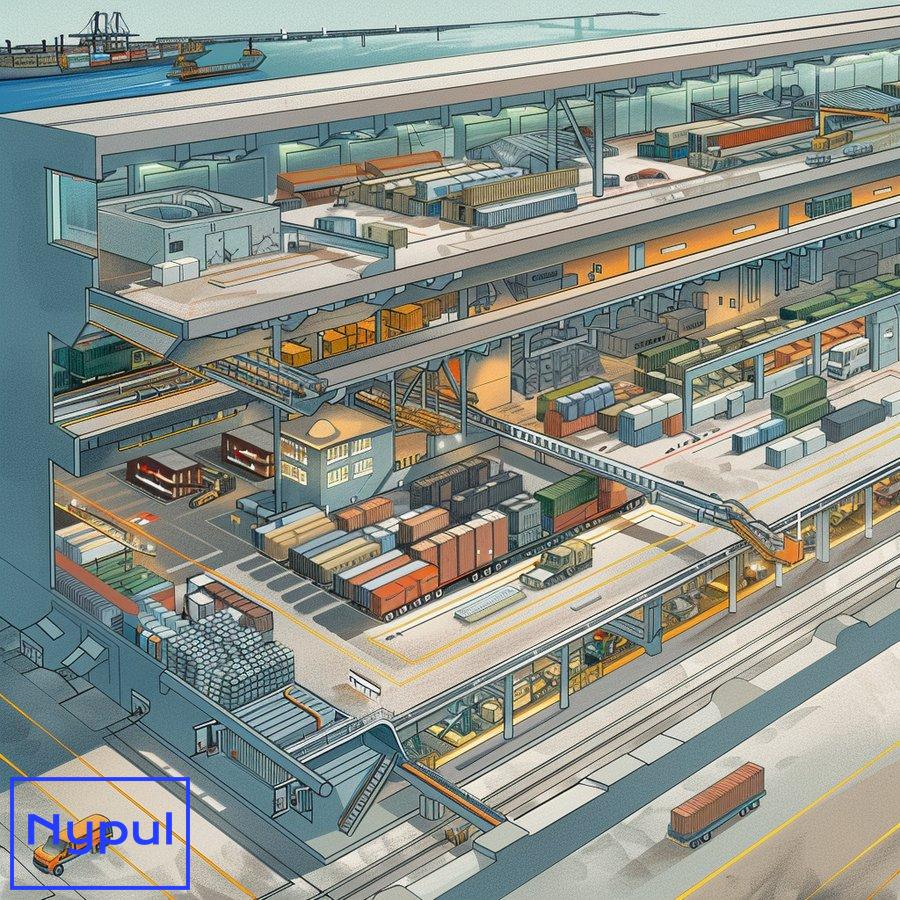

What is port congestion and why does it occur?

Port congestion happens when ships arrive at a port faster than the port can handle the loading and unloading of cargo. This leads to long queues of vessels waiting at anchorage for an available berth.

There are several key factors that contribute to port congestion:

High cargo volume and limited capacity: When cargo volume exceeds a port’s handling capacity, it causes bottlenecks and delays. Ports may lack sufficient berths, cranes, storage space, or inland transportation to efficiently process the inflow of ships and goods.

Labor shortages and disruptions: Efficient port operations rely on having enough skilled workers, including crane operators, truck drivers, and logistics personnel. Labor shortages, disputes, or strikes can severely slow down cargo handling and cause congestion.

Poor scheduling and communication: Lack of coordination between the arrival times of ships, availability of port resources, and inland transport can result in congestion. If there are communication gaps between ocean carriers, ports, and land transport providers, it leads to inefficient scheduling and overbooking of berths.

Weather and environmental disruptions: Adverse weather conditions like storms, fog, or wind can force ports to temporarily halt operations for safety reasons. Natural disasters such as hurricanes or floods can damage port infrastructure and cause extended disruptions that back up ship traffic.

Inefficient customs and regulatory processes: Slow or complex customs procedures, inspections, and paperwork can delay the release of cargo from ports. Stringent security or environmental regulations can also increase processing times if ports lack the systems to expedite compliance.

The compounding effect of these factors turns ports into congestion points that can have far-reaching impacts on global supply chains. Congested ports mean longer shipping times, higher transportation costs, and knock-on delays for manufacturers and consumers waiting on critical goods.

Some key congestion metrics that ports monitor include:

| Metric | Description | Ideal Range |

|---|---|---|

| Vessel waiting time | Time from ship arrival to berthing | < 24 hours |

| Berth occupancy rate | Percent of time berths are occupied | 65-75% |

| Crane productivity | Container moves per hour per crane | 25-40 |

| Truck turnaround time | Time from truck entry to exit | 30-60 min |

| Dwell time | Time cargo remains in port | 3-5 days |

Ports aim to minimize vessel wait times, optimize berth and crane utilization, efficiently process trucks, and clear cargo quickly to prevent congestion. However, the dynamic nature of maritime trade means that ports are susceptible to spikes in volume that can overwhelm their capacity and disrupt the delicate balance needed for fluid operations.

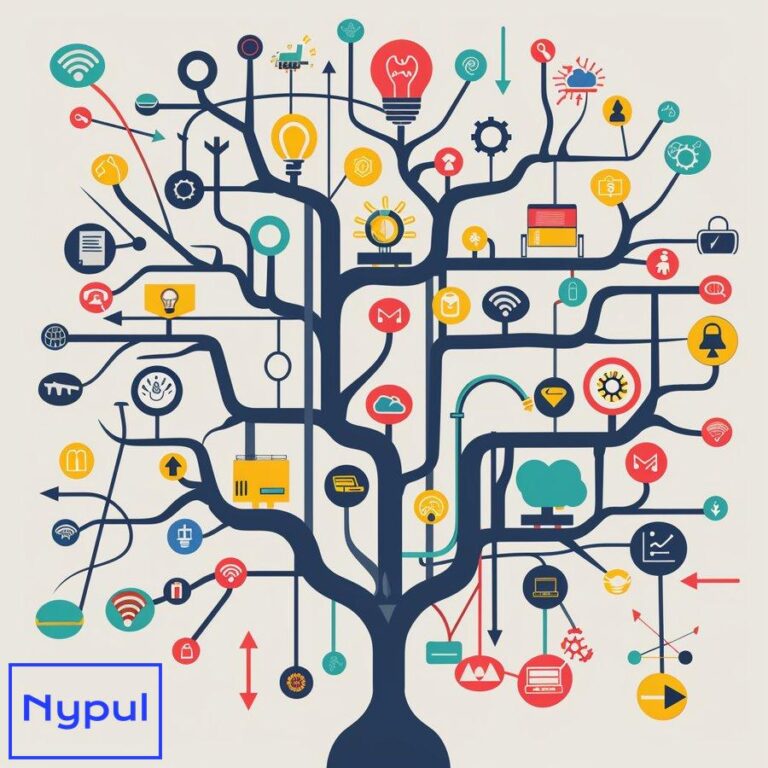

How can technology mitigate port congestion?

Technology plays a vital role in giving ports the tools to predict, monitor, and respond to congestion. By digitizing processes and leveraging data analytics, ports can make smarter decisions to keep cargo flowing smoothly.

Vessel Traffic Management Systems: Modern ports use advanced software to track real-time positioning data of every vessel in their waters. This gives port authorities and ocean carriers visibility to manage traffic, optimize berthing assignments, and adjust arrival schedules to avoid congestion.

Internet of Things (IoT) Sensors: Smart sensors on cranes, vehicles, and infrastructure feed real-time data to port management systems. This allows ports to monitor equipment health, automate fault detection, and optimize maintenance schedules to maximize asset uptime and productivity.

Artificial Intelligence (AI) and Machine Learning: AI algorithms can analyze huge volumes of historical and real-time port data to generate valuable insights. Machine learning models can predict congestion based on weather patterns, shipping volumes, and resource availability. This allows ports to proactively allocate labor, equipment, and storage space.

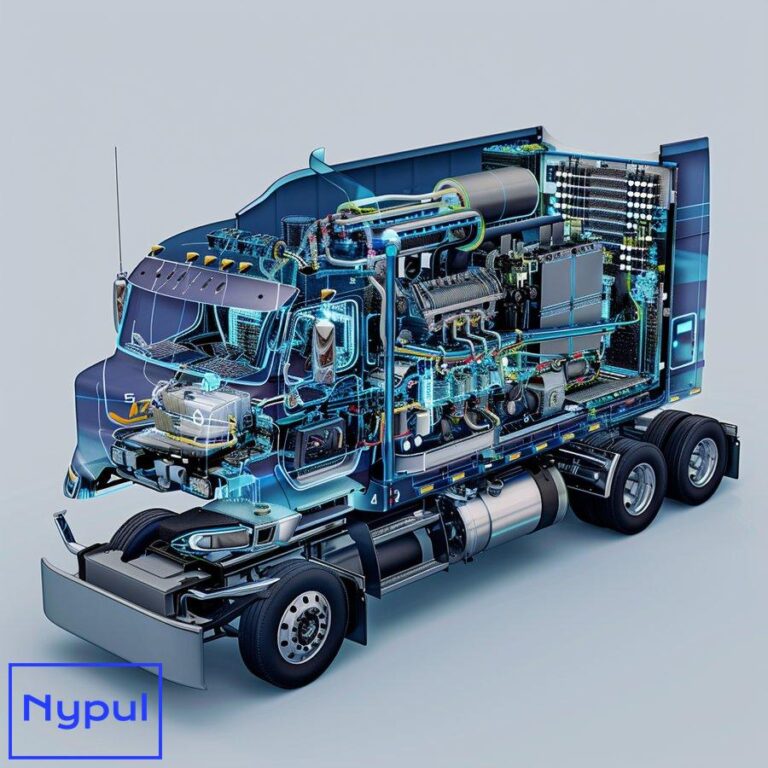

Automation and Robotics: Automated cargo handling equipment like stacking cranes, guided vehicles, and robotic arms can significantly boost the speed and accuracy of loading/unloading operations. Automation reduces human error, increases safety, and allows ports to run 24/7 without labor constraints.

Blockchain and Distributed Ledgers: Blockchain technology enables secure, transparent sharing of data across the complex web of port stakeholders. Smart contracts can automate paperwork, while distributed ledgers give real-time visibility of cargo status. This streamlines customs clearance and inland transportation.

Digital Twins: Some leading ports are developing virtual replicas of their entire operations using real-time data. These digital twins allow ports to simulate “what-if” scenarios, optimize resource allocation, and test the impact of operational changes before implementing them.

5G and Edge Computing: 5G networks enable high-speed, low-latency connectivity across the port ecosystem. Edge computing processes data closer to the source, allowing for real-time decision making. Together, 5G and edge computing will unlock new possibilities for autonomous vehicles, remote-controlled cranes, and intelligent automation.

By embracing these technologies, ports can transition from siloed, reactive operations to data-driven, proactive ecosystems. Digitalization not only mitigates congestion, but also positions ports to handle the ever-increasing demands of global trade.

What operational strategies can ports implement to reduce congestion?

While technology provides the tools, ports must also adopt proven operational strategies to keep congestion at bay. Key approaches include:

Appointment Systems for Trucks: Implementing mandatory appointment systems for trucks to pick up or drop off containers can drastically reduce gate congestion. By spreading truck arrivals evenly across the day, ports avoid peak congestion and improve turnaround times.

Extended Gate Hours: Keeping port gates open for longer hours, especially at night and on weekends, increases the window for trucks to access the port. This reduces daytime congestion and allows ports to better utilize their resources.

Improved Yard Planning: Strategic stacking and segregation of containers in the yard can minimize unnecessary moves and speed up loading/unloading. For example, grouping containers by vessel, size, or destination allows cranes to work more efficiently.

Flexible Labor Scheduling: Having the ability to quickly scale up labor during peak periods is critical for congestion management. Ports can cross-train workers, use temporary staffing, or implement overtime to meet surges in demand.

Off-dock Container Storage: Moving excess containers to off-dock storage facilities frees up valuable yard space and reduces on-terminal congestion. This allows ports to focus on their core operations of loading and unloading ships.

Intermodal Rail Prioritization: Encouraging the use of on-dock or near-dock rail for inland cargo transport can alleviate pressure on port gates and roads. Rail is more efficient for long-haul freight and reduces the number of trucks entering the port.

Vessel Schedule Optimization: Collaborating with ocean carriers to optimize vessel arrival schedules can prevent bunching of ships and spread out cargo volumes. This may involve adjusting sailing speeds, rerouting ships, or shifting to off-peak berthing windows.

Performance Metrics and KPIs: Defining, measuring, and reporting key performance indicators (KPIs) allows ports to identify bottlenecks, track progress, and drive continuous improvement. Common KPIs include:

- Vessel turnaround time

- Crane moves per hour

- Truck gate throughput

- Container dwell time

- Equipment utilization rates

By setting targets, benchmarking against industry peers, and regularly reviewing KPIs, ports can stay focused on operational excellence.

Implementing these strategies requires change management, stakeholder buy-in, and a continuous improvement mindset. But the payoff in terms of reduced congestion, increased efficiency, and improved customer service can be substantial.

How does collaboration between stakeholders help alleviate port congestion?

Port congestion is not a problem that ports can solve in isolation. It requires close coordination and collaboration among all stakeholders in the maritime supply chain.

Ocean Carriers: Shipping lines are the ports’ primary customers and have a huge impact on congestion levels. By sharing vessel schedules, cargo forecasts, and booking data in advance, carriers can help ports plan resources and avoid overbooking. Carriers can also adjust their schedules to avoid peak congestion periods and spread out cargo volumes.

Terminal Operators: As the direct managers of port operations, terminal operators are on the front lines of congestion management. They need to work closely with carriers, truckers, and railroads to synchronize cargo handoffs and keep everyone informed of any disruptions. Collaboration on data sharing, performance reporting, and process improvement is essential.

Trucking Companies: Drayage carriers play a critical role in moving containers in and out of ports. By participating in appointment systems, providing accurate ETAs, and sharing real-time tracking data, truckers can help ports better plan gate operations and yard assignments. Collaboration on off-peak hours, chassis management, and empty container returns can also reduce congestion.

Railroads: On-dock and near-dock rail provide a vital relief valve for port congestion by shifting long-haul freight from trucks. Rail operators need to collaborate with ports on infrastructure planning, train scheduling, and car supply to maximize rail throughput. Seamless data exchange on cargo status and train arrivals/departures is critical.

Cargo Owners: Shippers and consignees can contribute to congestion relief by providing accurate and timely booking information, being flexible on delivery dates, and promptly picking up import containers. They can also collaborate with ports and carriers on off-peak delivery programs and container reuse initiatives.

Government Agencies: Customs, border protection, and transportation authorities play a key role in facilitating trade flows and ensuring compliance. Collaboration on data harmonization, risk assessment, and inspection processes can help streamline cargo clearance and reduce congestion. Governments can also provide funding and policy support for port infrastructure and technology upgrades.

Industry Associations: Organizations like the International Association of Ports and Harbors (IAPH) and the World Shipping Council (WSC) provide forums for stakeholders to share best practices, develop standards, and advocate for industry interests. Collaboration through these groups can drive systemic improvements in port performance and resilience.

Effective collaboration requires trust, transparency, and a willingness to share data and resources for the greater good. Some key enablers of collaboration include:

- Secure digital platforms for real-time data sharing

- Standardized data formats and APIs for interoperability

- Regular performance reporting and benchmarking

- Joint planning and forecasting sessions

- Shared KPIs and incentive structures

- Dedicated relationship managers and governance committees

By working together, stakeholders can unlock efficiencies, reduce waste, and create a more resilient and sustainable maritime supply chain that benefits everyone.

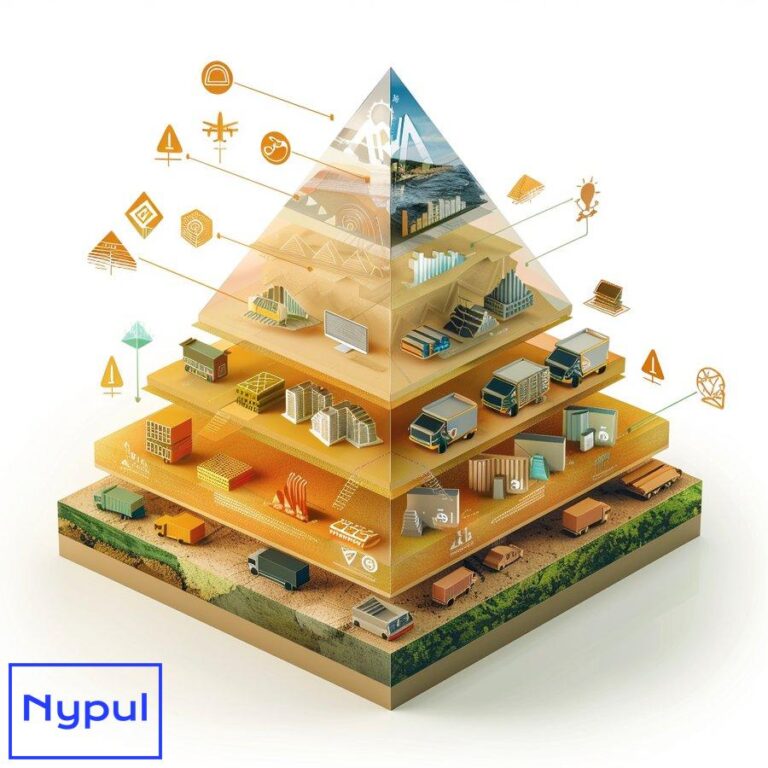

What infrastructure improvements are essential for congestion mitigation?

Investing in modern, efficient infrastructure is a key strategy for ports to stay ahead of congestion as trade volumes continue to grow. Some critical infrastructure improvements include:

Berth Expansion and Deepening: Adding new berths and deepening existing ones allows ports to handle more and larger vessels simultaneously. This increases overall capacity and reduces the likelihood of ships waiting for an open berth.

Larger Cranes and Yard Equipment: Upgrading to taller, wider, and faster ship-to-shore cranes enables ports to load and unload mega-vessels more efficiently. Investing in modern yard cranes, stackers, and tractors increases the speed and density of container handling and storage.

Automated Gates and Traffic Flows: Implementing automated gate systems with OCR cameras, RFID readers, and weigh-in-motion scales can significantly speed up truck processing and reduce congestion. Redesigning traffic flows with dedicated lanes, staging areas, and digital signage can also improve circulation and safety.

Expanded Rail Infrastructure: Building new on-dock or near-dock rail terminals and adding track capacity allows ports to move more cargo by train. This reduces reliance on trucks and eases congestion on port roads and gates. Double-stack rail capability and electrification can further boost efficiency and sustainability.

Smart Lighting and Utilities: Upgrading to LED lighting, solar power, and smart grid systems can reduce energy costs, improve visibility, and enhance safety for 24/7 port operations. Resilient backup power and water supplies are also critical for business continuity during disruptions.

Cybersecurity and IT Upgrades: As ports become more digitized, investing in robust cybersecurity measures, redundant networks, and disaster recovery systems is essential to protect against cyber threats and ensure reliability. Upgrading IT infrastructure and software can also enable faster data processing and decision-making.

Intermodal Connectors: Improving the roads, bridges, and tunnels that connect ports to highways and rail networks is critical for smooth cargo flows. Collaborating with local and regional governments on infrastructure planning and funding can help ports stay ahead of congestion bottlenecks.

Green Infrastructure: Investing in shore power systems, electric charging stations, and alternative fuel facilities can help ports reduce emissions and comply with environmental regulations. Green infrastructure can also make ports more attractive to shipping lines and investors focused on sustainability.

Ports need to prioritize infrastructure investments based on their unique growth plans, customer needs, and financial resources. Some key considerations include:

- Aligning infrastructure with demand forecasts and industry trends

- Conducting cost-benefit analyses and feasibility studies

- Securing funding through public-private partnerships, grants, and user fees

- Engaging stakeholders and communities in planning and design

- Building in flexibility and scalability for future growth

- Ensuring compatibility with existing systems and standards

Infrastructure projects can take years to plan, approve, and construct, so ports need to take a long-term view and start early. By proactively investing in the right infrastructure, ports can create a strong foundation for efficient, resilient, and sustainable operations that can weather any storm of congestion.

How do policy and regulatory measures impact port congestion?

Government policies and regulations play a significant role in shaping the operating environment for ports and their ability to manage congestion. Some key areas of impact include:

Trade Facilitation: Policies that simplify and harmonize customs procedures, documentation, and inspections can greatly reduce congestion at ports. For example, the World Trade Organization’s Trade Facilitation Agreement (TFA) sets global standards for streamlining border processes and promoting cooperation among agencies.

Infrastructure Investment: Governments can provide funding, financing, and incentives for ports to invest in congestion-reducing infrastructure like berths, cranes, and intermodal connectors. Programs like the US Department of Transportation’s INFRA grants and the EU’s Connecting Europe Facility support critical port projects.

Environmental Regulations: Policies aimed at reducing air and water pollution from ships and port operations can impact congestion by requiring changes to equipment, fuels, and processes. For example, the International Maritime Organization’s (IMO) low-sulfur fuel mandate has led some ports to invest in shore power and LNG bunkering facilities.

Security and Safety: Regulations related to port security, worker safety, and cargo screening can affect the speed and efficiency of port operations. For example, the US SAFE Port Act requires 100% scanning of inbound containers, which can slow down cargo flows if not properly resourced.

Competition and Antitrust: Policies that promote fair competition and prevent anticompetitive practices in the maritime industry can help ensure that ports are operating efficiently and not contributing to congestion.