How Does Weather Impact Logistics

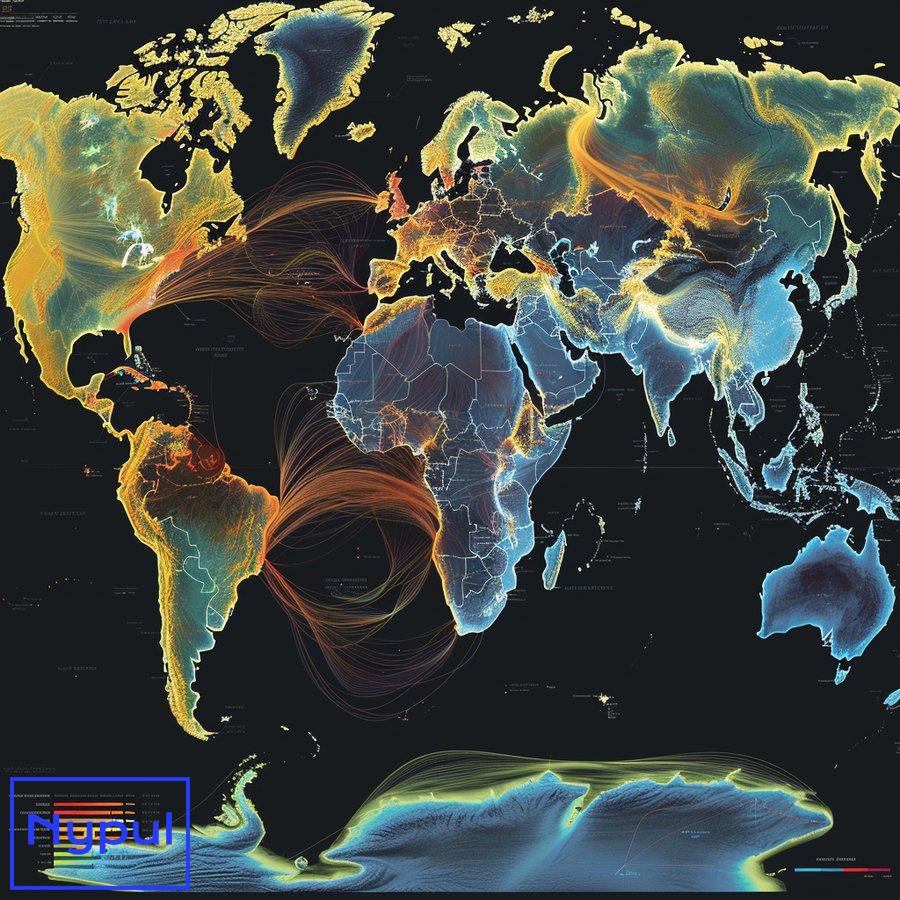

Weather plays a crucial role in the complex world of logistics, influencing every aspect of the supply chain from transportation to inventory management. This article delves into the multifaceted relationship between weather and logistics, exploring its impacts on various modes of transportation, economic consequences, risk mitigation strategies, and the role of technology in addressing weather-related challenges.

How does weather affect different modes of transportation in logistics?

Weather conditions significantly impact all modes of transportation used in logistics, each with its unique vulnerabilities and challenges. Understanding these effects is crucial for logistics managers and transportation planners to ensure efficient and safe operations.

Road Transportation

Trucks, the backbone of many logistics operations, face numerous weather-related challenges. Heavy rain, snow, and ice can make roads slippery and dangerous, leading to accidents and delays. Extreme temperatures can affect vehicle performance, with cold weather potentially causing engine problems and hot weather increasing the risk of tire blowouts.

Visibility issues caused by fog, heavy rain, or snowstorms can slow down traffic or even lead to road closures. In severe cases, flooding can render roads impassable, forcing trucks to take longer alternative routes or halt operations entirely.

Air Transportation

Air freight is particularly susceptible to weather disruptions. Strong winds, thunderstorms, and heavy snowfall can lead to flight delays or cancellations. Fog and low visibility conditions may force airports to reduce their operational capacity or close temporarily.

Extreme temperatures also pose challenges for air transportation. Very hot weather can affect aircraft performance, potentially requiring weight restrictions that limit cargo capacity. Cold weather, on the other hand, necessitates de-icing procedures, which can cause delays and increase operational costs.

Sea Transportation

Maritime logistics face unique weather-related challenges. High winds and rough seas can slow down vessels, increasing fuel consumption and transit times. In extreme cases, storms may force ships to alter their routes or seek shelter in ports, causing significant delays.

Ice formation in colder regions can obstruct shipping lanes, requiring the use of icebreakers or alternative routes. Fog can reduce visibility in busy ports, slowing down loading and unloading operations or even causing collisions.

Rail Transportation

While generally more resilient to weather conditions than other modes, rail transportation is not immune to weather impacts. Heavy snowfall can block tracks, requiring snow removal operations. Extreme heat can cause rail tracks to expand and buckle, necessitating speed restrictions to ensure safety.

Flooding poses a significant risk to rail infrastructure, potentially washing out tracks or damaging signaling equipment. Lightning strikes can also disrupt signaling systems, causing delays and safety concerns.

Intermodal Transportation

Weather impacts on intermodal transportation are compounded, as disruptions in one mode can have cascading effects on others. For example, if air freight is delayed due to a storm, the trucks scheduled to pick up the cargo at the destination airport will also be affected, potentially disrupting the entire supply chain.

The table below summarizes the primary weather-related challenges for each transportation mode:

| Transportation Mode | Primary Weather Challenges |

|---|---|

| Road | Slippery conditions, reduced visibility, flooding |

| Air | Wind, storms, fog, extreme temperatures |

| Sea | High winds, rough seas, ice, fog |

| Rail | Snow, extreme heat, flooding, lightning |

| Intermodal | Compounded effects from multiple modes |

Understanding these weather-related impacts on different transportation modes allows logistics professionals to develop more resilient and flexible transportation strategies. This knowledge is essential for effective contingency planning and risk management in logistics operations.

What are the economic impacts of weather-related disruptions on supply chains?

Weather-related disruptions can have significant and far-reaching economic impacts on supply chains, affecting businesses of all sizes across various industries. These impacts can be both direct and indirect, often resulting in substantial financial losses and operational challenges.

Direct Economic Impacts

The most immediate economic impacts of weather-related disruptions are often the direct costs associated with delayed or damaged shipments, increased transportation expenses, and lost sales.

Delayed Shipments: When weather disrupts transportation, shipments may be delayed, leading to missed delivery deadlines. This can result in penalties for late deliveries, dissatisfied customers, and potential loss of future business. In industries with time-sensitive products, such as fresh produce or pharmaceuticals, delays can lead to spoilage and product loss.

Increased Transportation Costs: Adverse weather conditions often necessitate the use of alternative, more expensive transportation routes or modes. For example, if a storm closes a major shipping port, companies may need to reroute cargo to other ports or switch to air freight, significantly increasing transportation costs.

Damaged Goods: Extreme weather events can damage goods in transit or in storage. Flooding can destroy warehoused inventory, while extreme temperatures can affect the quality of temperature-sensitive products. These losses can be substantial, particularly for high-value or perishable goods.

Lost Sales: Weather disruptions can lead to stock-outs at retail locations, resulting in lost sales opportunities. In e-commerce, delivery delays due to weather can lead to order cancellations and customer dissatisfaction.

Indirect Economic Impacts

Beyond the immediate costs, weather-related disruptions can have broader, long-term economic impacts on supply chains and the businesses that rely on them.

Reduced Productivity: Weather disruptions can lead to reduced productivity across the supply chain. Factory closures due to severe weather, transportation delays, and disrupted communication can all contribute to decreased output and efficiency.

Increased Inventory Costs: To mitigate the risk of weather-related disruptions, companies may choose to maintain higher inventory levels. While this can help ensure product availability during disruptions, it also increases inventory carrying costs and ties up working capital.

Insurance Premiums: Frequent weather-related losses can lead to increased insurance premiums for logistics providers and businesses operating in high-risk areas. These increased costs are often passed on to customers, affecting overall supply chain costs.

Market Share Loss: Persistent weather-related disruptions can damage a company’s reputation for reliability, potentially leading to loss of market share to competitors with more resilient supply chains.

Economic Ripple Effects: Supply chain disruptions can have ripple effects throughout the economy. For example, a disruption in the supply of key components can affect multiple industries, leading to production slowdowns and economic losses far beyond the initial impact.

The table below illustrates the potential economic impacts of different types of weather events on supply chains:

| Weather Event | Potential Economic Impacts |

|---|---|

| Hurricane | Port closures, infrastructure damage, widespread transportation disruptions, inventory loss |

| Snowstorm | Road closures, flight cancellations, reduced productivity, increased heating costs |

| Drought | Reduced agricultural output, higher raw material costs, water scarcity impacts on production |

| Extreme Heat | Increased energy costs, reduced worker productivity, potential equipment failures |

| Flooding | Warehouse damage, road closures, inventory loss, increased insurance costs |

Quantifying Economic Impacts

Quantifying the full economic impact of weather-related disruptions on supply chains is challenging due to the complex interplay of direct and indirect effects. However, some studies have attempted to estimate these costs:

A report by the World Economic Forum estimated that natural disasters, many of which are weather-related, cause an average annual economic loss of $150 billion globally.

The U.S. National Centers for Environmental Information reported that in 2022 alone, there were 18 weather and climate disaster events with losses exceeding $1 billion each in the United States, with a total cost of $165 billion.

These figures underscore the significant economic stakes involved in managing weather-related risks in supply chains. The ability to anticipate, prepare for, and respond effectively to weather-related disruptions is becoming increasingly critical for businesses seeking to maintain competitive advantage and financial stability in an increasingly volatile climate.

How can companies use weather forecasting to optimize logistics planning?

Weather forecasting has become an indispensable tool for companies seeking to optimize their logistics planning. By leveraging accurate and timely weather information, businesses can make informed decisions, improve operational efficiency, and mitigate risks associated with adverse weather conditions.

Integration of Weather Data into Logistics Systems

Modern logistics systems increasingly incorporate weather data as a critical input for planning and decision-making. This integration allows for real-time adjustments and proactive measures to address potential weather-related challenges.

Route Optimization: Weather forecasts can be used to optimize transportation routes. By considering predicted weather conditions along different routes, logistics planners can choose the safest and most efficient paths for shipments. This may involve avoiding areas of expected severe weather or adjusting departure times to minimize the impact of forecasted adverse conditions.

Mode Selection: Weather forecasts can inform decisions about which transportation mode to use for specific shipments. For instance, if severe storms are predicted to affect air travel, planners might opt for ground transportation for less time-sensitive cargo.

Capacity Planning: Accurate weather forecasts allow companies to adjust their capacity planning. If severe weather is expected to cause delays or disruptions in certain areas, businesses can proactively increase capacity in other regions to maintain service levels.

Inventory Management: Weather forecasts can inform inventory management decisions. For example, retailers might increase stock levels of weather-related products (e.g., snow shovels before a forecasted snowstorm) or adjust inventory locations to ensure product availability despite potential transportation disruptions.

Advanced Weather Forecasting Technologies

Companies are increasingly leveraging advanced weather forecasting technologies to enhance their logistics planning:

High-Resolution Models: Modern weather models provide highly detailed forecasts for specific locations and time periods. These models can predict localized weather events that might affect particular routes or facilities.

Ensemble Forecasting: This technique uses multiple forecast models to provide a range of possible weather scenarios. It helps logistics planners understand the uncertainty in weather predictions and plan for different potential outcomes.

Machine Learning and AI: Artificial intelligence and machine learning algorithms can analyze vast amounts of historical weather and logistics data to identify patterns and improve forecast accuracy. These technologies can also help predict the specific impacts of weather events on logistics operations.

IoT and Real-Time Data: Internet of Things (IoT) devices, such as weather stations and sensors on vehicles, can provide real-time weather data. This information can be integrated with forecasts to provide a more accurate and up-to-date picture of weather conditions affecting logistics operations.

Implementing Weather-Based Decision Support Systems

To effectively use weather forecasting in logistics planning, companies are implementing sophisticated decision support systems:

Risk Assessment Tools: These tools combine weather forecasts with logistics data to assess the risk of disruptions to specific shipments or routes. They can help prioritize which shipments or operations need attention or modification due to weather risks.

Automated Alert Systems: Companies can set up automated systems that alert relevant personnel when weather forecasts indicate potential disruptions. These alerts can trigger predefined contingency plans or prompt manual interventions.

Scenario Planning: Using weather forecasts, companies can develop and regularly update scenario plans for different weather events. This allows for quicker and more effective responses when adverse weather occurs.

Collaborative Platforms: Weather-based decision support systems can facilitate collaboration between different parts of the supply chain. For example, a manufacturer can share weather-related production delays with distributors and retailers, allowing them to adjust their plans accordingly.

The table below illustrates how different types of weather forecasts can be applied to various aspects of logistics planning:

| Forecast Type | Application in Logistics Planning |

|---|---|

| Short-term (1-3 days) | Daily route planning, immediate inventory adjustments |

| Medium-term (4-10 days) | Weekly capacity planning, proactive rerouting |

| Long-term (seasonal) | Strategic inventory positioning, long-haul route planning |

| Severe weather alerts | Emergency response planning, temporary operational changes |

Challenges and Considerations

While weather forecasting offers significant benefits for logistics planning, there are challenges to consider:

Forecast Accuracy: Despite advancements, weather forecasts are not always 100% accurate, especially for longer-term predictions. Companies need to balance the benefits of early planning with the risk of acting on inaccurate forecasts.

Data Integration: Integrating weather data with existing logistics systems can be complex and may require significant investment in technology and training.

Overreliance on Technology: While weather forecasting tools are valuable, they should not replace human judgment entirely. Experienced logistics professionals should interpret and apply forecast data in the context of their specific operations.

Regional Variations: Weather forecasting accuracy and availability of detailed data can vary by region. Companies operating globally need to account for these variations in their planning processes.

By effectively leveraging weather forecasting in their logistics planning, companies can enhance their operational resilience, improve customer service, and gain a competitive edge in an increasingly weather-sensitive business environment. The key lies in combining advanced forecasting technologies with robust decision-making processes and a deep understanding of how weather impacts specific logistics operations.

What strategies can businesses employ to mitigate weather-related risks in logistics?

Mitigating weather-related risks in logistics requires a comprehensive approach that combines proactive planning, operational flexibility, and strategic investments. Businesses that effectively manage these risks can maintain operational continuity, protect their assets, and enhance their competitive position in the face of increasingly unpredictable weather patterns.

Diversification of Transportation Routes and Modes

One of the most effective strategies for mitigating weather-related risks is diversification. This approach involves developing multiple options for moving goods, reducing reliance on any single route or mode of transportation.

Multi-Modal Transportation: Utilizing a combination of transportation modes (e.g., truck, rail, air, and sea) allows businesses to switch between modes when one is affected by adverse weather. For example, if air freight is disrupted by a storm, cargo can be redirected to ground transportation.

Alternative Routes: Identifying and maintaining relationships with carriers that operate on alternative routes can provide options when primary routes are affected by weather. This may include using different ports, airports, or road networks.

Geographically Distributed Network: Establishing a network of distribution centers in different geographic regions can help isolate the impact of localized weather events and maintain service to unaffected areas.

Flexible Supply Chain Design

Creating flexibility within the supply chain allows businesses to adapt quickly to changing weather conditions and minimize disruptions.

Postponement Strategies: Delaying final product configuration or customization until closer to the point of sale can provide more flexibility in responding to weather-related disruptions.

Agile Inventory Management: Implementing systems that allow for rapid reallocation of inventory between locations can help maintain product availability despite weather-related transportation challenges.

Supplier Diversification: Developing relationships with multiple suppliers in different geographic regions can reduce the risk of weather-related supply shortages.

Enhanced Visibility and Communication

Improving visibility across the supply chain and maintaining clear communication channels are crucial for effective risk mitigation.

Real-Time Tracking: Implementing systems that provide real-time tracking of shipments and weather conditions allows for proactive decision-making and rapid response to emerging risks.

Collaborative Platforms: Utilizing platforms that facilitate information sharing between suppliers, logistics providers, and customers can improve coordination and decision-making during weather events.

Early Warning Systems: Developing or subscribing to early warning systems for severe weather can provide valuable lead time for implementing contingency plans.

Risk Assessment and Contingency Planning

Systematic risk assessment and detailed contingency planning are essential components of a comprehensive weather risk mitigation strategy.

Regular Risk Assessments: Conducting periodic assessments of weather-related risks to identify vulnerabilities in the supply chain and prioritize mitigation efforts.

Scenario Planning: Developing detailed plans for various weather scenarios, including specific actions to be taken at different stages of a weather event.

Stress Testing: Regularly testing the supply chain’s resilience to different types of weather disruptions can help identify weaknesses and improve preparedness.

Infrastructure and Asset Protection

Investing in infrastructure and asset protection can significantly reduce the impact of severe weather events on logistics operations.

Weather-Resistant Facilities: Upgrading warehouses and distribution centers to withstand extreme weather conditions, such as reinforcing roofs, improving drainage systems, and installing backup power generators.

Climate-Controlled Transportation: Investing in climate-controlled transportation equipment to protect sensitive goods from temperature extremes during transit.

Preventive Maintenance: Implementing rigorous maintenance schedules for vehicles and equipment to ensure they can operate reliably in challenging weather conditions.

Financial Risk Management

Implementing financial strategies to mitigate the economic impact of weather-related disruptions is an important aspect of overall risk management.

Weather Insurance: Purchasing specialized weather insurance policies that provide coverage for specific weather-related risks and their impacts on logistics operations.

Contractual Protections: Incorporating weather-related clauses in contracts with suppliers and customers to allocate risk and define responsibilities during weather disruptions.

Financial Reserves: Maintaining adequate financial reserves to cover potential losses and additional expenses associated with weather-related disruptions.

The table below summarizes key weather-related risks and corresponding mitigation strategies:

| Weather-Related Risk | Mitigation Strategies |

|---|---|

| Transportation Delays | Multi-modal options, alternative routes, real-time tracking |

| Supply Shortages | Supplier diversification, strategic inventory positioning |

| Infrastructure Damage | Weather-resistant facilities, preventive maintenance |

| Operational Disruptions | Flexible supply chain design, contingency planning |

| Financial Losses | Weather insurance, contractual protections, financial reserves |

Technology and Innovation

Leveraging advanced technologies can significantly enhance a business’s ability to mitigate weather-related risks in logistics.

Predictive Analytics: Utilizing big data and machine learning algorithms to predict potential weather impacts and optimize logistics decisions.

Internet of Things (IoT): Deploying IoT sensors to monitor weather conditions, asset status, and environmental factors in real-time, enabling proactive risk management.

Blockchain Technology: Implementing blockchain solutions to enhance supply chain transparency and traceability, facilitating faster and more coordinated responses to weather-related disruptions.

Autonomous Vehicles: Investing in autonomous vehicle technology that can operate more safely and efficiently in adverse weather conditions.

Employee Training and Safety

Ensuring that employees are well-trained and equipped to handle weather-related challenges is crucial for effective risk mitigation.

Weather Safety Training: Providing comprehensive training on weather-related safety procedures and decision-making protocols for logistics personnel.

Personal Protective Equipment: Supplying appropriate protective gear for employees working in adverse weather conditions.

Flexible Work Arrangements: Implementing policies that allow for remote work or flexible schedules during severe weather events to ensure employee safety and maintain operational continuity.

By employing a combination of these strategies, businesses can significantly enhance their resilience to weather-related risks in logistics. The key is to develop a comprehensive approach that addresses risks at multiple levels of the supply chain, from strategic planning to day-to-day operations. This multi-faceted approach not only helps mitigate immediate weather-related risks but also builds long-term resilience in an increasingly unpredictable climate.

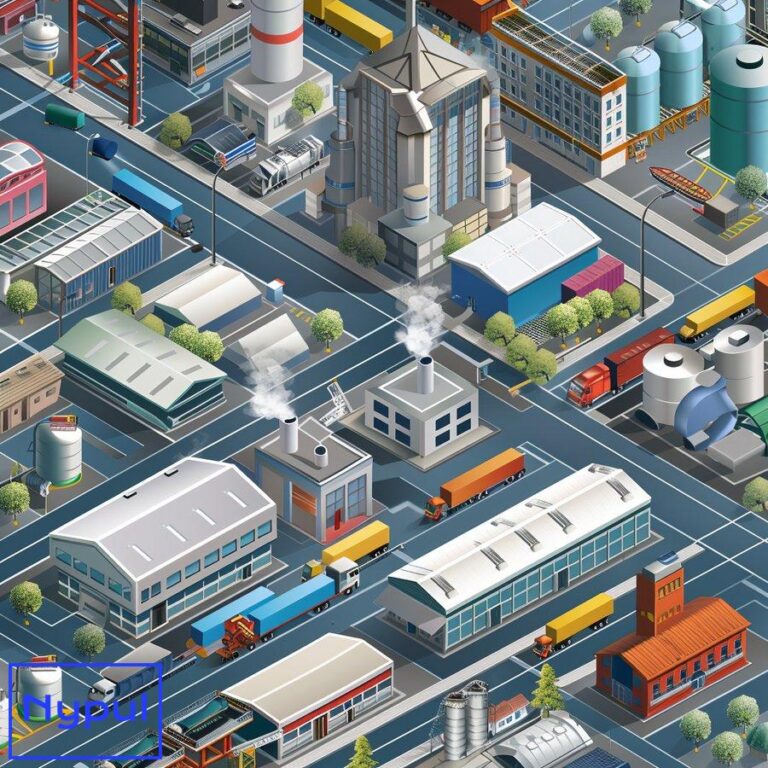

How do extreme weather events impact inventory management and warehousing?

Extreme weather events pose significant challenges to inventory management and warehousing operations, affecting everything from storage conditions to demand forecasting. Understanding these impacts is crucial for developing effective strategies to maintain operational efficiency and product integrity in the face of severe weather.

Physical Impacts on Warehouses and Inventory

Extreme weather events can directly affect warehouse structures and the inventory stored within them.

Structural Damage: Hurricanes, tornadoes, and severe storms can cause significant damage to warehouse buildings, potentially compromising the safety of stored goods. High winds can damage roofs, while flooding can affect foundations and lower levels of storage facilities.

Water Damage: Flooding, whether from storms, hurricanes, or heavy rainfall, can lead to extensive damage to inventory, especially goods stored at ground level. Even minor water intrusion can cause mold growth, affecting product quality and safety.

Temperature Extremes: Heatwaves or extreme cold can affect temperature-sensitive products if warehouses lack adequate climate control systems. This is particularly critical for pharmaceuticals, food products, and certain chemicals.

Power Outages: Severe weather often leads to power outages, which can disrupt climate control systems, security measures, and automated inventory management systems. For cold storage facilities, prolonged power outages can result in significant inventory losses.

Access Issues: Heavy snowfall, flooding, or debris from storms can make warehouses inaccessible, preventing the movement of goods in or out of the facility.

Inventory Management Challenges

Extreme weather events can disrupt normal inventory management practices and require rapid adjustments to maintain operational efficiency.

Demand Fluctuations: Severe weather can cause sudden spikes or drops in demand for certain products. For example, hurricanes may increase demand for emergency supplies, while reducing demand for non-essential items.

Supply Chain Disruptions: Weather-related disruptions in transportation can lead to delays in receiving inventory, potentially causing stockouts or overstocking as businesses try to compensate.

Inventory Relocation: In anticipation of severe weather, businesses may need to quickly relocate inventory to safer locations, requiring efficient tracking and management systems.

Increased Spoilage: For perishable goods, weather-related power outages or transportation delays can lead to increased spoilage rates, necessitating more frequent inventory turns and write-offs.

Safety Stock Adjustments: The increased uncertainty caused by extreme weather may require businesses to maintain higher levels of safety stock, impacting inventory carrying costs and warehouse space utilization.

Warehousing Operational Impacts

Extreme weather events can significantly affect day-to-day warehousing operations.

Staffing Challenges: Severe weather can make it difficult or unsafe for warehouse staff to come to work, potentially leading to operational slowdowns or temporary closures.

Equipment Malfunctions: Extreme temperatures or humidity can affect the performance of warehouse equipment such as forklifts, conveyor systems, and automated storage and retrieval systems.

Increased Maintenance Requirements: Harsh weather conditions can accelerate wear and tear on warehouse infrastructure and equipment, necessitating more frequent maintenance and repairs.

Changes in Picking and Packing Processes: Weather-related challenges may require adjustments to normal picking and packing processes to protect goods from exposure to elements during loading and unloading.

Inventory Visibility Issues: Rapid movement of inventory in response to weather threats can lead to challenges in maintaining accurate inventory records, especially if normal tracking procedures are disrupted.

Strategies for Mitigating Weather Impacts on Inventory and Warehousing

To address these challenges, businesses can implement several strategies:

Robust Infrastructure: Investing in weather-resistant warehouse designs, including reinforced structures, elevated storage areas, and improved drainage systems.

Climate Control Systems: Installing advanced climate control and monitoring systems to maintain optimal storage conditions, with backup power sources to ensure continuity during outages.

Flexible Inventory Management Systems: Implementing agile inventory management software that can quickly adjust to sudden changes in demand or supply chain disruptions.

Distributed Warehousing Network: Establishing a network of warehouses in different geographic locations to spread weather-related risks and maintain service continuity.

Enhanced Forecasting: Utilizing advanced forecasting tools that incorporate weather data to better predict demand fluctuations and supply chain disruptions.

Inventory Segmentation: Strategically organizing inventory based on value, vulnerability to weather, and criticality to operations, ensuring the most important and weather-sensitive items receive priority protection.

Emergency Response Plans: Developing and regularly updating detailed plans for various weather scenarios, including protocols for inventory protection, relocation, and recovery.

Staff Training: Providing comprehensive training to warehouse staff on weather-related safety procedures and emergency response protocols.

The table below summarizes the key impacts of different extreme weather events on inventory management and warehousing, along with potential mitigation strategies:

| Weather Event | Primary Impacts | Mitigation Strategies |

|---|---|---|

| Hurricanes/Floods | Water damage, power outages, access issues | Elevated storage, backup power, waterproof packaging |

| Extreme Heat | Spoilage, equipment stress, worker safety | Advanced cooling systems, adjusted work schedules |

| Severe Cold/Snow | Frozen inventory, access issues, equipment failure | Insulation improvements, snow removal plans |

| Tornadoes | Structural damage, inventory loss | Reinforced structures, distributed warehousing |

| Prolonged Drought | Water scarcity for operations, fire risk | Water conservation measures, enhanced fire protection |

Long-Term Considerations

As extreme weather events become more frequent and severe due to climate change, businesses must also consider long-term strategies for inventory management and warehousing:

Climate Risk Assessment: Conducting regular assessments of climate-related risks to warehouse locations and supply chains to inform long-term planning and investment decisions.

Sustainable Warehouse Design: Incorporating sustainable and resilient design principles in new warehouse construction, such as green roofs for better insulation and stormwater management.

Technology Integration: Investing in emerging technologies like IoT sensors, AI-driven predictive maintenance, and blockchain for enhanced inventory tracking and management in challenging conditions.

Collaboration and Information Sharing: Developing industry-wide standards and platforms for sharing best practices and real-time information on weather-related inventory and warehousing challenges.

By understanding the multifaceted impacts of extreme weather on inventory management and warehousing, and implementing comprehensive mitigation strategies, businesses can enhance their resilience and maintain operational efficiency even in the face of severe weather events. This proactive approach not only protects assets and ensures business continuity but also provides a competitive advantage in an increasingly unpredictable climate.

What role does technology play in managing weather-related logistics challenges?

Technology plays a pivotal role in helping businesses navigate the complex challenges posed by weather-related disruptions in logistics. From advanced forecasting tools to real-time tracking systems, technology provides the means to anticipate, respond to, and mitigate the impacts of adverse weather conditions on supply chains.

Advanced Weather Forecasting and Predictive Analytics

Modern weather forecasting technologies have significantly improved the ability to predict and prepare for weather-related logistics challenges.

High-Resolution Modeling: Advanced weather models provide detailed forecasts for specific locations and timeframes, allowing logistics managers to make more informed decisions about routing and scheduling.

Machine Learning Algorithms: AI and machine learning techniques analyze vast amounts of historical weather and logistics data to identify patterns and improve forecast accuracy. These algorithms can predict not just weather conditions but also their likely impacts on specific logistics operations.

Ensemble Forecasting: This technique uses multiple forecast models to provide a range of possible weather scenarios, helping logistics planners understand the uncertainty in predictions and plan for different outcomes.

Impact-Based Forecasting: Beyond predicting weather conditions, these systems forecast the specific impacts on logistics operations, such as likely delays, road closures, or port disruptions.

Real-Time Monitoring and Tracking Systems

Technologies that provide real-time visibility into weather conditions and asset locations are crucial for managing weather-related challenges.

IoT Sensors: Internet of Things (IoT) devices deployed across the supply chain provide real-time data on weather conditions, asset locations, and environmental factors affecting goods in transit or storage.

GPS Tracking: Advanced GPS systems offer precise location data for vehicles and shipments, allowing for real-time route adjustments in response to changing weather conditions.

RFID Technology: Radio-Frequency Identification tags help track inventory movement and conditions, particularly useful for monitoring temperature-sensitive goods during extreme weather events.

Satellite Imaging: Satellite technology provides broad-scale visibility of weather patterns and their impacts on transportation infrastructure, aiding in strategic decision-making.

Automated Decision Support Systems

These systems integrate weather data with logistics information to provide actionable insights and automate certain decision-making processes.

Risk Assessment Tools: Algorithms that combine weather forecasts with logistics data to assess the risk of disruptions to specific shipments or routes, helping prioritize risk mitigation efforts.

Route Optimization Software: Advanced algorithms that continuously recalculate optimal routes based on real-time weather and traffic data, minimizing weather-related delays and fuel consumption.

Capacity Planning Tools: Systems that adjust capacity plans based on weather forecasts, ensuring adequate resources are available to handle weather-related surges or disruptions.

Automated Alert Systems: Platforms that generate automated alerts and recommended actions when weather forecasts indicate potential disruptions to logistics operations.

Blockchain and Distributed Ledger Technology

Blockchain technology enhances transparency and traceability in supply chains, which is particularly valuable during weather-related disruptions.

Smart Contracts: Automated agreements that can trigger actions or payments based on predefined weather conditions, streamlining the handling of weather-related contingencies.

Enhanced Traceability: Immutable records of a product’s journey through the supply chain, helping to quickly identify and respond to weather-impacted shipments.

Collaborative Platforms: Blockchain-based systems that facilitate secure information sharing among supply chain partners, improving coordination during weather events.

Autonomous and Robotic Systems

Autonomous technologies can enhance safety and efficiency in challenging weather conditions.

Autonomous Vehicles: Self-driving trucks and drones that can operate more safely and efficiently in adverse weather, potentially reducing weather-related accidents and delays.

Warehouse Automation: Robotic systems in warehouses that can continue operations during weather events that might be unsafe for human workers.

Automated Port Operations: AI-driven port management systems that can optimize operations based on weather forecasts, minimizing disruptions from storms or high winds.

Advanced Analytics and Simulation

These tools help businesses understand and prepare for the complex impacts of weather on logistics operations.

Digital Twins: Virtual replicas of supply chains that can simulate the impacts of various weather scenarios, helping to identify vulnerabilities and test mitigation strategies.

Predictive Maintenance: Analytics that forecast when weather conditions are likely to cause equipment failures, allowing for proactive maintenance to prevent weather-related breakdowns.

Demand Forecasting: Advanced models that incorporate weather data to predict how weather events will affect demand for different products, helping optimize inventory management.

The table below summarizes key technologies and their applications in managing weather-related logistics challenges:

| Technology | Application in Weather-Related Logistics Management |

|---|---|

| AI/Machine Learning | Improved weather forecasting, predictive analytics for logistics impacts |

| IoT Sensors | Real-time monitoring of weather conditions and asset status |

| GPS/RFID | Precise tracking of shipments and inventory in weather-affected areas |

| Blockchain | Enhanced supply chain transparency and automated weather-based contracts |

| Autonomous Systems | Safer and more efficient operations in adverse weather conditions |

| Digital Twins | Simulation of weather impacts on supply chains for better preparedness |

Challenges and Considerations

While technology offers powerful tools for managing weather-related logistics challenges, there are several considerations to keep in mind:

Data Integration: Effectively integrating diverse data sources (weather, logistics, market data) can be complex and may require significant investment in IT infrastructure.

Technology Adoption: Implementing new technologies across complex supply chains can be challenging, requiring change management and training initiatives.

Cybersecurity: As logistics operations become more technology-dependent, ensuring the security of systems and data becomes increasingly critical.

Overreliance on Technology: While technology provides valuable insights, human judgment and experience remain crucial in interpreting data and making final decisions.

Cost Considerations: Advanced technologies can require significant upfront investment, and businesses must carefully evaluate the return on investment.

Ethical and Privacy Concerns: The use of AI and extensive data collection raises questions about data privacy and the ethical use of predictive technologies.

Technology plays an indispensable role in helping businesses manage weather-related logistics challenges. By leveraging advanced forecasting, real-time monitoring, automated decision support, and other cutting-edge technologies, companies can enhance their ability to anticipate, respond to, and mitigate the impacts of adverse weather on their supply chains. As weather patterns become increasingly unpredictable due to climate change, the role of technology in logistics management is likely to become even more critical, driving ongoing innovation in this field.

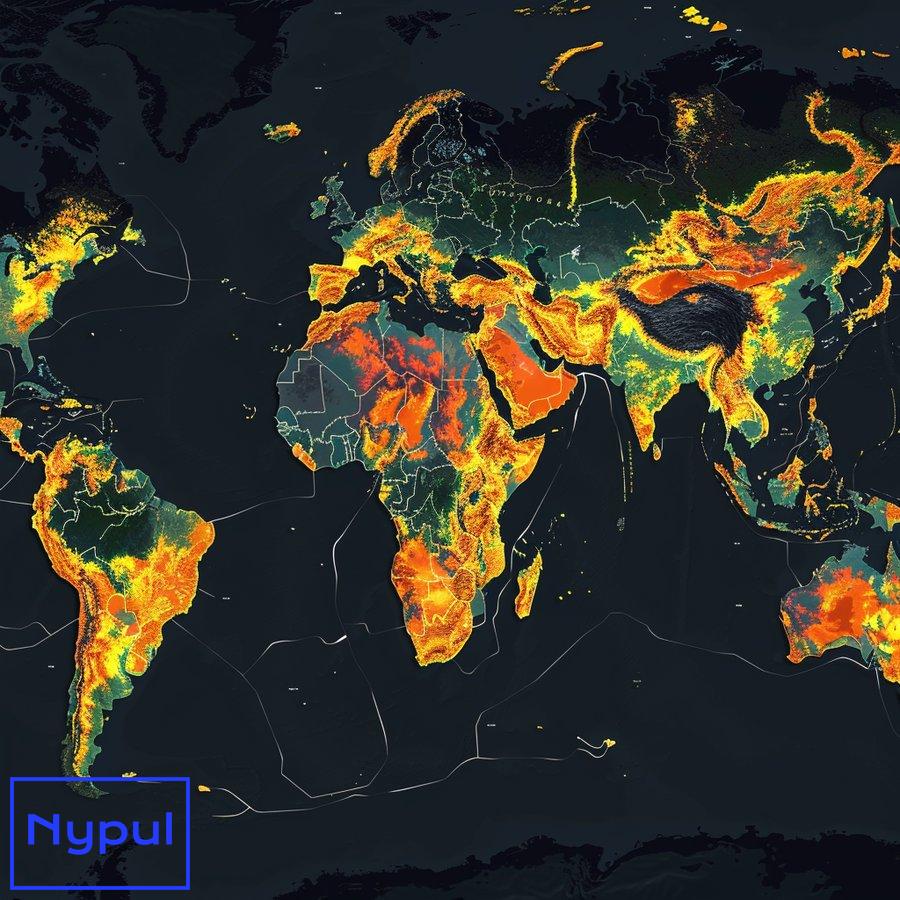

How does climate change influence long-term logistics strategies?

Climate change is fundamentally altering the landscape of global logistics, forcing businesses to reevaluate and adapt their long-term strategies. The increasing frequency and severity of extreme weather events, rising sea levels, and shifting climate patterns are creating new challenges and opportunities that logistics professionals must address in their strategic planning.

Reassessment of Transportation Networks

Climate change is prompting a comprehensive reassessment of transportation networks and routes.

Sea Level Rise: Rising sea levels threaten coastal infrastructure, including ports and low-lying transportation routes. Long-term logistics strategies must consider the viability of current port facilities and the potential need for relocation or significant infrastructure upgrades.

Arctic Shipping Routes: Melting Arctic ice is opening new shipping lanes, potentially reducing transit times between Asia and Europe. However, these routes come with their own set of challenges, including unpredictable ice conditions and limited infrastructure.

Inland Waterway Changes: Changing precipitation patterns affect river levels, impacting inland waterway transportation. Strategies must account for potential disruptions to river shipping and the need for alternative transportation modes.

Rail and Road Infrastructure: Extreme weather events and changing temperature patterns can damage rail and road infrastructure. Long-term planning must include more resilient infrastructure design and increased maintenance budgets.

Shift in Global Production and Distribution Patterns

Climate change is influencing where goods are produced and how they are distributed.

Agricultural Shifts: Changing climate patterns are altering agricultural production zones, necessitating adjustments in food supply chains and storage facilities.

Near-Shoring and Reshoring: To reduce vulnerability to climate-related disruptions in extended supply chains, some companies are moving production closer to end markets.

Diversification of Sourcing: Climate risks are encouraging businesses to diversify their sourcing locations to reduce dependence on climate-vulnerable regions.

Adaptation of Warehousing and Storage Facilities

Climate change considerations are influencing the design and location of warehousing and storage facilities.

Flood-Resistant Design: Increased flood risks are driving the adoption of flood-resistant warehouse designs and the relocation of facilities to higher ground.

Temperature Control: More frequent and severe heatwaves necessitate improved cooling systems in warehouses, particularly for temperature-sensitive goods.

Distributed Network: A trend towards more distributed warehousing networks helps mitigate the risk of climate-related disruptions in any single location.

Energy Efficiency: Rising temperatures and energy costs are driving investments in energy-efficient warehouse designs and renewable energy sources.

Changes in Inventory Management Strategies

Climate change is influencing how companies approach inventory management.

Increased Safety Stocks: Greater uncertainty in supply chains due to climate-related disruptions is leading some companies to maintain higher levels of safety stock.

Dynamic Inventory Allocation: More flexible inventory management systems are being implemented to quickly reallocate stock in response to climate-related disruptions.

Seasonal Adjustments: Changing seasonal patterns are altering traditional inventory cycles, requiring more adaptive inventory planning.

Focus on Sustainability and Emissions Reduction

Climate change concerns are driving a greater focus on sustainability in logistics operations.

Low-Emission Transportation: Companies are investing in electric and alternative fuel vehicles to reduce carbon emissions and meet increasingly stringent regulations.

Green Warehousing: Adoption of sustainable warehousing practices, including energy-efficient lighting, solar power, and green building materials.

Carbon Footprint Tracking: Implementation of systems to trackand reduce carbon emissions across the supply chain, often in response to regulatory pressures and customer demands.

Circular Economy Initiatives: Development of reverse logistics capabilities to support recycling and reuse programs, reducing waste and resource consumption.

Risk Management and Resilience Planning

Climate change is necessitating more robust risk management and resilience planning in logistics strategies.

Climate Risk Assessments: Regular assessments of climate-related risks to logistics infrastructure and operations are becoming standard practice.

Scenario Planning: Development of detailed scenarios for various climate change impacts to inform long-term decision-making.

Insurance Strategies: Evolving insurance products and strategies to address climate-related risks in logistics operations.

Redundancy and Flexibility: Building redundancy and flexibility into logistics networks to enhance resilience to climate-related disruptions.

Technology Integration for Climate Adaptation

Long-term logistics strategies are increasingly incorporating advanced technologies to address climate change challenges.

AI and Machine Learning: Utilization of AI for better climate prediction and its impacts on logistics operations.

IoT and Sensor Networks: Deployment of extensive sensor networks to monitor environmental conditions and infrastructure status in real-time.

Blockchain for Transparency: Implementation of blockchain technology to enhance supply chain transparency and traceability, crucial for managing climate-related risks.

Autonomous and Robotic Systems: Investment in autonomous vehicles and robotics to enhance safety and efficiency in challenging climate conditions.

The table below summarizes key climate change impacts and corresponding long-term logistics strategies:

| Climate Change Impact | Long-Term Logistics Strategy |

|---|---|

| Sea Level Rise | Port infrastructure upgrades, inland facility relocation |

| Extreme Weather Events | Enhanced risk assessment, resilient infrastructure design |

| Changing Agricultural Zones | Flexible supply chain networks, diversified sourcing |

| Emissions Regulations | Investment in low-emission transportation and warehousing |

| Water Scarcity | Water-efficient operations, alternative cooling technologies |

Collaboration and Stakeholder Engagement

Climate change is driving increased collaboration across the logistics industry and beyond.

Industry Partnerships: Formation of industry-wide initiatives to address common climate-related challenges and share best practices.

Public-Private Partnerships: Collaboration with governments and international organizations on climate adaptation and mitigation strategies.

Supplier Engagement: Working closely with suppliers to enhance climate resilience throughout the supply chain.

Customer Education: Engaging customers on the impacts of climate change on logistics and the need for more sustainable practices.

Policy and Regulatory Considerations

Long-term logistics strategies must account for evolving climate-related policies and regulations.

Carbon Pricing: Preparation for potential carbon pricing mechanisms that could affect transportation costs.

Emissions Reporting: Development of systems to comply with increasingly stringent emissions reporting requirements.

Adaptation Regulations: Anticipation of regulations mandating climate adaptation measures for logistics infrastructure.

International Agreements: Alignment of logistics strategies with international climate agreements and targets.

Human Resource and Training Implications

Climate change is influencing human resource strategies in the logistics sector.

Skill Development: Investment in training programs to develop employee skills in climate risk management and sustainable logistics practices.

Health and Safety: Enhanced health and safety measures to protect workers from extreme weather conditions.

Change Management: Implementation of change management programs to support the transition to more climate-resilient operations.

Climate change is profoundly reshaping long-term logistics strategies, requiring businesses to adapt to a more volatile and unpredictable operating environment. Successful strategies will need to balance resilience, sustainability, and efficiency, leveraging new technologies and collaborative approaches to navigate the challenges posed by a changing climate. As the impacts of climate change continue to unfold, the ability to anticipate and adapt to these changes will become a critical competitive advantage in the logistics industry.

What are the safety considerations for logistics operations during adverse weather conditions?

Safety is paramount in logistics operations, and adverse weather conditions significantly amplify the risks involved. Ensuring the safety of personnel, assets, and cargo during challenging weather requires a comprehensive approach that encompasses planning, training, equipment, and real-time decision-making.

Road Transportation Safety

Road transportation is particularly vulnerable to adverse weather conditions, requiring specific safety measures.

Driver Training: Comprehensive training programs for drivers on handling vehicles in various weather conditions, including snow, ice, heavy rain, and high winds.

Vehicle Maintenance: Regular and thorough maintenance checks, with particular attention to tires, brakes, and windshield wipers to ensure optimal performance in adverse conditions.

Route Planning: Careful planning of routes to avoid areas prone to weather-related hazards, such as flood-prone roads or mountain passes susceptible to snow and ice.

Rest Policies: Strict enforcement of rest policies, recognizing that adverse weather can increase driver fatigue.

Emergency Kits: Equipping vehicles with emergency kits containing items such as blankets, food, water, and first-aid supplies.

Real-Time Weather Monitoring: Providing drivers with access to real-time weather information and the authority to make safety-based decisions.

Air Transportation Safety

Air transportation faces unique challenges during adverse weather, necessitating stringent safety protocols.

Pre-Flight Weather Assessments: Thorough weather briefings and risk assessments before each flight.

De-Icing Procedures: Rigorous de-icing protocols to ensure aircraft safety in cold weather conditions.

Wind and Visibility Limits: Strict adherence to wind speed and visibility limits for takeoffs and landings.

Alternate Airport Planning: Comprehensive planning for alternate landing sites in case of unexpected weather changes.

Crew Training: Regular training for flight crews on handling various weather-related scenarios.

Maritime Transportation Safety

Maritime logistics operations must contend with a range of weather-related hazards at sea and in port.

Weather Routing: Utilization of advanced weather routing systems to avoid severe storms and optimize safe passage.

Port Safety Protocols: Implementation of clear protocols for port operations during high winds, heavy rain, or storm surges.

Cargo Securing: Enhanced procedures for securing cargo to prevent shifting or loss during rough seas.

Emergency Response Plans: Detailed plans for responding to weather-related emergencies at sea, including evacuation procedures.

Crew Safety Training: Regular drills and training on handling vessels in extreme weather conditions.

Warehouse and Distribution Center Safety

Adverse weather can pose significant risks to warehouse and distribution center operations.

Structural Integrity Checks: Regular inspections of building structures, particularly roofs, to ensure they can withstand extreme weather events.

Flood Preparedness: Implementation of flood prevention measures, including elevated storage areas and water pumping systems.

Snow and Ice Management: Comprehensive snow and ice removal plans for parking lots, loading docks, and walkways.

Temperature Control: Ensuring proper temperature control systems are in place to protect workers and temperature-sensitive inventory during extreme heat or cold.

Emergency Power Systems: Installation and regular testing of backup power systems to maintain critical operations during power outages.

Personnel Safety Measures

Protecting the safety of logistics personnel during adverse weather is crucial.

Personal Protective Equipment (PPE): Providing appropriate PPE for different weather conditions, such as high-visibility gear for low visibility situations.

Work-Rest Schedules: Implementing adjusted work-rest schedules during extreme weather to prevent fatigue and exposure-related illnesses.

Communication Systems: Ensuring robust communication systems are in place to keep all personnel informed of weather conditions and safety protocols.

Remote Work Policies: Developing policies that allow non-essential personnel to work remotely during severe weather events.

Health Monitoring: Implementing systems to monitor the health and well-being of workers exposed to extreme weather conditions.

Technology and Equipment for Weather Safety

Leveraging technology and specialized equipment can significantly enhance safety in adverse weather conditions.

Weather Monitoring Systems: Deployment of advanced weather monitoring and alert systems across logistics networks.

Telematics: Use of telematics in vehicles to monitor driving behavior and provide real-time feedback during adverse weather.

Autonomous Systems: Implementation of autonomous or semi-autonomous systems for high-risk operations in severe weather.

Specialized Vehicles: Investment in vehicles designed for specific weather challenges, such as all-terrain vehicles for snow and flood conditions.

Safety Management Systems and Protocols

Comprehensive safety management systems are essential for navigating the challenges posed by adverse weather.

Risk Assessment Procedures: Regular and systematic assessment of weather-related risks across all logistics operations.

Incident Reporting and Analysis: Thorough reporting and analysis of weather-related incidents to improve future safety measures.

Safety Audits: Conducting regular safety audits with a specific focus on weather-related preparedness.

Continuous Improvement: Implementing a culture of continuous improvement in safety practices, incorporating lessons learned from each weather event.

The table below summarizes key safety considerations for different aspects of logistics operations during adverse weather:

| Logistics Area | Key Safety Considerations |

|---|---|

| Road Transportation | Driver training, vehicle maintenance, route planning |

| Air Transportation | Pre-flight assessments, de-icing procedures, alternate planning |

| Maritime Transportation | Weather routing, cargo securing, emergency response plans |

| Warehousing | Structural integrity, flood preparedness, temperature control |

| Personnel | PPE, work-rest schedules, health monitoring |

Regulatory Compliance and Industry Standards

Adhering to regulations and industry standards is crucial for maintaining safety during adverse weather.

Compliance Monitoring: Implementing systems to ensure ongoing compliance with weather-related safety regulations across all operations.

Industry Best Practices: Actively participating in industry forums and adopting best practices for weather-related safety.

Documentation and Record-Keeping: Maintaining detailed records of weather-related safety measures and incidents for regulatory purposes and internal improvement.

Stakeholder Communication

Effective communication with stakeholders is vital for maintaining safety during adverse weather conditions.

Customer Communication: Keeping customers informed about potential weather-related delays or changes to ensure they don’t pressure operators to take unnecessary risks.

Supplier Coordination: Working closely with suppliers to ensure they understand and adhere to safety protocols during adverse weather.

Community Engagement: Engaging with local communities to coordinate safety efforts, particularly in areas prone to severe weather events.

Ensuring safety in logistics operations during adverse weather conditions requires a multifaceted approach that combines thorough planning, advanced technology, comprehensive training, and a culture of safety awareness. By prioritizing safety and implementing robust measures across all aspects of logistics operations, companies can protect their personnel, assets, and cargo while maintaining operational continuity in challenging weather conditions. As climate change leads to more frequent and severe weather events, the importance of these safety considerations in logistics will only continue to grow.