How Is the Cold Container Space Temperature Regulated

What are cold containers and why is temperature regulation crucial?

Cold containers, also known as reefer containers or refrigerated containers, are specialized shipping units designed to transport temperature-sensitive goods such as perishable foods, pharmaceuticals, and chemicals. These containers are equipped with advanced temperature control systems that maintain precise temperature ranges, ensuring the safety and quality of the cargo throughout the supply chain.

Temperature regulation is crucial in cold containers for several reasons:

-

Maintaining product integrity: Exposure to improper temperatures can cause spoilage, degradation, or contamination of the cargo, rendering it unfit for consumption or use.

-

Compliance with regulations: Many industries, such as the pharmaceutical and food industries, have strict regulations regarding the transportation of temperature-sensitive products. Proper temperature control is necessary to meet these regulatory requirements.

-

Reducing waste and losses: Temperature fluctuations during transit can lead to significant losses due to product spoilage. Effective temperature regulation minimizes waste and ensures that the cargo arrives at its destination in optimal condition.

-

Preserving product value: Temperature-sensitive goods often have high value, and maintaining their quality is essential to protect the investment and ensure customer satisfaction.

How does the refrigeration cycle work in cold containers?

The refrigeration cycle is the core mechanism that regulates the temperature inside cold containers. This cycle is based on the principles of thermodynamics and involves the transfer of heat from the container’s interior to the outside environment. The refrigeration cycle consists of four main components: the compressor, condenser, expansion valve, and evaporator.

-

Compressor: The compressor is the heart of the refrigeration system. It draws in low-pressure, low-temperature refrigerant vapor from the evaporator and compresses it into a high-pressure, high-temperature vapor.

-

Condenser: The high-pressure, high-temperature vapor enters the condenser, where it dissipates heat to the outside environment, causing the refrigerant to condense into a high-pressure liquid.

-

Expansion valve: The high-pressure liquid refrigerant passes through the expansion valve, where it experiences a sudden drop in pressure and temperature. This process creates a low-pressure, low-temperature liquid-vapor mixture.

-

Evaporator: The low-pressure, low-temperature liquid-vapor mixture enters the evaporator, where it absorbs heat from the container’s interior, causing the refrigerant to evaporate into a low-pressure vapor. This process lowers the temperature inside the container.

The refrigerant then returns to the compressor, and the cycle repeats, continuously removing heat from the container’s interior and maintaining the desired temperature.

What components make up a cold container’s temperature control system?

A cold container’s temperature control system consists of several key components that work together to regulate the temperature and ensure optimal conditions for the cargo. These components include:

-

Refrigeration unit: The refrigeration unit is responsible for cooling the air inside the container. It typically includes a compressor, condenser, evaporator, and expansion valve.

-

Temperature sensors: Temperature sensors are strategically placed inside the container to monitor the air temperature. These sensors provide feedback to the control system, allowing for precise temperature regulation.

-

Control system: The control system is the “brain” of the temperature control system. It processes data from the temperature sensors and adjusts the refrigeration unit accordingly to maintain the desired temperature.

-

Air circulation fans: Air circulation fans ensure even distribution of cool air throughout the container, preventing hot spots and ensuring consistent temperature.

-

Insulation: High-quality insulation is crucial for maintaining the desired temperature inside the container. It minimizes heat transfer from the outside environment, reducing the workload on the refrigeration unit.

-

Fresh air vents: Fresh air vents allow for controlled air exchange, which is necessary for removing gases like ethylene that can accelerate the ripening process in some fruits and vegetables.

-

Backup power supply: In case of power outages or emergencies, a backup power supply, such as a generator or battery, ensures that the temperature control system continues to function, protecting the cargo.

How is temperature monitored and controlled in cold containers?

Temperature monitoring and control in cold containers are critical to ensuring the safety and quality of the cargo. Modern cold containers are equipped with advanced monitoring and control systems that provide precise temperature regulation and real-time data.

Temperature monitoring

-

Sensors: Multiple temperature sensors are strategically placed inside the container to monitor the air temperature at various locations. These sensors provide continuous feedback to the control system.

-

Data loggers: Data loggers record temperature data at regular intervals, creating a detailed history of the temperature conditions during transit. This information can be used for quality assurance and troubleshooting purposes.

-

Remote monitoring: Some cold containers are equipped with remote monitoring capabilities, allowing shippers and receivers to track temperature data in real-time via web-based platforms or mobile apps.

Temperature control

-

Set point control: The control system allows users to set a specific target temperature for the container. The refrigeration unit then works to maintain this set point by cycling on and off as needed.

-

Differential control: Differential control involves setting a temperature range rather than a specific set point. The refrigeration unit maintains the temperature within this range, reducing the frequency of on/off cycles and improving energy efficiency.

-

Intelligent control algorithms: Advanced control systems use algorithms that analyze temperature data and make adjustments to optimize performance. These algorithms can account for factors such as ambient temperature, cargo load, and door openings to maintain the desired temperature.

-

Alarms and notifications: Temperature control systems are equipped with alarms and notifications that alert users when the temperature deviates from the set range. This allows for prompt intervention to prevent cargo damage.

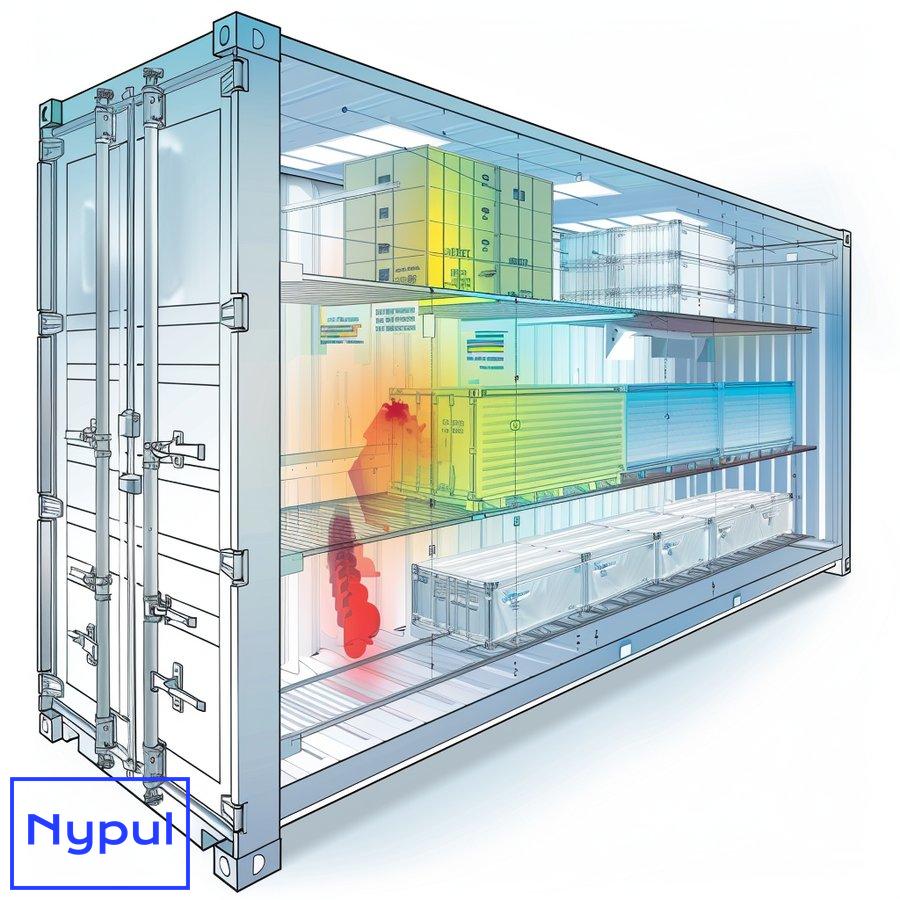

Why is proper airflow management essential in cold containers?

Proper airflow management is crucial in cold containers to ensure even temperature distribution and maintain the desired conditions for the cargo. Effective airflow management involves the following:

-

Air circulation: Air circulation fans ensure that cool air from the refrigeration unit is evenly distributed throughout the container. This prevents hot spots and ensures that all areas of the container are maintained at the desired temperature.

-

Air flow patterns: The design of the container and the placement of the cargo influence air flow patterns. Proper cargo loading and the use of air flow channels or ducts can optimize air circulation and prevent stagnant areas.

-

Air exchange: Fresh air vents allow for controlled air exchange, which is necessary for removing gases like ethylene that can accelerate the ripening process in some fruits and vegetables. The amount of air exchange is carefully regulated to maintain the desired temperature and humidity levels.

-

Cargo compatibility: When loading multiple types of cargo, it is essential to consider their compatibility in terms of temperature and airflow requirements. Incompatible cargo should be separated to prevent cross-contamination and ensure proper airflow.

-

Maintenance: Regular maintenance of the air circulation fans and vents is necessary to ensure optimal performance and prevent blockages that can impede airflow.

How do cold containers maintain optimal humidity levels?

Maintaining optimal humidity levels is crucial in cold containers to prevent moisture-related issues such as condensation, mold growth, and product spoilage. Cold containers employ various strategies to manage humidity levels:

-

Dehumidification: Some cold containers are equipped with dehumidification systems that remove excess moisture from the air. This is particularly important when transporting goods that are sensitive to high humidity levels, such as certain pharmaceuticals and electronics.

-

Humidification: For cargo that requires higher humidity levels, such as fresh produce, cold containers may incorporate humidification systems. These systems add moisture to the air to prevent drying and maintain the desired humidity range.

-

Ventilation: Fresh air vents not only allow for air exchange but also help regulate humidity levels. By introducing dry outside air, ventilation can lower the humidity inside the container when needed.

-

Cargo packaging: The packaging used for the cargo can also impact humidity levels. Proper packaging, such as using moisture-absorbing materials or gas-permeable films, can help maintain the desired humidity range and protect the cargo from moisture-related issues.

-

Monitoring and control: Temperature and humidity sensors work together to provide feedback to the control system. The control system then makes adjustments to the dehumidification or humidification systems to maintain the optimal humidity levels for the specific cargo being transported.

What power sources are used for cold container temperature regulation?

Cold containers rely on various power sources to ensure continuous operation of their temperature control systems. The choice of power source depends on factors such as the mode of transportation, duration of the journey, and availability of power infrastructure.

Shore power

-

Shore power: When cold containers are stationary, such as at a port or a warehouse, they can be connected to shore power, which is the main electrical grid. This provides a reliable and consistent power source for the temperature control system.

-

Reefer points: Reefer points are electrical outlets specifically designed for connecting cold containers to shore power. These points are commonly found at ports, warehouses, and intermodal facilities.

Generator power

-

Gensets: When shore power is not available, cold containers can be equipped with diesel-powered generator sets (gensets). These gensets are integrated into the container and provide the necessary power for the temperature control system during transit.

-

Clip-on gensets: Clip-on gensets are portable generators that can be attached to the cold container when needed. They are particularly useful for road transportation or when the container is being transferred between different modes of transport.

Battery power

-

Battery backup: Many cold containers have battery backup systems that provide power in case of primary power failure. These batteries can maintain the temperature control system for a limited period, allowing for emergency situations or temporary power interruptions.

-

Solar power: Some cold containers incorporate solar panels to charge the battery backup system. This renewable energy source can extend the battery’s runtime and reduce reliance on generator power.

What challenges arise in regulating cold container temperatures?

Regulating temperatures in cold containers can present various challenges that must be addressed to ensure the safety and quality of the cargo. Some of the main challenges include:

Temperature fluctuations

-

Ambient temperature changes: Fluctuations in ambient temperature, such as during different seasons or climates, can affect the temperature inside the cold container and challenge the refrigeration system’s ability to maintain the desired set point.

-

Door openings: Each time the container doors are opened, warm air can enter, causing a temporary rise in temperature. Frequent door openings, such as during loading and unloading, can lead to significant temperature fluctuations.

-

Cargo loading: The temperature of the cargo itself can impact the container’s temperature when loaded. Warm cargo can cause a temporary increase in temperature until the refrigeration system can stabilize the environment.

Power interruptions

-

Electrical outages: Power interruptions, whether due to grid failures or issues with the container’s power supply, can disrupt the temperature control system and lead to temperature fluctuations or loss of power.

-

Equipment malfunctions: Breakdowns or malfunctions in the refrigeration unit, control system, or other components can cause temperature control failures, potentially leading to cargo damage.

Condensation and humidity issues

-

Moisture buildup: Improper humidity management can lead to condensation, which can promote mold growth, corrosion, and other moisture-related issues that can damage the cargo or the container itself.

-

Frost accumulation: In cold environments, excessive moisture can lead to frost buildup on the evaporator coils or other surfaces, reducing the efficiency of the refrigeration system and potentially causing blockages.

Cargo compatibility challenges

-

Temperature range conflicts: When transporting multiple types of cargo with different temperature requirements in the same container, it can be challenging to maintain the optimal conditions for each product.

-

Ethylene sensitivity: Some fruits and vegetables release ethylene gas, which can accelerate the ripening process in other produce. Improper air exchange or incompatible cargo can lead to ethylene buildup and premature spoilage.

To address these challenges, cold container operators must implement robust monitoring systems, backup power sources, regular maintenance, and proper cargo loading and compatibility practices. By anticipating and mitigating these challenges, cold container operators can ensure the reliable and safe transportation of temperature-sensitive goods.