How to Calculate Drayage Costs

What is Drayage and Why is it Important in Logistics?

Drayage, a crucial component of the logistics industry, refers to the transportation of goods over a short distance, typically from a port or rail terminal to a warehouse or distribution center. This service is essential for moving cargo efficiently between different modes of transportation, such as ships, trains, and trucks.

Importance of Drayage in the Supply Chain:

– Facilitates the smooth flow of goods from ports to inland destinations

– Enables timely delivery of cargo to warehouses and distribution centers

– Helps businesses maintain optimal inventory levels and meet customer demands

– Plays a vital role in the overall efficiency and cost-effectiveness of the supply chain

Drayage services are often provided by specialized trucking companies that have the necessary equipment, expertise, and permits to operate within port facilities and navigate congested urban areas. By outsourcing drayage to these providers, businesses can focus on their core competencies while ensuring that their cargo is handled professionally and efficiently.

What are the Key Factors that Influence Drayage Costs?

Several key factors can significantly impact the cost of drayage services. Understanding these factors is essential for businesses looking to optimize their transportation costs and make informed decisions when selecting a drayage provider.

Distance and Location:

The distance between the port or rail terminal and the final destination is one of the primary factors affecting drayage costs. Longer distances generally result in higher transportation costs due to increased fuel consumption and driver hours. Additionally, the location of the facilities involved can influence costs, as some areas may have higher labor rates, tolls, or congestion levels.

Cargo Volume and Weight:

The volume and weight of the cargo being transported also play a significant role in determining drayage costs. Larger and heavier shipments may require specialized equipment, such as flatbed trucks or heavy-duty trailers, which can increase costs. Moreover, shipments that exceed standard container dimensions or weight limits may incur additional fees.

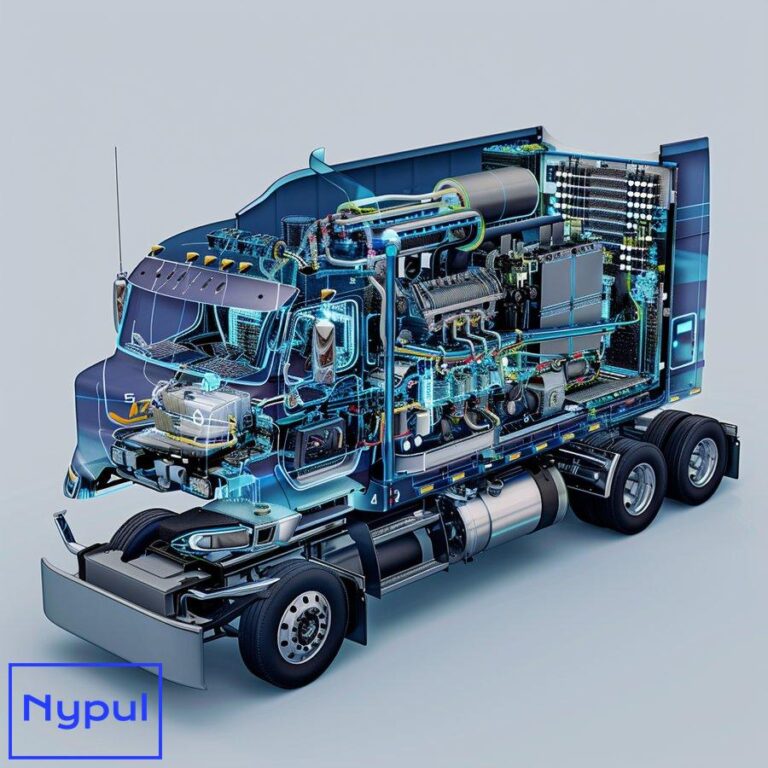

Equipment and Vehicle Type:

The type of equipment and vehicles used for drayage can affect costs. Standard 20-foot or 40-foot containers are the most common, but some cargo may require specialized equipment, such as refrigerated containers or open-top containers. The availability and cost of these specialized options can vary depending on the drayage provider and location.

Seasonal Demand and Market Conditions:

Drayage costs can fluctuate based on seasonal demand and overall market conditions. During peak shipping seasons, such as the months leading up to holidays, drayage providers may experience higher demand, leading to increased rates. Similarly, market conditions, such as fuel prices, labor costs, and regulatory changes, can impact the overall cost of drayage services.

How do Different Pricing Models Affect Drayage Calculations?

Drayage providers offer various pricing models, each with its own advantages and implications for cost calculations. Understanding these different models can help businesses select the most suitable option for their specific needs and budget.

Per-Trip Pricing:

Per-trip pricing is a straightforward model where the drayage provider charges a fixed rate for each individual trip, regardless of the time taken or distance traveled. This model offers predictability and simplicity, making it easier for businesses to budget for drayage costs. However, it may not be the most cost-effective option for shorter distances or trips with minimal delays.

Hourly Pricing:

With hourly pricing, the drayage provider charges based on the actual time spent on the job, including loading, unloading, and transit times. This model can be advantageous for businesses with shorter distances or unpredictable wait times, as they only pay for the actual time used. However, it can be more challenging to estimate costs upfront, and delays can quickly increase the total cost.

Mileage-Based Pricing:

Mileage-based pricing calculates costs based on the distance traveled between the origin and destination. This model is more suitable for longer distances and can provide a more accurate representation of the actual transportation costs. However, it may not account for additional factors such as wait times or congestion, which can impact the overall cost.

Flat Rate Pricing:

Some drayage providers offer flat rate pricing for specific routes or regions, where a fixed price is charged regardless of the actual time or distance involved. This model provides predictability and can be beneficial for businesses with consistent shipping patterns within a defined area. However, it may not be the most cost-effective option for shipments outside the designated zones or those with unique requirements.

| Pricing Model | Advantages | Disadvantages |

|---|---|---|

| Per-Trip | – Predictable costs – Simple to budget |

– May not be cost-effective for shorter distances or minimal delays |

| Hourly | – Pay only for actual time used – Beneficial for shorter distances or unpredictable wait times |

– Challenging to estimate costs upfront – Delays can increase total cost |

| Mileage-Based | – Suitable for longer distances – Accurate representation of transportation costs |

– May not account for wait times or congestion |

| Flat Rate | – Predictable costs for specific routes or regions | – May not be cost-effective for shipments outside designated zones or with unique requirements |

What Additional Fees and Surcharges Should be Considered in Drayage Costs?

In addition to the base rates associated with different pricing models, several additional fees and surcharges can impact the total cost of drayage services. Being aware of these potential extra costs is crucial for accurate budgeting and cost estimation.

Fuel Surcharges:

Fuel surcharges are often applied to drayage rates to account for fluctuations in fuel prices. These surcharges are typically calculated as a percentage of the base rate and can vary depending on the current fuel market conditions. It’s essential to clarify with the drayage provider how fuel surcharges are determined and applied to avoid unexpected costs.

Detention and Demurrage Fees:

Detention fees are charged when a container or trailer is held beyond the agreed-upon free time at the pickup or delivery location. These fees compensate the drayage provider for the additional time their equipment is tied up and unavailable for other jobs. Demurrage fees, on the other hand, are charged by the port or rail terminal when a container is not picked up or returned within the allotted free time. Both detention and demurrage fees can quickly accumulate, so it’s crucial to plan accordingly and minimize delays.

Accessorial Charges:

Accessorial charges cover additional services or requirements beyond the standard pickup and delivery. These may include:

– Liftgate service for loading or unloading

– Inside delivery or pickup

– Residential delivery

– Hazardous materials handling

– Overweight or oversize loads

It’s important to communicate any special requirements or requests to the drayage provider upfront to ensure accurate quoting and avoid unexpected accessorial charges.

Tolls and Congestion Fees:

Depending on the route and location, drayage shipments may incur tolls or congestion fees. These costs are often passed on to the customer and can vary based on the specific road, bridge, or port involved. When requesting a quote, provide detailed information about the origin and destination to allow the drayage provider to accurately account for any applicable tolls or fees.

How Can You Calculate Drayage Costs Step-by-Step?

Calculating drayage costs involves several steps to ensure an accurate estimate. By following this step-by-step process, businesses can better understand the factors influencing their drayage expenses and make informed decisions when selecting a provider.

Step 1: Determine the Origin and Destination

Clearly identify the pickup and delivery locations, including the specific port, rail terminal, warehouse, or distribution center. This information is essential for the drayage provider to determine the distance, route, and any associated fees or surcharges.

Step 2: Specify Cargo Details

Provide accurate information about the cargo, including:

– Type of goods

– Weight and dimensions

– Number of containers or trailers required

– Any special handling requirements (e.g., refrigeration, hazardous materials)

These details help the drayage provider determine the appropriate equipment and any necessary accessorial charges.

Step 3: Choose a Pricing Model

Select a pricing model that best suits your needs, considering factors such as distance, cargo volume, and potential delays. Discuss the available options with the drayage provider and assess which model aligns with your budget and requirements.

Step 4: Request a Quote

Provide the drayage provider with the origin, destination, cargo details, and preferred pricing model to request a quote. Be sure to ask about any additional fees, surcharges, or accessorial charges that may apply to your shipment.

Step 5: Review and Compare Quotes

Obtain quotes from multiple drayage providers to compare rates and services. Carefully review each quote, paying attention to the following:

– Base rate and pricing model

– Fuel surcharges

– Detention and demurrage policies

– Accessorial charges

– Insurance coverage and liability limits

Step 6: Negotiate and Finalize

If necessary, negotiate rates or terms with the drayage provider to ensure the best value for your business. Once you have selected a provider, finalize the agreement and provide any necessary documentation or information to streamline the drayage process.

By following these steps and carefully considering the various factors influencing drayage costs, businesses can make informed decisions and optimize their transportation expenses.

Which Tools and Resources Can Assist in Accurate Drayage Cost Estimation?

Several tools and resources are available to help businesses accurately estimate drayage costs and make informed decisions when selecting a provider. By leveraging these resources, companies can streamline their drayage process and optimize transportation expenses.

Online Drayage Cost Calculators:

Many drayage providers and logistics platforms offer online cost calculators that allow users to input origin, destination, and cargo details to receive instant quotes. These tools can provide a quick and convenient way to estimate costs and compare rates from multiple providers. However, it’s essential to verify the accuracy of these estimates and ensure they account for all applicable fees and surcharges.

Freight Marketplaces and Comparison Platforms:

Online freight marketplaces and comparison platforms, such as Freightos, Convoy, and uShip, connect businesses with a network of drayage providers and allow users to request quotes, compare rates, and book services. These platforms often provide additional features, such as real-time tracking, document management, and performance metrics, to help businesses optimize their drayage operations.

Industry Associations and Resources:

Industry associations, such as the Intermodal Association of North America (IANA) and the American Trucking Associations (ATA), offer valuable resources and insights into drayage costs and best practices. These organizations provide industry reports, benchmarking data, and educational materials that can help businesses stay informed about market trends and make data-driven decisions.

Logistics Software and Transportation Management Systems (TMS):

Logistics software and transportation management systems can help businesses automate and optimize their drayage operations. These tools often include cost estimation features, allowing users to input shipment details and receive accurate quotes based on real-time market data. Additionally, TMS platforms can help businesses manage carrier relationships, track shipments, and analyze performance metrics to identify cost-saving opportunities.

Consultation with Logistics Experts:

Engaging with logistics experts, such as consultants or third-party logistics providers (3PLs), can provide valuable insights and guidance on drayage cost estimation. These professionals have extensive industry knowledge and can help businesses navigate complex pricing models, identify cost-saving opportunities, and develop strategic partnerships with drayage providers.

By utilizing these tools and resources, businesses can enhance their ability to accurately estimate drayage costs, make informed decisions, and optimize their transportation expenses.

How Can Businesses Optimize Their Drayage Costs?

Optimizing drayage costs is essential for businesses looking to improve their bottom line and maintain a competitive edge in the market. By implementing strategic initiatives and best practices, companies can reduce their drayage expenses while ensuring the efficient and reliable movement of their cargo.

Consolidate Shipments:

Consolidating multiple smaller shipments into a single larger load can help reduce drayage costs by minimizing the number of trips required. By working with a logistics provider or utilizing a consolidation service, businesses can combine their cargo with that of other shippers to achieve better economies of scale and lower per-unit transportation costs.

Optimize Container Utilization:

Maximizing container utilization is crucial for reducing drayage costs. By efficiently loading and unloading containers, businesses can minimize the number of containers required and reduce associated fees. Strategies for optimizing container utilization include:

– Using space-saving packaging techniques

– Properly planning and staging cargo

– Employing efficient loading and unloading practices

Implement Just-in-Time (JIT) Delivery:

Just-in-Time (JIT) delivery is a strategy that involves coordinating shipments to arrive at the precise time they are needed, minimizing storage and handling costs. By synchronizing drayage operations with production schedules and customer demands, businesses can reduce the need for extensive inventory holding and minimize associated drayage expenses.

Develop Strategic Carrier Relationships:

Building strong, long-term relationships with drayage providers can lead to cost savings and improved service levels. By partnering with reliable carriers and negotiating favorable rates and terms, businesses can secure competitive pricing and ensure the consistent availability of equipment and resources. Additionally, fostering open communication and collaboration with carriers can help identify opportunities for process improvements and cost reductions.

Leverage Technology and Data Analytics:

Utilizing technology and data analytics can help businesses optimize their drayage operations and reduce costs. Transportation management systems (TMS) and logistics software can provide real-time visibility into shipment status, enabling better decision-making and proactive problem-solving. By analyzing historical data and performance metrics, businesses can identify trends, inefficiencies, and areas for improvement, allowing them to make data-driven decisions that reduce drayage expenses.

Continuously Monitor and Adjust:

Regularly monitoring and adjusting drayage strategies is essential for ongoing cost optimization. By tracking key performance indicators (KPIs) such as on-time delivery rates, container utilization, and cost per shipment, businesses can identify areas for improvement and make necessary adjustments to their processes. Continuously seeking feedback from carriers, customers, and internal stakeholders can also provide valuable insights into opportunities for cost savings and service enhancements.

| Strategy | Benefits | Implementation |

|---|---|---|

| Consolidate Shipments | – Reduces number of trips – Lowers per-unit transportation costs |

– Work with logistics providers or consolidation services – Combine cargo with other shippers |

| Optimize Container Utilization | – Minimizes number of containers required – Reduces associated fees |

– Use space-saving packaging techniques – Plan and stage cargo efficiently – Employ efficient loading and unloading practices |

| Implement Just-in-Time (JIT) Delivery | – Minimizes storage and handling costs – Reduces need for extensive inventory holding |

– Coordinate shipments with production schedules and customer demands – Synchronize drayage operations with just-in-time principles |

| Develop Strategic Carrier Relationships | – Secures competitive pricing – Ensures consistent availability of equipment and resources |

– Partner with reliable carriers – Negotiate favorable rates and terms – Foster open communication and collaboration |

| Leverage Technology and Data Analytics | – Provides real-time visibility into shipment status – Enables data-driven decision-making |

– Utilize transportation management systems (TMS) and logistics software – Analyze historical data and performance metrics – Identify trends, inefficiencies, and areas for improvement |

| Continuously Monitor and Adjust | – Identifies areas for improvement – Allows for ongoing cost optimization |

– Track key performance indicators (KPIs) – Seek feedback from carriers, customers, and internal stakeholders – Make necessary adjustments to processes |

By implementing these strategies and continuously monitoring and adjusting their drayage operations, businesses can effectively optimize their costs and improve the efficiency of their transportation processes.