How to Factor in Delivery Costs

What are the components of delivery costs?

Understanding the components of delivery costs is essential for businesses aiming to optimize their logistics operations. Delivery costs encompass various elements that directly influence the final price a customer pays for shipping. Key components include:

-

Transportation Mode: The choice between air, sea, or land transportation significantly impacts costs. Air freight is typically the most expensive but offers speed, while sea freight is more economical for larger shipments but slower.

-

Distance: The distance between the origin and destination plays a crucial role in determining shipping costs. Longer distances generally incur higher transportation fees due to increased fuel consumption and labor costs.

-

Package Characteristics: The weight, dimensions, and nature of the package affect shipping rates. Heavier and bulkier items incur higher costs due to the additional resources required for handling and transportation.

-

Fuel Prices: Fluctuations in fuel prices can drastically alter shipping costs. Companies must account for these variations in their pricing strategies.

-

Customs and Duties: For international shipments, customs fees and duties can add significant costs. Understanding the regulations of the destination country is vital for accurate cost estimation.

-

Insurance: Protecting shipments with insurance can add to overall costs but is often necessary for high-value items.

-

Handling Fees: Additional fees may apply for special handling requirements, such as fragile items or hazardous materials.

-

Warehousing Costs: If goods need to be stored before delivery, warehousing fees can contribute to overall delivery costs.

-

Technology and Management Systems: The use of logistics management systems can streamline operations but may involve initial setup costs.

A comprehensive understanding of these components allows businesses to make informed decisions regarding their logistics strategies, ultimately leading to cost savings and improved customer satisfaction.

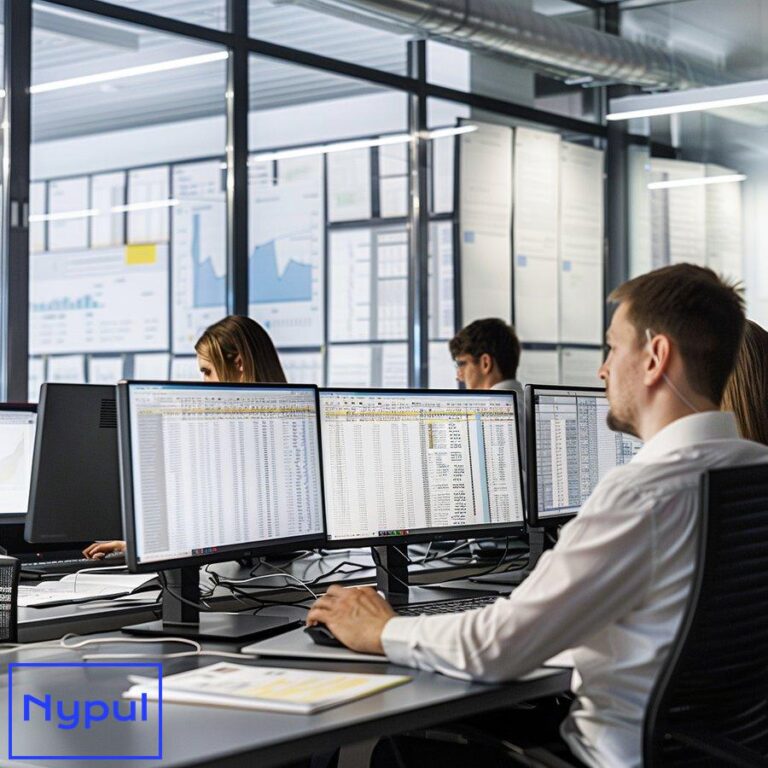

How do distance and package characteristics affect shipping expenses?

![]()

Distance and package characteristics are two of the most influential factors in determining shipping expenses.

Distance

The distance from the warehouse to the final destination directly correlates with shipping costs. As the distance increases, so do the associated costs, which can be broken down into several components:

-

Fuel Consumption: Longer distances require more fuel, leading to higher transportation costs. Fuel prices can fluctuate, further complicating cost predictions.

-

Labor Costs: Increased travel time means higher labor costs, as drivers are compensated for longer hours.

-

Handling Operations: Longer distances often involve more handling operations, which can increase the risk of damage and necessitate additional labor.

Package Characteristics

The characteristics of the package, including weight, dimensions, and special handling requirements, also play a significant role in determining shipping costs.

-

Weight: Heavier packages generally incur higher shipping fees. Shipping carriers often use weight-based pricing models, where costs increase with the weight of the shipment.

-

Dimensions: The size of the package can affect how many items can be loaded onto a vehicle. Larger packages may require more space, leading to higher costs per unit shipped.

-

Special Handling: Items that require special handling, such as fragile or hazardous materials, may incur additional fees. Businesses must ensure they are aware of these costs when pricing their products.

Summary Table of Influencing Factors on Shipping Costs

| Factor | Impact on Costs |

|---|---|

| Distance | Increases fuel and labor costs |

| Weight | Higher weight leads to increased fees |

| Dimensions | Larger dimensions reduce vehicle capacity |

| Special Handling | Additional fees for fragile/hazardous items |

Understanding the interplay between distance and package characteristics allows businesses to make strategic decisions that can lead to cost savings and enhanced efficiency in their logistics operations.

Which methods can accurately calculate delivery costs?

Accurate calculation of delivery costs is vital for businesses to maintain profitability and competitiveness. Several methods can be employed to achieve this accuracy:

![]()

1. Cost-Plus Pricing

This method involves calculating the total cost of delivering a product, including all associated expenses, and adding a markup for profit. It ensures that all costs are covered, but may not always reflect market conditions.

2. Market-Based Pricing

Market-based pricing involves analyzing competitor pricing and market trends to set delivery costs. This method is useful for businesses operating in highly competitive environments, as it helps ensure prices remain attractive to customers.

3. Weight and Dimension Pricing

Many shipping carriers use weight and dimension pricing models, where costs are calculated based on the weight and size of the package. This method is straightforward and allows for quick estimates.

4. Zone-Based Pricing

Zone-based pricing considers the distance from the shipping origin to the delivery destination. Carriers divide regions into zones, and shipping costs vary based on the zone a package is being shipped to.

5. Freight Class Pricing

For freight shipments, the National Motor Freight Classification (NMFC) system categorizes items into classes based on their characteristics. Each class has a specific rate, allowing for more accurate cost calculations based on the nature of the goods.

Summary Table of Delivery Cost Calculation Methods

| Method | Description | Pros | Cons |

|---|---|---|---|

| Cost-Plus Pricing | Total costs plus markup | Covers all costs | May not reflect market conditions |

| Market-Based Pricing | Based on competitor prices | Competitive pricing | May not cover all costs |

| Weight and Dimension | Based on weight and size | Simple and quick estimates | May not account for all variables |

| Zone-Based Pricing | Based on delivery zones | Reflects distance | Can be complex to manage |

| Freight Class Pricing | Based on NMFC classification | Accurate for freight shipments | Requires understanding of classifications |

Employing a combination of these methods can provide businesses with a comprehensive approach to accurately calculating delivery costs, ensuring they remain competitive while maintaining profitability.

How can businesses optimize their delivery cost structure?

Optimizing delivery cost structures is essential for businesses looking to enhance profitability and customer satisfaction. Several strategies can be employed to achieve this optimization:

1. Route Optimization

Implementing route optimization software can significantly reduce transportation costs. By analyzing delivery routes, businesses can identify the most efficient paths, minimizing fuel consumption and labor costs.

2. Consolidation of Shipments

Consolidating multiple shipments into a single delivery can reduce costs. This approach maximizes vehicle capacity and minimizes the number of trips required, leading to significant savings.

3. Negotiating with Carriers

Building strong relationships with carriers can lead to better rates and service agreements. Regularly negotiating contracts can help businesses secure favorable terms and reduce overall shipping costs.

4. Utilizing Technology

Investing in logistics management software can streamline operations and improve efficiency. These systems can provide real-time data on shipping costs, enabling businesses to make informed decisions.

5. Improving Warehouse Efficiency

Enhancing warehouse operations can lead to reduced handling costs. Implementing best practices for inventory management, order picking, and packing can minimize delays and improve overall efficiency.

6. Training Staff

Training employees on best practices for logistics and delivery can lead to improved efficiency and reduced costs. Well-trained staff are better equipped to handle challenges and optimize operations.

Summary Table of Cost Optimization Strategies

| Strategy | Description | Benefits |

|---|---|---|

| Route Optimization | Software to find efficient delivery paths | Reduces fuel and labor costs |

| Consolidation of Shipments | Combining multiple deliveries into one | Maximizes vehicle capacity |

| Negotiating with Carriers | Building relationships for better rates | Secures favorable shipping terms |

| Utilizing Technology | Implementing logistics management software | Streamlines operations |

| Improving Warehouse Efficiency | Enhancing inventory and packing processes | Minimizes handling costs |

| Training Staff | Educating employees on logistics best practices | Increases operational efficiency |

By implementing these strategies, businesses can effectively optimize their delivery cost structures, leading to improved profitability and customer satisfaction.

What strategies help integrate delivery costs into pricing models?

Integrating delivery costs into pricing models is essential for businesses to ensure profitability while remaining competitive. Several strategies can facilitate this integration:

1. Transparent Pricing

Adopting a transparent pricing model that clearly outlines delivery costs can enhance customer trust. By providing a breakdown of costs, businesses can justify their pricing and improve customer satisfaction.

2. Dynamic Pricing Models

Implementing dynamic pricing models that adjust based on delivery costs can help businesses remain competitive. This approach allows for flexibility in pricing, accommodating fluctuations in shipping expenses.

3. Bundling Services

Offering bundled services that include delivery can simplify pricing for customers. This strategy can enhance perceived value and encourage customers to choose comprehensive service packages.

4. Incorporating Delivery Costs into Product Pricing

Integrating delivery costs directly into product pricing can streamline the purchasing process. This approach ensures that customers are aware of total costs upfront, reducing the likelihood of abandoned carts.

5. Customer Segmentation

Understanding customer segments and their willingness to pay can inform pricing strategies. Tailoring delivery options and costs based on customer preferences can enhance overall satisfaction.

Summary Table of Strategies for Integrating Delivery Costs

| Strategy | Description | Benefits |

|---|---|---|

| Transparent Pricing | Clear breakdown of delivery costs | Enhances customer trust |

| Dynamic Pricing Models | Adjusts prices based on delivery costs | Maintains competitiveness |

| Bundling Services | Offers comprehensive service packages | Increases perceived value |

| Incorporating Delivery Costs | Includes costs in product pricing | Reduces abandoned carts |

| Customer Segmentation | Tailors delivery options to customer preferences | Enhances overall satisfaction |

Integrating delivery costs into pricing models can lead to improved customer experiences and increased profitability for businesses.

Which tools and technologies streamline delivery cost management?

The logistics industry has seen significant advancements in technology, enabling businesses to streamline delivery cost management. Several tools and technologies can facilitate this process:

1. Logistics Management Software

Comprehensive logistics management software allows businesses to track shipments, manage inventory, and analyze costs in real-time. These systems provide valuable insights that can help optimize operations.

2. Route Optimization Tools

Route optimization tools utilize algorithms to determine the most efficient delivery routes. By minimizing travel time and fuel consumption, businesses can significantly reduce shipping costs.

3. Warehouse Management Systems (WMS)

WMS solutions enhance warehouse operations by improving inventory accuracy, order picking, and packing processes. Efficient warehouse management can lead to reduced handling costs and improved delivery times.

4. Transportation Management Systems (TMS)

TMS solutions help businesses manage transportation operations, from carrier selection to shipment tracking. These systems can provide insights into costs and performance, enabling better decision-making.

5. Data Analytics Tools

Data analytics tools enable businesses to analyze shipping data and identify trends. By leveraging data, companies can make informed decisions regarding pricing, route optimization, and carrier selection.

Summary Table of Tools for Streamlining Delivery Cost Management

| Tool/Technology | Description | Benefits |

|---|---|---|

| Logistics Management Software | Tracks shipments and manages inventory | Provides real-time insights |

| Route Optimization Tools | Determines efficient delivery routes | Reduces travel time and costs |

| Warehouse Management Systems | Enhances warehouse operations | Improves inventory accuracy |

| Transportation Management Systems | Manages transportation operations | Enables better decision-making |

| Data Analytics Tools | Analyzes shipping data and trends | Informs pricing and optimization |

Utilizing these tools and technologies can significantly enhance delivery cost management, leading to improved efficiency and profitability.

How do international shipments impact delivery cost calculations?

International shipments introduce a range of complexities that can significantly impact delivery cost calculations. Several factors must be considered when calculating costs for international shipping:

1. Customs Duties and Taxes

Customs duties and taxes vary by country and can add substantial costs to international shipments. Businesses must be aware of the regulations in both the origin and destination countries to accurately estimate these fees.

2. Exchange Rates

Fluctuations in exchange rates can affect the cost of shipping internationally. Businesses should monitor currency exchange rates to ensure accurate pricing and cost calculations.

3. Shipping Regulations

Different countries have varying shipping regulations, which can impact costs. Compliance with these regulations is essential to avoid delays and additional fees.

4. Insurance Costs

International shipments often require additional insurance coverage due to increased risks. Understanding the insurance requirements for different countries can help businesses accurately calculate costs.

5. Transportation Modes

The choice of transportation mode for international shipments can significantly impact costs. Air freight is faster but more expensive, while sea freight is more economical but slower. Businesses must weigh the trade-offs between speed and cost.

Summary Table of Factors Impacting International Shipment Costs

| Factor | Impact on Costs |

|---|---|

| Customs Duties and Taxes | Varies by country, adding significant costs |

| Exchange Rates | Fluctuations affect overall pricing |

| Shipping Regulations | Compliance is essential to avoid fees |

| Insurance Costs | Additional coverage may be needed |

| Transportation Modes | Choice affects speed and cost |

Understanding these factors allows businesses to navigate the complexities of international shipping and accurately calculate delivery costs, ensuring competitiveness in the global market.