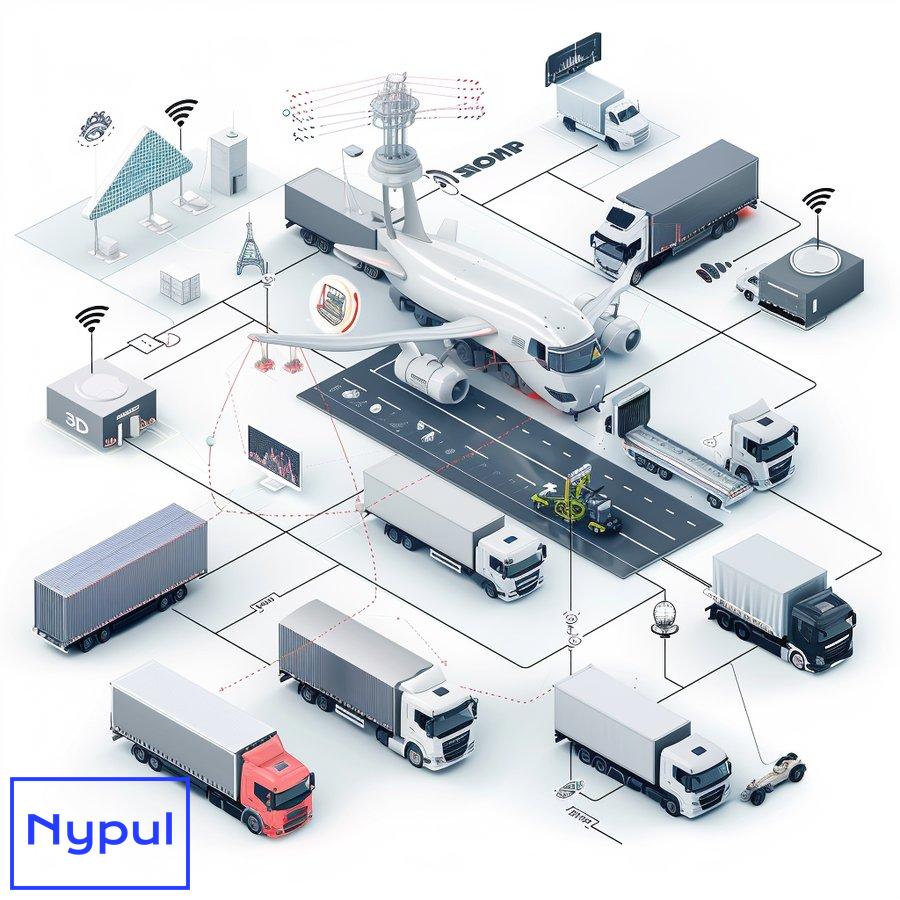

How to Optimize Truck Load

What is truck load optimization and why is it important?

Truck load optimization refers to the strategic process of maximizing the use of available space and weight capacity in a truck or trailer to transport goods efficiently. This practice involves carefully planning and arranging cargo to utilize every cubic inch of space while adhering to weight limits and safety regulations.

The importance of truck load optimization cannot be overstated in the logistics and transportation industry. Efficient loading directly impacts a company’s bottom line, operational effectiveness, and environmental footprint.

Cost Reduction

Optimized loads translate to fewer trips required to transport the same volume of goods. This reduction in trips leads to significant cost savings in several areas:

Fuel Consumption: Fewer trips mean less fuel used overall, which is often one of the largest operational expenses for trucking companies.

Labor Costs: Optimized loads reduce the total driver hours needed to complete deliveries, potentially lowering overtime costs and improving driver satisfaction.

Vehicle Wear and Tear: Reduced mileage on trucks results in lower maintenance costs and extended vehicle lifespans.

Improved Operational Efficiency

Truck load optimization enhances overall operational efficiency in multiple ways:

Increased Throughput: By maximizing the cargo space in each truck, companies can move more goods with the same number of vehicles, increasing their overall shipping capacity.

Faster Turnaround Times: Efficient loading and unloading processes, which are part of load optimization, reduce dwell times at warehouses and distribution centers.

Better Resource Utilization: Optimized loads allow for more effective use of trucks, trailers, and drivers, potentially reducing the need for additional equipment or personnel.

Enhanced Customer Satisfaction

Load optimization contributes to improved customer satisfaction through:

On-Time Deliveries: Efficient loading and routing lead to more predictable and timely deliveries, meeting or exceeding customer expectations.

Reduced Damage: Proper load planning minimizes the risk of cargo shifting or being damaged during transit, ensuring goods arrive in optimal condition.

Competitive Pricing: Cost savings from optimized operations can be passed on to customers, making a company’s services more attractive in a competitive market.

Environmental Impact

In an era of increasing environmental awareness, truck load optimization plays a crucial role in reducing the carbon footprint of logistics operations:

Reduced Emissions: Fewer trips and more efficient use of fuel directly translate to lower greenhouse gas emissions.

Less Traffic Congestion: Optimized loads mean fewer trucks on the road, potentially reducing traffic congestion in urban areas.

Resource Conservation: Efficient use of trucks and fuel contributes to overall resource conservation efforts.

Regulatory Compliance

Load optimization helps ensure compliance with various transportation regulations:

Weight Limits: Proper load planning ensures trucks stay within legal weight limits for roads and bridges.

Hours of Service: Optimized routes and loads help drivers stay within mandated hours of service regulations.

Safety Standards: Correct load distribution enhances vehicle stability and safety on the road.

Truck load optimization is not just a best practice; it’s a necessity for modern logistics operations. By maximizing the efficiency of each trip, companies can significantly reduce costs, improve service quality, minimize environmental impact, and stay competitive in an increasingly challenging market. As we delve deeper into specific strategies and technologies in the following sections, the multifaceted benefits of load optimization will become even more apparent.

How can you assess your current load efficiency?

Assessing your current load efficiency is a critical step in identifying areas for improvement and establishing a baseline for future optimization efforts. This process involves analyzing various aspects of your loading operations and gathering relevant data to paint a comprehensive picture of your current performance.

Data Collection and Analysis

The first step in assessing load efficiency is to collect and analyze relevant data:

Load Factor: Calculate the percentage of available space or weight capacity utilized in each shipment. This can be done by dividing the actual load (in volume or weight) by the maximum capacity of the truck or container.

Shipment Records: Review historical shipment data to identify patterns in load sizes, frequencies, and destinations.

Vehicle Utilization: Analyze how often your trucks are running at full capacity versus partial loads.

Route Information: Examine route data to understand the relationship between load efficiency and travel distances.

To facilitate this analysis, consider implementing a transportation management system (TMS) or utilizing existing logistics software to automatically collect and process this data.

Key Metrics for Load Efficiency Assessment

Several key metrics can provide insight into your current load efficiency:

| Metric | Description | Calculation |

|---|---|---|

| Cube Utilization | Percentage of available volume used | (Volume of loaded cargo / Total available volume) x 100 |

| Weight Utilization | Percentage of weight capacity used | (Weight of loaded cargo / Maximum weight capacity) x 100 |

| Empty Miles Percentage | Percentage of miles driven without cargo | (Empty miles / Total miles) x 100 |

| Average Load Size | Average volume or weight of shipments | Total cargo volume or weight / Number of shipments |

| On-Time Delivery Rate | Percentage of deliveries made within promised timeframe | (On-time deliveries / Total deliveries) x 100 |

Visual Inspection and Load Audits

While data analysis is crucial, visual inspections and load audits can provide additional insights:

Physical Inspections: Regularly observe loading processes and completed loads to identify inefficiencies or wasted space.

Photographic Evidence: Take photos of loaded trucks before departure to document space utilization and identify patterns.

Load Diagrams: Create diagrams of typical loads to visualize space usage and potential areas for improvement.

Employee Feedback

Engage with employees directly involved in the loading process:

Driver Surveys: Collect feedback from drivers about load stability, weight distribution, and ease of loading/unloading.

Warehouse Staff Input: Consult with warehouse staff about challenges they face in preparing and loading shipments.

Dispatcher Insights: Gather information from dispatchers about recurring issues with load planning or route efficiency.

Benchmarking

Compare your performance against industry standards and competitors:

Industry Reports: Review industry benchmarks for load efficiency metrics in your specific sector.

Peer Comparisons: If possible, engage in data sharing with industry peers to compare performance.

Carrier Feedback: For shippers using third-party carriers, request feedback on load efficiency compared to other clients.

Technology Assessment

Evaluate your current use of technology in load planning and execution:

Software Capabilities: Assess whether your current software tools provide adequate support for load optimization.

Data Integration: Determine if your systems effectively integrate data from various sources (e.g., warehouse management, order processing, transportation management).

Automation Level: Evaluate the degree of automation in your load planning processes.

Identifying Improvement Opportunities

Based on your assessment, identify specific areas for improvement:

Underutilized Space: Look for patterns of consistently underutilized space in certain types of shipments or routes.

Frequent Partial Loads: Identify routes or customers that frequently result in partial truckloads.

Inefficient Product Mix: Analyze whether certain product combinations lead to poor space utilization.

Seasonal Variations: Determine if load efficiency varies significantly during different seasons or peak periods.

Setting Baseline and Goals

Establish a clear baseline for your current load efficiency:

Current Performance: Document your current performance across key metrics.

Goal Setting: Based on your assessment and industry benchmarks, set realistic improvement goals for each metric.

Action Plan: Develop a preliminary action plan to address the most significant opportunities for improvement.

Assessing your current load efficiency is not a one-time task but an ongoing process. Regular evaluations help track progress, identify new challenges, and continuously refine your optimization strategies. By thoroughly understanding your current performance, you can make informed decisions about where to focus your optimization efforts and how to measure their impact effectively.

What strategies can maximize cargo space utilization?

Maximizing cargo space utilization is a critical aspect of truck load optimization. Effective strategies in this area can significantly increase the amount of cargo transported per trip, leading to cost savings and improved operational efficiency. Here are key strategies to consider:

Proper Load Planning

Effective load planning is the foundation of maximizing cargo space utilization:

3D Load Planning Software: Utilize advanced software that can create optimal loading patterns based on the dimensions and weight of each item. These tools can often suggest the best arrangement to maximize space usage while considering factors like weight distribution and load stability.

Mixed Palletization: Instead of shipping partial pallets, combine items from different orders onto single pallets when possible. This approach can significantly reduce wasted space between and above pallets.

Cube Optimization: Focus on maximizing the cubic space of the trailer, not just the floor space. This might involve stacking compatible items or using specialized racking systems to utilize vertical space effectively.

Flexible Packaging Solutions

Adapting packaging to optimize space can yield significant improvements:

Right-Sized Packaging: Use packaging that fits the product snugly, reducing empty space within boxes. This might involve custom packaging solutions for frequently shipped items.

Collapsible Containers: For return trips or multi-stop routes, consider using collapsible containers that can be easily stacked when empty.

Vacuum Packaging: For compressible goods, vacuum packaging can significantly reduce the volume of each item, allowing for more efficient use of space.

Load Stabilization Techniques

Proper stabilization allows for more efficient stacking and space utilization:

Dunnage Bags: Use inflatable dunnage bags to fill void spaces between pallets or boxes, preventing shifting during transit and allowing for tighter packing.

Strapping and Wrapping: Utilize appropriate strapping and wrapping techniques to secure loads, enabling higher stacking and more compact arrangements.

Custom Load Bars: Implement adjustable load bars to create separate compartments within the trailer, allowing for better organization and space utilization, especially for mixed loads.

Innovative Loading Equipment

Specialized equipment can facilitate more efficient loading and space utilization:

Double-Deck Trailers: For light but bulky items, double-deck trailers can nearly double the available floor space.

Sliding Systems: Implement sliding floor or roof systems that allow for easier loading and unloading, enabling tighter packing of goods.

Tailored Racking Systems: Use customized racking systems designed for specific product types or mixed loads to maximize vertical space utilization.

Product and Order Consolidation

Strategic consolidation can lead to better space utilization:

Order Bundling: Combine multiple small orders going to the same destination or along the same route into single shipments.

Cross-Docking: Utilize cross-docking techniques to consolidate incoming shipments from multiple suppliers into full truckloads for outbound delivery.

Milk Runs: Implement milk run strategies where a single truck makes multiple pickups before a final delivery, consolidating partial loads from different sources.

Dimensional Weight Pricing Strategies

Adapt to dimensional weight pricing models used by many carriers:

Optimize for Dimensional Weight: Design packaging and loading strategies that optimize for dimensional weight pricing, which considers both the actual weight and the dimensional weight of shipments.

Educate Customers: Work with customers to optimize their ordering patterns and packaging to reduce dimensional weight charges and improve overall load efficiency.

Dynamic Load Planning

Implement dynamic approaches to load planning:

Real-Time Adjustments: Use real-time data to adjust load plans based on last-minute changes or cancellations.

Predictive Analytics: Leverage historical data and predictive analytics to anticipate space requirements and optimize load planning in advance.

Collaborative Loading

Explore collaborative loading opportunities:

Shipper Collaboration: Partner with other shippers to combine partial loads going to similar destinations.

Carrier Partnerships: Work closely with carriers to identify opportunities for load consolidation or backhaul utilization.

Training and Best Practices

Invest in training and establishing best practices:

Staff Training: Provide comprehensive training to loading staff on space utilization techniques and the importance of efficient loading.

Standard Operating Procedures: Develop and implement standard operating procedures for loading that prioritize space utilization.

Regular Audits: Conduct regular audits of loaded trucks to identify areas for improvement and ensure adherence to best practices.

Continuous Improvement

Implement a culture of continuous improvement:

Regular Reviews: Conduct periodic reviews of loading practices and their outcomes.

Feedback Loops: Establish feedback mechanisms from drivers, warehouse staff, and customers to identify issues and opportunities for improvement.

Benchmarking: Regularly benchmark your space utilization metrics against industry standards and your own historical performance.

By implementing a combination of these strategies, companies can significantly improve their cargo space utilization. The key is to approach the challenge holistically, considering all aspects of the loading process from packaging design to final delivery. Regular assessment and adaptation of these strategies ensure ongoing optimization and efficiency gains in an ever-changing logistics landscape.

How can technology improve load optimization?

Technology plays a pivotal role in enhancing load optimization, offering tools and systems that can significantly improve efficiency, accuracy, and decision-making in the loading process. The integration of advanced technologies can transform load optimization from a manual, time-consuming task into a streamlined, data-driven operation. Here’s how various technologies contribute to improved load optimization:

3D Load Planning Software

Advanced 3D load planning software is at the forefront of technological solutions for load optimization:

Automated Load Plans: These systems can generate optimal loading configurations in seconds, considering factors such as item dimensions, weight, fragility, and loading sequence.

Visual Representation: 3D visualization allows planners to see the proposed load arrangement before physical loading begins, enabling quick adjustments and validation.

Multi-Parameter Optimization: Advanced algorithms can simultaneously optimize for multiple factors, including space utilization, weight distribution, and loading/unloading efficiency.

Real-Time Adjustments: Some systems can adapt load plans in real-time as new information becomes available or as changes occur in the shipping manifest.

Transportation Management Systems (TMS)

Modern TMS platforms offer comprehensive tools for load optimization:

Integrated Planning: TMS systems can integrate load planning with route optimization, carrier selection, and scheduling, ensuring a holistic approach to transportation efficiency.

Data Centralization: By centralizing shipping data, TMS enables better decision-making for load consolidation and optimization across multiple shipments and locations.

Performance Analytics: Advanced analytics within TMS can track load efficiency over time, identifying trends and opportunities for improvement.

Artificial Intelligence and Machine Learning

AI and ML technologies are revolutionizing load optimization:

Predictive Analytics: Machine learning algorithms can analyze historical data to predict optimal loading patterns for different types of shipments and routes.

Continuous Learning: AI systems can learn from each shipment, continuously refining their optimization strategies based on real-world outcomes.

Complex Problem Solving: AI can handle complex optimization problems that involve multiple variables and constraints, often finding solutions that human planners might overlook.

Internet of Things (IoT) and Sensors

IoT devices and sensors provide real-time data that can enhance load optimization:

Real-Time Monitoring: Sensors can track the position and condition of goods during transit, allowing for dynamic load adjustments in multi-stop routes.

Capacity Utilization Tracking: IoT devices can provide accurate, real-time data on how much space is being utilized in a trailer, enabling better decision-making for additional pickups or load consolidation.

Environmental Monitoring: Sensors can track conditions like temperature and humidity, ensuring optimal placement of sensitive goods within the load.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies are emerging as valuable tools in load planning and execution:

Training: VR can be used to train loading personnel in optimal techniques without the need for physical goods or vehicles.

Guided Loading: AR systems can provide visual guidance to loaders, showing them exactly where and how to place each item for optimal space utilization.

Virtual Load Inspection: VR allows planners to virtually “walk through” a proposed load, identifying potential issues before physical loading begins.

Mobile Applications

Mobile apps are enhancing the flexibility and responsiveness of load optimization:

On-the-Go Planning: Mobile load planning apps allow for adjustments to be made from anywhere, enabling quick responses to last-minute changes.

Driver Feedback: Apps can facilitate real-time communication between drivers and planners, allowing for immediate adjustments based on actual loading conditions.

Photo Documentation: Mobile apps can be used to capture and share photos of loaded trailers, enabling remote verification of load plans and identification of improvement opportunities.

Blockchain Technology

While still in early stages for load optimization, blockchain offers potential benefits:

Enhanced Traceability: Blockchain can provide an immutable record of how goods were loaded, transported, and unloaded, which can be valuable for dispute resolution and continuous improvement.

Smart Contracts: Blockchain-based smart contracts could automate certain aspects of load optimization, such as triggering consolidation of shipments based on predefined criteria.

Robotics and Automation

Automated loading systems are becoming more prevalent in warehouses and distribution centers:

Automated Guided Vehicles (AGVs): AGVs can execute precise loading plans, maximizing space utilization and reducing human error.

Robotic Palletizers: These systems can create optimally stacked pallets, considering factors like weight distribution and item fragility.

Automated Storage and Retrieval Systems (AS/RS): These systems can efficiently retrieve and stage items for loading, supporting more complex and efficient load plans.