How to Reduce Turnaround Time

What is turnaround time and why is it crucial in logistics?

Turnaround time in logistics refers to the total duration from when a vehicle or vessel arrives at a facility to when it departs after completing all necessary operations. This critical metric encompasses various activities, including unloading, processing, loading, and administrative tasks. For trucking companies, port operators, and warehouse managers, understanding and optimizing turnaround time is essential for maintaining efficiency and competitiveness in the fast-paced world of supply chain management.

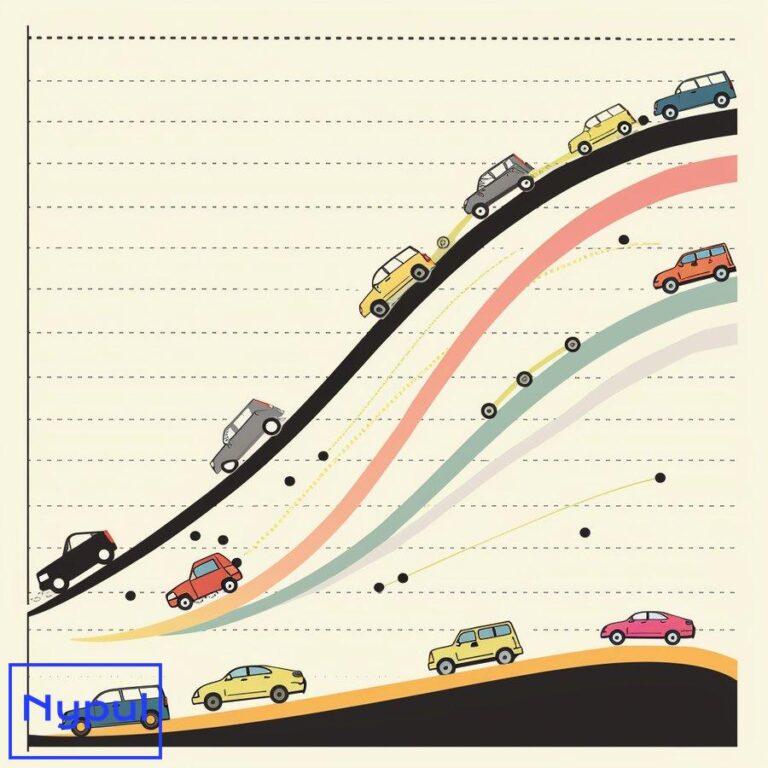

The significance of turnaround time in logistics cannot be overstated. It directly impacts operational efficiency, customer satisfaction, and overall profitability. A shorter turnaround time translates to increased productivity, as it allows for more shipments to be processed within a given timeframe. This efficiency boost can lead to substantial cost savings and improved resource utilization.

Impact on operational costs

Reducing turnaround time has a direct correlation with operational costs. When vehicles or vessels spend less time at facilities, it minimizes idle time and associated expenses such as fuel consumption, labor costs, and equipment wear and tear. For instance, a trucking company that reduces its average turnaround time at distribution centers from 3 hours to 2 hours can potentially increase the number of deliveries per day, thereby improving asset utilization and reducing per-shipment costs.

Customer satisfaction and competitive advantage

In an era where customers expect rapid delivery and real-time updates, minimizing turnaround time is crucial for meeting and exceeding these expectations. Faster turnaround times enable logistics providers to offer shorter lead times, more reliable delivery schedules, and improved tracking capabilities. This enhanced service level can significantly boost customer satisfaction and loyalty, providing a competitive edge in the market.

Supply chain resilience

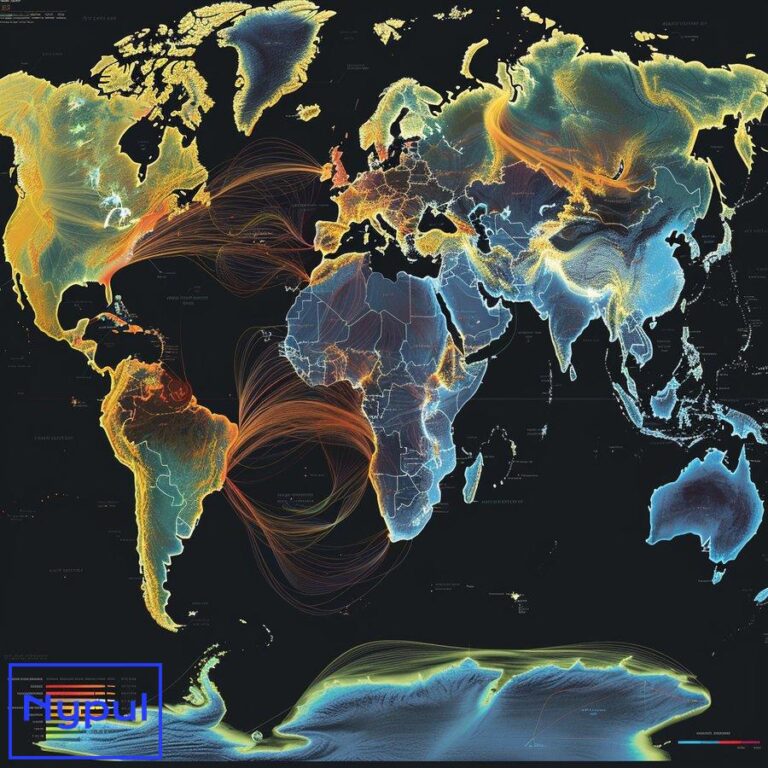

Efficient turnaround times contribute to overall supply chain resilience. By reducing bottlenecks and improving the flow of goods, logistics operations become more adaptable to sudden changes in demand or unexpected disruptions. This flexibility is particularly valuable in today’s volatile global market, where factors such as natural disasters, geopolitical events, or pandemics can quickly impact supply chains.

Environmental considerations

Reducing turnaround time also aligns with sustainability goals. Shorter waiting times for vehicles and vessels result in decreased fuel consumption and lower emissions. This reduction in carbon footprint not only benefits the environment but also helps companies meet increasingly stringent environmental regulations and corporate sustainability targets.

Key factors influencing turnaround time

Several factors contribute to the overall turnaround time in logistics operations:

Documentation and administrative processes: The efficiency of paperwork handling, customs clearance, and other administrative tasks can significantly impact turnaround time.

Loading and unloading operations: The speed and effectiveness of cargo handling, including the use of appropriate equipment and optimized loading patterns, play a crucial role.

Yard management: Efficient organization of the facility layout and vehicle/container movements within the yard can reduce waiting times and improve flow.

Technology integration: The use of advanced systems for scheduling, tracking, and process automation can streamline operations and reduce delays.

Staff training and performance: Well-trained and motivated personnel can execute tasks more quickly and efficiently, contributing to faster turnaround times.

Communication and coordination: Effective information sharing among all stakeholders, including carriers, facility operators, and customs authorities, is essential for smooth operations.

Understanding these factors and their interplay is crucial for logistics professionals aiming to optimize turnaround time. By addressing each aspect systematically, companies can achieve significant improvements in their overall operational efficiency.

In conclusion, turnaround time is a fundamental metric in logistics that impacts every aspect of the supply chain. Its optimization is not just a matter of operational efficiency but a strategic imperative for companies looking to thrive in the competitive logistics landscape. As we delve deeper into specific strategies and technologies for reducing turnaround time, it’s important to keep in mind the far-reaching effects of these improvements on cost-effectiveness, customer satisfaction, and overall business success.

How can you effectively analyze current processes to identify inefficiencies?

Analyzing current processes to identify inefficiencies is a critical step in reducing turnaround time in logistics operations. This systematic approach allows companies to pinpoint bottlenecks, redundancies, and areas for improvement. By thoroughly examining existing workflows, organizations can develop targeted strategies to streamline operations and enhance overall efficiency.

Process mapping and visualization

The first step in analyzing current processes is to create detailed process maps or flowcharts. These visual representations provide a clear overview of the entire operation, from the arrival of a vehicle or vessel to its departure. Process mapping helps identify:

- Sequential steps in the operation

- Decision points and potential bottlenecks

- Parallel processes and their interdependencies

- Handoff points between different departments or stakeholders

Tools such as Business Process Model and Notation (BPMN) or value stream mapping can be particularly useful for this purpose. These methodologies not only illustrate the current state but also help in envisioning an improved future state.

Data collection and analysis

Gathering comprehensive data on current operations is crucial for identifying inefficiencies. This involves:

Time studies: Measure the duration of each process step to identify time-consuming activities.

Volume analysis: Assess the quantity of transactions or shipments processed over different time periods to understand peak times and capacity constraints.

Error rates: Track the frequency and types of errors or exceptions that occur, as these often lead to delays and rework.

Resource utilization: Monitor the usage of equipment, personnel, and facilities to identify underutilized or overburdened resources.

Advanced analytics tools and business intelligence software can help in processing large volumes of data and uncovering patterns or trends that may not be immediately apparent.

Benchmarking

Comparing your organization’s performance against industry standards or best practices can reveal areas where your processes fall short. Benchmarking can involve:

- Internal comparisons between different facilities or teams within your organization

- External comparisons with competitors or industry leaders

- Cross-industry benchmarking to identify innovative practices from other sectors

Key performance indicators (KPIs) for benchmarking in logistics might include average turnaround time, dock-to-stock time, or perfect order rate.

Root cause analysis

When inefficiencies are identified, it’s essential to dig deeper to understand their underlying causes. Techniques such as the “5 Whys” or fishbone diagrams can help uncover the root causes of problems. For example, if long waiting times are observed at a particular stage, asking “why” repeatedly might reveal issues such as:

- Inadequate staffing during peak hours

- Outdated equipment slowing down operations

- Inefficient communication between departments

- Poorly designed facility layout

Stakeholder feedback

Engaging with employees, customers, and partners who are directly involved in the processes can provide valuable insights. Methods for gathering stakeholder feedback include:

Employee surveys: Collect input from frontline workers who often have firsthand knowledge of operational challenges.

Customer feedback: Analyze complaints, suggestions, and satisfaction scores to identify areas where inefficiencies impact service quality.

Partner interviews: Engage with carriers, suppliers, and other partners to understand their perspectives on process bottlenecks.

Technology audit

Assessing the current technology stack and its effectiveness in supporting operations is crucial. This audit should cover:

- Warehouse Management Systems (WMS)

- Transportation Management Systems (TMS)

- Enterprise Resource Planning (ERP) systems

- Internet of Things (IoT) devices and sensors

- Data analytics and reporting tools

Identify any gaps in technology adoption or integration issues that may be contributing to inefficiencies.

Simulation and modeling

Advanced simulation tools can help analyze complex logistics processes and test various scenarios without disrupting actual operations. These models can:

- Predict the impact of changes in volume, staffing, or equipment

- Identify optimal process configurations

- Test the effectiveness of proposed improvements before implementation

Lean methodology application

Applying lean principles to logistics processes can reveal non-value-adding activities or waste. The seven types of waste in lean methodology (Transport, Inventory, Motion, Waiting, Overproduction, Over-processing, and Defects) provide a framework for identifying inefficiencies in logistics operations.

Continuous improvement culture

Fostering a culture of continuous improvement encourages ongoing analysis and refinement of processes. This can involve:

- Regular process review meetings

- Employee suggestion programs

- Kaizen events or rapid improvement workshops

By instilling this mindset across the organization, inefficiencies can be identified and addressed on an ongoing basis, rather than through sporadic audits.

Quantifying inefficiencies

To prioritize improvement efforts, it’s important to quantify the impact of identified inefficiencies. This can be done by:

- Calculating the time and cost associated with each inefficiency

- Estimating the potential savings or improvements that could be achieved by addressing each issue

- Assessing the difficulty or complexity of implementing solutions

This quantification helps in building a business case for process improvements and allocating resources effectively.

In conclusion, effectively analyzing current processes to identify inefficiencies requires a multi-faceted approach that combines data analysis, stakeholder engagement, and systematic evaluation methodologies. By employing these techniques, logistics organizations can gain a comprehensive understanding of their operations, pinpoint areas for improvement, and develop targeted strategies to reduce turnaround time and enhance overall efficiency. The insights gained from this analysis form the foundation for implementing meaningful changes that can significantly impact the bottom line and competitive positioning of the company.

What strategies can streamline documentation and paperwork?

Streamlining documentation and paperwork is a crucial aspect of reducing turnaround time in logistics operations. Efficient handling of documents not only accelerates processes but also minimizes errors and improves overall operational efficiency. Here are key strategies to streamline documentation and paperwork in logistics:

Digitization and electronic documentation

The transition from paper-based systems to digital platforms is perhaps the most impactful strategy for streamlining documentation. Digitization offers numerous benefits:

Reduced processing time: Digital documents can be instantly transmitted, accessed, and processed, eliminating the need for physical handling and transportation of paperwork.

Improved accuracy: Digital systems can incorporate validation checks and automated data entry, reducing human errors in documentation.

Enhanced searchability: Electronic documents can be quickly retrieved and searched, saving time in locating specific information.

Space savings: Digital storage eliminates the need for physical filing systems, freeing up valuable warehouse or office space.

Environmental benefits: Reducing paper usage aligns with sustainability goals and can improve a company’s environmental footprint.

Implementing a robust Document Management System (DMS) is key to effective digitization. A DMS should offer features such as version control, access permissions, and integration with other business systems.

Standardization of documents

Adopting standardized document formats across the organization and, where possible, with partners and customers, can significantly streamline processes. Standardization involves:

Template creation: Develop standardized templates for common documents such as bills of lading, invoices, and customs declarations.

Data field consistency: Ensure that data fields are consistent across different documents to facilitate easy information transfer and integration.

Compliance with industry standards: Align document formats with industry standards (e.g., UN/EDIFACT for electronic data interchange) to improve interoperability with partners and regulatory bodies.

Automated data capture and processing

Leveraging technology for automated data capture can dramatically reduce manual data entry and associated errors. Key technologies include:

Optical Character Recognition (OCR): OCR technology can automatically extract data from scanned documents, converting them into editable and searchable formats.

Electronic Data Interchange (EDI): EDI enables the automated exchange of standardized electronic documents between business partners, eliminating the need for manual data entry.

Barcode and RFID scanning: These technologies allow for quick and accurate capture of shipment and inventory data, reducing the need for manual documentation.

Artificial Intelligence (AI) and Machine Learning (ML): Advanced AI and ML algorithms can be employed to interpret complex documents, extract relevant information, and even predict and flag potential issues or discrepancies.

Blockchain for document verification

Blockchain technology offers a secure and transparent way to manage and verify documents in the supply chain. Benefits include:

Immutability: Once recorded on the blockchain, document information cannot be altered, ensuring the integrity of records.

Real-time visibility: All authorized parties can access the latest version of documents simultaneously, reducing delays and miscommunications.

Smart contracts: Blockchain-based smart contracts can automate document processing based on predefined conditions, further streamlining operations.

Mobile documentation solutions

Implementing mobile solutions for documentation can significantly enhance flexibility and speed in logistics operations:

Mobile apps: Develop or adopt mobile applications that allow for document creation, scanning, and submission from any location.

Cloud-based access: Ensure that documentation systems are accessible via cloud platforms, enabling real-time updates and access from various devices.

Digital signatures: Implement digital signature capabilities to allow for quick and legally binding document approvals on mobile devices.

Process automation and workflow optimization

Automating document workflows can eliminate bottlenecks and reduce processing times:

Automated routing: Implement systems that automatically route documents to the appropriate personnel or department based on predefined rules.

Approval workflows: Create digital approval processes that notify relevant parties and track the status of document approvals in real-time.

Integration with business systems: Ensure that documentation systems are integrated with other business software (e.g., ERP, WMS, TMS) to enable seamless data flow and reduce duplicate data entry.

Regulatory compliance and e-documentation

Staying abreast of regulatory changes and adopting e-documentation practices accepted by customs and other regulatory bodies is crucial:

Single Window systems: Participate in government-led Single Window initiatives that allow for the submission of standardized information to fulfill all regulatory requirements in one place.

Pre-clearance programs: Utilize pre-clearance programs offered by customs authorities to expedite document processing and reduce delays at borders.

Continuous monitoring of regulatory changes: Implement systems to stay updated on changes in documentation requirements across different jurisdictions and quickly adapt processes accordingly.

Training and change management

The success of any documentation streamlining initiative heavily depends on user adoption and proficiency:

Comprehensive training programs: Develop training modules for all staff involved in documentation processes, ensuring they are comfortable with new systems and procedures.

Change management strategies: Implement change management techniques to address resistance and ensure smooth transition to new documentation practices.

Regular refresher courses: Conduct periodic training sessions to reinforce best practices and introduce new features or updates to documentation systems.

Collaborative platforms and vendor portals

Implementing collaborative platforms can enhance communication and document sharing with partners and vendors:

Vendor portals: Create dedicated portals where vendors can directly input and access relevant documentation, reducing the need for manual data transfer.

Collaborative document editing: Utilize tools that allow for real-time collaborative editing of documents, reducing back-and-forth communication and version control issues.

Performance metrics and continuous improvement

Establishing key performance indicators (KPIs) for documentation processes is essential for ongoing optimization:

Document processing time: Track the average time taken to process different types of documents.

Error rates: Monitor the frequency of errors in documentation and their sources.

System uptime and responsiveness: Ensure that digital documentation systems are reliable and perform efficiently under varying loads.

Regularly review these metrics and solicit feedback from users to identify areas for further improvement and refinement of documentation processes.

In conclusion, streamlining documentation and paperwork in logistics requires a multifaceted approach that leverages technology, standardization, and process optimization. By implementing these strategies, logistics companies can significantly reduce turnaround times, improve accuracy, and enhance overall operational efficiency. The key lies in choosing the right combination of solutions that align with the specific needs and capabilities of the organization, while also considering the broader ecosystem of partners, customers, and regulatory bodies involved in the logistics process.

How can loading and unloading operations be optimized?

Optimizing loading and unloading operations is a critical component in reducing turnaround time in logistics. These processes often represent significant bottlenecks in the supply chain, and their efficiency can have a substantial impact on overall operational performance. Here’s a comprehensive look at strategies to optimize loading and unloading operations:

Facility layout and design

The physical layout of loading and unloading areas plays a crucial role in operational efficiency:

Dock design: Implement drive-through docks where possible to reduce maneuvering time for vehicles. Ensure sufficient space between docks to accommodate various vehicle sizes.

Staging areas: Designate adequate staging areas near docks for pre-sorted cargo, enabling quick loading and unloading.

Traffic flow: Design one-way traffic patterns to minimize congestion and reduce the risk of accidents.

Lighting and visibility: Ensure proper lighting in all areas to enhance safety and efficiency, especially during night operations.

Weather protection: Install canopies or enclosed docks to protect operations from adverse weather conditions, maintaining efficiency regardless of external factors.

Equipment selection and utilization

Choosing the right equipment and using it effectively can significantly speed up loading and unloading processes:

Forklifts and pallet jacks: Select equipment with appropriate capacity and maneuverability for your specific needs. Consider electric models for indoor use to reduce emissions and noise.

Conveyor systems: Implement conveyor belts for high-volume, uniform cargo to streamline movement from trucks to storage areas or vice versa.

Automated Guided Vehicles (AGVs): For large facilities, AGVs can automate the movement of goods, reducing labor requirements and improving consistency.

Dock levelers and seals: Install hydraulic dock levelers to accommodate different truck heights and dock seals to maintain temperature control and security during loading/unloading.

Mobile loading ramps: Use portable loading ramps for flexibility in handling various vehicle types and sizes.