What Are Drayage Containers

What are drayage containers and why are they important?

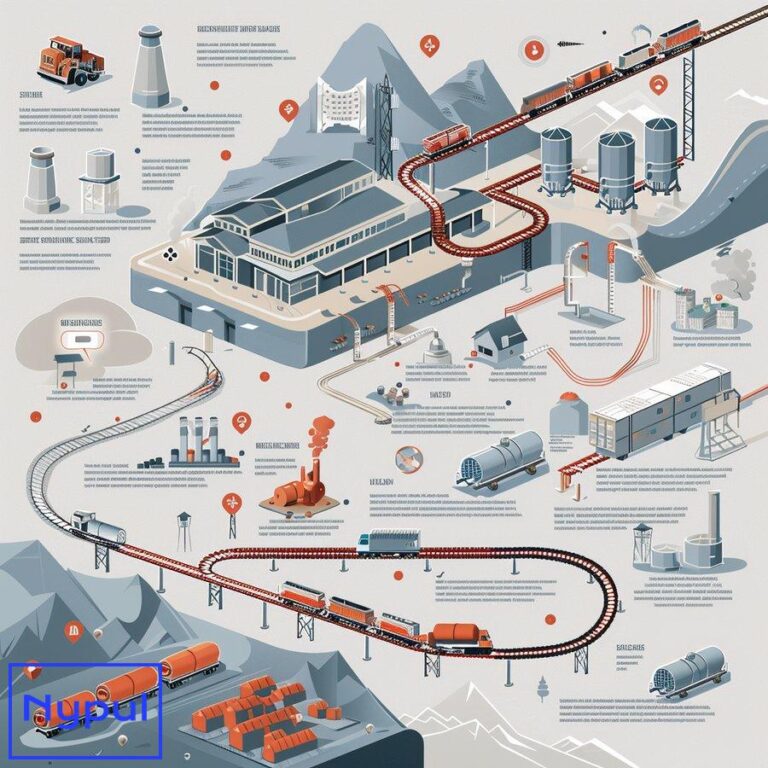

Drayage containers are specialized shipping containers used in the drayage process, which involves the short-distance transportation of goods, typically between ports, rail yards, and warehouses. The significance of drayage containers lies in their role as a vital link in the intermodal transportation chain, facilitating the efficient movement of freight across various transportation modes, including trucks, ships, and trains.

Drayage containers are designed to be easily transferred between different modes of transport without the need for repacking. This feature is crucial for maintaining the integrity of the cargo and ensuring timely deliveries. According to the Intermodal Association of North America (IANA), approximately 95% of all manufactured goods worldwide utilize drayage at some point in their supply chain journey, underscoring the importance of drayage containers in global logistics.

The Role of Drayage Containers in Logistics

Drayage containers serve several essential functions within the logistics framework:

-

Facilitating Intermodal Transport: Drayage containers allow for seamless transitions between different transport modes, reducing delays and improving efficiency.

-

Supporting Supply Chain Efficiency: By ensuring that cargo moves swiftly from one point to another, drayage containers help prevent bottlenecks in the supply chain, which can lead to increased costs and customer dissatisfaction.

-

Enhancing Cargo Security: Standardized containers provide a secure environment for goods, minimizing the risk of damage or theft during transit.

The importance of drayage containers cannot be overstated. They are fundamental to the logistics industry, ensuring that goods reach their destinations efficiently and safely.

What are the different types and sizes of drayage containers?

Drayage containers come in various types and sizes, each designed to accommodate specific cargo needs. Understanding these variations is crucial for logistics professionals and businesses looking to optimize their shipping processes.

Types of Drayage Containers

-

Standard Dry Containers: The most common type, typically used for general cargo. They come in sizes of 20 feet and 40 feet.

-

Refrigerated Containers (Reefers): Designed for perishable goods, these containers maintain a controlled temperature.

-

Open Top Containers: Used for oversized cargo that cannot fit through standard container doors. These containers have a removable top.

-

Flat Rack Containers: Ideal for heavy loads and machinery, these containers have no sides or roof, allowing for easy loading.

-

Tank Containers: Specifically designed for transporting liquids, these containers are equipped with a cylindrical tank.

Sizes of Drayage Containers

Drayage containers are standardized in size to facilitate easy handling and transport. The most common sizes include:

-

20-foot containers: Typically used for smaller loads, capable of carrying up to 28,000 pounds.

-

40-foot containers: Suitable for larger shipments, with a maximum weight capacity of around 60,000 pounds.

-

45-foot containers: Often used for high-cube cargo, providing additional space for bulkier items.

| Container Type | Size (feet) | Max Weight Capacity (pounds) |

|---|---|---|

| Standard Dry | 20 | 28,000 |

| Standard Dry | 40 | 60,000 |

| Refrigerated (Reefer) | 20 | 28,000 |

| Refrigerated (Reefer) | 40 | 60,000 |

| Open Top | 20 | 28,000 |

| Flat Rack | 20 | 48,000 |

| Tank | 20 | 26,000 |

Understanding the types and sizes of drayage containers is essential for businesses to select the appropriate container for their shipping needs, ensuring efficiency and cost-effectiveness in their logistics operations.

How do drayage containers function in intermodal transportation?

Drayage containers play a pivotal role in intermodal transportation, which involves the use of multiple modes of transport to move goods from origin to destination. The functionality of drayage containers within this system is characterized by several key processes.

Seamless Transition Between Modes

Drayage containers are designed for easy transfer between different transport modes, such as trucks, trains, and ships. This seamless transition is facilitated by standardized container sizes and handling equipment, allowing for quick loading and unloading.

Efficient Cargo Handling

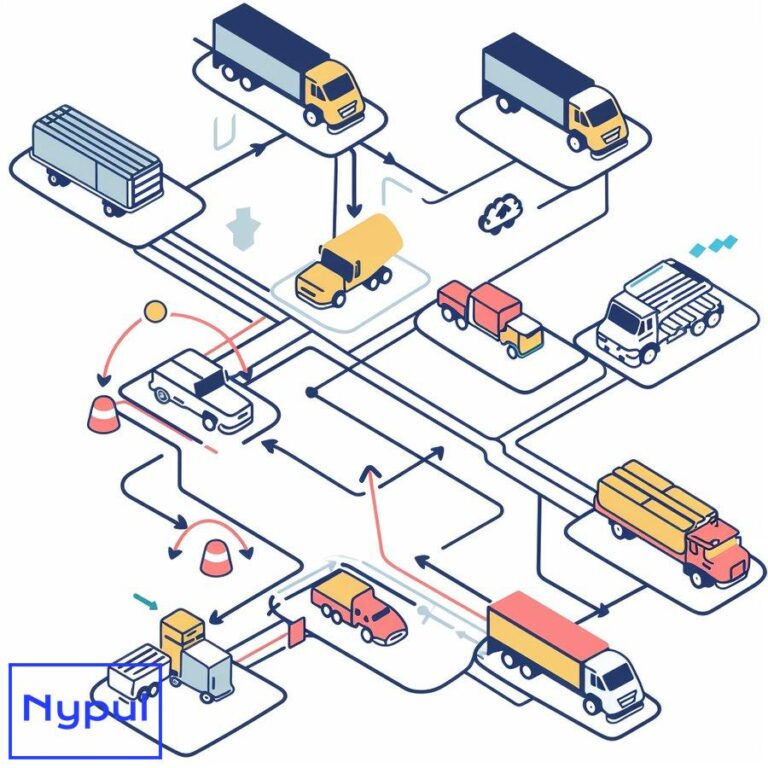

When a drayage container arrives at a port or rail terminal, it is typically transferred to a drayage truck for short-distance transport. This process involves:

-

Arrival at the Terminal: The container is delivered to the terminal by a shipping vessel or train.

-

Inspection and Documentation: Upon arrival, the container is inspected for damage, and necessary documentation is processed.

-

Transfer to Drayage Truck: The container is loaded onto a drayage truck for transport to its next destination, such as a warehouse or another transportation hub.

Intermodal Connections

Drayage containers facilitate connections between various transportation modes, ensuring that cargo can be efficiently moved to its final destination. For example, a container may travel by ship from Asia to the Port of Los Angeles, then be transferred to a drayage truck for transport to a rail yard, where it will be loaded onto a train for delivery to the Midwest.

Impact on Supply Chain Efficiency

The efficient functioning of drayage containers in intermodal transportation significantly impacts overall supply chain efficiency. Delays in drayage can lead to bottlenecks, affecting the timely delivery of goods. Therefore, optimizing drayage operations is essential for maintaining a smooth supply chain.

What role do drayage containers play in port operations?

Drayage containers are integral to port operations, serving as the primary means of transporting cargo between ships and inland destinations. Their role encompasses several critical functions that ensure the efficient movement of goods through ports.

Connection Between Maritime and Land Transport

Drayage containers serve as the bridge between maritime and land transport. When a container ship arrives at a port, drayage trucks are responsible for transporting the containers to various destinations, including warehouses, distribution centers, and rail terminals. This connection is crucial for maintaining the flow of goods and preventing congestion at ports.

Efficient Cargo Distribution

Ports handle a vast volume of containers daily, and drayage containers facilitate the swift distribution of this cargo. The process includes:

-

Unloading Containers: Containers are unloaded from ships and temporarily stored at the port.

-

Sorting and Routing: Drayage operators sort containers based on their next destination, optimizing routes for timely deliveries.

-

Transport to Final Destination: Drayage trucks transport containers to their designated locations, ensuring efficient cargo distribution.

Mitigating Congestion

Ports often face congestion due to high volumes of incoming and outgoing containers. Drayage containers help mitigate this issue by enabling quick transfers from ships to trucks, reducing the time containers spend at the port. Efficient drayage operations can significantly alleviate congestion, improving overall port efficiency.

Enhancing Security and Compliance

Drayage containers also play a role in enhancing security and compliance within port operations. Containers are typically sealed and tracked, ensuring that cargo remains secure during transit. Additionally, proper documentation and adherence to regulations are essential for smooth port operations, and drayage containers facilitate this process.

How are drayage containers managed and tracked in logistics?

Effective management and tracking of drayage containers are essential for optimizing logistics operations. Various strategies and technologies are employed to ensure that containers are accounted for and efficiently moved through the supply chain.

Container Management Systems

Container management systems (CMS) are software solutions designed to track and manage containers throughout their lifecycle. These systems provide real-time visibility into container locations, status, and availability, enabling logistics professionals to make informed decisions.

Tracking Technologies

Several tracking technologies are utilized to monitor drayage containers, including:

-

GPS Tracking: Global Positioning System (GPS) technology provides real-time location data for containers, allowing logistics managers to track their movements.

-

RFID Tags: Radio Frequency Identification (RFID) tags are attached to containers, enabling automated tracking and inventory management.

-

Barcode Scanning: Barcodes on containers can be scanned at various points in the supply chain, providing data on container movements and status.

Data Analytics and Reporting

Data analytics tools are employed to analyze container movement patterns, identify inefficiencies, and optimize routing. By leveraging data, logistics professionals can enhance operational efficiency and reduce costs associated with drayage operations.

Collaboration with Stakeholders

Effective management of drayage containers requires collaboration among various stakeholders, including shipping lines, trucking companies, and port authorities. Clear communication and coordination are essential for ensuring that containers are moved efficiently and that all parties are informed of container status.

What challenges exist in drayage container usage and efficiency?

Despite their importance, the usage and efficiency of drayage containers face several challenges that can impact logistics operations. Understanding these challenges is crucial for developing strategies to mitigate their effects.

Congestion at Ports

One of the most significant challenges in drayage container usage is congestion at ports. High volumes of incoming and outgoing containers can lead to delays, affecting the timely movement of goods. Congestion can result from various factors, including labor shortages, equipment availability, and increased shipping volumes.

Equipment Shortages

The availability of drayage trucks and containers is critical for efficient operations. Equipment shortages can arise due to increased demand, maintenance issues, or supply chain disruptions. A lack of available trucks can lead to delays in transporting containers from ports to their final destinations.

Regulatory Compliance

Drayage operations must adhere to various regulations and compliance requirements, including safety standards and environmental regulations. Navigating these regulations can be complex and time-consuming, potentially impacting the efficiency of drayage operations.

Rising Costs

The costs associated with drayage operations, including fuel prices, labor costs, and maintenance expenses, have been on the rise. These increasing costs can strain logistics budgets and necessitate careful planning and management to maintain profitability.

Technology Integration

While technology offers numerous benefits for tracking and managing drayage containers, integrating new technologies into existing operations can be challenging. Logistics companies must invest in training and infrastructure to effectively leverage technology for improved efficiency.

How is technology improving drayage container operations?

Technology plays a transformative role in enhancing drayage container operations, addressing many of the challenges faced in the logistics industry. Various technological advancements are being implemented to improve efficiency, visibility, and overall performance.

Automation and Robotics

Automation technologies are being increasingly adopted in drayage operations, streamlining processes and reducing labor costs. Automated systems can handle tasks such as container loading and unloading, improving efficiency and minimizing human error.

Advanced Tracking Solutions

Innovative tracking solutions, including GPS and RFID technologies, provide real-time visibility into container movements. These solutions enable logistics professionals to monitor container locations, optimize routing, and reduce delays.

Data Analytics and Machine Learning

Data analytics and machine learning algorithms are being utilized to analyze container movement patterns and predict potential delays. By leveraging data, logistics companies can make informed decisions to optimize operations and improve efficiency.

Cloud-Based Management Systems

Cloud-based container management systems allow for seamless collaboration among stakeholders, providing real-time access to container data. These systems enhance communication and coordination, ensuring that all parties are informed of container status and movements.

Sustainability Initiatives

Technology is also being employed to promote sustainability in drayage operations. Electric and hybrid drayage trucks are being developed to reduce emissions and improve fuel efficiency, contributing to a more sustainable logistics industry.

In conclusion, drayage containers are a vital component of the logistics and transportation industry, facilitating the efficient movement of goods across various modes of transport. By understanding the types, functions, and challenges associated with drayage containers, logistics professionals can optimize their operations and enhance supply chain efficiency. The integration of technology continues to improve drayage operations, addressing challenges and paving the way for a more efficient and sustainable future in logistics.