What Are Strategies That Can Be Used to Ensure Efficiency and Cost Containment in Supply Chain Management

Why are efficiency and cost containment crucial in supply chain management?

Efficiency and cost containment form the backbone of successful supply chain management. These two elements are inextricably linked, working in tandem to create a lean, agile, and profitable operation.

Supply chain efficiency refers to the optimization of processes, resources, and technologies to deliver products or services to customers in the most effective manner possible. This encompasses everything from sourcing raw materials to delivering the final product to the end consumer. When a supply chain operates efficiently, it minimizes waste, reduces lead times, and improves overall productivity.

Cost containment, on the other hand, focuses on controlling and reducing expenses throughout the supply chain without sacrificing quality or performance. This involves identifying areas of unnecessary spending, negotiating better terms with suppliers, and implementing cost-saving measures across all stages of the supply chain.

The importance of these two factors cannot be overstated in today’s competitive business landscape. Companies that excel in supply chain efficiency and cost containment gain several critical advantages:

Improved Profitability

Efficient supply chains reduce operational costs, leading to higher profit margins. By streamlining processes and eliminating waste, companies can significantly lower their cost of goods sold (COGS) and increase their bottom line.

Enhanced Competitiveness

In markets where product differentiation is challenging, supply chain excellence can be a key differentiator. Companies with efficient and cost-effective supply chains can offer competitive pricing without sacrificing quality, giving them an edge over rivals.

Increased Customer Satisfaction

Efficient supply chains lead to faster delivery times, better product availability, and more consistent quality. These factors directly contribute to improved customer satisfaction and loyalty.

Greater Flexibility and Responsiveness

An efficient supply chain is more agile and can adapt quickly to changes in demand or market conditions. This flexibility allows companies to seize new opportunities and mitigate risks more effectively.

Sustainability

Efficient supply chains often have a lower environmental impact due to reduced waste, optimized transportation, and better resource utilization. This aligns with growing consumer and regulatory demands for sustainable business practices.

To illustrate the impact of efficiency and cost containment, consider the following comparison between two hypothetical companies in the same industry:

| Metric | Company A (Efficient Supply Chain) | Company B (Inefficient Supply Chain) |

|---|---|---|

| Inventory Turnover | 12 times per year | 6 times per year |

| Order Fulfillment Time | 2 days | 5 days |

| Transportation Costs | 5% of revenue | 10% of revenue |

| Supplier Lead Time | 10 days | 20 days |

| Customer Satisfaction | 95% | 80% |

As the table demonstrates, Company A’s focus on efficiency and cost containment results in faster inventory turnover, quicker order fulfillment, lower transportation costs, shorter supplier lead times, and higher customer satisfaction. These advantages translate into tangible business benefits, including improved cash flow, higher profitability, and stronger customer relationships.

However, achieving supply chain efficiency and cost containment is not without its challenges. It requires a holistic approach that considers all aspects of the supply chain, from supplier relationships to last-mile delivery. Companies must invest in technology, process improvement, and employee training to realize these benefits fully.

Some key strategies for improving efficiency and containing costs in supply chain management include:

Implementing Advanced Analytics

Leveraging data analytics and artificial intelligence can help companies forecast demand more accurately, optimize inventory levels, and identify inefficiencies in their supply chain processes.

Adopting Lean Principles

Applying lean manufacturing principles across the supply chain can help eliminate waste, reduce lead times, and improve overall efficiency.

Enhancing Supplier Collaboration

Building strong, collaborative relationships with suppliers can lead to better terms, improved quality, and more reliable deliveries.

Optimizing Transportation Networks

Using advanced routing software and consolidating shipments can significantly reduce transportation costs and improve delivery times.

Investing in Automation

Automating repetitive tasks in warehouses and distribution centers can increase efficiency, reduce errors, and lower labor costs.

Continuous Improvement

Implementing a culture of continuous improvement ensures that the supply chain is constantly evolving and adapting to new challenges and opportunities.

The pursuit of efficiency and cost containment in supply chain management is not a one-time effort but an ongoing process. As markets evolve, technologies advance, and customer expectations change, companies must continually reassess and refine their supply chain strategies to maintain their competitive edge.

In conclusion, efficiency and cost containment are crucial in supply chain management because they directly impact a company’s profitability, competitiveness, customer satisfaction, and overall business performance. By focusing on these areas, companies can create resilient, agile supply chains that drive business success in an increasingly complex and competitive global marketplace.

How can technology optimize supply chain operations?

Technology plays a pivotal role in optimizing supply chain operations, transforming traditional, often siloed processes into interconnected, data-driven ecosystems. The integration of advanced technologies across the supply chain enables companies to achieve unprecedented levels of visibility, efficiency, and responsiveness.

Internet of Things (IoT)

IoT devices are revolutionizing supply chain management by providing real-time data on asset location, condition, and performance. These smart sensors can be attached to products, vehicles, and equipment, offering continuous monitoring throughout the supply chain.

Benefits of IoT in Supply Chain:

– Real-time tracking of inventory and shipments

– Predictive maintenance for equipment

– Improved quality control through environmental monitoring

– Enhanced visibility into supply chain operations

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML algorithms can analyze vast amounts of data to identify patterns, predict trends, and make intelligent decisions. In supply chain management, these technologies are particularly valuable for demand forecasting, inventory optimization, and risk management.

Applications of AI/ML in Supply Chain:

– Demand forecasting with higher accuracy

– Dynamic pricing strategies

– Automated supplier selection and evaluation

– Anomaly detection for quality control and fraud prevention

Blockchain Technology

Blockchain offers a secure, transparent way to track transactions and maintain records across the supply chain. This technology can significantly improve traceability, reduce fraud, and enhance trust among supply chain partners.

Advantages of Blockchain in Supply Chain:

– Enhanced traceability of products from source to consumer

– Improved transparency in transactions

– Reduced paperwork and administrative costs

– Increased security and fraud prevention

Cloud Computing

Cloud-based supply chain management systems provide scalable, accessible platforms for collaboration and data sharing across the entire supply chain network. These systems enable real-time visibility and decision-making capabilities.

Benefits of Cloud Computing in Supply Chain:

– Improved collaboration among supply chain partners

– Real-time data access and visibility

– Scalability to accommodate business growth

– Reduced IT infrastructure costs

Robotics and Automation

Robotic systems and automation technologies are transforming warehouses and distribution centers, increasing efficiency and accuracy in order fulfillment processes.

Impact of Robotics and Automation:

– Increased picking and packing speeds

– Reduced labor costs

– Improved accuracy in order fulfillment

– 24/7 operational capability

Advanced Analytics

Big data analytics tools enable companies to process and analyze large volumes of supply chain data, uncovering insights that drive strategic decision-making.

Benefits of Advanced Analytics:

– Improved demand forecasting

– Optimization of inventory levels

– Identification of cost-saving opportunities

– Enhanced risk management

Digital Twin Technology

Digital twins create virtual replicas of physical supply chain assets and processes, allowing for simulation and optimization in a risk-free environment.

Advantages of Digital Twin Technology:

– Scenario planning and risk assessment

– Process optimization

– Predictive maintenance

– Enhanced decision-making through simulation

To illustrate the impact of these technologies on supply chain optimization, consider the following comparison:

| Supply Chain Function | Traditional Approach | Technology-Enabled Approach |

|---|---|---|

| Inventory Management | Periodic manual counts | Real-time tracking with IoT sensors |

| Demand Forecasting | Historical data analysis | AI-powered predictive analytics |

| Supplier Management | Manual evaluation and selection | Automated supplier scoring and blockchain-verified transactions |

| Warehouse Operations | Manual picking and packing | Robotic automation and AI-optimized processes |

| Transportation | Static routing | Dynamic, AI-optimized routing with real-time traffic data |

| Quality Control | Random sampling | IoT-enabled continuous monitoring |

The technology-enabled approach clearly demonstrates significant improvements across all supply chain functions, leading to increased efficiency, reduced costs, and enhanced overall performance.

Implementing these technologies requires careful planning and consideration of several factors:

Integration Challenges

Integrating new technologies with existing systems can be complex and time-consuming. Companies must ensure seamless data flow and compatibility across different platforms.

Data Security and Privacy

With increased data collection and sharing, robust security measures are essential to protect sensitive information and maintain compliance with data protection regulations.

Skills Gap

Adopting advanced technologies often requires specialized skills. Companies may need to invest in training existing staff or hiring new talent to effectively leverage these technologies.

Return on Investment (ROI)

While technology can offer significant benefits, the initial investment can be substantial. Companies must carefully evaluate the potential ROI and prioritize technologies that align with their strategic goals.

Change Management

Implementing new technologies often requires changes in processes and workflows. Effective change management strategies are crucial to ensure successful adoption and minimize disruption.

To maximize the benefits of technology in supply chain optimization, companies should consider the following strategies:

Develop a Clear Technology Roadmap

Create a comprehensive plan that aligns technology investments with business objectives and prioritizes implementations based on potential impact and feasibility.

Foster a Culture of Innovation

Encourage experimentation and continuous learning to drive technology adoption and innovation across the organization.

Collaborate with Technology Partners

Partner with technology providers and startups to stay at the forefront of innovation and gain access to specialized expertise.

Prioritize Data Quality and Governance

Implement robust data management practices to ensure the accuracy and reliability of data used in decision-making processes.

Invest in Cybersecurity

Develop comprehensive cybersecurity strategies to protect against potential threats and ensure the integrity of supply chain data and systems.

Embrace Continuous Improvement

Regularly assess the performance of implemented technologies and seek opportunities for further optimization and innovation.

Technology is rapidly transforming supply chain operations, offering unprecedented opportunities for optimization and innovation. By strategically implementing and leveraging these advanced technologies, companies can create more efficient, responsive, and resilient supply chains that drive competitive advantage in an increasingly complex global marketplace.

The key to success lies not just in adopting new technologies, but in effectively integrating them into existing processes and cultivating a culture of continuous improvement and innovation. As technology continues to evolve, companies that remain agile and open to new possibilities will be best positioned to thrive in the dynamic world of supply chain management.

What strategies improve inventory management and demand forecasting?

Effective inventory management and accurate demand forecasting are critical components of a well-functioning supply chain. These interrelated processes directly impact a company’s ability to meet customer demand while minimizing costs associated with excess inventory or stockouts. Implementing robust strategies in these areas can lead to significant improvements in overall supply chain performance.

Inventory Management Strategies

ABC Analysis

This method categorizes inventory items based on their value and importance. ‘A’ items are the most valuable and require close monitoring, ‘B’ items are of medium value, and ‘C’ items are the least valuable.

Benefits of ABC Analysis:

– Focused attention on high-value items

– Optimized resource allocation

– Improved inventory turnover rates

Just-In-Time (JIT) Inventory

JIT aims to reduce inventory levels by receiving goods only as they are needed in the production process. This strategy minimizes holding costs and reduces waste.

Advantages of JIT:

– Reduced inventory holding costs

– Improved cash flow

– Minimized obsolescence risk

Economic Order Quantity (EOQ)

EOQ is a calculation that determines the optimal order quantity that minimizes total inventory costs, including holding costs and ordering costs.

Benefits of EOQ:

– Balanced inventory levels

– Reduced overall inventory costs

– Improved order efficiency

Vendor-Managed Inventory (VMI)

In VMI, suppliers take responsibility for maintaining an agreed inventory level for their customers. This shifts the burden of inventory management to the supplier.

Advantages of VMI:

– Reduced inventory management costs for the buyer

– Improved supplier-buyer relationships

– Decreased stockouts

Cycle Counting

This inventory auditing method involves continuously counting a small subset of inventory on a regular basis, rather than conducting a full physical inventory count annually.

Benefits of Cycle Counting:

– Improved inventory accuracy

– Early detection of discrepancies

– Reduced disruption to operations

Demand Forecasting Strategies

Time Series Analysis

This method uses historical data to identify patterns and trends, which are then used to forecast future demand.

Advantages of Time Series Analysis:

– Captures seasonal patterns

– Identifies long-term trends

– Relatively simple to implement

Causal Forecasting

This approach considers external factors that may influence demand, such as economic indicators, marketing campaigns, or competitor actions.

Benefits of Causal Forecasting:

– Incorporates external influences on demand

– Provides insights into demand drivers

– Potentially more accurate for long-term forecasts

Collaborative Planning, Forecasting, and Replenishment (CPFR)

CPFR involves collaboration between suppliers and retailers to develop more accurate forecasts and replenishment plans.

Advantages of CPFR:

– Improved forecast accuracy

– Enhanced supply chain visibility

– Stronger supplier-retailer relationships

Machine Learning and AI-Driven Forecasting

Advanced algorithms can analyze large datasets to identify complex patterns and generate highly accurate demand forecasts.

Benefits of ML/AI Forecasting:

– Ability to process vast amounts of data

– Continuous learning and improvement

– Consideration of multiple variables simultaneously

Demand Sensing

This technique uses real-time data from various sources to make short-term demand predictions, allowing for rapid adjustments to changing market conditions.

Advantages of Demand Sensing:

– Improved short-term forecast accuracy

– Rapid response to demand fluctuations

– Enhanced supply chain agility

To illustrate the impact of these strategies, consider the following comparison between a company using traditional methods and one implementing advanced inventory management and demand forecasting strategies:

| Metric | Traditional Approach | Advanced Strategies |

|---|---|---|

| Inventory Turnover | 6 times per year | 12 times per year |

| Forecast Accuracy | 70% | 90% |

| Stockout Rate | 5% | 1% |

| Inventory Holding Costs | 25% of inventory value | 15% of inventory value |

| Order Fill Rate | 92% | 98% |

The company using advanced strategies demonstrates significantly improved performance across all metrics, leading to lower costs, higher customer satisfaction, and improved overall supply chain efficiency.

To successfully implement these strategies, companies should consider the following best practices:

Integrate Inventory Management and Demand Forecasting Systems

Ensure that inventory management systems are tightly integrated with demand forecasting tools to enable real-time adjustments based on the latest predictions.

Leverage Advanced Analytics

Utilize big data analytics and machine learning algorithms to process large volumes of data and generate more accurate forecasts.

Implement Real-Time Inventory Tracking

Use IoT devices and RFID technology to maintain accurate, real-time visibility of inventory levels across the supply chain.

Develop Cross-Functional Collaboration

Foster collaboration between sales, marketing, finance, and supply chain teams to ensure that all relevant information is considered in forecasting and inventory decisions.

Continuously Monitor and Adjust

Regularly review the performance of inventory management and forecasting strategies, and make adjustments as needed to improve accuracy and efficiency.

Invest in Employee Training

Ensure that staff are well-trained in using new tools and technologies, and understand the importance of accurate data input and analysis.

Establish Clear Performance Metrics

Define and track key performance indicators (KPIs) to measure the effectiveness of inventory management and demand forecasting strategies.

Consider Segmentation

Implement different strategies for different product categories or customer segments to optimize inventory management and forecasting accuracy.

Embrace Flexibility

Develop contingency plans and maintain flexibility in inventory management to respond quickly to unexpected changes in demand or supply disruptions.

Utilize Scenario Planning

Develop multiple demand scenarios to prepare for various potential outcomes and ensure the supply chain can adapt to different situations.

Effective inventory management and demand forecasting are crucial for optimizing supply chain performance. By implementing a combination of traditional and advanced strategies, companies can significantly improve their ability to meet customer demand while minimizing costs and risks associated with inventory management.

The key to success lies in choosing the right mix of strategies that align with the company’s specific needs and market conditions, and continuously refining these approaches based on performance data and changing business requirements. As technology continues to evolve, companies that remain open to adopting new tools and methodologies will be best positioned to achieve excellence in inventory management and demand forecasting, driving overall supply chain success.

How can supplier relationships and procurement processes be enhanced?

Strong supplier relationships and efficient procurement processes are fundamental to a well-functioning supply chain. These elements directly impact a company’s ability to secure quality materials, manage costs, and respond to market changes effectively. Enhancing these areas can lead to significant improvements## How can supplier relationships and procurement processes be enhanced?

Strong supplier relationships and efficient procurement processes are fundamental to a well-functioning supply chain. These elements directly impact a company’s ability to secure quality materials, manage costs, and respond to market changes effectively. Enhancing these areas can lead to significant improvements in overall supply chain performance.

Building Strong Supplier Relationships

Effective Communication

Clear and open communication is essential for fostering strong relationships with suppliers. Regular updates on demand forecasts, production schedules, and any potential issues can help build trust and collaboration.

Benefits of Effective Communication:

– Reduces misunderstandings

– Enhances responsiveness to changes

– Strengthens partnerships

Collaboration and Partnership

Viewing suppliers as partners rather than mere vendors can lead to mutually beneficial relationships. Collaborative planning, joint problem-solving, and shared goals can strengthen ties between companies.

Advantages of Collaboration:

– Improved innovation through shared insights

– Enhanced flexibility in responding to market changes

– Better alignment of objectives

Performance Evaluation and Feedback

Regularly assessing supplier performance through metrics such as quality, delivery times, and responsiveness is crucial. Providing constructive feedback helps suppliers understand expectations and areas for improvement.

Benefits of Performance Evaluation:

– Identifies high-performing suppliers

– Encourages continuous improvement

– Strengthens accountability

Supplier Development Programs

Investing in supplier development initiatives can enhance capabilities and foster loyalty. Training programs, technology sharing, or joint process improvements can lead to better outcomes for both parties.

Advantages of Supplier Development:

– Improved quality and efficiency

– Increased supplier loyalty

– Enhanced competitiveness

Long-Term Contracts

Establishing long-term contracts with key suppliers can provide stability and predictability for both parties. These agreements often lead to better pricing, priority service, and collaborative planning.

Benefits of Long-Term Contracts:

– Reduced procurement costs

– Improved supply chain stability

– Enhanced relationship longevity

Enhancing Procurement Processes

Centralized Procurement Systems

Implementing a centralized procurement system allows for better visibility and control over purchasing activities. This approach can streamline processes, reduce duplication, and improve compliance with company policies.

Advantages of Centralized Procurement:

– Improved negotiation power through bulk buying

– Enhanced data analysis for informed decision-making

– Streamlined approval processes

Strategic Sourcing

Adopting a strategic sourcing approach involves analyzing the entire supply chain to identify the best suppliers based on cost, quality, reliability, and service. This method emphasizes long-term value rather than short-term savings.

Benefits of Strategic Sourcing:

– Enhanced supplier selection

– Improved total cost of ownership (TCO)

– Greater alignment with business goals

Technology Integration in Procurement

Leveraging technology such as e-procurement platforms can automate purchasing processes, reduce manual errors, and improve efficiency. These systems facilitate better tracking, reporting, and compliance.

Advantages of Technology Integration:

– Increased procurement speed

– Enhanced data accuracy

– Improved visibility into spending patterns

Supplier Risk Management

Establishing a robust supplier risk management framework is essential for identifying potential risks associated with suppliers. This includes assessing financial stability, geopolitical risks, and compliance issues.

Benefits of Supplier Risk Management:

– Mitigated risks through proactive measures

– Enhanced resilience against supply chain disruptions

– Improved decision-making regarding supplier selection

To illustrate the impact of these strategies on supplier relationships and procurement processes, consider the following comparison:

| Metric | Traditional Approach | Enhanced Approach |

|---|---|---|

| Supplier Lead Time | 4 weeks | 2 weeks |

| Cost Savings | 5% | 15% |

| Supplier Quality Rating | 75% | 95% |

| Procurement Cycle Time | 30 days | 15 days |

| Supplier Retention Rate | 60% | 90% |

As shown in the table, companies that enhance their supplier relationships and procurement processes experience significant improvements across key metrics. Shorter lead times, greater cost savings, higher quality ratings, reduced cycle times, and improved supplier retention rates all contribute to a more efficient supply chain.

To successfully implement these enhancements in supplier relationships and procurement processes, companies should consider the following best practices:

Develop a Supplier Relationship Management (SRM) Program

Establishing an SRM program helps formalize the approach to managing supplier relationships. This includes regular meetings, performance reviews, and collaborative initiatives.

Invest in Training for Procurement Teams

Ensuring that procurement teams are well-trained in negotiation techniques, market analysis, and relationship management is crucial for enhancing procurement effectiveness.

Utilize Data Analytics for Decision-Making

Leveraging data analytics tools can provide insights into supplier performance trends, spending patterns, and potential risks. This information supports informed decision-making.

Foster a Culture of Collaboration Across Departments

Encouraging collaboration between procurement teams and other departments (such as finance or operations) ensures that all relevant perspectives are considered in sourcing decisions.

Regularly Review Supplier Contracts

Conducting periodic reviews of supplier contracts ensures that terms remain favorable and aligned with changing business needs. This practice also provides opportunities for renegotiation based on performance.

By focusing on enhancing supplier relationships and optimizing procurement processes, companies can create a more resilient supply chain capable of adapting to market fluctuations while achieving cost efficiencies. The goal is not only to secure high-quality materials at competitive prices but also to build long-lasting partnerships that drive innovation and growth.

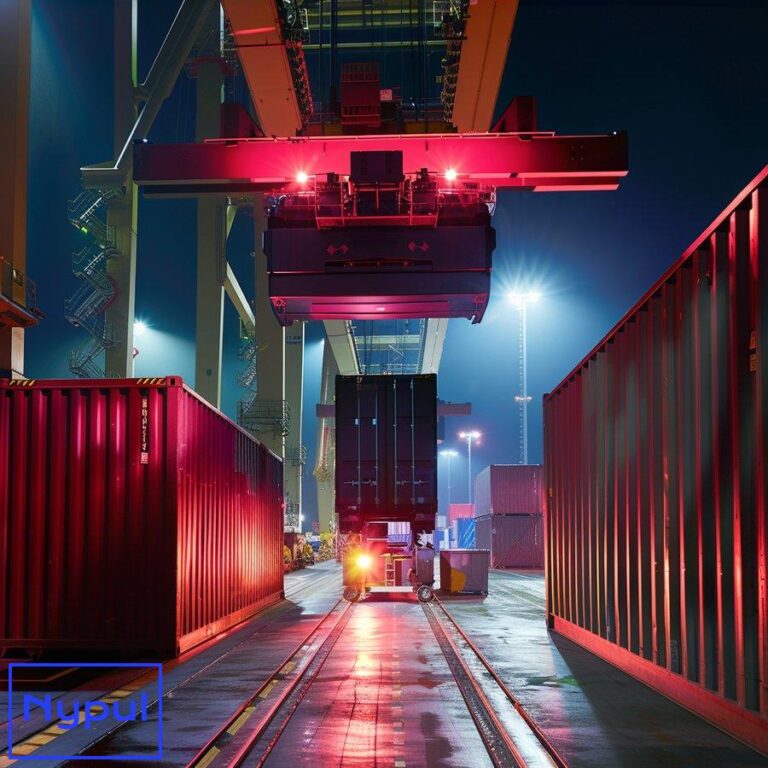

What methods optimize transportation and logistics in the supply chain?

![]()

Transportation and logistics are critical components of supply chain management that directly affect operational efficiency, customer satisfaction, and overall costs. Optimizing these areas involves implementing various methods designed to improve delivery performance while minimizing expenses.

Transportation Optimization Strategies

Route Optimization

Utilizing advanced routing software allows companies to determine the most efficient routes for deliveries based on real-time traffic data, weather conditions, and delivery windows.

Benefits of Route Optimization:

– Reduced fuel consumption

– Lower transportation costs

– Improved delivery times

Consolidation of Shipments

Combining multiple orders into a single shipment can significantly reduce transportation costs by maximizing vehicle capacity. This strategy involves careful planning to ensure timely deliveries while minimizing freight expenses.

Advantages of Shipment Consolidation:

– Decreased shipping costs per unit

– Reduced environmental impact through fewer trips

– Improved resource utilization

Freight Auditing

Regularly auditing freight bills ensures that charges are accurate and identifies any discrepancies or overcharges by carriers. This process helps companies recover lost funds while optimizing shipping expenses.

Benefits of Freight Auditing:

– Cost recovery from billing errors

– Increased accountability among carriers

– Enhanced negotiation leverage during contract renewals

Carrier Selection Optimization

Evaluating carriers based on performance metrics such as reliability, cost-effectiveness, service levels, and capacity is essential for optimizing transportation choices. Establishing strong partnerships with reliable carriers enhances overall logistics performance.

Advantages of Carrier Selection Optimization:

– Improved service quality through reliable carriers

– Better cost management through competitive bidding

– Enhanced flexibility in transportation options

Last-Mile Delivery Solutions

Optimizing last-mile delivery is crucial for enhancing customer satisfaction. Strategies may include using local distribution centers or implementing crowd-sourced delivery solutions to improve efficiency in urban areas.

Benefits of Last-Mile Delivery Optimization:

– Faster delivery times leading to increased customer satisfaction

– Reduced delivery costs through localized solutions

– Greater adaptability to changing consumer preferences

Logistics Optimization Methods

Warehouse Management Systems (WMS)

Implementing WMS helps streamline warehouse operations by automating inventory tracking, order fulfillment processes, and resource allocation. These systems improve accuracy while reducing labor costs.

Advantages of WMS Implementation:

– Increased inventory accuracy

– Enhanced order processing speed

– Improved space utilization within warehouses

Cross-Docking Techniques

Cross-docking involves transferring goods directly from inbound shipments to outbound deliveries without storing them in between. This method minimizes handling time while reducing storage costs.

Benefits of Cross-Docking:

– Faster order fulfillment

– Reduced inventory holding costs

– Improved flow of goods through the supply chain

To illustrate the impact of these optimization methods on transportation and logistics performance, consider the following comparison:

| Metric | Traditional Approach | Optimized Approach |

|---|---|---|

| Average Delivery Time | 5 days | 2 days |

| Transportation Costs per Unit | $10 | $6 |

| Order Accuracy Rate | 85% | 98% |

| Freight Claims Rate | 3% | 1% |

| Last-Mile Delivery Cost | $5 per package | $3 per package |

The optimized approach demonstrates significant improvements across all metrics compared to traditional methods. Faster delivery times, lower transportation costs per unit, higher order accuracy rates, reduced freight claims rates, and decreased last-mile delivery costs contribute to enhanced overall supply chain efficiency.

To successfully implement these optimization methods in transportation and logistics management, companies should consider the following best practices:

Invest in Technology Solutions

Adopting advanced technologies such as transportation management systems (TMS) or warehouse management systems (WMS) enables better visibility into operations while improving decision-making capabilities.

Foster Collaboration Among Stakeholders

Encouraging collaboration between logistics providers, suppliers, customers, and internal teams enhances communication while improving overall operational efficiency.

Continuously Monitor Performance Metrics

Regularly tracking key performance indicators (KPIs) related to transportation costs, delivery times, order accuracy rates, etc., allows companies to identify areas needing improvement promptly.

By focusing on optimizing transportation methods alongside logistics operations within their supply chains; organizations can achieve significant efficiencies leading ultimately towards improved customer satisfaction levels while maintaining cost-effective practices throughout their operations!

How does lean manufacturing contribute to supply chain efficiency?

Lean manufacturing is a philosophy aimed at minimizing waste while maximizing productivity within production processes. By applying lean principles across the entire supply chain— from raw material sourcing through final product delivery—companies can achieve remarkable improvements in efficiency that translate into cost savings and enhanced customer satisfaction.

Key Principles of Lean Manufacturing

- Value Stream Mapping (VSM)

VSM involves analyzing each step involved in delivering a product or service from start to finish. By identifying non-value-added activities (waste), companies can streamline processes accordingly.

Benefits of VSM:

– Enhanced visibility into workflows

– Identification of bottlenecks

– Opportunities for process improvement

- Continuous Improvement (Kaizen)

The Kaizen philosophy emphasizes ongoing incremental improvements rather than large-scale changes. Encouraging employees at all levels to suggest enhancements fosters a culture focused on efficiency.

Advantages of Continuous Improvement:

– Empowered workforce

– Sustained momentum towards operational excellence

– Increased employee engagement

- Just-In-Time (JIT) Production

JIT aims at producing only what is needed when it’s needed—minimizing excess inventory while ensuring timely availability.

Benefits of JIT Production:

– Reduced holding costs

– Increased responsiveness

– Lower risk associated with obsolescence

- Standardization of Processes

Establishing standardized work procedures enhances consistency across operations while reducing variability.

Advantages of Standardization:

– Improved quality control

– Easier training for new employees

– Streamlined workflows

- Pull System vs Push System

Lean manufacturing favors pull systems where production is based on actual demand rather than forecasts—reducing overproduction risks.

Benefits of Pull Systems:

– Better alignment with customer needs

– Decreased inventory levels

– Increased flexibility

Impact on Supply Chain Efficiency

By integrating lean manufacturing principles into their operations; organizations experience several key benefits that enhance their overall supply chain efficiency:

-

Reduced Lead Times:

Lean practices streamline workflows leading towards faster production cycles resulting ultimately into shorter lead times across entire chains! -

Lower Inventory Levels:

Minimizing waste translates directly into reduced inventory levels—freeing up working capital while decreasing carrying costs associated with excess stock! -

Improved Quality:

Standardized processes coupled with continuous improvement efforts yield higher product quality—resulting in fewer defects & returns—a win-win scenario! -

Enhanced Flexibility:

Lean methodologies promote adaptability allowing businesses quickly pivot when faced unexpected changes in demand or market conditions! -

Increased Customer Satisfaction:

Faster response times combined with higher-quality products lead directly towards improved customer satisfaction—building loyalty & repeat business!

To illustrate these impacts quantitatively; consider this comparison between two hypothetical manufacturers employing different approaches:

| Metric | Traditional Manufacturing Approach | Lean Manufacturing Approach |

|---|---|---|

| Average Lead Time | 10 days | 4 days |

| Inventory Turnover Ratio | 4 times/year | 12 times/year |

| Defect Rate | 5% | 1% |

| Overall Equipment Effectiveness (OEE) | 70% | 90% |

| Customer Satisfaction Score | 80/100 | 95/100 |

The lean manufacturing approach clearly demonstrates significant enhancements across all metrics compared with traditional methods; resulting ultimately towards improved operational efficiencies coupled with higher levels customer satisfaction!

Implementing Lean Manufacturing Practices

To successfully implement lean manufacturing principles within an organization’s existing structure; several best practices should be followed:

-

Engage Employees at All Levels:

Encouraging participation from frontline workers fosters ownership & accountability—leading towards greater buy-in during implementation phases! -

Provide Training & Resources:

Investing time/resources into educating employees about lean concepts ensures everyone understands their roles within this transformative journey! -

Establish Clear Goals & Metrics:

Defining specific objectives alongside measurable KPIs allows organizations track progress effectively throughout implementation phases! -

Foster a Culture of Continuous Improvement:

Creating an environment where feedback is valued encourages ongoing refinement efforts—ensuring sustained momentum towards operational excellence! -

Leverage Technology Solutions:

Utilizing digital tools/software enables real-time data monitoring & analysis—facilitating informed decision-making across all levels!

By embracing lean manufacturing principles; organizations stand poised not only enhance their internal efficiencies but also strengthen overall supply chains—ultimately driving sustainable growth amidst ever-evolving market landscapes!

What risk management strategies ensure supply chain resilience?

Supply chains face numerous risks ranging from natural disasters to geopolitical tensions that threaten operational continuity & profitability! Implementing effective risk management strategies ensures resilience against unexpected disruptions while maintaining smooth operations throughout challenging circumstances!

Identifying Risks Within Supply Chains

Before developing robust risk management strategies; organizations must first identify potential vulnerabilities within their respective supply chains! Common categories include:

-

Operational Risks:

These stem from internal processes such as equipment failures or labor shortages impacting production capabilities! -

Supply Risks:

Dependence upon single-source suppliers increases vulnerability—particularly if those suppliers face financial difficulties or natural disasters disrupting output! -

Market Risks:

Fluctuations in demand due economic downturns or shifts consumer preferences pose challenges requiring agility adapt quickly changing landscapes! -

Geopolitical Risks:

Political instability abroad may disrupt trade routes impacting timely deliveries & increasing costs associated tariffs imposed foreign goods! -

Environmental Risks:

Natural disasters like hurricanes or earthquakes can severely disrupt logistics networks leading substantial delays affecting overall service levels!

Developing Risk Management Strategies

Once risks have been identified; organizations should develop comprehensive strategies mitigate them effectively! Key approaches include:

-

Diversification Strategies:

Reducing dependence upon single-source suppliers by establishing multiple sources mitigates risks associated disruptions impacting specific vendors! -

Inventory Buffering Techniques:

Maintaining safety stock levels provides cushion against unexpected spikes demands ensuring continuity during unforeseen circumstances! -

Scenario Planning Exercises:

Conducting regular scenario planning sessions enables organizations anticipate potential disruptions ahead time—allowing proactive measures taken before crises arise! -

Supplier Relationship Management (SRM):

Fostering strong partnerships with key suppliers enhances collaboration during challenging situations facilitating quicker resolutions issues arise! -

Technology Utilization:

Leveraging technology solutions such as predictive analytics tools provides insights into potential risks enabling informed decision-making regarding mitigation efforts! -

Regular Risk Assessments:

Conducting periodic assessments ensures identification emerging threats allowing adjustments made accordingly maintain resilience throughout evolving landscapes! -

Crisis Response Plans:

Developing comprehensive crisis response plans outlines specific actions taken during emergencies ensuring swift recovery minimizing disruptions operations! -

Training Programs:

Investing time/resources into training employees about risk awareness fosters culture proactive engagement ensuring everyone understands their role maintaining resilience!

Measuring Supply Chain Resilience Effectiveness

To evaluate effectiveness implemented risk management strategies; organizations should track several key performance indicators (KPIs):

-

Supply Chain Disruption Frequency:

Monitoring how often disruptions occur provides insights effectiveness mitigation efforts employed previously! -

Recovery Time After Disruptions:

Assessing average time taken restore normalcy post-disruption indicates agility response plans implemented previously! -

Cost Impact Due Disruptions:

Calculating financial losses incurred during disruptions highlights areas needing improvement regarding preparedness future incidents! -

Supplier Performance During Crises:

Evaluating how well suppliers respond crises indicates strength partnerships established previously—providing insights opportunities strengthen collaborations further! -

Employee Engagement Levels During Crises:

Assessing employee engagement during crises reveals effectiveness training programs implemented previously ensuring everyone understands roles responsibilities maintaining resilience!

To illustrate these concepts quantitatively; consider this comparison between two hypothetical companies employing different approaches towards risk management:

| Metric | Company A (Traditional Approach) | Company B (Risk-Aware Approach) |

|---|---|---|

| Average Recovery Time After Disruptions | 10 days | 3 days |

| Supply Chain Disruption Frequency | 5 incidents/year | 1 incident/year |

| Cost Impact Due Disruptions | $500K/year | $100K/year |

| Supplier Performance Rating During Crises | 70% | 95% |

| Employee Engagement Score During Crises | 60/100 | 90/100 |

The risk-aware approach clearly demonstrates significant improvements across all metrics compared traditional methods; resulting ultimately towards enhanced operational resilience amidst challenging circumstances!

Conclusion on Risk Management Strategies

In conclusion; developing effective risk management strategies ensures resilience within today’s complex global supply chains facing numerous uncertainties! By identifying vulnerabilities proactively implementing robust mitigation measures organizations position themselves thrive amidst adversity maintaining smooth operations even during challenging circumstances! The goal lies not only safeguarding against immediate threats but also fostering cultures adaptability agility necessary navigate ever-evolving landscapes successfully!

How can performance metrics drive supply chain improvements?

Performance metrics serve as vital tools for measuring success within supply chains by providing actionable insights into various aspects operations! Tracking relevant KPIs enables organizations identify strengths weaknesses allowing informed decisions drive continuous improvement initiatives throughout entire networks!

Key Performance Indicators (KPIs)

Identifying appropriate KPIs tailored specific organizational goals essential effective measurement success within supply chains! Commonly utilized KPIs include:

-

Order Fulfillment Rate:

Measures percentage orders fulfilled accurately within specified timeframe indicating effectiveness order processing systems employed! -

Inventory Turnover Ratio:

Calculates frequency inventory sold replenished over given period reflecting efficiency inventory management practices utilized! -

Lead Time Variability:

Assesses consistency lead times experienced customers highlighting potential inefficiencies within logistics networks requiring attention improvement efforts! -

Cost Per Order Fulfilled:

Calculates total costs associated fulfilling individual orders providing insights profitability order processing activities undertaken! -

Perfect Order Rate:

Measures percentage orders delivered complete accurate condition## How can performance metrics drive supply chain improvements?

Performance metrics serve as vital tools for measuring success within supply chains by providing actionable insights into various aspects operations! Tracking relevant KPIs enables organizations identify strengths weaknesses allowing informed decisions drive continuous improvement initiatives throughout entire networks!

Key Performance Indicators (KPIs)

Identifying appropriate KPIs tailored specific organizational goals essential effective measurement success within supply chains! Commonly utilized KPIs include:

-

Order Fulfillment Rate:

Measures percentage orders fulfilled accurately within specified timeframe indicating effectiveness order processing systems employed! -

Inventory Turnover Ratio:

Calculates frequency inventory sold replenished over given period reflecting efficiency inventory management practices utilized! -

Lead Time Variability:

Assesses consistency lead times experienced customers highlighting potential inefficiencies within logistics networks requiring attention improvement efforts! -

Cost Per Order Fulfilled:

Calculates total costs associated fulfilling individual orders providing insights profitability order processing activities undertaken! -

Perfect Order Rate:

Measures percentage orders delivered complete accurate condition on-time meeting customer expectations demonstrating overall supply chain effectiveness!

Leveraging Metrics for Improvement

Tracking relevant KPIs alone insufficient driving meaningful change—organizations must leverage insights gained to implement targeted improvement initiatives! Key strategies include:

-

Aligning Metrics with Strategic Goals:

Ensuring KPIs directly support organizational objectives ensures improvement efforts yield maximum impact! Regularly reviewing alignment crucial adapting evolving business landscapes! -

Establishing Baseline Performance:

Determining current performance levels provides foundation measure progress against future improvement initiatives! Consistent data collection essential establishing reliable baselines! -

Setting Realistic Targets:

Defining achievable yet challenging goals motivates teams strive excellence while maintaining morale! Targets should balance ambition with feasibility based historical performance! -

Communicating Metrics Transparently:

Sharing KPI results openly across organization fosters culture accountability transparency! Empowering employees interpret data drive improvement ideas! -

Incentivizing Metric-Driven Behavior:

Linking compensation recognition to KPI performance encourages teams prioritize improvement initiatives! Rewards should be equitable aligned with individual contributions! -

Conducting Root Cause Analysis:

Investigating underlying causes performance gaps enables targeted solutions address core issues! Fishbone diagrams 5 Whys effective tools facilitate analysis! -

Implementing Continuous Improvement:

Embracing Kaizen philosophy encourages ongoing refinement processes driving sustained excellence! Empowering employees suggest ideas fosters culture innovation! -

Leveraging Technology Solutions:

Utilizing advanced analytics tools enables real-time monitoring KPIs providing insights drive informed decisions! Integrating data sources provides holistic view supply chain performance!

Illustrating Impact of Metrics-Driven Improvement

To demonstrate impact metrics-driven improvement initiatives, consider following comparison:

| Metric | Pre-Improvement | Post-Improvement |

|---|---|---|

| Order Fulfillment Rate | 85% | 95% |

| Inventory Turnover Ratio | 6x/year | 12x/year |

| Lead Time Variability | 20% | 5% |

| Cost Per Order Fulfilled | $50 | $35 |

| Perfect Order Rate | 75% | 90% |

Implementing targeted improvement initiatives based on KPI insights yielded significant enhancements across all metrics! Improved order fulfillment, increased inventory turns, reduced lead time variability, lower costs per order, and higher perfect order rates demonstrate the power of leveraging performance data to drive supply chain excellence!

Challenges & Best Practices

While metrics-driven improvement offers immense potential, organizations may face several challenges implementing effectively:

-

Data Quality & Availability:

Ensuring accuracy consistency data collected essential meaningful analysis! Investing resources data governance crucial! -

Resistance to Change:

Employees may be reluctant embrace new KPIs fearing negative consequences! Communicating benefits transparently builds trust facilitates adoption! -

Misalignment of Incentives:

Poorly designed incentive structures may encourage suboptimal behavior! Aligning rewards with holistic supply chain objectives essential! -

Lack of Cross-Functional Collaboration:

Siloed departments hinder end-to-end visibility! Fostering collaboration across functions enables comprehensive improvement efforts! -

Inability to Interpret Data:

Employees may struggle interpret complex data! Providing training resources empowers teams leverage insights effectively!

To overcome these challenges, organizations should consider following best practices:

-

Establish Data Governance Frameworks:

Defining clear data ownership policies ensures integrity consistency metrics! -

Communicate Improvement Initiatives Transparently:

Sharing rationale KPIs and expected benefits builds trust facilitates buy-in! -

Align Incentives with Supply Chain Objectives:

Designing holistic reward structures encourages collaborative behavior! -

Invest in Cross-Functional Training:

Educating teams on end-to-end supply chain processes enhances visibility! -

Utilize Intuitive Data Visualization Tools:

Leveraging dashboards and reports tailored user needs enables data-driven decision making!

By embracing metrics-driven improvement, organizations position themselves drive continuous excellence within their supply chains! Leveraging performance data enables targeted initiatives that enhance efficiency, reduce costs, and improve customer satisfaction—ultimately strengthening competitive advantage in dynamic global markets!