What Are the 5 Freight Handling Equipment Used During the Various Phases of Cargo Transit at the Port

Why is freight handling equipment crucial for port operations?

Freight handling equipment forms the backbone of modern port operations, enabling the efficient movement and processing of vast quantities of cargo. Without specialized machinery, ports would struggle to meet the demands of global trade and commerce.

Increased productivity and throughput

Advanced cargo handling equipment dramatically boosts a port’s productivity and cargo throughput capacity. Powerful cranes can load and unload container ships in a fraction of the time it would take manually. Automated guided vehicles and terminal tractors swiftly transport containers between ships, storage yards, and land transport. This acceleration of cargo processing allows ports to handle more vessels and greater cargo volumes.

Enhanced safety

Purpose-built freight handling equipment significantly improves safety for port workers. Heavy lifting and container movements that would be extremely hazardous if done manually are instead performed by machines designed specifically for those tasks. Cranes, forklifts, and other equipment keep workers at a safe distance from suspended loads. Automation further reduces risks by minimizing human involvement in dangerous operations.

Optimized space utilization

Modern container handling equipment enables ports to maximize the use of limited space. Gantry cranes and straddle carriers allow containers to be stacked higher and denser than ever before. Automated storage and retrieval systems can pack containers tightly while maintaining rapid access. This vertical utilization of space is crucial as many ports face constraints on horizontal expansion.

Improved cargo tracking and management

Advanced freight handling equipment often incorporates technologies that enhance cargo tracking and management. RFID scanners, optical character recognition, and other systems integrated into cranes and vehicles allow for real-time tracking of container movements. This data feeds into port management systems, providing visibility across operations and enabling more efficient planning and coordination.

Reduced environmental impact

Many modern types of port equipment are designed with environmental sustainability in mind. Electric and hybrid systems are becoming increasingly common, reducing emissions and noise pollution. More efficient engines and energy recovery systems in diesel-powered equipment also help lower fuel consumption and emissions. This aligns with growing pressure on ports to minimize their environmental footprint.

Adaptability to different cargo types

Specialized freight handling equipment allows ports to efficiently process a wide variety of cargo types. While containers dominate many ports, equipment like heavy-lift cranes, conveyor systems, and specialized forklifts enable the handling of break-bulk, bulk, and project cargo. This versatility is crucial for ports serving diverse industries and trade routes.

Cost-effectiveness in the long run

While the initial investment in advanced freight handling equipment can be substantial, it often proves highly cost-effective over time. Increased productivity means more revenue-generating cargo can be processed. Reduced labor costs, lower maintenance requirements, and improved energy efficiency all contribute to long-term savings. Additionally, ports with state-of-the-art equipment are better positioned to attract shipping lines and maintain competitiveness.

Integration with digital systems

Modern freight handling equipment is increasingly designed to integrate seamlessly with port management information systems and other digital platforms. This connectivity enables real-time data exchange, predictive maintenance, and optimization of equipment deployment. The result is smoother overall port operations and better decision-making capabilities for port managers.

In essence, freight handling equipment is not just a collection of machines, but a critical system that determines a port’s capacity, efficiency, safety, and competitiveness in the global maritime trade network. As international trade continues to grow and evolve, the role of this equipment in port operations will only become more crucial.

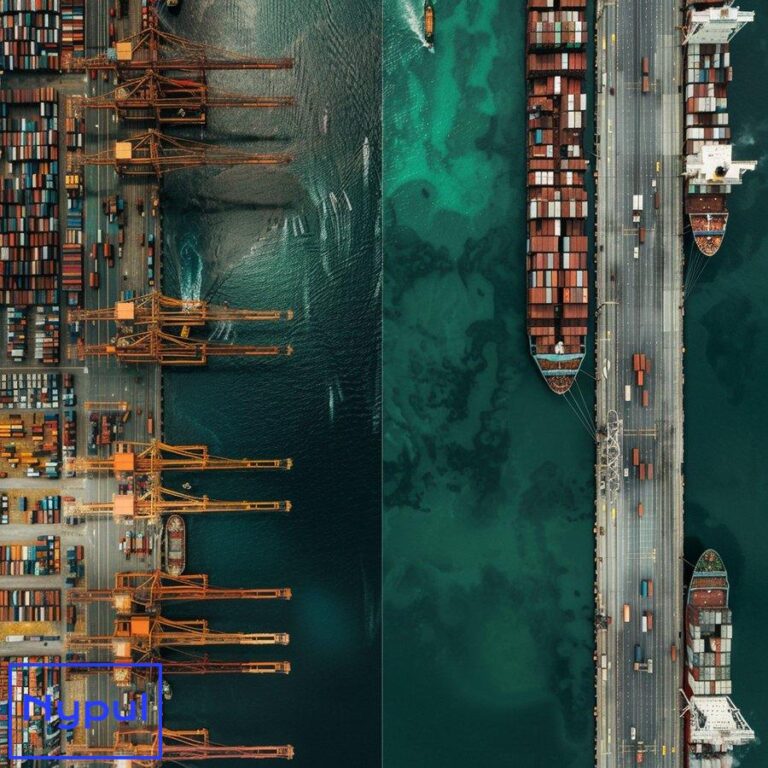

How do Ship-to-Shore (STS) Gantry Cranes revolutionize container transfers?

Ship-to-Shore (STS) Gantry Cranes have fundamentally transformed the process of transferring containers between ships and land, becoming the centerpiece of modern container terminal operations. These massive structures, often towering over 100 meters high, have revolutionized port efficiency and capacity in several key ways:

Rapid loading and unloading

STS cranes dramatically accelerate the process of loading and unloading container ships. A single modern STS crane can typically handle between 30-40 container moves per hour. This speed is crucial for reducing ship turnaround times, allowing ports to service more vessels and handle greater cargo volumes. The rapid transfer of containers also helps shipping lines maintain tight schedules, which is essential in the just-in-time logistics systems that many industries rely on.

Increased reach and capacity

As container ships have grown larger, STS cranes have evolved to keep pace. Modern cranes can reach across ships up to 24 containers wide, accommodating the largest vessels in service today. Their lifting capacity has also increased, with many able to handle loads of 65 tons or more. This allows for the efficient handling of not just standard containers but also oversized and heavy project cargo.

Precision and safety

STS cranes offer a level of precision in container handling that was previously unattainable. Advanced control systems, often incorporating semi-automated or fully automated functions, ensure accurate positioning of containers. This precision reduces the risk of damage to cargo and equipment while also enhancing safety for port workers. Many modern STS cranes feature anti-sway technologies and sophisticated sensors to further improve safety and efficiency.

Integration with port management systems

Modern STS cranes are typically integrated with broader port management information systems. This connectivity allows for real-time tracking of container movements, optimized crane deployment, and seamless coordination with other port equipment and processes. The data generated by these cranes feeds into analytics systems that help port managers make informed decisions about resource allocation and process improvements.

Adaptability to different vessel types

While primarily designed for container ships, many STS cranes can be adapted to handle other vessel types. Some models feature adjustable spreaders that can accommodate different container sizes or even non-containerized cargo. This versatility is particularly valuable for ports that handle a diverse range of ship types and cargo.

Environmental considerations

The latest generation of STS cranes often incorporates features designed to reduce environmental impact. These may include regenerative power systems that capture energy from lowering containers, LED lighting for improved energy efficiency, and noise reduction technologies. Some ports are even experimenting with fully electric STS cranes to further reduce emissions.

Impact on port layout and design

The capabilities of STS cranes have significantly influenced port layout and design. Their ability to handle larger ships has led to the development of deeper berths and wider quays. The high-speed operation of these cranes has necessitated more efficient container yard designs and improved landside transport links to handle the increased flow of containers.

Workforce implications

While STS cranes have reduced the need for manual labor in some aspects of port operations, they have also created demand for highly skilled operators and technicians. The complexity of these machines requires specialized training and expertise, leading to the development of new job roles within ports.

Table: Evolution of STS Crane Capabilities

| Feature | 1960s Cranes | Modern Cranes |

|---|---|---|

| Max Reach | 12-13 containers wide | Up to 24 containers wide |

| Lifting Capacity | 20-30 tons | 65+ tons |

| Lifting Speed | 20-30 m/min | Up to 90 m/min |

| Automation Level | Manual operation | Semi or fully automated |

| Environmental Features | Basic | Regenerative power, LED lighting |

| Integration | Standalone | Fully integrated with port systems |

The revolution brought about by STS Gantry Cranes extends beyond mere mechanical improvements. These machines have become the lynchpin of container port operations, shaping everything from ship design to global supply chain strategies. As international trade continues to grow and evolve, STS cranes will undoubtedly continue to play a central role in the efficiency and capability of the world’s ports.

What role do Rubber-Tyred Gantry (RTG) Cranes play in container yard management?

Rubber-Tyred Gantry (RTG) Cranes are pivotal in efficient container yard management, serving as the workhorses of modern container terminals. These versatile machines play a multifaceted role in organizing, stacking, and retrieving containers within the port area. Their impact on container yard operations is profound and multifaceted:

Efficient space utilization

RTG cranes excel at maximizing the use of limited yard space. They can create dense, high container stacks, typically up to 5 or 6 containers high and 6 or 7 rows wide. This vertical stacking capability allows ports to significantly increase their storage capacity without expanding their physical footprint. The ability to create such compact storage arrangements is particularly crucial for ports in urban areas or those with limited expansion possibilities.

Flexible yard operations

The mobility of RTG cranes, enabled by their rubber tyres, provides unparalleled flexibility in yard operations. Unlike rail-mounted gantry cranes, RTGs can be easily moved between different areas of the container yard as needed. This flexibility allows port operators to quickly adapt to changing storage requirements, efficiently manage different types of cargo, and optimize yard layouts in response to evolving operational needs.

Rapid container retrieval and placement

RTG cranes are designed for swift and precise container movements. Modern RTGs can typically perform 20-25 container moves per hour. This speed is crucial for maintaining efficient yard operations, especially in busy ports where quick turnaround times are essential. The ability to rapidly locate, retrieve, and place containers supports smooth intermodal transfers and helps prevent bottlenecks in the overall port logistics chain.

Enhanced inventory management

Many RTG cranes are equipped with advanced technologies that support real-time inventory management. Integrated systems can track the exact location of each container within the yard, making retrieval more efficient and reducing the likelihood of misplaced containers. This capability is particularly valuable in large terminals handling thousands of containers daily.

Improved safety and reduced ground handling

By enabling high stacking and providing precise control over container movements, RTG cranes significantly reduce the need for ground-level container handling. This minimizes the movement of heavy equipment like reach stackers and forklifts within the yard, leading to improved safety for port workers and reduced risk of container damage.

Environmental considerations

The latest generation of RTG cranes often incorporates eco-friendly features. Many modern RTGs are hybrid or fully electric, significantly reducing emissions and noise pollution compared to their diesel-powered predecessors. Some models also feature regenerative energy systems that capture and reuse energy from lowering containers, further enhancing their environmental performance.

Integration with automation systems

RTG cranes are increasingly being integrated into automated terminal operations. Some models can operate semi-autonomously or even fully autonomously, guided by sophisticated control systems. This automation potential not only increases efficiency but also improves consistency in operations and can lead to reduced labor costs over time.

Support for intermodal operations

RTG cranes play a crucial role in facilitating smooth intermodal transfers. They can efficiently load and unload containers from trucks and rail cars, supporting seamless transitions between different modes of transport. This capability is essential for ports that serve as key nodes in complex logistics networks.

Customization and adaptability

RTG cranes can be customized to meet specific port requirements. Variations in lifting capacity, stacking height, and span width allow ports to select cranes that best fit their operational needs and physical constraints. Some RTGs are also equipped with specialized attachments for handling non-standard containers or even break-bulk cargo, adding to their versatility.

Table: Comparison of RTG Crane Types

| Feature | Diesel RTG | Hybrid RTG | Fully Electric RTG |

|---|---|---|---|

| Power Source | Diesel engine | Diesel-electric hybrid | Electric (from grid) |

| Emissions | Highest | Reduced | Lowest (zero on-site) |

| Noise Level | Highest | Reduced | Lowest |

| Operational Cost | Highest | Medium | Lowest |

| Initial Investment | Lowest | Medium | Highest |

| Maintenance Needs | Highest | Medium | Lowest |

| Energy Efficiency | Lowest | Improved | Highest |

The role of RTG cranes in container yard management extends far beyond simple container movement. These machines are integral to the overall efficiency, flexibility, and sustainability of modern port operations. As ports continue to face challenges such as increasing cargo volumes, limited space, and environmental pressures, the importance of RTG cranes in effective yard management is likely to grow even further. Their evolution will continue to shape the design and operation of container terminals worldwide.

How do Reach Stackers enhance versatility in container handling?

Reach Stackers have emerged as indispensable assets in modern port operations, offering unparalleled versatility in container handling. These powerful machines combine the lifting capabilities of a crane with the mobility of a forklift, providing a flexible solution for various container handling tasks. Their impact on port operations is multifaceted and significant:

Multifunctional capability

Reach Stackers excel in their ability to perform a wide range of tasks. They can stack containers in rows, load and unload trucks and rail cars, and even assist in vessel operations in smaller ports. This versatility makes them invaluable in ports that handle diverse cargo types or have fluctuating operational needs. A single Reach Stacker can often replace multiple specialized machines, streamlining equipment fleets and reducing capital investment.

Rapid deployment and mobility

The wheeled design of Reach Stackers allows for quick movement across the port area. Unlike fixed cranes or rail-mounted equipment, Reach Stackers can be rapidly deployed to different locations as needed. This mobility is particularly advantageous in managing peak periods, addressing unexpected operational challenges, or reconfiguring container stacks. The ability to swiftly respond to changing operational demands enhances overall port efficiency.

High stacking capability

Modern Reach Stackers can typically stack containers up to 5 high in the first row, with some models capable of even greater heights. This vertical stacking ability allows ports to maximize space utilization, particularly in smaller terminals or those with limited expansion possibilities. The combination of high stacking and mobility enables dynamic reconfiguration of container yards to optimize space usage.

Handling of various container types

Reach Stackers are designed to handle a wide variety of container types and sizes. From standard 20-foot and 40-foot containers to specialized units like refrigerated containers, flat racks, and even oversized project cargo, Reach Stackers can adapt to different load requirements. This flexibility is crucial for ports that serve diverse industries and handle mixed cargo types.

Support for intermodal operations

In intermodal terminals, Reach Stackers play a vital role in facilitating smooth transitions between different transport modes. They can efficiently transfer containers between trucks, trains, and storage areas, supporting seamless intermodal logistics chains. This capability is particularly valuable in inland ports and distribution centers that serve as crucial nodes in complex supply networks.

Enhanced maneuverability in tight spaces

The design of Reach Stackers allows for exceptional maneuverability, even in confined spaces. Their ability to operate effectively in narrow aisles and tight corners makes them ideal for smaller ports or terminals with layout constraints. This maneuverability can help optimize yard layouts and improve overall space utilization.

Reduced ground pressure

Compared to some other heavy container handling equipment, Reach Stackers distribute their weight over a larger area, resulting in lower ground pressure. This characteristic can be advantageous in ports with less robust ground infrastructure or those built on reclaimed land, as it reduces the risk of surface damage and the need for extensive ground reinforcement.

Operational flexibility in varying conditions

Reach Stackers can operate effectively in a wide range of weather conditions. Their enclosed cab design protects operators from the elements, allowing for continued operations in adverse weather. This resilience contributes to consistent port productivity and helps minimize weather-related disruptions.

Cost-effective solution for medium-volume ports

For medium-sized ports or those with fluctuating container volumes, Reach Stackers offer a cost-effective alternative to large, fixed infrastructure investments. Their versatility allows ports to scale operations up or down more easily, adapting to changing market conditions without the need for significant capital expenditures on specialized equipment.

Training and skill development

The operation of Reach Stackers requires skilled personnel, contributing to the development of a highly trained workforce in ports. The versatility of these machines means that operators must be proficient in a wide range of handling techniques, enhancing their overall value to port operations.

Table: Reach Stacker Capabilities Comparison

| Feature | Standard Reach Stacker | Advanced Reach Stacker |

|---|---|---|

| Max Lifting Capacity | 45 tons | Up to 100 tons |

| Max Stacking Height | 5 containers | Up to 6 containers |

| Intermodal Handling | Basic | Advanced (rail, barge) |

| Fuel Efficiency | Standard | Improved (hybrid options) |

| Automation Features | Limited | Advanced (semi-autonomous) |

| Specialized Attachments | Basic spreader | Multiple attachments |

| Operator Assistance | Basic controls | Advanced control systems |

| Environmental Features | Standard emissions | Reduced emissions, noise |

The versatility of Reach Stackers in container handling extends far beyond their basic lifting and stacking capabilities. These machines have become integral to the flexible and efficient operation of modern ports, particularly those facing space constraints or handling diverse cargo types. As port operations continue to evolve in response to changing global trade patterns and technological advancements, the role of Reach Stackers in enhancing operational versatility is likely to grow even more significant. Their ongoing development will continue to shape container handling strategies and contribute to the overall adaptability and resilience of port operations worldwide.

What makesWhat makes Terminal Tractors essential for internal container movement?

Terminal Tractors, also known as yard trucks, hostlers, or shunt trucks, play a crucial role in the internal movement of containers within port facilities. These specialized vehicles are designed to efficiently transport containers and trailers over short distances, serving as the vital link between different operational areas of a port. Their essentiality in port operations stems from several key factors:

High maneuverability in tight spaces

Terminal Tractors are specifically engineered for optimal maneuverability in confined port environments. Their compact design and tight turning radius allow them to navigate narrow lanes, congested areas, and sharp corners with ease. This agility is crucial in maximizing space utilization and maintaining smooth traffic flow within the port.

Rapid coupling and decoupling

One of the most significant advantages of Terminal Tractors is their ability to quickly connect and disconnect from trailers. The elevated cab design allows drivers to easily align with and couple to trailers without leaving their seat. This feature dramatically reduces the time spent on each container move, enhancing overall port productivity.

Continuous operation capability

Terminal Tractors are built for durability and continuous operation. Many models are designed to run for extended periods without overheating or requiring frequent maintenance breaks. This reliability is essential in maintaining consistent container movement flows, especially during peak operational periods.

Versatility in handling different trailer types

These vehicles can handle a wide variety of trailer types and sizes, from standard container chassis to specialized equipment. This versatility makes them indispensable in ports that handle diverse cargo types and container configurations.

Integration with automated systems

Modern Terminal Tractors are increasingly being integrated into automated port operations. Some models can be operated remotely or as part of an automated guided vehicle (AGV) system. This integration enhances overall port efficiency and supports the trend towards smart, digitally-connected port operations.

Improved safety features

Terminal Tractors are equipped with numerous safety features tailored to the port environment. These may include enhanced visibility from the elevated cab, collision avoidance systems, and stability control mechanisms. Such features are crucial in maintaining safe operations in busy port areas where multiple vehicles and personnel are constantly in motion.

Cost-effective transportation solution

Compared to larger, more specialized equipment, Terminal Tractors offer a cost-effective solution for internal container movements. Their relatively lower purchase and maintenance costs, combined with fuel efficiency and operational versatility, make them an economical choice for ports of various sizes.

Support for intermodal operations

Terminal Tractors play a vital role in facilitating smooth intermodal transfers. They efficiently move containers between ship-side operations, storage yards, rail terminals, and truck loading areas. This seamless movement is essential for maintaining the efficiency of the entire logistics chain.

Adaptability to port layout changes

As ports evolve and expand, Terminal Tractors provide the flexibility to adapt to changing layouts and operational requirements. Unlike fixed infrastructure or rail-based systems, these vehicles can easily be redeployed to serve new areas or altered traffic patterns within the port.

Environmental considerations

The latest generation of Terminal Tractors includes models with improved fuel efficiency and reduced emissions. Some ports are even adopting electric or hybrid Terminal Tractors as part of their sustainability initiatives, helping to reduce the overall environmental impact of port operations.

Table: Comparison of Terminal Tractor Types

| Feature | Diesel Terminal Tractor | Electric Terminal Tractor |

|---|---|---|

| Power Source | Diesel engine | Electric motors |

| Emissions | Higher | Zero on-site emissions |

| Noise Level | Higher | Significantly lower |

| Operational Range | Extended | Limited by battery capacity |

| Refueling/Recharging Time | Quick refueling | Longer recharging time |

| Maintenance Requirements | Regular engine maintenance | Reduced mechanical maintenance |

| Initial Cost | Lower | Higher |

| Operational Cost | Higher fuel costs | Lower energy costs |

Terminal Tractors have become an indispensable component of efficient port operations. Their unique combination of maneuverability, versatility, and efficiency makes them essential for the smooth flow of containers within port facilities. As ports continue to face challenges such as increasing cargo volumes, space constraints, and environmental pressures, the role of Terminal Tractors in optimizing internal container movements will likely become even more critical.

How do Forklifts and Side Loaders handle non-containerized cargo?

Forklifts and Side Loaders play a crucial role in handling non-containerized cargo, providing versatility and efficiency in managing diverse types of freight. These machines are essential for ports that handle break-bulk, project cargo, and other non-standard shipments. Their importance in port operations stems from their ability to adapt to various cargo types and sizes.

Versatility in cargo handling

Forklifts and Side Loaders excel in handling a wide range of non-containerized cargo. This includes palletized goods, crates, machinery, steel coils, timber, and oversized project cargo. Their adaptability allows ports to efficiently process diverse shipments without relying solely on specialized equipment for each cargo type.

Precision in cargo placement

These machines offer precise control in lifting and placing cargo. Forklifts, with their front-mounted forks, can navigate tight spaces and stack items with accuracy. Side Loaders, featuring side-mounted forks, are particularly adept at handling long items like pipes or lumber, allowing for careful positioning in storage areas or on transport vehicles.

Adaptability to different load sizes

Forklifts and Side Loaders come in various sizes and capacities, ranging from small electric models for light loads to heavy-duty diesel-powered units capable of lifting several tons. This range allows ports to match the right equipment to specific cargo requirements, ensuring efficient handling regardless of the load size.

Support for intermodal transfers

These machines play a vital role in facilitating the transfer of non-containerized cargo between different modes of transport. They can efficiently load and unload trucks, railcars, and even assist in ship-to-shore operations for smaller vessels. This capability is crucial for maintaining smooth logistics chains for break-bulk and project cargo.

Enhanced storage efficiency

Forklifts and Side Loaders contribute significantly to efficient use of storage space. Their ability to stack cargo vertically and access high shelving units allows ports to maximize their storage capacity. Side Loaders, in particular, excel in creating dense, organized storage arrangements for long items that are challenging to stack with other equipment.

Flexibility in operational areas

Unlike some larger, specialized port equipment, Forklifts and Side Loaders can operate in various areas of the port. They can move easily between warehouses, open storage yards, and quayside areas, providing flexibility in cargo handling operations.

Rapid deployment and mobility

The compact size and maneuverability of these machines allow for quick deployment to different areas of the port as needed. This mobility is particularly valuable when dealing with time-sensitive cargo or responding to sudden changes in operational requirements.

Customization options

Forklifts and Side Loaders can be equipped with various attachments to handle specific types of cargo. These may include clamps for handling paper rolls, rotating attachments for drums, or specialized forks for unusual load shapes. This customization enhances their versatility in handling diverse non-containerized cargo.

Cost-effective solution for varied cargo

For ports that handle a mix of containerized and non-containerized cargo, Forklifts and Side Loaders offer a cost-effective solution. Their versatility reduces the need for multiple specialized machines, potentially lowering overall equipment investment and maintenance costs.

Safety in handling fragile or high-value cargo

The precise control offered by Forklifts and Side Loaders is particularly valuable when handling fragile or high-value non-containerized cargo. Operators can exercise careful control over load movements, reducing the risk of damage during handling and transport.

Table: Comparison of Forklift and Side Loader Capabilities

| Feature | Standard Forklift | Heavy-Duty Side Loader |

|---|---|---|

| Typical Load Capacity | 2-5 tons | 5-50 tons |

| Max Lift Height | Up to 6 meters | Up to 8 meters |

| Cargo Specialization | Pallets, crates | Long items, heavy loads |

| Maneuverability | High in tight spaces | Excellent for long loads |

| Operational Area | Versatile (indoor/outdoor) | Primarily outdoor |

| Stacking Efficiency | Vertical stacking | Efficient for long items |

| Customization Options | Various attachments | Specialized long forks |

| Fuel Options | Electric, LPG, Diesel | Primarily Diesel |

Forklifts and Side Loaders are indispensable in ports that handle non-containerized cargo. Their versatility, precision, and adaptability make them crucial for efficiently managing the diverse range of freight that passes through modern ports. As global trade continues to involve a mix of containerized and non-containerized cargo, the role of these machines in ensuring smooth port operations remains vital. Their ongoing development, including the integration of advanced technologies and eco-friendly power systems, will continue to enhance their capabilities in handling the evolving demands of non-containerized cargo in port environments.

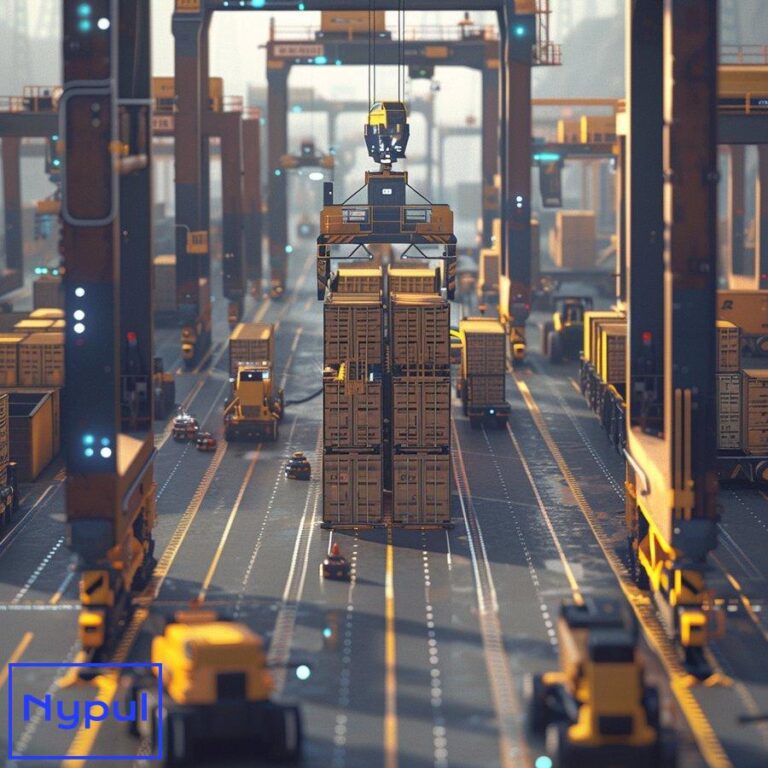

How do these five types of equipment integrate for seamless port logistics?

The integration of Ship-to-Shore (STS) Gantry Cranes, Rubber-Tyred Gantry (RTG) Cranes, Reach Stackers, Terminal Tractors, and Forklifts/Side Loaders forms the backbone of efficient port logistics. This harmonious integration creates a seamless flow of cargo from ship to shore and beyond, maximizing productivity and minimizing bottlenecks. The synergy between these equipment types is crucial for modern port operations.

Coordinated container handling

The process begins with STS Gantry Cranes unloading containers from ships. These cranes work in tandem with Terminal Tractors, which quickly transport containers to the storage yard. Here, RTG Cranes or Reach Stackers take over, efficiently organizing and stacking containers. This coordinated handoff ensures a continuous flow of containers, preventing congestion at the quayside.

Flexible yard management

RTG Cranes and Reach Stackers work together to optimize container yard operations. While RTGs handle the bulk of container movements within designated lanes, Reach Stackers provide flexibility in handling containers in less structured areas or for special handling requirements. This combination allows for efficient space utilization and quick response to changing operational needs.

Intermodal transfer efficiency

Terminal Tractors play a crucial role in bridging different operational areas. They shuttle containers between ship-side operations, storage yards, and landside transport interfaces. This constant movement, coordinated with the activities of STS and RTG cranes, ensures smooth transitions between different stages of the logistics chain.

Handling diverse cargo types

While the majority of cargo may be containerized, Forklifts and Side Loaders integrate seamlessly to handle non-containerized freight. They work alongside other equipment to ensure that break-bulk cargo, project loads, and other special items are efficiently processed without disrupting the flow of container operations.

Optimized traffic flow

The integration of these equipment types necessitates careful planning of port traffic flows. Terminal Tractors, for instance, operate on designated routes that minimize interference with RTG and Reach Stacker operations. This orchestrated movement prevents congestion and enhances overall port efficiency.

Real-time coordination through technology

Modern ports integrate these equipment types not just physically but also digitally. Advanced port management systems coordinate the activities of different machines in real-time, optimizing their deployment and minimizing idle time. This digital integration is key to achieving seamless logistics operations.

Adaptability to operational peaks

The combination of these equipment types provides ports with the flexibility to handle operational peaks. For instance, during high-volume periods, additional Reach Stackers can be deployed to support RTG operations, or extra Terminal Tractors can be assigned to ensure swift container movement from ship to yard.

Enhanced safety through integration

The integration of these equipment types includes coordinated safety protocols. For example, Terminal Tractors and Forklifts operate in designated areas to avoid conflicts with larger equipment like STS and RTG cranes. This integrated approach to safety helps reduce accidents and improves overall operational security.

Efficient energy management

Modern port equipment often features energy-saving technologies. The integration of these systems allows for optimized energy use across the port. For instance, regenerative energy from STS and RTG cranes can be fed back into the port’s power grid, potentially powering electric Terminal Tractors or Forklifts.

Scalability and flexibility

The integration of these five equipment types allows ports to scale operations efficiently. Smaller ports might rely more heavily on versatile equipment like Reach Stackers and Forklifts, while larger ports can emphasize the use of STS and RTG cranes for high-volume container handling. This scalability ensures that ports of all sizes can optimize their operations.

Table: Integration of Port Equipment in Cargo Handling Process

| Stage | Primary Equipment | Supporting Equipment | Key Integration Aspect |

|---|---|---|---|

| Ship Unloading | STS Gantry Cranes | Terminal Tractors | Synchronized timing for continuous flow |

| Transport to Yard | Terminal Tractors | – | Coordinated routing with yard operations |

| Yard Stacking | RTG Cranes | Reach Stackers | Complementary operations for efficient stacking |

| Intermodal Transfer | Terminal Tractors | Reach Stackers | Flexible handling for various transport modes |

| Non-Container Cargo | Forklifts/Side Loaders | Terminal Tractors | Integrated handling of diverse cargo types |

The seamless integration of these five types of equipment is fundamental to efficient port logistics. This integration goes beyond mere physical coordination; it encompasses a holistic approach to port operations, including digital systems, energy management, and safety protocols. As ports continue to evolve in response to increasing trade volumes and technological advancements, the synergy between these equipment types will become even more critical. Future developments are likely to focus on enhancing this integration through advanced automation, AI-driven coordination, and even more environmentally sustainable operations, further streamlining the complex process of moving cargo through ports efficiently and safely.