What Are the Drayage Classifications

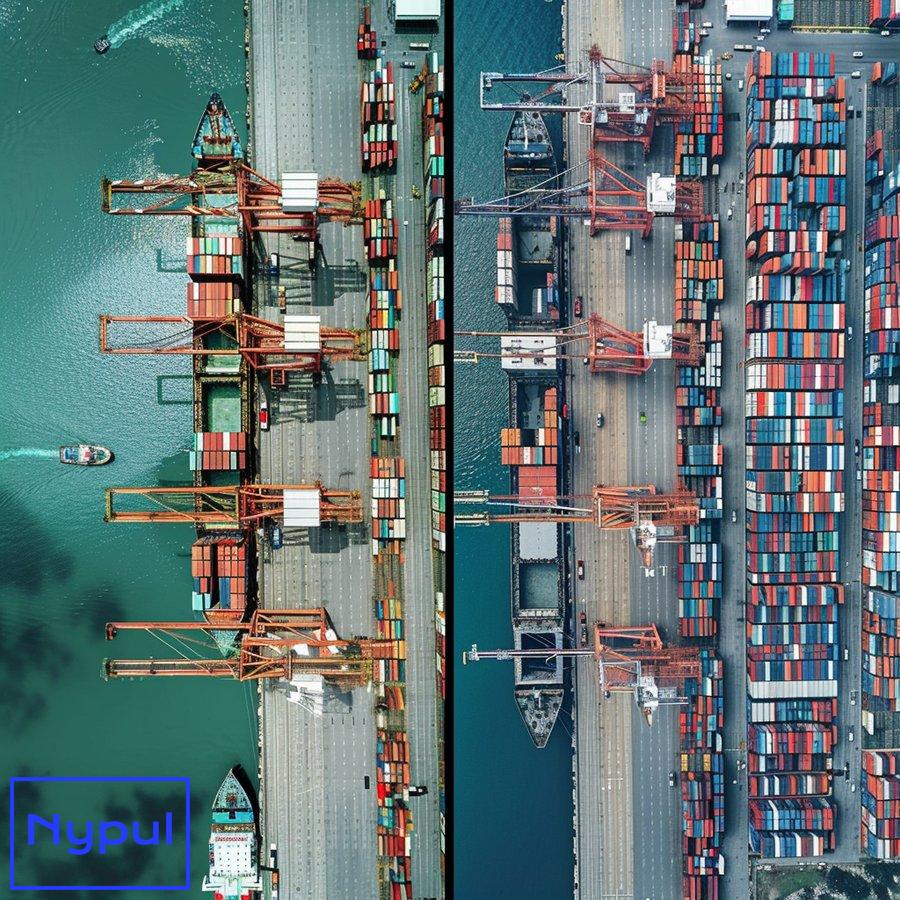

What is Drayage and Why is it Important?

Drayage is the transportation of goods over a short distance, typically from a port or rail terminal to a warehouse or distribution center. It is a crucial link in the supply chain, connecting the long-haul transportation of goods via ship or rail with their final destination.

Efficient drayage operations are essential for keeping the supply chain moving smoothly. Delays or disruptions in drayage can lead to bottlenecks and increased costs throughout the entire logistics process. By ensuring that goods are quickly and reliably transported from ports and terminals to their next destination, drayage helps businesses maintain their inventory levels and meet customer demand.

Drayage also plays an important role in international trade. With the vast majority of global trade moving by ship, ports are key nodes in the supply chain. Drayage carriers are responsible for moving containers from the port to inland locations, allowing imported goods to be distributed throughout the country. Similarly, drayage is critical for getting export cargo from production facilities to the port so it can be loaded onto outbound ships.

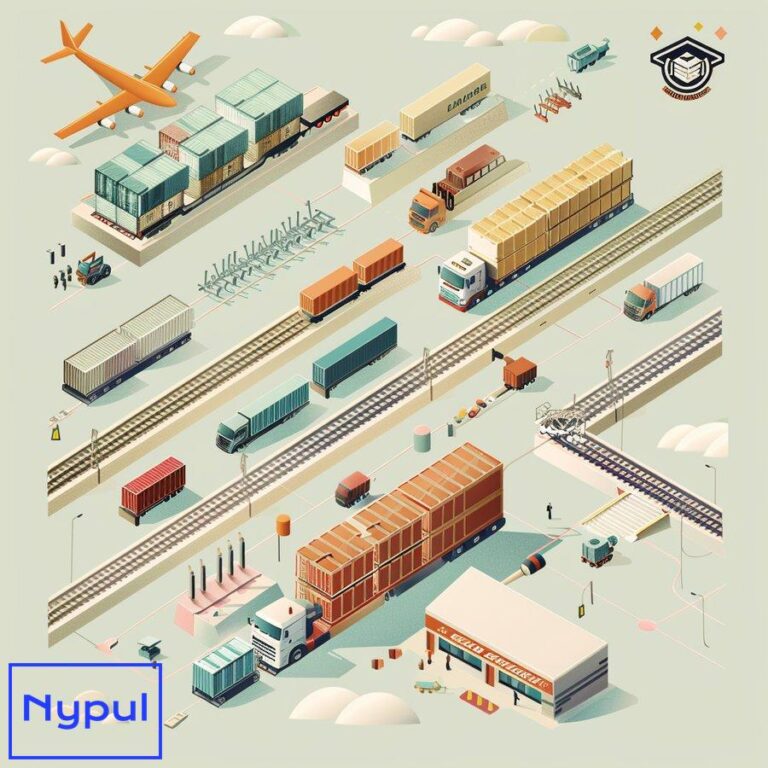

What Are the Six Drayage Classifications?

![]()

There are six main drayage classifications that logistics professionals should be aware of:

Expedited Drayage: Expedited drayage provides fast, time-sensitive transportation of goods. It is often used for high-priority shipments that need to be delivered quickly.

Inter-Carrier Drayage: Inter-carrier drayage involves the transfer of cargo between two different carriers, such as from a ship to a rail car.

Intra-Carrier Drayage: Intra-carrier drayage is the movement of goods within the same carrier’s network, such as from a rail terminal to a rail yard.

Pier Drayage: Pier drayage refers to the movement of containers from a port terminal to a nearby off-dock container yard or intermodal facility.

Shuttle Drayage: Shuttle drayage is the transportation of containers between two points within a port or rail facility, such as from a container yard to a loading dock.

Door-to-Door Drayage: Door-to-door drayage provides complete transportation from the shipper’s location to the final destination, with the drayage carrier handling all pick-up and delivery.

How Does Expedited Drayage Differ from Standard Drayage?

The key difference between expedited and standard drayage is the speed and priority of the shipment. Expedited drayage is used when goods need to be delivered urgently and cannot wait for regular drayage service. This could be due to a tight deadline, a just-in-time production schedule, or an unexpected need for inventory replenishment.

With expedited drayage, carriers typically provide dedicated equipment and drivers to ensure the fastest possible transit time. Shipments are given top priority and may move directly from origin to destination without passing through terminals or consolidation points. Special handling, such as temperature control or additional security, can often be arranged for expedited loads.

However, the increased speed and priority of expedited drayage comes at a cost. Rates for expedited service are usually significantly higher than for standard drayage. The dedicated resources required also mean that expedited capacity can be limited, especially during peak shipping periods.

Standard drayage, in contrast, operates on regular schedules and routes. Containers are typically consolidated at terminals before being delivered to their final destination. Transit times are longer but costs are lower. For most shipments, standard drayage provides reliable and cost-effective transportation.

What’s the Difference Between Inter-Carrier and Intra-Carrier Drayage?

Inter-carrier and intra-carrier drayage both involve the movement of goods over a short distance, but they differ in terms of the carriers involved.

Inter-carrier drayage is the transfer of cargo from one transportation provider to another. A common example is moving a shipping container from a port terminal operated by a steamship line to a rail terminal operated by a railroad. The drayage carrier provides the link between the two different carriers, allowing the cargo to continue its journey.

Intra-carrier drayage, on the other hand, is the movement of goods within a single carrier’s network. For example, a railroad might use drayage to reposition empty rail cars or to shuttle loaded cars between two of its own terminals. In this case, the same transportation provider is responsible for the entire movement.

The key distinction is that inter-carrier drayage involves a change of custody between different carriers, while intra-carrier drayage is handled entirely within one carrier’s system. Inter-carrier movements often require more coordination and may be subject to additional handoffs and potential delays. Intra-carrier drayage can be more streamlined since a single carrier controls the entire process.

How Do Pier and Shuttle Drayage Impact Port Operations?

Pier and shuttle drayage are essential for efficient port operations. Pier drayage moves containers from the port terminal to an off-dock container yard or intermodal facility. This frees up space on the terminal and allows containers to be sorted and staged for further transportation by rail or truck. Without pier drayage, terminals would quickly become congested, slowing down vessel loading and unloading operations.

Shuttle drayage supports the movement of containers within the port complex. Containers often need to be shuttled between different terminals or from a terminal to an on-dock rail facility. Efficient shuttle drayage keeps containers flowing smoothly through the port and helps optimize the use of terminal space and equipment.

Both pier and shuttle drayage face challenges from port congestion. As container volumes have grown, many ports have struggled to keep up, leading to long truck queues and slow turn times. Drayage carriers often bear the cost of these delays in the form of detention and demurrage charges or lost productivity.

Some ports have implemented appointment systems and extended gate hours to help manage congestion and improve drayage efficiency. Off-dock container yards can also relieve pressure on port terminals by providing additional storage capacity and allowing for more flexible drayage operations. By working together, ports, terminals, and drayage providers can enhance the flow of containers and reduce costs throughout the supply chain.

What Makes Door-to-Door Drayage Unique?

Door-to-door drayage provides a complete transportation solution from the shipper’s dock to the consignee’s location. Unlike other drayage services that only handle one leg of the journey, door-to-door drayage covers the entire process, including pick-up, line haul, and final delivery. This makes it a convenient option for shippers who want to streamline their logistics and deal with a single provider.

The door-to-door model offers several advantages. First, it simplifies the supply chain by reducing the number of handoffs between carriers. This can help minimize delays, miscommunication, and potential damage to the cargo. Second, door-to-door service provides a single point of contact and accountability for the entire shipment. If any issues arise, the shipper only needs to communicate with one party to resolve them.

However, door-to-door drayage also has some unique challenges. Coordinating pick-up and delivery times can be complex, especially if the shipper and consignee have limited scheduling flexibility. Drayage carriers also need to be prepared to handle a wide range of cargo types and customer requirements.

Another consideration is cost. Door-to-door rates may be higher than port-to-port or terminal-to-door rates since they include the line haul portion of the move. However, this cost may be offset by reduced handling fees and administrative expenses.

Ultimately, the choice between door-to-door and other drayage options depends on the shipper’s specific needs and priorities. For some, the convenience and simplicity of door-to-door service outweigh the potential cost premium. Others may prefer the flexibility of arranging their own line haul and only using drayage for the local portions of the move.

How Do Factors Like Distance and Cargo Type Influence Drayage Classification?

Several key factors can influence how a drayage move is classified, including distance, cargo type, and service requirements. Understanding these factors is important for shippers and carriers to ensure that drayage is priced and executed correctly.

Distance

The distance of the drayage move is a primary factor in determining its classification. Longer distances generally fall into the category of inter-carrier drayage, as they often involve transferring the cargo between different modes or carriers. For example, a container being drayed from a port to a rail terminal 50 miles away would be considered inter-carrier drayage.

Shorter distances, on the other hand, are more likely to be classified as intra-carrier or shuttle drayage. These moves typically occur within a single carrier’s network or facility, such as shuttling a container from one marine terminal to another within the same port complex.

Cargo Type

The type of cargo being transported can also affect drayage classification. Some types of cargo require specialized equipment or handling, which may limit the number of carriers able to transport it. For example, hazardous materials or oversized loads may need to be drayed by carriers with specific certifications and equipment.

Refrigerated cargo is another example where the cargo type influences drayage. Reefer containers require constant power to maintain temperature control, so they must be drayed by carriers with gensets or other power sources. This specialized equipment can affect the cost and availability of drayage for these shipments.

Service Requirements

Finally, the service requirements of the shipment can impact its drayage classification. Expedited drayage, for instance, is defined by its fast transit times and priority handling. Shipments that require expedited service will be classified and priced differently than standard drayage moves.

Other service factors that can influence drayage classification include:

– Appointment times or delivery windows

– Security or escort requirements

– Customs clearance or documentation needs

– Specialized handling or equipment requests

These requirements can affect the resources and time needed to complete the drayage move, which in turn can impact its classification and cost.

By understanding how factors like distance, cargo type, and service needs affect drayage classification, shippers and carriers can better plan and execute these critical transportation moves. Proper classification ensures that drayage is performed by qualified carriers with the right equipment and capabilities to meet the unique requirements of each shipment.

Choosing the Right Drayage Classification

With the various drayage classifications available, it’s important for shippers to choose the right type of service for their specific needs. Several factors should be considered when making this decision.

Urgency and Priority

The first consideration is the urgency and priority of the shipment. If the cargo is time-sensitive or must be delivered on a tight deadline, expedited drayage may be the best option. Expedited service provides fast transit times and guaranteed delivery windows to ensure that critical shipments arrive on time.

For less urgent shipments, standard drayage classifications like inter-carrier or door-to-door may be sufficient. These services operate on regular schedules and can be more cost-effective for shipments that don’t require expedited handling.

Cargo Characteristics

The type and characteristics of the cargo should also be factored into the drayage classification decision. Oversized, hazardous, or refrigerated cargo may require specialized drayage services that can accommodate their unique handling needs. Shippers should work with carriers that have the necessary equipment and certifications to transport these types of loads safely and compliantly.

For standard containerized cargo, any of the main drayage classifications may be suitable. The choice will depend on other factors like distance, cost, and service requirements.

Distance and Location

The distance and location of the drayage move can affect the choice of classification. Longer distances or moves between different carriers may require inter-carrier drayage. Shorter shuttles within a port or terminal are best suited for intra-carrier or shuttle drayage.

Door-to-door drayage can be a good option for shipments that need to be picked up and delivered to specific locations beyond the port or terminal. This classification provides a complete transportation solution from origin to destination.

Cost Considerations

Finally, cost is always a factor in transportation decisions. Some drayage classifications, like expedited and door-to-door, may have higher rates than standard terminal-to-terminal moves. Shippers need to weigh the value of the enhanced service against the increased cost.

In some cases, using multiple drayage classifications for different legs of the journey may be the most cost-effective option. For example, a shipper might use inter-carrier drayage to move a container from the port to a rail terminal, then use door-to-door drayage for the final delivery to the consignee.

Ultimately, the right drayage classification will depend on the unique needs and priorities of each shipment. By carefully considering factors like urgency, cargo type, distance, and cost, shippers can select the classification that best fits their transportation requirements. Working closely with experienced drayage providers can also help ensure that cargo is moved efficiently and reliably through the supply chain.