What Are the Fundamentals of Cargo Securement

Why is cargo securement crucial for transportation safety?

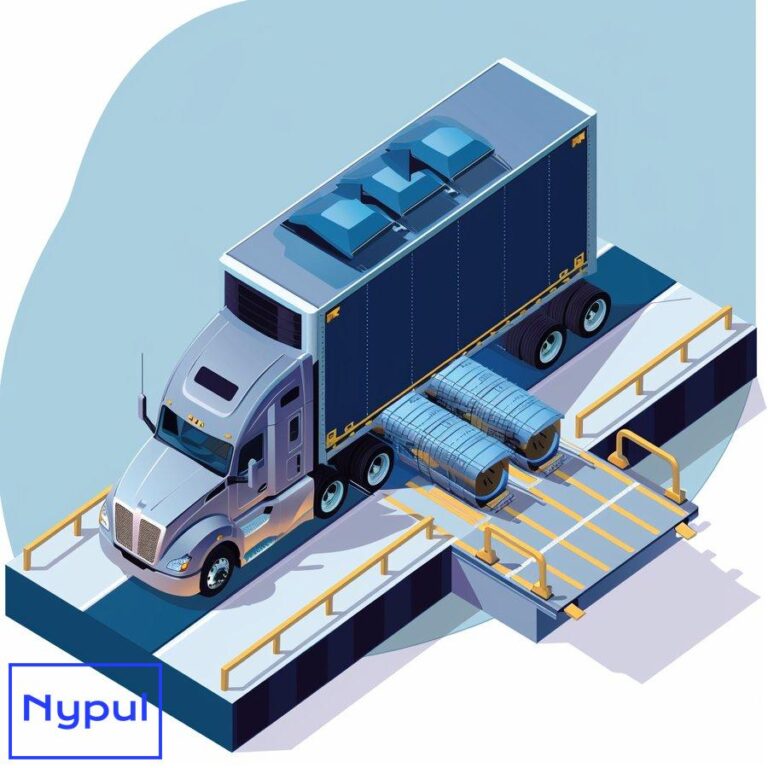

Cargo securement plays a pivotal role in ensuring the safety of goods during transportation. The primary objective is to prevent cargo from shifting, falling, or being damaged while in transit. This is not just about preserving the integrity of the load; it also directly impacts the safety of drivers, other road users, and the overall efficiency of logistics operations.

The consequences of inadequate cargo securement can be severe. Loose or improperly secured cargo can lead to accidents, resulting in injuries or fatalities. According to the Federal Motor Carrier Safety Administration (FMCSA), unsecured loads are a leading cause of road incidents involving commercial vehicles. The economic implications are equally significant, as accidents can lead to costly damages, legal liabilities, and increased insurance premiums.

![]()

Key Reasons for Cargo Securement Importance:

-

Safety of Road Users: Properly secured cargo minimizes the risk of accidents caused by shifting loads.

-

Protection of Goods: Effective securement protects cargo from damage during transit, ensuring that products arrive in optimal condition.

-

Compliance with Regulations: Adhering to cargo securement regulations helps avoid fines and legal repercussions.

-

Operational Efficiency: Secure loads enhance vehicle stability and fuel efficiency, contributing to smoother transportation processes.

Understanding these fundamental aspects underscores why investing time and resources into effective cargo securement practices is essential for all stakeholders involved in transportation logistics.

What are the fundamental principles of effective cargo securement?

Effective cargo securement is governed by several fundamental principles that ensure safety and compliance. These principles serve as guidelines for securing various types of cargo effectively.

1. Weight Distribution

Proper weight distribution is critical for maintaining vehicle stability. Cargo should be evenly distributed across the trailer’s axles to prevent overloading one side, which can lead to tipping or loss of control.

2. Use of Appropriate Tie-Downs

Selecting the right tie-downs based on the type and weight of the cargo is essential. Different materials (such as nylon, polyester, or chain) have varying strengths and applications.

3. Securement Techniques

Utilizing proper techniques such as blocking, bracing, and strapping ensures that cargo remains in place during transit. Each technique serves a specific purpose and should be applied according to the nature of the load.

4. Regular Inspections

Conducting regular inspections before and during transit helps identify potential issues with securement systems. This proactive approach can prevent accidents caused by unforeseen failures.

5. Compliance with Regulations

Adhering to federal and state regulations regarding cargo securement is non-negotiable. Understanding these regulations ensures that all practices meet legal standards.

6. Training and Education

Continuous training for drivers and logistics personnel on best practices for cargo securement fosters a culture of safety and compliance within organizations.

These principles form the foundation for effective cargo securement strategies, ensuring that all stakeholders prioritize safety throughout the transportation process.

Which essential equipment is required for proper cargo securement?

The right equipment is crucial for achieving effective cargo securement. Various tools and devices are designed specifically to hold loads securely in place during transportation.

1. Tie-Down Straps

Tie-down straps are among the most common equipment used in cargo securement. They come in various materials and strengths:

-

Ratchet Straps: Offer high tension and are adjustable.

-

Cam Buckle Straps: Easier to use but provide less tension than ratchet straps.

2. Chains and Binders

Chains are often used for securing heavy or bulky items. They provide superior strength but require binders to tighten them effectively.

3. Dunnage

Dunnage refers to materials used to fill voids between cargo items or between items and trailer walls. This prevents movement during transport.

4. Corner Protectors

Corner protectors help distribute pressure from tie-downs evenly across the load, preventing damage to both the cargo and securing equipment.

5. Load Bars

Load bars are adjustable bars that fit between trailer walls to create additional pressure against cargo, preventing it from shifting during transit.

6. Edge Protectors

Edge protectors are used to safeguard tiedown straps from sharp edges on cargo items, prolonging their lifespan and maintaining effectiveness.

The selection of appropriate equipment depends on various factors such as load type, weight, dimensions, and specific requirements dictated by regulations or company policies.

| Equipment Type | Description | Common Uses |

|---|---|---|

| Tie-Down Straps | Adjustable straps used for securing loads | General cargo transport |

| Chains and Binders | Heavy-duty chains with tightening mechanisms | Securing heavy machinery or equipment |

| Dunnage | Materials used to fill gaps in loads | Preventing movement between items |

| Corner Protectors | Devices that distribute pressure on tiedowns | Protecting fragile corners |

| Load Bars | Adjustable bars used between trailer walls | Stabilizing loose items |

| Edge Protectors | Protects straps from sharp edges | Extending strap life |

How do you determine the correct number and positioning of tiedowns?

Determining the correct number and positioning of tiedowns is essential for effective cargo securement. Several factors influence these decisions:

1. Weight of Cargo

The weight of the load significantly affects how many tiedowns are needed. A general rule is that one tiedown should be used for every 10 feet (3 meters) of cargo length if it weighs up to 5,000 pounds (2,268 kg). For heavier loads, additional tiedowns may be necessary.

2. Type of Cargo

Different types of cargo require varying numbers of tiedowns based on their shape, size, and stability:

-

Flat Loads: Typically require fewer tiedowns due to their stability.

-

Bulk Loads: May need more tiedowns due to their tendency to shift during transit.

3. Positioning Guidelines

Proper positioning enhances effectiveness:

-

Tiedowns should be placed at angles no greater than 45 degrees from horizontal.

-

The use of multiple tie-downs at different points along the load increases security.

4. Manufacturer Recommendations

Always refer to manufacturer guidelines when securing specific types of equipment or goods, as they often provide detailed recommendations on tiedown requirements based on testing data.

Example Calculation

For a load weighing 8,000 pounds (3,628 kg) that is 12 feet (3.66 meters) long:

- Calculate tiedown requirement:

-

8,000 lbs / 5,000 lbs = 1.6 (round up to 2)

-

Determine number based on length:

- For 12 feet: 2 tiedowns required

Positioning Strategy

When positioning tiedowns:

-

Place one near each end of the load.

-

Ensure that each tiedown creates a direct pull toward the vehicle’s anchor points without excessive slack.

By following these guidelines, transportation professionals can ensure that their loads are secured effectively while adhering to safety regulations.

What are the specific securement requirements for different types of cargo?

Cargo types vary widely in terms of shape, weight distribution, and stability characteristics; therefore, specific securement requirements must be tailored accordingly:

General Freight

For general freight such as boxes or pallets:

-

Tiedown Requirement: One tiedown per 10 feet (3 meters) or one for every 5,000 pounds (2,268 kg).

-

Securement Method: Use a combination of tie-down straps across multiple points on pallets or boxes.

Heavy Equipment

Heavy machinery requires specialized techniques due to its weight:

-

Tiedown Requirement: Typically three or more tiedowns depending on weight.

-

Securement Method: Chains with binders are recommended due to their strength; use dunnage beneath tracks or wheels if necessary for stabilization.

Bulk Commodities

Bulk commodities like gravel or sand have unique challenges:

-

Tiedown Requirement: Not applicable since these materials usually do not shift when properly contained in a bulk container.

-

Securement Method: Ensure containers are sealed tightly; use tarps if necessary to prevent spillage during transport.

Vehicles

Transporting vehicles requires careful consideration:

-

Tiedown Requirement: At least four tiedowns per vehicle.

-

Securement Method: Use wheel straps over each tire; additionally secure through frame points if available.

Hazardous Materials

Hazardous materials have strict regulations:

-

Tiedown Requirement: Follow specific guidelines set by regulatory bodies like OSHA.

-

Securement Method: Use specialized containers designed for hazardous materials; ensure all labels are visible during transport.

| Cargo Type | Tiedown Requirement | Securement Method |

|---|---|---|

| General Freight | One per 10 feet or per 5,000 lbs | Tie-down straps across multiple points |

| Heavy Equipment | Three or more depending on weight | Chains with binders; dunnage if needed |

| Bulk Commodities | Not applicable | Sealed containers; use tarps if necessary |

| Vehicles | At least four per vehicle | Wheel straps over tires; frame points |

| Hazardous Materials | Follow OSHA guidelines | Specialized containers; visible labeling |

Understanding these requirements ensures compliance with regulations while promoting safe transportation practices tailored to each type of cargo.

How should drivers inspect and maintain cargo securement systems?

Regular inspection and maintenance of cargo securement systems are vital components in ensuring ongoing safety during transportation operations. Drivers play a crucial role in this process through diligent practices before departure and throughout transit.

Pre-trip Inspection

Before hitting the road:

- Visual Check:

- Inspect all tie-downs for signs of wear or damage.

-

Ensure that all securing devices are properly attached without fraying or corrosion.

-

Weight Distribution:

- Verify that weight is evenly distributed across axles.

-

Adjust load positioning if necessary before securing it again.

-

Anchor Points:

- Examine anchor points on both trailer sides for integrity.

- Ensure they are free from debris or obstructions that could hinder effectiveness.

In-transit Monitoring

While driving:

- Periodic Checks:

- Stop periodically (every few hours) to check load security.

-

Look for any signs that may indicate shifting or loosening.

-

Adjustments:

- Tighten any loose straps immediately upon noticing them.

- Reassess weight distribution if any shifts occur during transit.

Post-trip Inspection

After reaching the destination:

- Unload Carefully:

- Remove securing devices systematically without damaging them.

-

Inspect all equipment post-use for any signs requiring repair or replacement.

-

Record Keeping:

- Maintain logs detailing inspections conducted before trips.

- Note any issues encountered along with corrective actions taken.

Maintenance Practices

To ensure long-term effectiveness:

- Regular Cleaning:

-

Clean tie-downs after use; remove dirt or debris that could compromise integrity over time.

-

Storage Conditions:

-

Store securing devices in dry areas away from direct sunlight when not in use.

-

Replacement Schedule:

- Implement a schedule for replacing worn-out equipment based on usage frequency rather than waiting until failure occurs.

By adhering strictly to these inspection protocols combined with proactive maintenance strategies, drivers can significantly enhance their ability to transport goods safely while minimizing risks associated with inadequate securement practices.

What training and certification options are available for cargo securement professionals?

Training and certification play vital roles in ensuring professionals involved in logistics understand best practices related to cargo securement effectively. Various options exist tailored towards enhancing knowledge about safe handling techniques while adhering strictly to regulations governing this area.

Formal Training Programs

Numerous organizations offer formal training programs focused specifically on cargo securement practices:

- Commercial Driver’s License (CDL) Training:

-

Most CDL programs include comprehensive modules covering essential aspects related specifically towards securing loads effectively before driving commercial vehicles.

-

Industry Certifications:

-

Organizations such as National Association of Small Trucking Companies (NASTC) provide specialized certifications focusing solely on safe loading/unloading procedures.

-

Online Courses:

- Several platforms offer online courses designed around educating individuals about proper techniques associated with different types/classes/categories associated with various freight modes.

Workshops & Seminars

Workshops conducted by industry experts provide hands-on experience alongside theoretical knowledge regarding best practices surrounding this topic:

- Local Workshops:

-

Many trucking associations host local workshops aimed at educating drivers about recent changes within regulatory frameworks surrounding load security.

-

Trade Shows/Seminars:

- Attending trade shows allows networking opportunities alongside learning sessions led by experienced professionals discussing innovations within this field.

Employer-Sponsored Training

Many companies invest heavily into developing their workforce through internal training programs tailored towards specific needs within their organization:

- Onboarding Programs:

-

New hires often undergo comprehensive onboarding sessions designed around educating them about company-specific policies/procedures surrounding load security.

-

Continuous Education Initiatives:

- Employers frequently provide ongoing education opportunities ensuring employees stay updated regarding evolving standards/regulations impacting their responsibilities over time.

By participating actively within these training initiatives combined with obtaining appropriate certifications where applicable ensures professionals remain competent while fostering safer environments throughout logistics operations overall.

How can technology enhance cargo securement practices?

Technology has revolutionized many aspects within logistics operations including enhancing methods surrounding effective cargo securement practices significantly over recent years:

Advanced Monitoring Systems

Technological advancements have led towards developing sophisticated monitoring systems capable providing real-time data regarding load conditions throughout transit periods:

- Telematics Solutions:

-

These systems utilize GPS technology alongside sensors integrated into trailers allowing operators track movements/conditions affecting loads remotely.

-

Load Stability Sensors:

- Innovative sensor technologies enable monitoring shifts occurring within loaded freight providing alerts immediately upon detecting potential issues requiring attention promptly.

Automation Tools

Automation tools streamline processes associated with securing loads efficiently reducing human error potential while improving overall accuracy levels:

- Automated Tensioning Systems:

-

These systems automatically adjust tension levels within tie-downs ensuring optimal security maintained consistently throughout transport durations without manual intervention required.

-

Robotics Integration:

- Robotics increasingly utilized within warehouses facilitate loading/unloading processes reducing risks associated with improper handling techniques impacting overall safety levels significantly.

Data Analytics

Leveraging data analytics enables organizations gain insights regarding performance metrics surrounding their operations leading towards enhanced decision-making capabilities:

- Predictive Analysis Tools:

- Analyzing historical data allows companies anticipate future challenges related specifically towards load management enabling proactive measures implemented beforehand mitigating risks effectively.

2 .Performance Tracking Software:

– Utilizing software solutions enables tracking performance metrics associated directly linked towards security measures taken allowing organizations assess effectiveness regularly improving upon existing strategies continuously over time.

By integrating technology into daily operations surrounding effective methods related towards securing freight enhances overall safety levels contributing positively towards achieving desired outcomes consistently throughout logistics processes overall.

What are the most common challenges in cargo securement and how can they be addressed?

Cargo securement presents several challenges that professionals frequently encounter during transportation operations requiring strategic approaches addressing them effectively:

Common Challenges

1 .Inadequate Training/Knowledge Gaps :

Many individuals lack sufficient understanding regarding proper techniques leading towards improper handling resulting increased risks associated unsafe conditions present during transit periods .

2 .Variability Among Cargo Types :

Different types/classes/categories freight necessitate unique approaches requiring flexibility adapt accordingly depending upon circumstances faced regularly .

3 .Regulatory Compliance Issues :

Keeping up-to-date evolving regulations governing this area may prove daunting causing confusion among stakeholders impacting overall effectiveness achieving desired outcomes consistently .

4 .Equipment Limitations :

Availability/accessibility suitable equipment required securing various types freight may pose significant obstacles hindering ability execute tasks efficiently .

5 .Environmental Factors :

Weather conditions such as rain/snow/ice may affect ability maintain adequate grip/slip resistance impacting overall effectiveness securing loads properly .

Addressing Challenges

1 .Investing In Comprehensive Training Programs :

Organizations should prioritize investing comprehensive training initiatives ensuring employees equipped knowledge/skills necessary perform tasks safely/effectively .

2 .Standardizing Procedures Across Operations :

Establishing standardized procedures enhances consistency among personnel enabling smoother transitions between different types freight encountered regularly .

3 .Regularly Reviewing Regulatory Updates :

Staying informed regarding changes within regulatory frameworks allows companies remain compliant avoiding potential fines/legal repercussions stemming non-compliance issues encountered frequently .

4 .Utilizing High-quality Equipment :

Investing quality equipment designed specifically meet demands posed by various types freight ensures reliability/security maintained consistently throughout transport durations .

5 .Implementing Contingency Plans For Environmental Factors :

Developing contingency plans addressing adverse weather conditions enables organizations respond proactively minimizing risks associated unexpected challenges faced regularly .

By recognizing prevalent challenges combined strategic approaches addressing them proactively fosters safer environments promoting successful outcomes consistently throughout logistics operations overall .

What documentation is necessary to ensure compliance with cargo securement regulations?

Documentation plays an integral role ensuring compliance with regulations governing proper methods surrounding effective means securing freight effectively throughout transportation processes requiring attention detail consistently maintained across all stages involved :

Essential Documentation

1 .Bill Of Lading :

This document outlines details regarding shipment including origin/destination descriptions providing critical information necessary verifying compliance standards adhered throughout journey undertaken .

2 .Inspection Reports :

Regularly conducted inspections generate reports documenting findings which serve as evidence demonstrating adherence established protocols concerning safe loading/unloading procedures followed diligently .

3 .Training Certificates :

Maintaining records pertaining employee training certifications provides evidence demonstrating workforce equipped knowledge/skills required perform tasks safely/effectively complying industry standards upheld consistently across board .

4 .Regulatory Compliance Records :

Keeping accurate records reflecting adherence regulatory frameworks governing this area ensures organizations remain compliant avoiding potential fines/legal repercussions stemming non-compliance issues encountered frequently .

5 .Incident Reports :

Documenting incidents occurring involving unsecured loads serves critical purpose identifying trends/patterns enabling organizations address root causes preventing future occurrences thereby enhancing overall safety levels significantly achieved consistently throughout logistics processes overall .

By maintaining comprehensive documentation encompassing all aspects related towards compliance ensures organizations uphold highest standards promoting successful outcomes consistently achieved throughout logistics operations overall fostering safer environments benefiting everyone involved ultimately leading towards improved efficiency/reduced costs experienced across board continuously over time .