What Are the Key Drivers of Supply Chain Management and Logistics Relationship

How do supply chain management and logistics interact?

Supply chain management (SCM) and logistics are two interconnected disciplines that work together to ensure the smooth flow of goods and services from suppliers to customers. SCM encompasses the entire process of managing the flow of materials, information, and finances as products move from origin to consumption. Logistics, on the other hand, focuses specifically on the transportation, warehousing, and distribution of these goods.

Entities and Relationships

- Supply Chain Management (SCM): Involves planning, controlling, and monitoring supply chain activities.

- Logistics: Encompasses transportation, warehousing, inventory management, and order fulfillment.

- Interaction: SCM provides the framework for logistics operations, while logistics executes the strategies set forth by SCM.

This interaction is critical for several reasons:

-

Efficiency: Effective SCM reduces costs and improves service levels through optimized logistics operations.

-

Responsiveness: Logistics enables SCM to respond quickly to changes in demand or supply conditions.

-

Visibility: Integrating logistics into SCM enhances visibility across the supply chain, allowing for better decision-making.

The synergy between these two entities leads to improved operational performance, reduced lead times, and increased customer satisfaction.

What role does customer demand play in shaping SCM and logistics?

Customer demand is a primary driver in shaping both supply chain management and logistics strategies. Understanding customer preferences and behaviors allows companies to align their operations effectively.

Key Drivers of Customer Demand

-

Market Trends: Changes in consumer preferences can lead to shifts in demand patterns.

-

Seasonality: Certain products experience spikes in demand during specific seasons or holidays.

-

Customization: Increasing demand for personalized products requires agile supply chain responses.

The impact of customer demand on SCM and logistics can be summarized as follows:

-

Inventory Management: Accurate demand forecasting helps maintain optimal inventory levels, reducing holding costs.

-

Production Planning: Understanding demand allows for better scheduling of production runs to meet customer needs without overproducing.

-

Distribution Strategies: Companies can optimize their logistics networks by determining the most efficient routes and methods for delivering products based on demand patterns.

By aligning supply chain strategies with customer demand, businesses can enhance their responsiveness, improve service levels, and ultimately drive customer loyalty.

How can cost efficiency be optimized in the SCM-logistics relationship?

Cost efficiency is a critical concern for businesses operating within supply chains. Optimizing the relationship between SCM and logistics can significantly reduce operational costs while maintaining service quality.

Strategies for Cost Optimization

-

Consolidation of Shipments: Combining multiple orders into a single shipment reduces transportation costs.

-

Route Optimization: Utilizing technology to determine the most efficient delivery routes minimizes fuel consumption and time.

-

Supplier Negotiation: Building strong relationships with suppliers can lead to better pricing terms and reduced costs.

The following table illustrates potential cost-saving opportunities within the SCM-logistics relationship:

| Cost Area | Optimization Strategy | Potential Savings |

|---|---|---|

| Transportation | Route optimization | 10-30% reduction |

| Inventory | Just-in-time inventory | 20-50% reduction |

| Warehousing | Cross-docking practices | 15-25% reduction |

| Procurement | Bulk purchasing agreements | 5-15% reduction |

By implementing these strategies, companies can achieve significant cost savings while enhancing overall supply chain performance.

Why is information flow crucial for effective SCM and logistics?

Information flow is the backbone of effective supply chain management and logistics. The ability to share accurate data among stakeholders ensures that everyone involved in the process has access to real-time information necessary for decision-making.

Importance of Information Flow

-

Visibility: Enhanced visibility into inventory levels, order statuses, and shipment tracking allows for proactive management of potential issues.

-

Coordination: Effective communication among suppliers, manufacturers, distributors, and retailers leads to better coordination of activities across the supply chain.

-

Decision-Making: Access to timely information enables stakeholders to make informed decisions that align with overall business objectives.

The following elements highlight how information flow impacts SCM and logistics:

-

Demand Forecasting: Accurate data on past sales trends helps companies predict future demand more effectively.

-

Supply Chain Collaboration: Sharing information fosters collaboration among partners, leading to improved efficiency and reduced lead times.

-

Risk Management: Real-time data allows for quicker identification of disruptions or delays, enabling rapid response strategies.

In conclusion, robust information flow is essential for optimizing supply chain operations and enhancing logistical efficiency.

How does globalization impact supply chain management and logistics?

Globalization has transformed supply chains by expanding markets beyond domestic borders. This shift presents both opportunities and challenges for supply chain management and logistics operations.

Effects of Globalization

-

Market Expansion: Companies can access new markets, increasing potential sales but also adding complexity to their supply chains.

-

Sourcing Opportunities: Globalization allows businesses to source materials from various countries at competitive prices but requires careful consideration of quality control and lead times.

-

Regulatory Compliance: Operating internationally necessitates adherence to diverse regulations across different countries, impacting logistics strategies.

The following table summarizes key impacts of globalization on SCM and logistics:

| Impact Area | Description | Implications |

|---|---|---|

| Market Access | Entry into new geographical markets | Increased competition |

| Supply Chain Complexity | Diverse sourcing options | Higher coordination needs |

| Regulatory Challenges | Different compliance requirements | Increased operational risk |

Globalization necessitates a strategic approach to managing supply chains effectively while navigating these complexities.

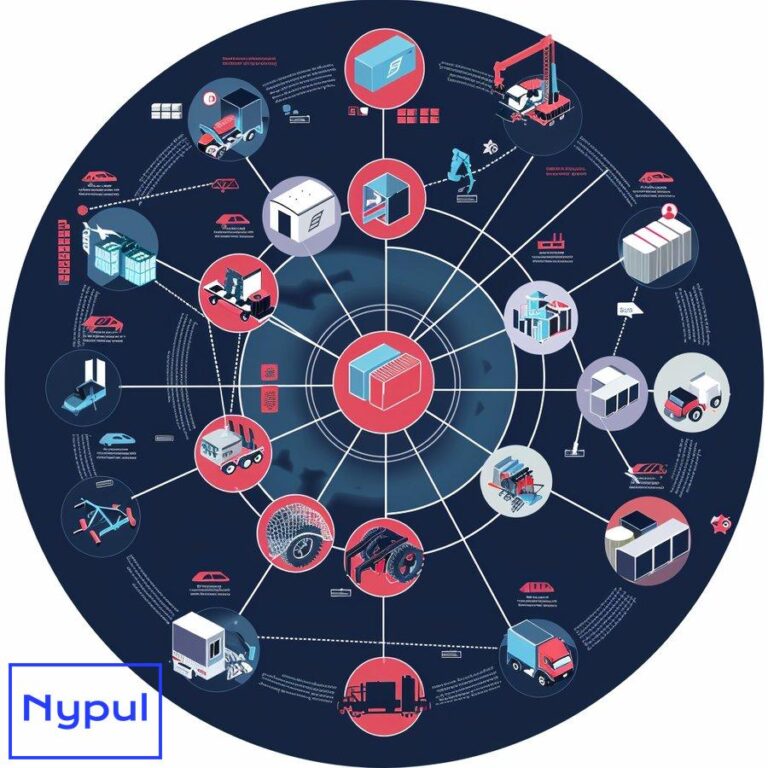

What technologies are driving innovation in SCM and logistics?

![]()

Technological advancements play a pivotal role in shaping modern supply chain management and logistics practices. Innovations enhance efficiency, reduce costs, and improve service delivery.

Key Technologies Influencing SCM and Logistics

-

Artificial Intelligence (AI): AI algorithms analyze vast amounts of data to optimize routing decisions and predict demand patterns.

-

Internet of Things (IoT): IoT devices provide real-time tracking of shipments and inventory levels, enhancing visibility across the supply chain.

-

Blockchain Technology: Blockchain ensures transparency by securely recording transactions across all parties involved in the supply chain.

The following table highlights how these technologies contribute to innovation:

| Technology | Application | Benefits |

|---|---|---|

| Artificial Intelligence | Demand forecasting | Improved accuracy |

| Internet of Things | Real-time tracking | Enhanced visibility |

| Blockchain | Secure transactions | Increased trust |

Adopting these technologies empowers organizations to streamline operations while adapting to evolving market demands.

How can risks be managed effectively in supply chains and logistics networks?

Effective risk management is vital for maintaining resilience within supply chains. Identifying potential risks early allows businesses to implement strategies that mitigate their impact on operations.

Risk Management Strategies

-

Risk Assessment: Regularly evaluating potential risks helps organizations understand vulnerabilities within their supply chains.

-

Contingency Planning: Developing contingency plans ensures that businesses are prepared for unexpected disruptions such as natural disasters or supplier failures.

-

Supplier Diversification: Relying on multiple suppliers reduces dependency risks associated with single-source suppliers.

The following table outlines common risks faced in supply chains along with mitigation strategies:

| Risk Type | Description | Mitigation Strategy |

|---|---|---|

| Supply Disruptions | Interruptions due to supplier issues | Diversification |

| Natural Disasters | Events affecting transportation routes | Contingency planning |

| Regulatory Changes | New laws impacting operations | Continuous monitoring |

Implementing a robust risk management framework enables organizations to navigate uncertainties effectively while maintaining operational continuity.

What is the importance of collaboration in SCM and logistics partnerships?

Collaboration among stakeholders within the supply chain enhances overall performance by fostering trust, improving communication, and aligning objectives across entities involved in production and distribution processes.

Benefits of Collaboration

-

Shared Resources: Collaborative partnerships allow companies to share resources such as warehousing space or transportation assets.

-

Innovation Opportunities: Working closely with partners can lead to joint innovation efforts that drive efficiency improvements or product development initiatives.

-

Enhanced Responsiveness: Collaboration improves coordination among partners, enabling quicker responses to changes in market conditions or customer demands.

The following table illustrates key benefits derived from effective collaboration:

| Benefit | Description | Impact |

|---|---|---|

| Cost Reduction | Shared resources lower operational costs | Increased margins |

| Improved Service Levels | Better communication enhances customer satisfaction | Higher retention rates |

Fostering collaboration within supply chains ultimately leads to stronger relationships among partners while driving competitive advantages.

How do regulatory compliance and standards affect SCM and logistics operations?

Regulatory compliance plays a critical role in shaping how organizations manage their supply chains. Adhering to industry standards ensures safety, quality control, environmental sustainability, and ethical practices throughout operations.

Impact of Regulatory Compliance

-

Operational Efficiency: Compliance with regulations may require specific processes or documentation that can streamline operations when properly integrated into workflows.

-

Cost Implications: Non-compliance can result in fines or penalties that significantly impact profitability; therefore investing in compliance measures pays off long-term.

-

Reputation Management: Companies demonstrating adherence to regulations build trust with consumers who prioritize ethical sourcing practices when making purchasing decisions.

The following table outlines common regulatory areas affecting SCM along with their implications:

| Regulatory Area | Description | Implications |

|---|---|---|

| Environmental Standards | Regulations governing waste disposal | Increased operational costs if not adhered |

| Safety Regulations | Laws ensuring safe working conditions | Liability exposure if ignored |

Understanding these regulatory frameworks is essential for organizations aiming not only for compliance but also competitive advantage through responsible practices.

In conclusion, navigating the complexities of supply chain management requires a holistic understanding of various drivers influencing its relationship with logistics. By focusing on collaboration, technology adoption, risk mitigation strategies, effective information flow management, cost optimization techniques along with regulatory compliance awareness; businesses can enhance their operational efficiencies while meeting customer demands successfully.