What Are the Key Factors That Contribute to Supply Chain Resilience

What is supply chain resilience and why is it crucial?

Supply chain resilience refers to the ability of a supply chain to prepare for, respond to, and recover from disruptions while maintaining continuity of operations and customer service. In today’s interconnected and volatile global business environment, supply chain resilience has become more critical than ever.

Disruptions to supply chains can arise from various sources, such as natural disasters, geopolitical events, economic crises, and even pandemics like COVID-19. These disruptions can lead to significant financial losses, damaged reputations, and loss of market share for companies that are not adequately prepared.

The importance of supply chain resilience lies in its ability to:

Ensure business continuity: A resilient supply chain can quickly adapt to and recover from disruptions, minimizing downtime and ensuring that products and services continue to reach customers.

Mitigate risks: By proactively identifying and addressing potential risks, a resilient supply chain can reduce the likelihood and impact of disruptions.

Maintain customer satisfaction: Resilient supply chains are better equipped to meet customer demands consistently, even in the face of disruptions, thus maintaining customer loyalty and trust.

Gain competitive advantage: Companies with resilient supply chains can respond more effectively to market changes and opportunities, giving them a competitive edge over less prepared rivals.

The table below summarizes the key benefits of supply chain resilience:

| Benefit | Description |

|---|---|

| Business continuity | Minimizes downtime and ensures uninterrupted operations |

| Risk mitigation | Proactively identifies and addresses potential risks |

| Customer satisfaction | Consistently meets customer demands and maintains loyalty |

| Competitive advantage | Responds effectively to market changes and opportunities |

In essence, supply chain resilience is crucial because it enables companies to navigate the complexities and uncertainties of the modern business landscape, ensuring their survival and success in the long run.

How does robust risk management contribute to supply chain resilience?

Robust risk management is a foundational element of building supply chain resilience. It involves proactively identifying, assessing, and mitigating potential risks that could disrupt the supply chain.

Effective risk management contributes to supply chain resilience in several ways:

Risk identification and assessment: By systematically identifying and assessing risks across the entire supply chain, companies can gain a comprehensive understanding of their vulnerabilities and prioritize their risk mitigation efforts.

Contingency planning: Robust risk management includes developing contingency plans for various disruption scenarios, enabling companies to respond quickly and effectively when disruptions occur.

Supplier risk management: Assessing and monitoring the risks associated with suppliers, such as financial stability, quality issues, and geopolitical risks, helps companies make informed decisions about supplier selection and diversification.

Continuous monitoring and improvement: Regular monitoring of risk indicators and performance metrics allows companies to detect potential disruptions early and take proactive measures to mitigate their impact.

The following table outlines a simple risk management framework that can be applied to supply chains:

| Step | Description |

|---|---|

| 1. Identify risks | Systematically identify potential risks across the supply chain |

| 2. Assess risks | Evaluate the likelihood and potential impact of each risk |

| 3. Prioritize risks | Prioritize risks based on their severity and the company’s risk appetite |

| 4. Develop mitigation strategies | Create contingency plans and risk mitigation strategies for high-priority risks |

| 5. Monitor and review | Continuously monitor risk indicators and review the effectiveness of mitigation strategies |

By implementing a robust risk management framework, companies can proactively address potential disruptions, minimize their impact, and build a more resilient supply chain that can withstand the challenges of the modern business environment.

What role does agility and flexibility play in building resilient supply chains?

Agility and flexibility are essential characteristics of resilient supply chains. They enable companies to quickly adapt to changing market conditions, customer demands, and disruptions.

Agility refers to the ability to rapidly respond to changes and opportunities in the market. In the context of supply chain resilience, agility allows companies to:

Adjust production and distribution: Agile supply chains can quickly scale production up or down and redirect distribution to meet shifting customer demands or compensate for disruptions in certain regions.

Implement new technologies: Agile companies are better equipped to adopt new technologies and processes that can improve efficiency, visibility, and responsiveness across the supply chain.

Collaborate with partners: Agility enables companies to form flexible partnerships and collaborate effectively with suppliers, logistics providers, and other stakeholders to address challenges and opportunities.

Flexibility, on the other hand, refers to the ability to adapt to changing circumstances without significantly increasing costs or compromising quality. Flexible supply chains can:

Accommodate customization: Flexible production systems can efficiently produce a wide range of products, allowing companies to meet diverse customer requirements and quickly introduce new offerings.

Leverage alternative sourcing: Flexible supply chains have multiple sourcing options for critical components and materials, reducing the risk of disruptions caused by single supplier failures.

Optimize inventory management: Flexibility in inventory management, such as the ability to quickly reposition inventory across the network, helps companies respond to localized disruptions and maintain customer service levels.

The table below compares the key characteristics of agile and flexible supply chains:

| Characteristic | Agile Supply Chains | Flexible Supply Chains |

|---|---|---|

| Responsiveness | Rapid response to changes and opportunities | Efficient adaptation to changing circumstances |

| Focus | Speed and responsiveness | Adaptability and cost-effectiveness |

| Production | Quick scaling and adjustment | Accommodates customization and variety |

| Sourcing | Collaborative partnerships | Multiple sourcing options |

| Inventory | Responsive to demand changes | Optimized across the network |

By cultivating agility and flexibility, companies can build supply chains that are better prepared to handle disruptions, capitalize on opportunities, and maintain a competitive edge in the face of uncertainty.

How can diversification of suppliers and resources enhance resilience?

Diversification of suppliers and resources is a key strategy for enhancing supply chain resilience. By reducing reliance on single sources and expanding the range of available options, companies can mitigate the risks associated with disruptions and ensure continuity of operations.

Supplier diversification involves sourcing materials, components, or services from multiple suppliers, often in different geographic locations. This approach offers several benefits:

Reduced vulnerability: By not relying on a single supplier, companies are less vulnerable to disruptions caused by supplier failures, natural disasters, or geopolitical events in specific regions.

Increased bargaining power: Having multiple supplier options gives companies more bargaining power, allowing them to negotiate better terms, prices, and quality.

Access to specialized expertise: Diversifying suppliers can give companies access to a wider range of specialized expertise and capabilities, fostering innovation and improving product quality.

Resource diversification involves expanding the range of materials, technologies, and processes used in the supply chain. This can enhance resilience by:

Mitigating material shortages: By having alternative material options, companies can maintain production even when primary materials are in short supply.

Enabling flexibility: A diverse range of resources allows companies to adapt more easily to changing customer requirements and market conditions.

Fostering innovation: Exposure to diverse resources can stimulate innovation and the development of new products and processes.

The following table summarizes the key benefits of supplier and resource diversification:

| Diversification Type | Benefits |

|---|---|

| Supplier Diversification | – Reduced vulnerability to disruptions – Increased bargaining power – Access to specialized expertise |

| Resource Diversification | – Mitigation of material shortages – Enabling flexibility – Fostering innovation |

To effectively implement diversification strategies, companies should:

Assess risk exposure: Identify the most critical suppliers and resources and evaluate the potential impact of disruptions.

Develop a diversification plan: Create a plan that balances the benefits of diversification with the associated costs and complexities.

Monitor and adjust: Continuously monitor the performance of diversified suppliers and resources and make adjustments as needed to optimize resilience and efficiency.

By diversifying suppliers and resources, companies can build more resilient supply chains that are better equipped to withstand disruptions and adapt to changing circumstances.

Why is end-to-end visibility critical for supply chain resilience?

End-to-end visibility is a critical component of supply chain resilience. It refers to the ability to track and monitor the flow of materials, products, and information across the entire supply chain, from raw material sourcing to final product delivery.

Comprehensive visibility enables companies to:

Anticipate and mitigate disruptions: By monitoring supply chain performance in real-time, companies can identify potential disruptions early and take proactive measures to mitigate their impact.

Optimize inventory management: Visibility into inventory levels, demand patterns, and supply chain capacity allows companies to make informed decisions about inventory positioning and replenishment, reducing the risk of stockouts or excess inventory.

Enhance collaboration: Sharing real-time data and insights across the supply chain enables better collaboration among stakeholders, facilitating joint problem-solving and decision-making.

Improve customer service: With end-to-end visibility, companies can provide accurate and timely information to customers about order status, delivery dates, and potential delays, enhancing customer satisfaction and trust.

The table below outlines the key areas where end-to-end visibility supports supply chain resilience:

| Area | Impact of Visibility |

|---|---|

| Risk Management | Early identification and mitigation of potential disruptions |

| Inventory Management | Optimized inventory levels and reduced risk of stockouts or excess inventory |

| Collaboration | Enhanced collaboration and joint problem-solving among stakeholders |

| Customer Service | Accurate and timely information for customers, improving satisfaction and trust |

To achieve end-to-end visibility, companies should invest in:

Integrated technology platforms: Implement supply chain management systems that integrate data from various sources, such as ERP, WMS, TMS, and IoT devices, to provide a unified view of the supply chain.

Data standardization and sharing: Establish data standards and protocols to ensure consistent and accurate data capture and sharing across the supply chain.

Collaborative partnerships: Foster strong relationships with suppliers, logistics providers, and other partners to encourage data sharing and collaborative decision-making.

Analytics and reporting: Leverage advanced analytics and reporting tools to derive actionable insights from supply chain data and support data-driven decision-making.

By investing in end-to-end visibility, companies can build more resilient supply chains that are better equipped to anticipate and respond to disruptions, optimize operations, and deliver superior customer service.

How does strategic inventory management support resilience?

Strategic inventory management plays a crucial role in supporting supply chain resilience. It involves optimizing inventory levels, positioning, and policies to ensure the right products are available at the right time and place, even in the face of disruptions.

Effective inventory management strategies for resilience include:

Safety stock: Maintaining additional inventory beyond expected demand to buffer against supply chain disruptions and ensure continuity of operations.

Multi-echelon inventory optimization: Strategically positioning inventory across the supply chain network, considering factors such as lead times, demand variability, and transportation costs, to minimize the risk of stockouts and improve responsiveness.

Postponement: Delaying final product configuration or customization until closer to the time of delivery, allowing companies to respond more quickly to changes in customer demand or supply chain disruptions.

Inventory pooling: Consolidating inventory from multiple locations or product lines to reduce overall inventory levels and increase flexibility in responding to localized disruptions.

The following table summarizes the benefits of these inventory management strategies for supply chain resilience:

| Strategy | Benefits for Resilience |

|---|---|

| Safety Stock | Buffers against disruptions and ensures continuity of operations |

| Multi-Echelon Inventory Optimization | Minimizes the risk of stockouts and improves responsiveness |

| Postponement | Enables quick response to changes in demand or supply chain disruptions |

| Inventory Pooling | Reduces overall inventory levels and increases flexibility in responding to localized disruptions |

To implement strategic inventory management for resilience, companies should:

Assess risk and criticality: Identify the most critical products and components and assess the potential impact of disruptions on their availability.

Develop inventory policies: Establish inventory policies that balance the costs of holding inventory with the benefits of improved resilience and customer service.

Leverage technology: Implement inventory management systems and advanced analytics to optimize inventory levels, positioning, and policies based on real-time data and insights.

Monitor and adjust: Continuously monitor inventory performance and adjust strategies as needed to adapt to changing market conditions and disruption risks.

By implementing strategic inventory management practices, companies can build more resilient supply chains that are better prepared to withstand disruptions, maintain customer service levels, and optimize costs.

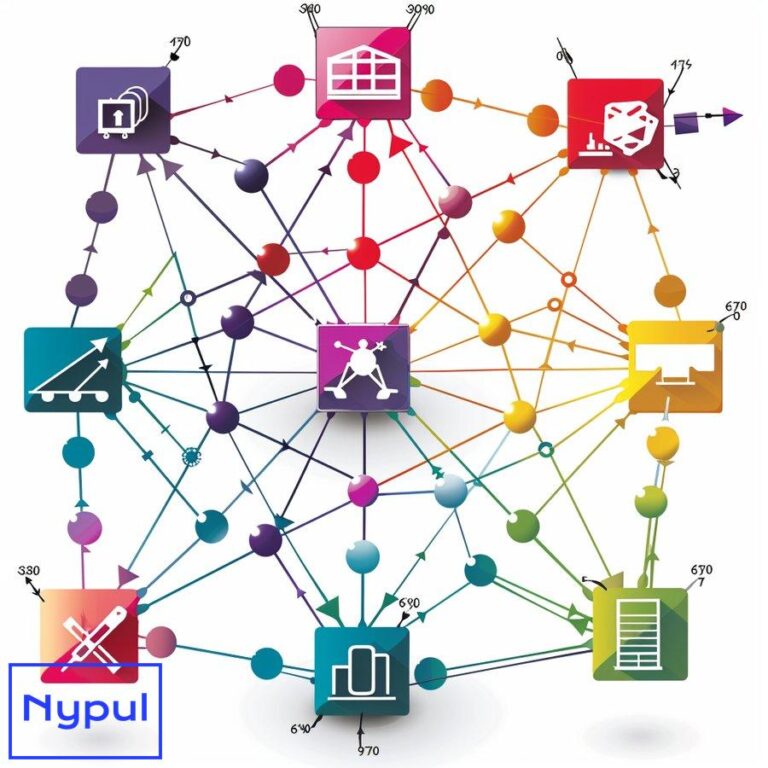

What technologies are key to improving supply chain resilience?

Several key technologies play a vital role in improving supply chain resilience by enhancing visibility, agility, and collaboration across the supply chain network.

Internet of Things (IoT): IoT devices, such as sensors and trackers, enable real-time monitoring of supply chain assets, inventory, and shipments, providing valuable data for risk management and decision-making.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can analyze vast amounts of supply chain data to identify patterns, predict disruptions, and recommend optimal actions for mitigating risks and improving resilience.

Blockchain: Blockchain technology provides a secure, transparent, and tamper-proof platform for recording and sharing supply chain data, enhancing trust and collaboration among stakeholders.

Cloud Computing: Cloud-based supply chain management systems enable real-time data sharing, collaboration, and decision-making across the supply chain network, improving agility and responsiveness to disruptions.

The table below summarizes the key benefits of these technologies for supply chain resilience:

| Technology | Benefits for Resilience |

|---|---|

| Internet of Things (IoT) | Real-time monitoring of supply chain assets, inventory, and shipments for risk management and decision-making |

| Artificial Intelligence (AI) and Machine Learning (ML) | Analysis of supply chain data to identify patterns, predict disruptions, and recommend optimal actions for mitigating risks |

| Blockchain | Secure, transparent, and tamper-proof platform for recording and sharing supply chain data, enhancing trust and collaboration |

| Cloud Computing | Real-time data sharing, collaboration, and decision-making across the supply chain network, improving agility and responsiveness |

To effectively leverage these technologies for resilience, companies should:

Develop a technology roadmap: Identify the most critical areas for technology investment based on the company’s specific resilience challenges and goals.

Integrate systems and data: Ensure that supply chain management systems and data sources are integrated and interoperable to enable seamless data sharing and collaboration.

Foster a data-driven culture: Encourage the use of data and analytics in decision-making across the supply chain organization, and provide training and support to build data literacy.

Collaborate with partners: Work closely with suppliers, logistics providers, and other partners to implement and leverage resilience-enhancing technologies across the supply chain network.

By strategically investing in and deploying these key technologies, companies can build more resilient supply chains that are better equipped to anticipate, withstand, and recover from disruptions in an increasingly complex and uncertain business environment.

How do strong supplier relationships and financial stability impact resilience?

Strong supplier relationships and financial stability are critical factors that contribute to supply chain resilience. They provide a foundation of trust, collaboration, and resources that enable companies to better withstand and recover from disruptions.

Supplier Relationships: Building strong, long-term relationships with key suppliers can enhance resilience in several ways:

Improved communication and collaboration: Strong relationships foster open communication and collaboration, enabling companies and suppliers to work together to identify and mitigate risks, develop contingency plans, and respond quickly to disruptions.

Increased flexibility and agility: Suppliers who have a deep understanding of a company’s needs and priorities are more likely to be flexible and responsive in the face of disruptions, adapting production schedules, delivery routes, or product specifications as needed.

Access to expertise and resources: Strong supplier relationships can provide access to specialized expertise, technologies, and resources that can help companies navigate disruptions and build resilience.

Financial Stability: The financial stability of both the company and its suppliers is essential for supply chain resilience:

Reduced risk of supplier failure: Financially stable suppliers are less likely to experience disruptions or failures that could impact the company’s operations and supply chain.

Ability to invest in resilience: Companies with strong financial positions are better able to invest in technologies, inventory, and other resources that enhance supply chain resilience.

Access to financing and insurance: Financially stable companies may have better access to financing and insurance options that can help mitigate the impact of disruptions and speed recovery.

The following table summarizes the key impacts of strong supplier relationships and financial stability on supply chain resilience:

| Factor | Impact on Resilience |

|——–|——————Increased flexibility and agility: Suppliers who have a deep understanding of a company’s needs and priorities are more likely to be flexible and responsive in the face of disruptions, adapting production schedules, delivery routes, or product specifications as needed.

Access to expertise and resources: Strong supplier relationships can provide access to specialized expertise, technologies, and resources that can help companies navigate disruptions and build resilience.

Financial Stability: The financial stability of both the company and its suppliers is essential for supply chain resilience:

Reduced risk of supplier failure: Financially stable suppliers are less likely to experience disruptions or failures that could impact the company’s operations and supply chain.

Ability to invest in resilience: Companies with strong financial positions are better able to invest in technologies, inventory, and other resources that enhance supply chain resilience.

Access to financing and insurance: Financially stable companies may have better access to financing and insurance options that can help mitigate the impact of disruptions and speed recovery.

The following table summarizes the key impacts of strong supplier relationships and financial stability on supply chain resilience:

| Factor | Impact on Resilience |

|---|---|

| Supplier Relationships | – Improved communication and collaboration – Increased flexibility and agility – Access to expertise and resources |

| Financial Stability | – Reduced risk of supplier failure – Ability to invest in resilience – Access to financing and insurance |

To build strong supplier relationships and maintain financial stability for resilience, companies should:

Foster trust and collaboration: Develop a culture of trust, transparency, and collaboration with suppliers, engaging in regular communication, joint planning, and problem-solving.

Implement supplier risk management: Assess and monitor the financial stability, performance, and risk exposure of key suppliers, and work with them to develop risk mitigation plans.

Maintain financial discipline: Implement strong financial management practices, such as cash flow management, cost control, and risk management, to maintain financial stability and resilience.

Invest in supplier development: Provide support and resources to help key suppliers improve their capabilities, financial stability, and resilience, recognizing that their success is critical to the company’s own resilience.

By prioritizing strong supplier relationships and financial stability, companies can build a foundation of trust, collaboration, and resources that enables them to better anticipate, withstand, and recover from supply chain disruptions, ultimately enhancing overall supply chain resilience.