What Are the Steps Involved in Intermodal Shipments

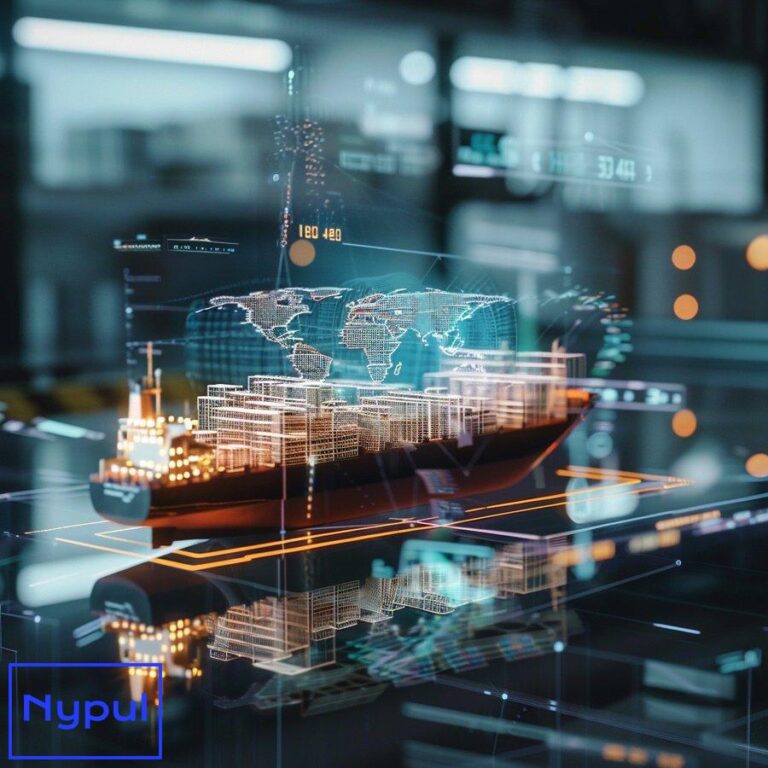

What is intermodal shipping and why is it important?

Intermodal shipping is a transportation method that involves moving freight using two or more modes of transport, such as trucks, trains, and ships, within a single journey without handling the freight itself when changing modes. The cargo is packed into intermodal containers or trailers that can be easily transferred between different vehicles and transported to the final destination.

Benefits of Intermodal Shipping

Cost-effectiveness: Intermodal shipping can be more cost-effective than using a single mode of transport, especially for long-distance shipments. By leveraging the strengths of each mode, shippers can optimize their supply chain and reduce overall transportation costs.

Environmental sustainability: Intermodal shipping is more environmentally friendly compared to road-only transport. Trains and ships are more fuel-efficient per ton-mile than trucks, resulting in lower greenhouse gas emissions.

Flexibility and scalability: Intermodal shipping offers flexibility in routing and the ability to scale operations based on demand. Shippers can choose the most efficient combination of modes based on factors such as distance, time constraints, and cargo type.

Improved safety and security: Intermodal containers provide a secure and sealed environment for goods, reducing the risk of damage, theft, or tampering during transit.

Intermodal shipping plays a crucial role in global trade by enabling the efficient and cost-effective movement of goods across long distances and international borders. It allows businesses to optimize their supply chains, reduce costs, and improve their environmental footprint.

How do you plan and book an intermodal shipment?

Planning and booking an intermodal shipment involves several key steps to ensure a smooth and efficient transportation process.

Determine Shipping Requirements

Identify the origin and destination of the shipment, including any specific delivery locations or requirements.

Specify the type and quantity of goods to be shipped, along with their dimensions, weight, and any special handling needs.

Establish the desired transit time and delivery date based on the urgency of the shipment and customer requirements.

Select Intermodal Service Providers

Research and compare intermodal service providers, such as freight forwarders, intermodal marketing companies (IMCs), or directly with rail carriers and drayage providers.

Evaluate their service offerings, routes, transit times, and pricing to find the best fit for your shipping needs.

Consider factors such as the provider’s reputation, reliability, tracking capabilities, and customer support.

Obtain Quotes and Book the Shipment

Request quotes from selected service providers based on your shipping requirements, including origin and destination, cargo details, and desired transit time.

Review and compare the quotes, considering factors such as price, service level, and any additional fees or surcharges.

Select the most suitable service provider and book the shipment, providing all necessary information and documentation.

Prepare Documentation and Cargo

Prepare and submit required documentation, such as the bill of lading, commercial invoice, packing list, and any necessary customs documents for international shipments.

Ensure that the cargo is properly packaged, labeled, and ready for pickup by the carrier or drayage provider.

Provide any special instructions or requirements to the service provider, such as delivery appointments or temperature control needs.

By carefully planning and booking your intermodal shipment, you can ensure that your cargo is transported efficiently and cost-effectively while meeting your specific shipping requirements.

What are the key steps in container loading and first mile drayage?

Container loading and first mile drayage are critical steps in the intermodal shipping process, ensuring that cargo is properly secured and transported to the rail terminal or port.

Container Loading

Cargo preparation: Ensure that the goods are properly packaged, labeled, and ready for loading into the container. This may include palletizing, shrink-wrapping, or using other protective measures.

Container inspection: Before loading, inspect the container for any damage, cleanliness, and suitability for the specific cargo. Address any issues to prevent damage or contamination during transit.

Loading and securing: Load the cargo into the container in a manner that maximizes space utilization and ensures proper weight distribution. Use appropriate securing methods, such as straps, dunnage, or air bags, to prevent shifting during transport.

Documentation and sealing: Complete and attach necessary documentation, such as the packing list and seal number, to the container. Apply a high-security seal to the container to prevent tampering and ensure integrity.

First Mile Drayage

Pickup arrangement: Schedule the pickup of the loaded container from the shipper’s facility or warehouse with a drayage provider. Provide necessary information, such as pickup date, time, and any special instructions.

Drayage truck arrival: The drayage truck arrives at the designated pickup location to collect the loaded container. The driver inspects the container, verifies the documentation, and signs the bill of lading.

Transport to rail terminal or port: The drayage truck transports the loaded container to the rail terminal or port, following the most efficient route and complying with any weight or traffic restrictions.

Gate check-in and handoff: Upon arrival at the rail terminal or port, the drayage truck goes through the gate check-in process, providing necessary documentation and information. The container is then handed off to the terminal operator for further processing and loading onto the train or ship.

By ensuring proper container loading and efficient first mile drayage, shippers can minimize the risk of damage, delays, and additional costs in the intermodal shipping process.

How does rail transportation work in intermodal shipping?

Rail transportation plays a vital role in intermodal shipping, offering an efficient and cost-effective way to move containers over long distances.

Rail Network and Terminals

Extensive rail network: Railroads operate an extensive network of tracks spanning across countries and continents, connecting major cities, ports, and industrial centers.

Intermodal terminals: Rail terminals are equipped with specialized facilities and equipment to handle the loading, unloading, and transfer of intermodal containers between trains and other modes of transport, such as trucks and ships.

Container Loading and Train Assembly

Container handling: At the rail terminal, containers are unloaded from drayage trucks using cranes or other lifting equipment and staged in a designated area for loading onto trains.

Train assembly: Containers are loaded onto specialized rail cars, such as well cars or spine cars, designed to securely hold intermodal containers. The train is assembled by coupling the loaded rail cars together and attaching them to one or more locomotives.

Rail Transport

Long-haul movement: Once the train is assembled, it departs the terminal and begins its journey along the designated rail route. Trains can efficiently transport large numbers of containers over long distances, often spanning hundreds or even thousands of miles.

Scheduled services: Railroads operate on fixed schedules, with trains departing and arriving at terminals based on predetermined timetables. This allows for reliable and predictable transit times for intermodal shipments.

Terminal Handling and Drayage

Container unloading: Upon arrival at the destination rail terminal, containers are unloaded from the train using cranes or other lifting equipment and staged in a designated area for pickup by drayage trucks.

Drayage to final destination: Drayage trucks collect the containers from the rail terminal and transport them to the final destination, such as a distribution center, warehouse, or customer facility.

Rail transportation in intermodal shipping offers several advantages, including cost-effectiveness for long-distance shipments, reduced traffic congestion on highways, and lower environmental impact compared to road-only transport.

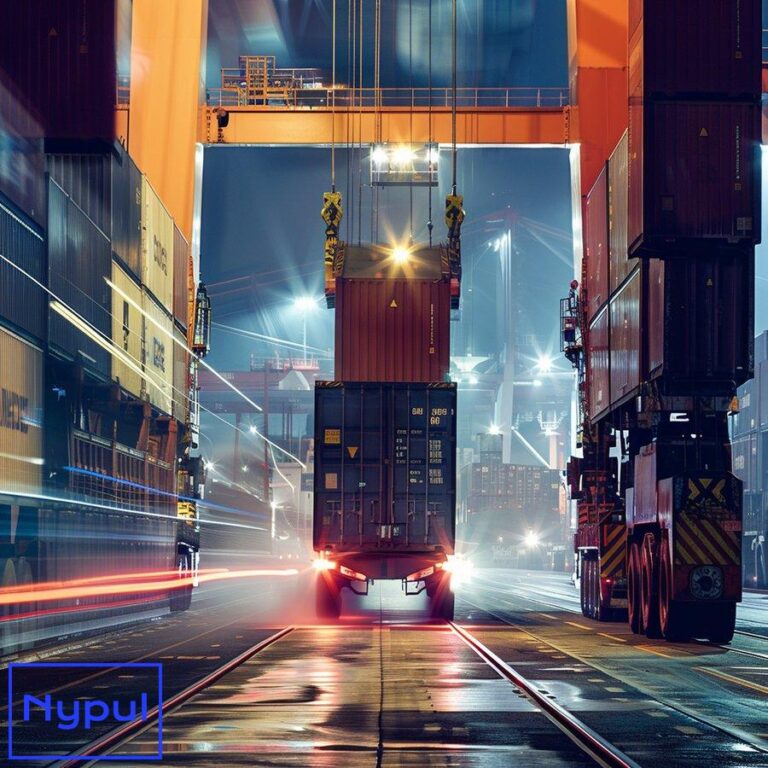

What happens during port operations and ocean freight for international shipments?

Port operations and ocean freight are essential components of international intermodal shipping, enabling the movement of containers across continents and oceans.

Port Operations

Container arrival: Containers are transported to the port by drayage trucks or trains, where they are staged in a designated area for loading onto the ship.

Container handling: Port cranes, such as ship-to-shore cranes or mobile harbor cranes, are used to load containers onto the ship. The cranes lift the containers from the staging area and carefully place them onto the ship’s deck or into the cargo hold.

Stowage planning: The loading process follows a precise stowage plan, which determines the placement of each container on the ship based on factors such as weight distribution, destination, and any special requirements (e.g., refrigerated containers).

Customs clearance: Before or during the loading process, containers undergo customs clearance procedures, which may include document verification, inspection, and the payment of any necessary duties or taxes.

Ocean Freight

Vessel loading: Once all containers are loaded and the ship is ready to depart, the vessel leaves the port and begins its ocean voyage to the destination port.

Sailing and routing: The ship follows a predetermined route, which may include stops at intermediate ports for additional loading or unloading of containers. The sailing time depends on factors such as distance, weather conditions, and the vessel’s speed.

Vessel tracking: Shippers can track the progress of their containers during the ocean voyage using vessel tracking systems provided by the shipping line or third-party services.

Port of Arrival

Vessel unloading: Upon arrival at the destination port, the ship is moored, and the containers are unloaded using port cranes. The process is similar to the loading operation, with cranes lifting containers from the ship and placing them onto the dock or onto drayage trucks or trains.

Customs clearance: Containers undergo another round of customs clearance procedures at the destination port, which may include document verification, inspection, and the payment of any necessary duties or taxes.

Drayage or rail transport: Once cleared by customs, containers are picked up by drayage trucks or loaded onto trains for transport to their final destination or to an inland intermodal terminal for further processing.

Port operations and ocean freight are critical links in the international intermodal shipping chain, enabling the efficient and secure movement of containers across global trade routes.

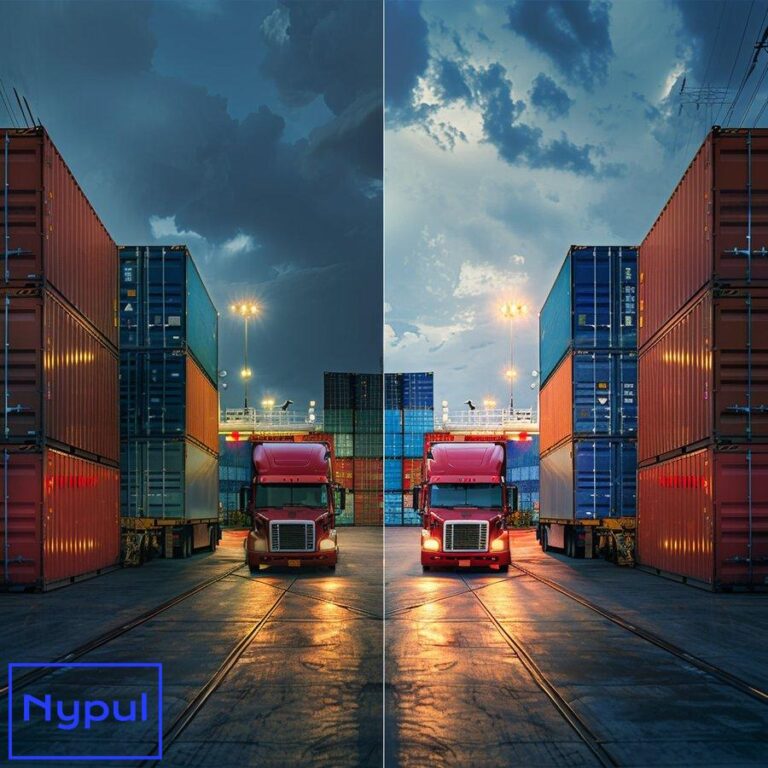

How is the last mile delivery handled in intermodal transport?

Last mile delivery is the final stage of the intermodal shipping process, where containers are transported from the destination rail terminal or port to the consignee’s facility or final delivery point.

Drayage from Terminal

Container pickup: Once the container arrives at the destination rail terminal or port and clears any necessary customs procedures, a drayage truck is dispatched to pick up the container.

Drayage truck loading: The container is loaded onto the drayage truck using terminal handling equipment, such as cranes or forklifts. The truck driver verifies the container information and signs the necessary documentation.

Transport to Final Destination

Routing and scheduling: The drayage provider plans the most efficient route from the terminal to the final delivery point, considering factors such as traffic conditions, road restrictions, and delivery appointments.

Compliance with regulations: Drayage trucks must comply with local, state, and federal regulations, such as weight limits, emissions standards, and hours-of-service rules for drivers.

Delivery and Unloading

Arrival at consignee’s facility: The drayage truck arrives at the consignee’s facility or designated delivery point at the scheduled time.

Unloading and container return: The container is unloaded from the truck using the consignee’s handling equipment or by the drayage provider, depending on the agreed-upon terms. The empty container is then returned to the drayage truck for transport back to the terminal or to another location for reloading.

Proof of delivery: The consignee signs the proof of delivery document, confirming receipt of the cargo in good condition. This document is then provided to the shipper or their designated party as evidence of successful delivery.

Challenges in Last Mile Delivery

Congestion and accessibility: Last mile delivery can be challenging in urban areas due to traffic congestion, limited parking, and narrow streets, which may restrict access for large drayage trucks.

Appointment scheduling: Coordinating delivery appointments with consignees can be complex, particularly when dealing with multiple shipments and limited receiving hours at the delivery location.

Driver shortages: The trucking industry often faces driver shortages, which can impact the availability and cost of drayage services for last mile delivery.

Efficient last mile delivery is crucial for ensuring timely and safe delivery of cargo to the final destination, completing the intermodal shipping process.

What documentation is required throughout the intermodal shipping process?

Proper documentation is essential throughout the intermodal shipping process to ensure smooth operations, compliance with regulations, and the transfer of liability between parties.

Key Documents

Bill of Lading (BOL): The BOL is a critical document that serves as a contract of carriage between the shipper and the carrier. It includes information such as the shipper and consignee details, cargo description, quantity, and any special instructions. The BOL is issued by the carrier and signed by both parties.

Commercial Invoice: The commercial invoice is a document that provides information about the goods being shipped, including the value, description, and quantity. It is used for customs clearance purposes and is typically prepared by the shipper.

Packing List: The packing list itemizes the contents of each package or container, including the quantity, weight, and dimensions of the goods. It helps in the identification and tracking of cargo throughout the shipping process.

Intermodal-Specific Documents

Intermodal Bill of Lading: An intermodal BOL is used when the shipment involves multiple modes of transport. It covers the entire journey from origin to destination and outlines the responsibilities of each carrier involved.

Equipment Interchange Receipt (EIR): The EIR is a document that records the transfer of a container between different parties, such as the drayage provider and the rail terminal. It includes information about the container’s condition and any damage noted during the interchange.

Rail Waybill: The rail waybill is a document issued by the rail carrier that details the movement of the container on the rail network, including the origin, destination, and any intermediate stops.

Customs and International Documents

Customs Invoice: A customs invoice is a document that provides information required by customs authorities for the clearance of international shipments, such as the value, description, and origin of the goods.

Certificate of Origin: The certificate of origin is a document that certifies the country where the goods were manufactured or produced. It is often required for international shipments to determine the applicability of tariffs and trade agreements.

Dangerous Goods Declaration: If the shipment contains hazardous materials, a dangerous goods declaration must be completed, providing information about the nature of the goods and any special handling requirements.

Accurate and complete documentation is crucial for ensuring the smooth flow of intermodal shipments, facilitating customs clearance, and maintaining the integrity of the cargo throughout the shipping process.

How can technology improve intermodal shipments?

Technology plays a vital role in enhancing the efficiency, visibility, and sustainability of intermodal shipments. Here are some key ways in which technology can improve the intermodal shipping process:

Visibility and Tracking

![]()

Real-time tracking: GPS-enabled devices and sensors can be attached to containers, allowing for real-time tracking of shipments throughout the intermodal journey. This provides shippers with up-to-date information on the location and status of their cargo.

Internet of Things (IoT): IoT devices can monitor various parameters of the container, such as temperature, humidity, and shock, ensuring that sensitive cargo remains within acceptable conditions during transit. Alerts can be triggered if any deviations occur, enabling proactive measures to be taken.

Blockchain: Blockchain technology can be used to create a secure, transparent, and immutable record of the shipping process, including documentation, ownership transfer, and payment transactions. This enhances trust and efficiency among stakeholders.

Optimization and Automation

Predictive analytics: By analyzing historical data and real-time information, predictive analytics can help optimize intermodal routes, identify potential bottlenecks, and improve overall network efficiency. This leads to reduced transit times and costs.

Automated terminal operations: Automated cranes, guided vehicles, and other equipment can streamline terminal operations, reducing the time required for container handling and improving safety. This increases the throughput capacity of intermodal terminals.

Intelligent scheduling: Advanced algorithms can optimize the scheduling of drayage trucks, trains, and vessels, considering factors such as traffic conditions, terminal congestion, and equipment availability. This minimizes delays and improves asset utilization.

Sustainability and Environmental Impact

Electric and hybrid vehicles: The adoption of electric and hybrid drayage trucks and cargo handling equipment can significantly reduce greenhouse gas emissions and improve air quality in and around intermodal terminals.

Fuel optimization: Technology can help optimize fuel consumption in intermodal transport by improving route planning, reducing idling times, and promoting eco-driving techniques. This leads to lower emissions and cost savings.

Modal shift optimization: By analyzing data on cargo characteristics, delivery requirements, and environmental factors, technology can help identify opportunities for modal shift, promoting the use of more sustainable modes like rail and barge transport when feasible.

Data Integration and Collaboration

Electronic data interchange (EDI): EDI enables the electronic exchange of standardized documents and data between stakeholders, reducing paperwork and manual errors. This streamlines communication and improves the accuracy of information throughout the intermodal shipping process.

Collaborative platforms: Cloud-based platforms can facilitate collaboration and data sharing among intermodal stakeholders, includingCollaborative platforms: Cloud-based platforms can facilitate collaboration and data sharing among intermodal stakeholders, including shippers, carriers, and logistics providers. This enhances communication, improves decision-making, and fosters a more integrated supply chain.

Conclusion

Technology is transforming intermodal shipping by enhancing visibility, optimizing operations, promoting sustainability, and facilitating collaboration across the supply chain. By leveraging these technological advancements, businesses can improve their intermodal shipping processes, reduce costs, and enhance customer satisfaction.

Summary

Intermodal shipping is a multifaceted process involving various steps from planning and booking to last mile delivery. Each stage requires careful consideration and coordination among multiple stakeholders. Understanding the intricacies of intermodal shipments, including the importance of documentation and the role of technology, is essential for businesses looking to optimize their logistics operations and remain competitive in the global market.

Through effective planning, efficient container loading, reliable rail transportation, seamless port operations, and strategic last mile delivery, companies can ensure their goods reach their destinations safely and on time. Embracing technology further enhances these processes, providing real-time visibility and improving overall efficiency. As the logistics landscape continues to evolve, staying informed about best practices and innovations in intermodal shipping will be key to success.