What Does Drayage in Shipping Mean

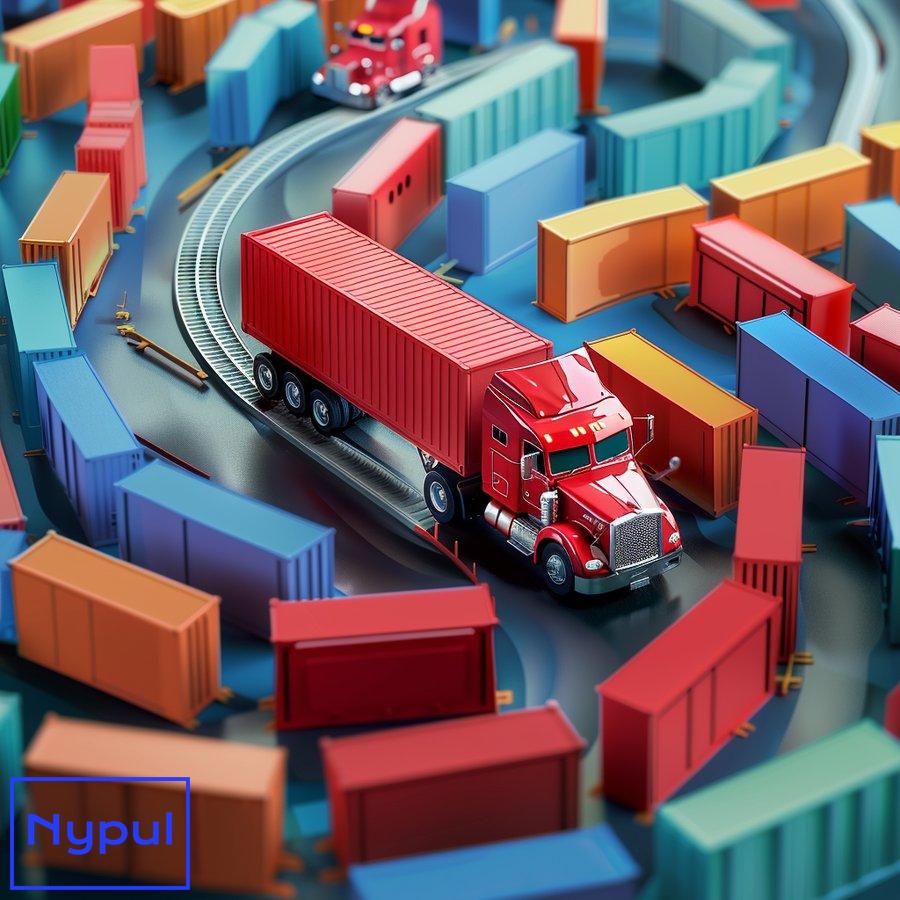

What is drayage in shipping?

Drayage refers to the transportation of shipping containers over short distances, typically within urban areas. This process is essential in logistics, serving as a critical link in the supply chain that connects various modes of transport, such as trucks, railways, and ships. The term itself originates from the word “dray,” which historically described a horse-drawn cart used for short-distance transport. Today, drayage is primarily executed using semi-trucks, facilitating the movement of freight from ports to warehouses, distribution centers, and other destinations.

Drayage is often characterized as the “first mile” of the shipping process. This designation highlights its importance; if the initial leg of transportation is inefficient or delayed, it can cause significant disruptions throughout the entire supply chain. For instance, if a shipping container arrives at a port but cannot be quickly transported to its next destination, it can lead to congestion and delays that ripple through logistics operations.

Drayage services are particularly prevalent in intermodal shipping, where goods are transported in standardized containers that can easily switch between different modes of transport without repacking. This efficiency is vital for maintaining the flow of goods across extensive supply chains. In the United States alone, millions of drayage movements occur annually, underscoring its significance in global trade.

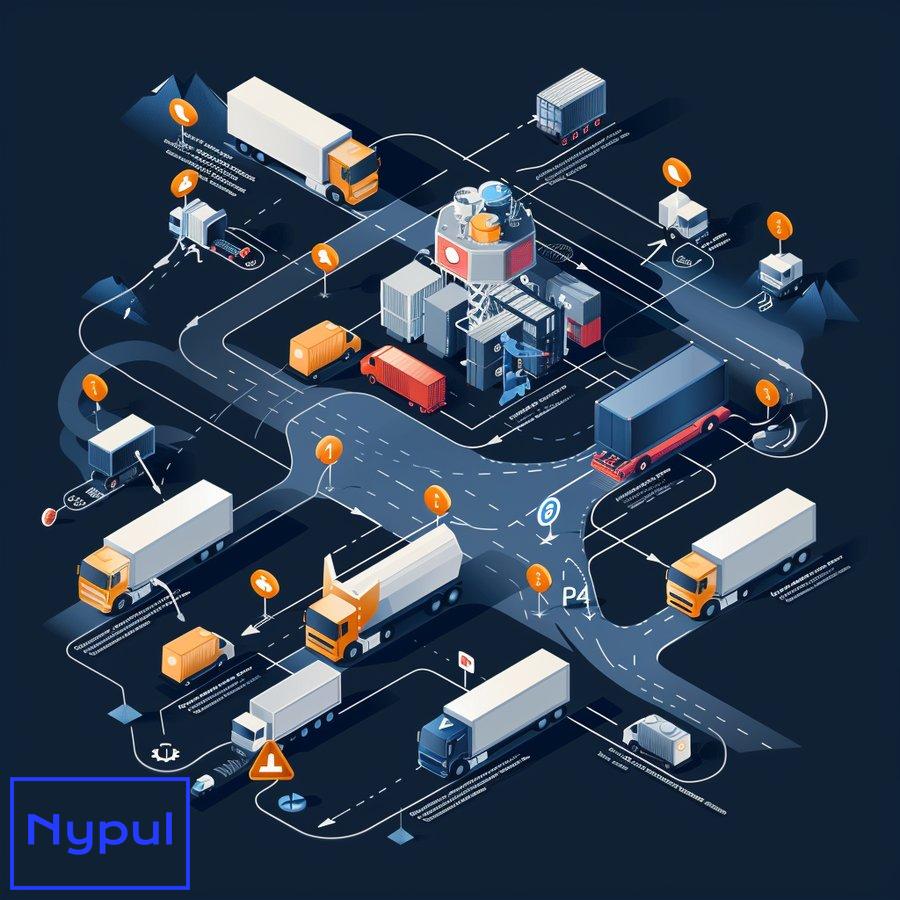

How does drayage fit into the supply chain?

Drayage plays an integral role in the broader supply chain, acting as the connective tissue that allows various transportation methods to work in harmony. Understanding its position within the supply chain involves recognizing the following components:

-

Intermodal Connections: Drayage facilitates the transfer of containers between different modes of transport, such as from ships to trucks or trains. This intermodal connectivity is essential for moving goods efficiently across long distances.

-

Urban Logistics: Within metropolitan areas, drayage services help distribute goods from central hubs to retail locations, warehouses, and other destinations. This local movement is crucial for ensuring that products reach consumers in a timely manner.

-

Supply Chain Efficiency: The effectiveness of drayage operations can significantly impact the overall efficiency of the supply chain. Delays in drayage can lead to bottlenecks, increased costs, and customer dissatisfaction.

A simplified visual representation of drayage’s role in the supply chain can be seen in the following table:

| Component | Description |

|---|---|

| Origin | Goods are picked up from manufacturers or warehouses. |

| Drayage | Short-distance transport to ports, rail yards, or warehouses. |

| Intermodal Transfer | Movement between different transport modes (e.g., ship to truck). |

| Final Destination | Delivery to retail locations or end consumers. |

This table illustrates the sequential flow of goods through the supply chain, emphasizing how drayage connects various stages.

What are the different types of drayage services?

![]()

Drayage services can be categorized into several types, each serving distinct functions within the logistics framework. Understanding these types is essential for businesses that rely on efficient freight transportation. The primary categories include:

![]()

-

Port or Pier Drayage: This involves transporting containers over short distances between ports and other facilities, such as warehouses or distribution centers. It is a common service used to move cargo from ships to land-based transport.

-

Intermodal Drayage: This service connects different modes of transport, such as moving containers from a port to a rail terminal. Intermodal drayage is crucial for facilitating seamless transitions between shipping methods.

-

Shuttle Drayage: This type of drayage involves moving containers to a temporary storage location for a short period. It is often used to keep containers safe until they are ready for further transport.

-

Intra-carrier Drayage: This refers to the transfer of containers within the same carrier’s network. It helps streamline operations by minimizing the need for multiple carriers.

-

Inter-carrier Drayage: This service involves transferring containers between different carriers, which may be necessary when a shipment requires multiple transport providers.

-

Expedited Drayage: This type of service is designed for time-sensitive freight, ensuring that goods are transported quickly over short distances.

-

Door-to-Door Drayage: Also known as retail drayage, this service delivers products directly from a transportation hub to the final destination, completing the last mile of logistics.

Each of these drayage types serves a specific purpose, contributing to the overall efficiency and effectiveness of the logistics process.

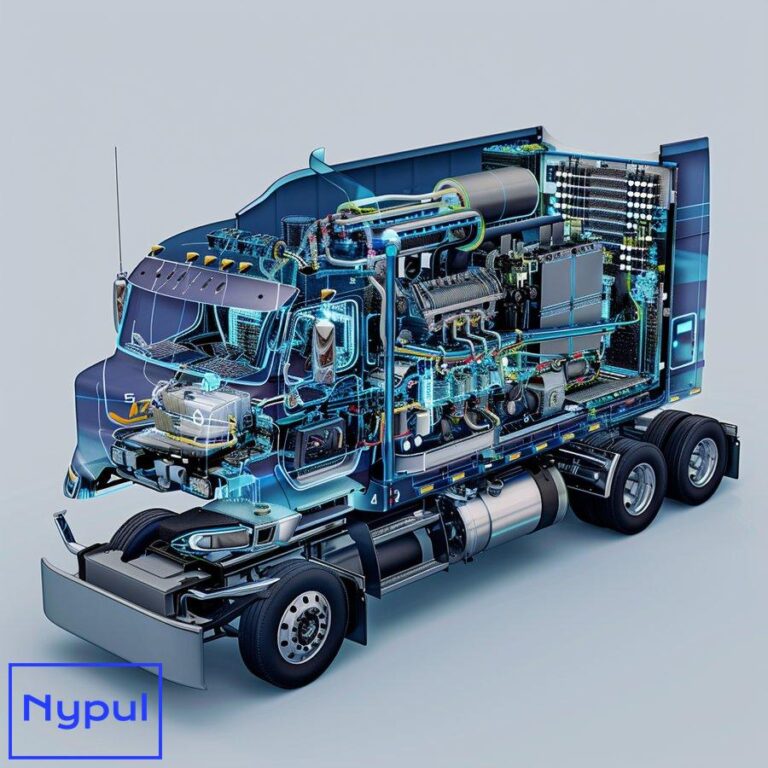

What equipment is used in drayage operations?

The equipment utilized in drayage operations is specialized to handle the unique demands of short-haul transportation. Key equipment includes:

-

Drayage Trucks: These are large semi-trucks specifically designed to transport shipping containers. They are equipped with chassis that can accommodate various container types, including standard dry containers, high cube containers, and refrigerated containers.

-

Chassis: A chassis is a wheeled frame that supports a shipping container during transport. Drayage trucks often require specialized chassis to ensure safe and efficient handling of containers.

-

Forklifts: In some cases, forklifts are used to load and unload containers at warehouses or distribution centers. They are essential for moving heavy cargo and ensuring that containers are properly positioned for transport.

-

Cranes: At ports and intermodal terminals, cranes are often employed to lift containers from ships onto trucks or trains. This equipment is vital for facilitating the transfer of heavy cargo.

-

Storage Facilities: Warehouses and distribution centers play a crucial role in drayage operations, providing temporary storage for containers before they are transported to their final destinations.

The following table summarizes the essential equipment used in drayage operations:

| Equipment | Purpose |

|---|---|

| Drayage Trucks | Transport shipping containers over short distances. |

| Chassis | Support containers during transport. |

| Forklifts | Load and unload containers at facilities. |

| Cranes | Lift containers between transport modes. |

| Storage Facilities | Provide temporary storage for containers. |

This equipment is vital for ensuring that drayage operations run smoothly and efficiently.

What challenges do drayage providers face?

Drayage providers encounter several challenges that can impact their operations and the overall efficiency of the supply chain. Key challenges include:

-

Port Congestion: Major ports often experience congestion due to high volumes of incoming and outgoing shipments. This can lead to delays in drayage services, causing backups in the supply chain.

-

Equipment Shortages: A lack of available chassis and trucks can hinder drayage operations. When equipment is in short supply, it can lead to increased wait times and inefficiencies.

-

Rising Costs: Fluctuating fuel prices and increased operational costs can affect the profitability of drayage services. Providers must navigate these financial challenges while maintaining competitive pricing.

-

Regulatory Compliance: Drayage providers must adhere to various regulations, including environmental standards and safety requirements. Compliance can add complexity to operations and increase costs.

-

Driver Shortages: The logistics industry faces a shortage of qualified drivers, which can limit the capacity of drayage providers. This shortage can lead to delays and increased competition for available drivers.

These challenges underscore the complexities of drayage operations and the need for effective management strategies to mitigate their impact.

How is drayage pricing determined?

Pricing for drayage services is influenced by several factors, making it essential for businesses to understand how costs are calculated. Key factors include:

-

Distance: The distance between the origin and destination significantly impacts pricing. Longer distances typically result in higher costs.

-

Weight of the Freight: Drayage fees are often calculated based on the weight of the container. A base fee is charged for every 100 pounds (45 kg) of weight, with additional costs applied for heavier shipments.

-

Port Fees: Many ports impose fees for container handling, storage, and other services. These fees can vary by location and impact overall drayage pricing.

-

Market Demand: Fluctuations in demand for drayage services can affect pricing. During peak shipping seasons, prices may rise due to increased competition for limited resources.

-

Service Type: Different types of drayage services may have varying costs. For example, expedited drayage services typically command higher fees due to their time-sensitive nature.

The following formula can be used to calculate drayage costs based on weight:

$$ \text{Total Drayage Cost} = \left( \frac{\text{Weight (lbs)}}{100} \right) \times \text{Drayage Rate} $$

This formula illustrates how weight and rate influence overall costs, emphasizing the importance of understanding pricing structures.

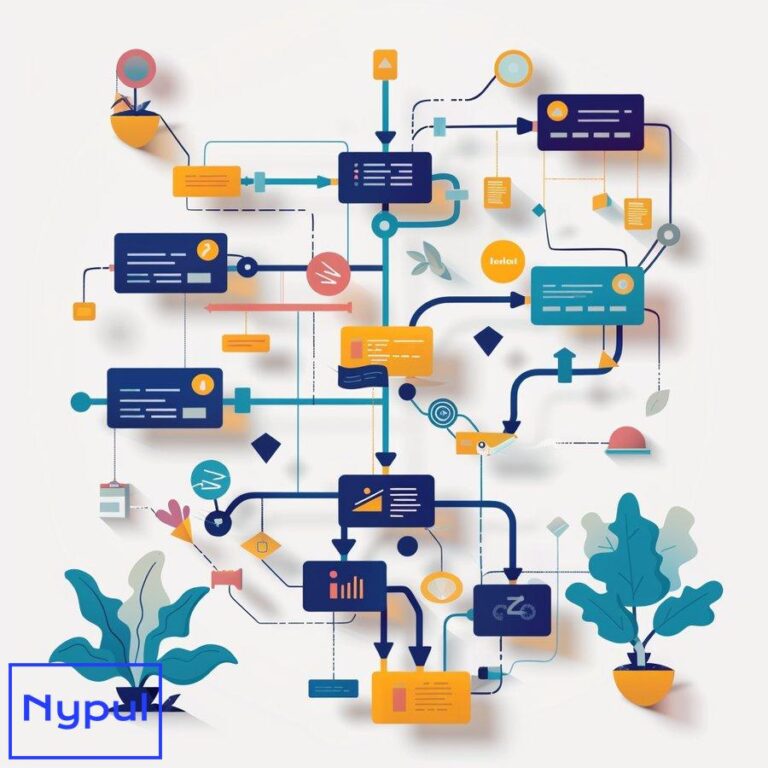

How is technology transforming drayage management?

Technology is playing a pivotal role in transforming drayage management, enhancing efficiency and streamlining operations. Key technological advancements include:

-

Tracking Systems: Real-time tracking systems allow drayage providers to monitor shipments throughout the transportation process. This visibility helps reduce delays and improve communication with customers.

-

Automated Dispatching: Automation in dispatching enables more efficient allocation of resources, reducing wait times and optimizing routes for drayage trucks.

-

Data Analytics: Advanced data analytics tools provide insights into operational performance, helping providers identify areas for improvement and make data-driven decisions.

-

Mobile Applications: Mobile apps facilitate communication between drivers and dispatchers, enabling real-time updates and enhancing coordination throughout the supply chain.

-

Blockchain Technology: Blockchain can improve transparency and security in drayage operations by providing a tamper-proof record of transactions and movements.

These technological innovations are reshaping the drayage landscape, enabling providers to operate more efficiently and respond to the evolving demands of the logistics industry.

In conclusion, drayage is a vital component of the shipping and logistics industry, serving as the crucial link that connects various transportation modes and facilitates the movement of goods. Understanding its significance, types, challenges, and the impact of technology is essential for businesses looking to optimize their supply chain operations.