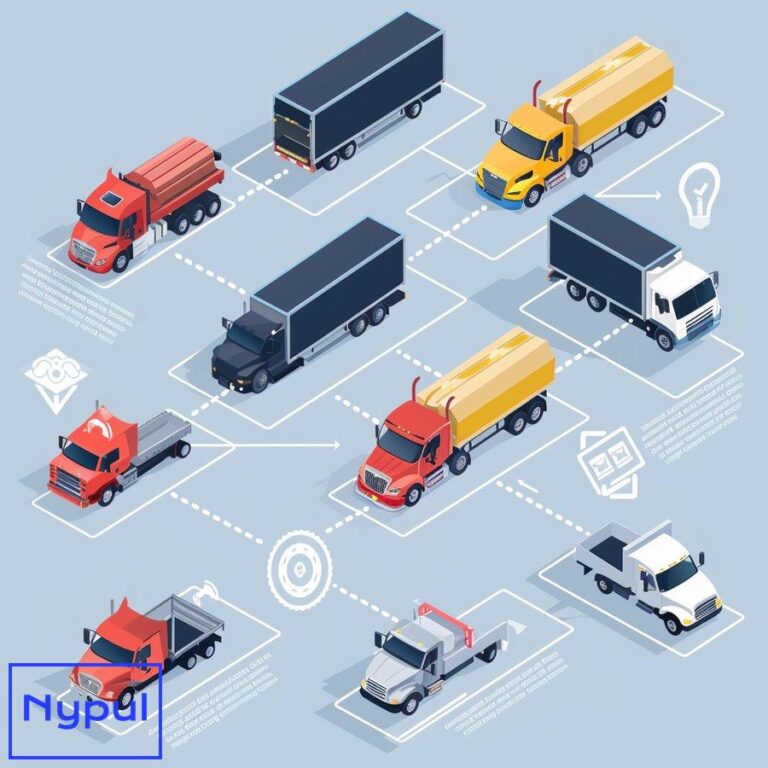

What Equipment Is Used in Cargo Handling

What are the main types of cargo handling equipment?

Cargo handling equipment forms the backbone of efficient logistics operations in ports, warehouses, and distribution centers worldwide. These specialized machines and tools enable the smooth movement, storage, and transportation of goods across the supply chain. The main types of cargo handling equipment can be broadly categorized into several groups based on their primary functions and the types of cargo they handle.

Lifting Equipment

Lifting equipment is designed to vertically move cargo from one level to another. This category includes:

Cranes: Cranes are versatile lifting devices used in various cargo handling scenarios. They come in different types:

- Container Cranes: Specifically designed for loading and unloading containers from ships.

- Gantry Cranes: Large overhead cranes that straddle a workspace, often used in shipyards and heavy manufacturing.

- Mobile Cranes: Mounted on wheels or tracks, providing flexibility in movement around a port or warehouse.

Forklifts: These versatile machines are essential in warehouses and smaller port operations. They come in various sizes and capacities, from small electric forklifts for indoor use to large diesel-powered models for outdoor operations.

Reach Stackers: Specialized vehicles used for handling intermodal containers in smaller ports and container yards.

Horizontal Transport Equipment

This category includes equipment designed to move cargo horizontally over short to medium distances:

Terminal Tractors: Also known as yard trucks, these vehicles are designed for moving trailers within a terminal or warehouse facility.

Automated Guided Vehicles (AGVs): Self-driving vehicles used in advanced port operations to transport containers between the quayside and storage areas.

Conveyor Systems: Used in warehouses and some bulk cargo operations to move goods along a fixed path.

Specialized Container Handling Equipment

Container handling requires specific equipment due to the standardized nature of shipping containers:

Straddle Carriers: These tall, narrow vehicles can lift and transport containers, straddling the load and the lane.

Rail-Mounted Gantry Cranes (RMGs): Used in intermodal yards to load and unload containers from trains.

Rubber-Tyred Gantry Cranes (RTGs): Similar to RMGs but mounted on rubber tires for greater flexibility in container yards.

Bulk Cargo Equipment

Bulk cargo, such as grain, coal, or ore, requires specialized handling equipment:

Grain Elevators: Used for loading and unloading bulk grain from ships and storage silos.

Conveyor Systems: Continuous belt systems for moving bulk materials over long distances.

Pneumatic Systems: Used for handling powdery or granular materials through pipes using air pressure.

Specialized Vehicles

Certain types of cargo require highly specialized handling equipment:

Ro-Ro (Roll-on/Roll-off) Ramps: Used for loading and unloading vehicles onto ships.

Heavy Lift Cranes: Designed for extremely heavy or oversized cargo that standard cranes cannot handle.

Refrigerated Container Handlers: Equipped to handle temperature-controlled containers for perishable goods.

Understanding the main types of cargo handling equipment is crucial for logistics professionals, port operators, and warehouse managers. Each type of equipment plays a specific role in ensuring the efficient movement of goods, and the choice of equipment depends on factors such as the type of cargo, the volume of operations, and the specific requirements of the facility.

When selecting cargo handling equipment, it’s essential to consider factors such as the equipment’s capacity, energy efficiency, maintenance requirements, and compatibility with existing systems. Additionally, as technology advances, many of these equipment types are becoming increasingly automated and integrated with IoT systems, further enhancing their efficiency and capabilities.

By leveraging the right mix of cargo handling equipment, businesses can optimize their operations, reduce handling times, minimize damage to goods, and ultimately improve their bottom line. As global trade continues to grow and evolve, the importance of efficient and effective cargo handling equipment will only increase, driving further innovations in this critical area of logistics.

How do lifting and horizontal transport equipment function in cargo operations?

Lifting and horizontal transport equipment are the workhorses of cargo operations, playing crucial roles in the efficient movement of goods within ports, warehouses, and distribution centers. These two categories of equipment work in tandem to ensure smooth cargo handling from arrival to departure. Let’s delve into how each type functions in cargo operations.

Lifting Equipment

Lifting equipment is designed to move cargo vertically, either to load/unload vessels and vehicles or to stack goods for storage. The primary function of lifting equipment is to overcome gravity and efficiently move cargo to different heights.

Cranes

Cranes are the most visible and versatile lifting equipment in cargo operations. They function by using a system of cables, pulleys, and a boom to lift and move heavy loads.

Ship-to-Shore (STS) Cranes: These massive cranes are used to load and unload container ships. They function by extending their boom over the ship, lowering a spreader (a device that locks onto the container’s corners), lifting the container, and moving it to the quayside or onto a waiting vehicle.

Operation Process:

1. The crane operator positions the boom over the target container on the ship.

2. The spreader is lowered and locks onto the container.

3. The container is lifted and moved horizontally along the boom.

4. The container is lowered onto the quayside or a waiting vehicle.

Rubber-Tyred Gantry (RTG) Cranes: These cranes operate in container yards, moving on rubber tires to provide flexibility in operations.

Function: RTGs straddle multiple lanes of stacked containers and a truck lane. They can lift containers from the stacks and place them onto trucks or vice versa.

Forklifts

Forklifts are versatile lifting machines used in various cargo operations, especially in warehouses and smaller port facilities.

Function: Forklifts use two parallel prongs (forks) that can be inserted under a pallet or into specially designed slots on cargo. The forks can be raised or lowered to lift the cargo to the desired height.

Operation Process:

1. The forklift approaches the cargo.

2. The forks are inserted under the pallet or into the cargo slots.

3. The hydraulic system lifts the forks and the cargo.

4. The forklift moves to the desired location and lowers the cargo.

Reach Stackers

Reach stackers are specialized vehicles used primarily for handling intermodal containers.

Function: They use a boom with a spreader attachment to lift and stack containers. The boom can extend forward, allowing the reach stacker to access containers in the second or third row of a stack.

Operation Process:

1. The reach stacker approaches the container.

2. The boom extends and lowers the spreader onto the container.

3. The spreader locks onto the container’s corner castings.

4. The container is lifted and can be moved or stacked as needed.

Horizontal Transport Equipment

Horizontal transport equipment moves cargo over ground level, facilitating the transfer of goods between different areas of a port or warehouse.

Terminal Tractors

Also known as yard trucks, these vehicles are designed for short-distance transport within a terminal or warehouse facility.

Function: Terminal tractors are used to move trailers or container chassis between the quayside and the container yard or to reposition containers within the facility.

Operation Process:

1. The tractor backs up to a trailer or chassis.

2. It connects to the trailer using a fifth wheel coupling.

3. The driver lifts the trailer’s landing gear.

4. The tractor then moves the trailer to its destination within the facility.

Automated Guided Vehicles (AGVs)

AGVs are self-driving vehicles used in advanced port operations to transport containers.

Function: AGVs move containers between the quayside and the storage area without human intervention, following predetermined paths and using sensors to avoid obstacles.

Operation Process:

1. The AGV receives instructions from the terminal operating system.

2. It moves to the designated pickup location.

3. The container is loaded onto the AGV by a crane.

4. The AGV transports the container to its designated drop-off point.

5. A crane or stacking equipment removes the container from the AGV.

Conveyor Systems

Conveyor systems are used in warehouses and some bulk cargo operations to move goods along a fixed path.

Function: Conveyors use a belt, rollers, or other mechanisms to move cargo continuously from one point to another.

Operation Process:

1. Cargo is placed on the conveyor at the input point.

2. The conveyor’s motor drives the belt or rollers.

3. The cargo moves along the conveyor path.

4. At the end of the conveyor, the cargo is either transferred to another conveyor or removed for further processing or storage.

The efficient functioning of lifting and horizontal transport equipment is crucial for smooth cargo operations. These machines work in concert to ensure that cargo moves swiftly and safely from ships to storage areas, and eventually to outbound transportation.

To illustrate the interplay between lifting and horizontal transport equipment, consider the process of unloading a container ship:

- The STS crane lifts a container from the ship.

- The crane places the container onto an AGV or terminal tractor.

- The AGV or tractor transports the container to the storage area.

- An RTG crane lifts the container from the AGV or tractor and stacks it in the yard.

This seamless integration of lifting and horizontal transport functions is what enables modern ports and warehouses to handle large volumes of cargo efficiently. As technology advances, these equipment types are becoming increasingly automated and integrated, further enhancing their efficiency and reducing the potential for human error.

Understanding how lifting and horizontal transport equipment function is essential for optimizing cargo operations. By leveraging the strengths of each equipment type and ensuring their smooth interaction, cargo handlers can minimize handling times, reduce the risk of damage to goods, and improve overall operational efficiency.

What specialized equipment is used for container handling?

Container handling requires specialized equipment due to the standardized nature of shipping containers and the high volume of container traffic in modern ports. These specialized machines are designed to efficiently move, stack, and transport containers, ensuring smooth operations in container terminals. Let’s explore the key types of specialized container handling equipment and their functions.

Ship-to-Shore (STS) Cranes

STS cranes, also known as container cranes or portainer cranes, are the giants of container terminals, designed specifically for loading and unloading containers from ships.

Key Features:

– Large boom that extends over the ship

– Trolley that moves along the boom

– Spreader that locks onto container corners

– Lift capacity typically ranging from 30 to 65 tons

– Ability to handle multiple container sizes (20ft, 40ft, 45ft)

Function: STS cranes transfer containers between ships and the quayside, serving as the critical link between sea and land operations.

Rubber-Tyred Gantry (RTG) Cranes

RTG cranes are versatile machines used in container yards for stacking and retrieving containers.

Key Features:

– Mobility on rubber tires

– Ability to straddle multiple rows of containers and a truck lane

– Typical stacking capability of 1-over-5 or 1-over-6 containers high

– Spreader for container handling

Function: RTGs organize and manage container stacks in the yard, facilitating efficient storage and retrieval of containers.

Rail-Mounted Gantry (RMG) Cranes

Similar to RTGs, but mounted on rails for more precise movement and potentially larger operating spans.

Key Features:

– Fixed path on rails

– Larger span than RTGs, often covering more container rows

– Higher stacking capability, sometimes up to 1-over-8 containers

– Often used in automated terminals

Function: RMGs are used for high-density container storage and retrieval, often in automated or semi-automated terminal operations.

Straddle Carriers

Straddle carriers are tall, narrow vehicles that can lift and transport containers independently.

Key Features:

– Ability to straddle a single container or a stack of containers

– Can lift containers up to 3 high

– Highly maneuverable

– Often used in a “decoupled” operation model

Function: Straddle carriers provide flexibility in container movement, able to transport containers between the quayside and the yard, as well as stack and retrieve containers in the yard.

Reach Stackers

Reach stackers are mobile container handling machines with a boom and spreader attachment.

Key Features:

– Extendable boom for reaching containers in the second or third row

– High lifting capacity (typically up to 45 tons)

– Versatility in handling different container sizes and types

Function: Reach stackers are used for container handling in smaller terminals or as support equipment in larger terminals, particularly useful for their flexibility and ability to stack containers up to 5 high.

Automated Guided Vehicles (AGVs) and Automated Straddle Carriers

These are self-driving vehicles used in advanced automated container terminals.

Key Features:

– Autonomous operation guided by terminal operating systems

– Electric or hybrid power systems for reduced emissions

– Sensors and safety systems for collision avoidance

– Integration with automated cranes and terminal management systems

Function: AGVs and automated straddle carriers transport containers between the quayside and the storage yard without human intervention, increasing efficiency and safety in terminal operations.

Empty Container Handlers

Specialized forklifts designed for handling empty containers.

Key Features:

– Top-lifting attachment for gripping containers from above

– Ability to stack empty containers up to 8 high

– Higher maneuverability compared to loaded container handlers

Function: Empty container handlers efficiently manage the storage and movement of empty containers within the terminal.

Comparison of Container Handling Equipment

To better understand the capabilities and use cases of different container handling equipment, let’s compare their key characteristics:

| Equipment Type | Mobility | Stacking Height | Best Use Case | Automation Potential |

|---|---|---|---|---|

| STS Crane | Fixed (on rails) | N/A (transfers to/from ship) | Ship loading/unloading | High |

| RTG Crane | Mobile (on tires) | 1-over-5 to 1-over-6 | Container yard operations | Medium to High |

| RMG Crane | Fixed (on rails) | Up to 1-over-8 | High-density storage | Very High |

| Straddle Carrier | Highly mobile | Up to 1-over-3 | Flexible container transport | High |

| Reach Stacker | Mobile | Up to 1-over-5 | Versatile handling, smaller terminals | Low |

| AGV | Mobile (automated) | N/A (transport only) | Automated terminals | Very High |

| Empty Container Handler | Mobile | Up to 8 high | Empty container management | Low |

The choice of container handling equipment depends on various factors, including the terminal’s size, throughput, layout, and automation strategy. Large container terminals often use a combination of these equipment types to optimize their operations.

For instance, a typical container handling process in a modern terminal might involve:

- An STS crane unloading a container from a ship

- An AGV or straddle carrier transporting the container to the yard

- An RTG or RMG crane stacking the container in the storage area

- A reach stacker retrieving the container for loading onto a truck or train

By understanding the capabilities and functions of each type of specialized container handling equipment, terminal operators can design efficient workflows, optimize their equipment fleet, and ensure smooth container handling operations. As container traffic continues to grow globally, the development of more efficient and automated container handling equipment remains a key focus in the port and logistics industry.

How is bulk cargo managed with specific equipment?

Bulk cargo, which includes materials like grain, coal, ore, and liquids, requires specialized equipment for efficient handling due to its loose, unpackaged nature. The management of bulk cargo involves a range of equipment designed to load, unload, transport, and store these materials in large quantities. Let’s explore the specific equipment used for managing different types of bulk cargo.

Dry Bulk Cargo Equipment

Dry bulk cargo includes materials like grain, coal, iron ore, and cement. The equipment used for handling these materials is designed to move large volumes efficiently while minimizing dust and spillage.

Ship Loaders and Unloaders

These are large machines used to load or unload dry bulk cargo from ships.

Key Features:

– Long booms that can reach into ship holds

– High-capacity conveyor systems

– Dust suppression systems

– Ability to handle various types of dry bulk materials

Function: Ship loaders transfer bulk cargo from shore storage onto ships, while unloaders remove cargo from ships and transfer it to shore-based storage or transport systems.

Operation Process:

1. For loading: Bulk material is fed into the ship loader from storage.

2. The loader’s boom is positioned over the ship’s hold.

3. Material is conveyed along the boom and deposited into the hold.

4. For unloading: The process is reversed, with the unloader’s boom reaching into the hold to extract the material.

Conveyor Systems

Conveyor systems are crucial for moving bulk materials over short to medium distances within a facility.

Key Features:

– Continuous operation

– Can be enclosed to prevent dust emissions

– Capable of moving materials horizontally, vertically, or at an incline

– Various belt types for different materials (e.g., troughed belts for loose materials)

Function: Conveyors transport bulk materials between different points in the handling process, such as from storage to ship loaders or from unloaders to storage areas.

Bucket Elevators

These are used for vertical transport of dry bulk materials.

Key Features:

– Series of buckets attached to a belt or chain

– Enclosed design to prevent spillage

– High lifting capacity

Function: Bucket elevators move bulk materials vertically, often used in grain elevators or to feed materials into storage silos.

Pneumatic Systems

Pneumatic systems use air pressure to move dry bulk materials through pipes.

Key Features:

– Enclosed system preventing dust emissions

– Suitable for powdery or granular materials

– Can transport materials over long distances and around obstacles

Function: Pneumatic systems are used for loading and unloading ships, transferring materials to storage, or moving materials within processing plants.

Stacker-Reclaimers

These large machines are used in bulk material stockyards.

Key Features:

– Long boom with a conveyor system

– Ability to both stack materials and reclaim them from stockpiles

– Can be rail-mounted for movement along stockpiles

Function: Stacker-reclaimers create and manage large stockpiles of bulk materials, allowing for efficient storage and retrieval.

Liquid Bulk Cargo Equipment

Liquid bulk cargo, such as oil, chemicals, and liquefied natural gas (LNG), requires different handling equipment due to its fluid nature.

Pumps and Pipelines

The primary means of moving liquid bulk cargo.

Key Features:

– High-capacity pumps for rapid transfer

– Specialized pipelines for different types of liquids

– Safety features to prevent spills and leaks

Function: Pumps and pipelines transfer liquid cargo between ships, storage tanks, and transport vehicles.

Storage Tanks

Large containers for storing liquid bulk cargo.

Key Features:

– Various designs for different types of liquids (e.g., floating roof tanks for volatile liquids)

– Safety features such as containment berms and fire suppression systems

– Instrumentation for monitoring liquid levels and quality

Function: Storage tanks hold liquid cargo before or after shipment, allowing for inventory management and distribution.

Loading Arms

Specialized equipment for transferring liquid cargo between ships and shore facilities.

Key Features:

– Articulated design for flexibility in connecting to ship manifolds

– Quick-connect couplings for rapid and secure connections

– Safety features such as emergency release systems

Function: Loading arms provide a secure connection for transferring liquid cargo, accommodating ship movement and tidal changes.

Efficiency Considerations in Bulk Cargo Management

Efficient management of bulk cargo requires careful selection and integration of handling equipment. Here are some key considerations:

Material Properties: The choice of equipment depends on the physical properties of the bulk material, such as density, flowability, and moisture content.

Throughput Requirements: The capacity of the equipment must match the required handling rates to avoid bottlenecks.

Environmental Concerns: Dust suppression and spill prevention are crucial, especially for dry bulk materials.

Energy Efficiency: Modern bulk handling equipment often incorporates energy-saving features, such as regenerative braking on conveyors.

Automation: Many bulk handling systems are now automated or semi-automated, improving efficiency and safety.

Maintenance: Regular maintenance is crucial to ensure continuous operation and prevent costly breakdowns.

Comparison of Bulk Cargo Handling Methods

| Handling Method | Suitable Materials | Advantages | Disadvantages |

|---|---|---|---|

| Conveyor Systems | Most dry bulk | Continuous operation, high capacity | Limited flexibility, dust generation |

| Pneumatic Systems | Powdery/granular materials | Enclosed system, flexible routing | Higher energy consumption, limited to certain materials |

| Bucket Elevators | Dry bulk, especially grains | Efficient vertical transport | Limited to vertical movement |

| Pumps and Pipelines | Liquids | Fast transfer, enclosed system | Limited to liquids, potential for leaks |

| Stacker-Reclaimers | Large volume dry bulk | Efficient stockpile management | High initial cost, less flexible |

Effective bulk cargo management requires a holistic approach, considering not just the individual pieces of equipment but how they work together as a system. By selecting the right equipment and optimizing its use, bulk cargo handlers can achieve high throughput rates, minimize environmental impact, and ensure safe operations.

As technology advances, we’re seeing innovations in bulk cargo handling equipment, such as:

- Smart sensors for real-time monitoring of equipment performance and cargo conditions

- Advanced automation systems for coordinated operation of multiple pieces of equipment

- Improved materials and designs for longer equipment life and reduced maintenance needs

- Enhanced dust suppression technologies for cleaner operations

These advancements are helping to make bulk cargo handling more efficient, safer, and more environmentally friendly. As global trade in bulk commodities continues to grow, the importance of effective bulk cargo management and the equipment that enables it will only increase.

What role does automation play in modern cargo handling?

Automation has become a game-changer in modern cargo handling, revolutionizing the way ports, warehouses, and distribution centers operate. By integrating advanced technologies, automation enhances efficiency, safety, and accuracy in cargo operations. Let’s explore the significant roles that automation plays in various aspects of cargo handling.

Container Terminal Automation

Container terminals have been at the forefront of automation in cargo handling. Automated container terminals utilize a range of technologies to minimize human intervention in container movement and stacking.

Automated Stacking Cranes (ASCs)

ASCs are rail-mounted gantry cranes that operate without human operators in the container yard.

Key Features:

– Remote operation or full automation

– High precision in container placement

– Ability to work 24/7 with minimal downtime

Function: ASCs manage container stacks, performing both storage and retrieval operations automatically based on instructions from the terminal operating system.

Automated Guided Vehicles (AGVs) and Automated Straddle Carriers

These self-driving vehicles transport containers between the quayside and the storage yard.

Key Features:

– Autonomous navigation using sensors and GPS

– Integration with terminal operating systems for real-time task allocation

– Electric or hybrid propulsion for reduced emissions

Function: AGVs and automated straddle carriers provide the crucial horizontal transport link in automated terminals, moving containers without human drivers.

Automated Quay Cranes

While fully automated quay cranes are less common, semi-automated systems are increasingly used.

Key Features:

– Automated positioning and container handling

– Remote operation for final positioning and locking

– Anti-sway systems for faster operation

Function: Automated quay cranes enhance the speed and precision of ship-to-shore container transfers.

Warehouse Automation

Automation in warehouses and distribution centers has significantly improved the efficiency of cargo handling and storage.

Automated Storage and Retrieval Systems (AS/RS)

These systems automatically place and retrieve cargo from storage locations.

Key Features:

– High-density storage utilization

– Rapid retrieval times

– Integration with warehouse management systems

Function: AS/RS optimizes space utilization and speeds up order fulfillment processes.

Automated Guided Vehicles (AGVs) in Warehouses

Similar to their use in container terminals, AGVs in warehouses automate the movement of goods.

Key Features:

– Ability to navigate complex warehouse layouts

– Integration with warehouse management systems

– Various types for different cargo (pallets, individual items)

Function: Warehouse AGVs automate the transport of goods between storage areas, packing stations, and loading docks.

Robotic Palletizers and Depalletizers

These robots automate the stacking and unstacking of goods on pallets.

Key Features:

– High speed and precision

– Ability to handle various package types and sizes

– Integration with conveyor systems and AGVs

Function: Robotic palletizers and depalletizers speed up the process of preparing goods for shipment or storage.

Bulk Cargo Automation

Automation in bulk cargo handling focuses on improving the efficiency and safety of material transfer and storage.

Automated Sampling and Quality Control

Automated systems can sample and analyze bulk materials during loading or unloading.

Key Features:

– Real-time analysis of material properties

– Automatic sampling at regular intervals

– Integration with cargo management systems

Function: These systems ensure quality control and proper blending of bulk materials without manual intervention.

Automated Stockyard Management

Automated stacker-reclaimers and conveyor systems manage bulk material stockpiles.

Key Features:

– Automated stockpile creation and reclamation

– Real-time inventory tracking

– Optimization of stockpile layouts for efficient space utilization

Function: Automated stockyard management ensures efficient use of storage space and rapid retrieval of materials.

Benefits of Automation in Cargo Handling

Automation brings numerous benefits to cargo handling operations:

Increased Efficiency: Automated systems can operate 24/7 with consistent performance, increasing throughput and reducing turnaround times.

Enhanced Safety: By reducing the need for human presence in dangerous areas, automation significantly improves workplace safety.

Improved Accuracy: Automated systems minimize human errors in cargo handling and inventory management.

Cost Reduction: While initial investment is high, automation can lead to long-term cost savings through reduced labor costs and increased efficiency.

Environmental Benefits: Many automated systems are electric-powered, reducing emissions compared to diesel-powered equipment.

Challenges and Considerations

While automation offers significant benefits, it also presents challenges:

High Initial Investment: The upfront costs of implementing automated systems can be substantial.

Workforce Transition: Automation may lead to job displacement, requiring strategies for workforce transition and retraining.

System Integration: Ensuring seamless integration between automated systems and existing operations can be complex.

Cybersecurity: Increased reliance on digital systems raises the importance of robust cybersecurity measures.

Flexibility: Some automated systems may be less flexible than manual operations in adapting to unexpected situations or changes in cargo types.

Future Trends in Cargo Handling Automation

As technology continues to advance, we can expect to see further developments in cargo handling automation:

Artificial Intelligence and Machine Learning: These technologies will enhance the decision-making capabilities of automated systems, allowing for more adaptive and efficient operations.

Internet of Things (IoT): Increased use of IoT devices will provide real-time data on cargo conditions and equipment performance, enabling predictive maintenance and optimized operations.

Autonomous Ships: The development of autonomous vessels will require new approaches to automated cargo handling at ports.

Drone Technology: Drones may be used for inventory management, security surveillance, and even small-scale cargo transport within facilities.

Comparison of Manual vs. Automated Cargo Handling

To illustrate the impact of automation, let’s compare manual and automated approaches in key areas of cargo handling:

| Aspect | Manual Handling | Automated Handling |

|---|---|---|

| Operating Hours | Limited by worker shifts | 24/7 operation possible |

| Accuracy | Subject to human error | High precision and consistency |

| Speed | Variable, affected by worker fatigue | Consistent high-speed operation |

| Safety | Higher risk of accidents | Reduced risk in dangerous areas |

| Flexibility | Can adapt to unexpected situations | May struggle with non-standard scenarios |

| Initial Cost | Lower upfront investment | High initial capital expenditure |

| Long-term Cost | Ongoing labor costs | Lower operating costs over time |

| Data Collection | Manual recording, prone to errors | Automatic, real-time data capture |

Automation plays a crucial role in modernizing cargo handling operations, offering significant improvements in efficiency, safety, and accuracy. As global trade continues to grow and labor costs increase in many regions, the trend towards automation in cargo handling is likely to accelerate. However, successful implementation requires careful planning, substantial investment, and a holistic approach that considers not just the technology but also its impact on workforce and existing operations.

The future of cargo handling lies in finding the right balance between automated systems and human expertise, creating smart ports and warehouses that can meet the growing demands of global trade while maintaining flexibility and resilience in the face of changing market conditions.

How does IoT enhance cargo handling equipment efficiency?

The Internet of Things (IoT) has emerged as a transformative technology in the logistics and cargo handling industry. By connecting various devices, sensors, and equipment to a centralized network, IoT enables real-time data collection, analysis, and decision-making, significantly enhancing the efficiency of cargo handling equipment. Let’s explore how IoT is revolutionizing different aspects of cargo handling operations.

Real-Time Equipment Monitoring

IoT sensors attached to cargo handling equipment provide continuous data on their operational status, performance, and condition.

Key Applications:

– Monitoring engine performance in vehicles like forklifts and reach stackers

– Tracking the operational hours of cranes and conveyor systems

– Measuring fuel consumption and energy usage

Benefits:

– Early detection of potential equipment failures

– Optimization of maintenance schedules

– Improved equipment utilization and energy efficiency

Predictive Maintenance

By analyzing data from IoT sensors, maintenance needs can be predicted before equipment failure occurs.

Key Applications:

– Monitoring vibration patterns in crane motors to detect misalignments

– Tracking wear and tear on conveyor belts

– Analyzing oil quality in hydraulic systems

Benefits:

– Reduced downtime due to unexpected equipment failures

– Lower maintenance costs through timely interventions

– Extended equipment lifespan

Location Tracking and Fleet Management

IoT enables real-time tracking of mobile equipment within ports, warehouses, and distribution centers.

Key Applications:

– Tracking the location and movement of forklifts and AGVs

– Monitoring the utilization rates of different equipment types

– Optimizing routes for internal transport vehicles

Benefits:

– Improved equipment utilization

– Reduced idle time and fuel consumption

– Enhanced operational planning and resource allocation

Environmental Monitoring

IoT sensors can monitor environmental conditions that affect cargo and equipment performance.

Key Applications:

– Tracking temperature and humidity in storage areas

– Monitoring air quality and dust levels in bulk cargo handling areas

– Detecting water ingress in sensitive equipment

Benefits:

– Improved cargo preservation, especially for perishable goods

– Enhanced safety in handling sensitive materials

– Reduced equipment damage due to environmental factors

Energy Management

IoT systems can optimize energy usage across cargo handling operations.

Key Applications:

– Smart lighting systems in warehouses and port areas

– Automated power management for equipment in idle states

– Monitoring and optimizing HVAC systems in storage facilities

Benefits:

– Reduced energy consumption and costs

– Lower carbon footprint

– Improved sustainability of operations

Safety and Security Enhancement

IoT contributes to safer and more secure cargo handling environments.

Key Applications:

– Proximity sensors on equipment to prevent collisions

– Wearable devices for worker safety monitoring

– Smart access control systems for secure areas

Benefits:

– Reduced accidents and injuries

– Enhanced cargo security

– Improved compliance with safety regulations

Cargo Tracking and Management

IoT enables detailed tracking of cargo throughout the handling process.

Key Applications:

– RFID tags for individual cargo items or containers

– Smart seals for monitoring container integrity

– Sensors for monitoring conditions of sensitive cargo

Benefits:

– Real-time visibility of cargo location and condition

– Improved inventory management

– Enhanced customer service through accurate tracking information

Integration with Terminal Operating Systems

IoT data can be integrated with terminal operating systems for comprehensive operational management.

Key Applications:

– Real-time equipment status updates to optimize task allocation

– Automated data entry for operational records

– Integration of IoT data with planning and scheduling systems

Benefits:

– Improved operational efficiency

– Reduced manual data entry errors

– Enhanced decision-making capabilities

Challenges in Implementing IoT in Cargo Handling

While IoT offers significant benefits, its implementation also presents challenges:

Data Security: The increased connectivity raises cybersecurity concerns, requiring robust security measures.

Data Management: Handling the large volumes of data generated by IoT devices requires advanced data management and analytics capabilities.

Integration: Integrating IoT systems with existing equipment and software can be complex and costly.

Standardization: Lack of universal standards for IoT in logistics can lead to compatibility issues.

ROI Justification: The initial investment in IoT infrastructure can be significant, requiring clear ROI calculations.

Comparison of Traditional vs. IoT-Enhanced Cargo Handling

To illustrate the impact of IoT on cargo handling efficiency, let’s compare traditional approaches with IoT-enhanced methods:

| Aspect | Traditional Approach || IoT-Enhanced Approach |

|——–|———————-|————————–|

| Equipment Maintenance | Scheduled based on fixed intervals or reactive to breakdowns | Predictive maintenance based on real-time equipment condition |

| Resource Allocation | Based on historical data and manual observation | Dynamic allocation using real-time equipment and cargo data |

| Energy Management | Fixed schedules or manual control | Automated, demand-based energy management |

| Safety Monitoring | Periodic manual inspections | Continuous, real-time monitoring with instant alerts |

| Inventory Tracking | Periodic manual counts or barcode scanning | Real-time tracking using RFID and IoT sensors |

| Performance Analysis | Based on periodic reports and manual data collection | Continuous performance monitoring with real-time analytics |

| Decision Making | Often reactive, based on limited data | Proactive, data-driven decision making |

Future Trends in IoT for Cargo Handling

As IoT technology continues to evolve, we can expect to see several emerging trends in cargo handling:

5G Integration: The rollout of 5G networks will enable faster, more reliable IoT communications, supporting real-time decision making and control.

Edge Computing: Processing data closer to the source will reduce latency and enable quicker responses in time-sensitive operations.

AI and Machine Learning: Advanced algorithms will enhance the predictive capabilities of IoT systems, leading to more intelligent and autonomous operations.

Digital Twins: Creating virtual replicas of physical assets and operations will enable advanced simulation and optimization of cargo handling processes.

Blockchain Integration: Combining IoT with blockchain technology will enhance the security and traceability of cargo throughout the supply chain.

The integration of IoT into cargo handling equipment and operations represents a significant leap forward in efficiency and productivity. By providing real-time visibility, predictive capabilities, and data-driven insights, IoT is transforming the way cargo is managed and moved. As the technology matures and becomes more widely adopted, we can expect to see even greater enhancements in the speed, accuracy, and reliability of cargo handling operations.

However, successful implementation of IoT in cargo handling requires a strategic approach. Organizations must carefully assess their needs, choose the right technologies, and ensure proper integration with existing systems. They must also address challenges related to data security, privacy, and workforce adaptation.

Ultimately, the goal of IoT in cargo handling is not just to collect data, but to transform that data into actionable insights that drive operational improvements. As the industry continues to embrace these technologies, we can expect to see more efficient, sustainable, and responsive cargo handling operations that are better equipped to meet the demands of global trade in the 21st century.

What safety features are essential in cargo handling equipment?

Safety is paramount in cargo handling operations, where heavy machinery, large loads, and complex processes create potential hazards. Essential safety features in cargo handling equipment are designed to protect workers, prevent accidents, and safeguard cargo. Let’s explore the critical safety features across various types of cargo handling equipment.

General Safety Features

These features are common across many types of cargo handling equipment:

Emergency Stop Systems

Emergency stop buttons or switches that immediately halt equipment operation in case of danger.

Key Features:

– Easily accessible and clearly marked

– Rapid response time

– Fail-safe design

Function: Allows operators or nearby workers to quickly stop equipment in emergency situations, preventing accidents or minimizing damage.

Overload Protection Systems

Mechanisms that prevent equipment from lifting or moving loads beyond their rated capacity.

Key Features:

– Load sensors and weight measurement devices

– Automatic shutdown or load-limiting functions

– Visual and audible overload warnings

Function: Prevents equipment failure, tipping, or structural damage due to excessive loads.

Visibility Enhancements

Features that improve the operator’s view of the work area and surrounding environment.

Key Features:

– High-visibility paint on equipment

– Mirrors and cameras for blind spot coverage

– LED lighting for night operations

Function: Reduces the risk of collisions and improves overall situational awareness.

Anti-Collision Systems

Technologies that detect and prevent potential collisions between equipment or with obstacles.

Key Features:

– Proximity sensors and radar systems

– Automatic braking or slowdown functions

– Warning alarms for operators and nearby workers

Function: Prevents accidents caused by equipment collisions or contact with fixed structures.

Specific Safety Features by Equipment Type

Different types of cargo handling equipment have unique safety requirements:

Cranes (Container and Gantry Cranes)

Load Moment Indicators (LMI)

Systems that monitor the crane’s lifting capacity in real-time based on boom angle and load weight.

Key Features:

– Continuous monitoring of load and boom position

– Visual and audible warnings when approaching capacity limits

– Automatic cut-off of lifting functions when limits are exceeded

Function: Prevents crane tipping and structural failure due to overloading.

Anti-Sway Systems

Mechanisms that reduce load swinging during crane operations.

Key Features:

– Computerized control of trolley and hoist movements

– Sensors to detect and counteract load sway

– Operator-assisted positioning for precise load placement

Function: Improves load control, reduces the risk of collisions, and enhances operational efficiency.

Wind Speed Monitors

Devices that measure wind speed and provide warnings or operational limits in high-wind conditions.

Key Features:

– Real-time wind speed and direction monitoring

– Automatic alarms at predetermined wind speed thresholds

– Integration with crane control systems for automatic shutdown

Function: Prevents accidents caused by wind-induced load instability or equipment stress.

Forklifts and Reach Stackers

Operator Presence Sensing Systems

Mechanisms that detect the presence of an operator in the correct operating position.

Key Features:

– Seat switches or pedal sensors

– Automatic engagement of parking brake when operator leaves seat

– Prevention of equipment operation without proper operator positioning

Function: Prevents unintended movement of the equipment when the operator is not in control.

Stability Control Systems

Technologies that enhance the stability of the equipment during operation.

Key Features:

– Sensors monitoring load weight, mast height, and tilt angle

– Automatic adjustment of speed and acceleration based on load conditions

– Warnings or intervention when approaching stability limits

Function: Reduces the risk of tipping or load shifting, especially when handling high or heavy loads.

Automated Guided Vehicles (AGVs)

Obstacle Detection and Avoidance Systems

Sensors and software that allow AGVs to detect and navigate around obstacles.

Key Features:

– Multiple sensor types (LIDAR, ultrasonic, camera)

– Real-time path planning and adjustment

– Automatic stopping when obstacles cannot be avoided

Function: Prevents collisions with fixed objects, other vehicles, or personnel in the operating area.

Safety-Rated Laser Scanners

Devices that create a safety zone around the AGV, stopping the vehicle if the zone is breached.

Key Features:

– Configurable safety zones based on speed and direction

– Ability to distinguish between static and moving obstacles

– Integration with vehicle control systems for immediate response

Function: Provides an additional layer of safety, especially in areas where AGVs interact with human workers.

Conveyor Systems

Emergency Pull Cords

Cables running along the length of the conveyor that can be pulled to stop the system.

Key Features:

– Easily accessible from any point along the conveyor

– Immediate system shutdown when activated

– Clear indication of activation point for quick response

Function: Allows workers to quickly stop the conveyor in case of entanglement or other emergencies.

Guard Rails and Safety Covers

Physical barriers that prevent access to moving parts of the conveyor.

Key Features:

– Covers for nip points and other pinch hazards

– Side guards to prevent falls into the conveyor

– Interlocked guards that stop the conveyor when opened

Function: Prevents accidental contact with moving parts and protects workers from falls.

Comparison of Safety Features Across Equipment Types

To illustrate the range of safety features across different cargo handling equipment, consider the following comparison:

| Safety Feature | Cranes | Forklifts | AGVs | Conveyors |

|---|---|---|---|---|

| Emergency Stop | ✓ | ✓ | ✓ | ✓ |

| Overload Protection | ✓ | ✓ | ✓ | ✓ (for powered rollers) |

| Anti-Collision Systems | ✓ | ✓ | ✓ | N/A |

| Operator Presence Sensing | N/A | ✓ | N/A | N/A |

| Stability Control | ✓ | ✓ | N/A | N/A |

| Obstacle Detection | Limited | Limited | ✓ | N/A |

| Safety Zones | N/A | N/A | ✓ | ✓ (around access points) |

| Wind Speed Monitoring | ✓ | N/A | N/A | N/A |

Emerging Trends in Cargo Handling Safety

As technology advances, new safety features are being developed and implemented:

Artificial Intelligence and Machine Learning: These technologies are being used to predict potential safety issues before they occur, based on analysis of operational data and patterns.

Virtual and Augmented Reality: VR and AR are being used for advanced operator training, allowing personnel to practice handling dangerous situations in a safe, simulated environment.

Wearable Technology: Smart helmets, vests, and watches can monitor worker health, detect falls, and provide instant communication in emergencies.

Drone Inspections: Drones are being used for safety inspections of high or hard-to-reach areas of cargo handling equipment, reducing the need for workers to access dangerous locations.

Importance of Safety Culture and Training

While technological safety features are crucial, they must be complemented by a strong safety culture and comprehensive training programs. Key aspects include:

- Regular safety training and refresher courses for all personnel

- Clear safety protocols and procedures for all operations

- Encouragement of safety reporting and near-miss documentation

- Regular safety audits and continuous improvement initiatives

By combining advanced safety features with a robust safety culture, cargo handling operations can significantly reduce the risk of accidents, protect workers, and ensure the integrity of cargo. As the industry continues to evolve, ongoing investment in safety technology and practices will remain essential to meet the challenges of increasingly complex and high-volume cargo handling operations.

How is equipment efficiency measured in cargo operations?

Measuring equipment efficiency in cargo operations is crucial for optimizing performance, reducing costs, and improving overall productivity. Various metrics and methodologies are used to assess the efficiency of different types of cargo handling equipment. Let’s explore the key measures and approaches used in the industry.

Key Performance Indicators (KPIs)

Several KPIs are commonly used to measure equipment efficiency in cargo operations:

Equipment Utilization Rate

This metric measures the percentage of time equipment is actively in use compared to its total available time.

Calculation: (Actual Operating Time / Total Available Time) x 100

Importance: High utilization rates indicate efficient use of equipment resources.

Moves Per Hour (MPH)

For container handling equipment, MPH measures the number of container moves completed in an hour.

Calculation: Total number of container moves / Number of operating hours

Importance: Higher MPH indicates faster operation and greater productivity.

Throughput

This measures the total volume or quantity of cargo handled by a piece of equipment in a given time period.

Calculation: Total cargo volume handled / Time period

Importance: Higher throughput indicates more efficient cargo handling.

Cycle Time

The time taken to complete one full operation cycle (e.g., loading and unloading a container).

Calculation: Total time for operation / Number of cycles completed

Importance: Shorter cycle times indicate more efficient operations.

Downtime Ratio

The percentage of time equipment is not operational due to maintenance, repairs, or other issues.

Calculation: (Total Downtime / Total Available Time) x 100

Importance: Lower downtime ratios indicate better equipment reliability and maintenance practices.

Energy Efficiency

Measures the amount of energy consumed per unit of cargo handled.

Calculation: Total energy consumed / Total cargo handled

Importance: Lower energy consumption per unit of cargo indicates more efficient operations and lower environmental impact.

Measuring Efficiency for Specific Equipment Types

Different types of cargo handling equipment require specific approaches to efficiency measurement:

Container Cranes

Gross Moves Per Hour (GMPH): The number of container moves a crane performs in an hour, including all operational delays.

Net Moves Per Hour (NMPH): The number of container moves per hour, excluding operational delays.

Crane Productivity Index (CPI): A composite measure that considers moves per hour, utilization rate, and downtime.

Forklifts and Reach Stackers

Lifts Per Hour: The number of load lifts performed in an hour.

Travel Distance Ratio: The ratio of loaded travel distance to total travel distance.

Fuel Efficiency: The amount of fuel consumed per operating hour or per move.

Automated Guided Vehicles (AGVs)

Vehicle Utilization Rate: The percentage of time AGVs are actively transporting cargo.

Average Speed: The average speed of AGVs during operations.

Battery Efficiency: For electric AGVs, the operating time per charge cycle.

Conveyor Systems

Throughput Rate: The volume of cargo moved per hour.

Uptime Percentage: The percentage of time the conveyor system is operational.

Energy Consumption Per Unit: The amount of energy used to move a unit of cargo along the conveyor.

Data Collection and Analysis Methods

Efficient measurement of equipment performance relies on robust data collection and analysis:

Telematics Systems

Advanced telematics systems collect real-time data on equipment performance, location, and status.

Key Features:

– GPS tracking for location and movement data

– Sensors for monitoring equipment status and performance

– Wireless data transmission for real-time reporting

Benefits:

– Accurate, real-time data collection

– Ability to track multiple efficiency metrics simultaneously

– Integration with management systems for comprehensive analysis

Terminal Operating Systems (TOS)

TOS platforms integrate data from various equipment and operations to provide a comprehensive view of terminal efficiency.

Key Features:

– Real-time tracking of container and equipment movements

– Integration of data from multiple equipment types

– Advanced analytics and reporting capabilities

Benefits:

– Holistic view of terminal operations

– Ability to identify bottlenecks and inefficiencies

– Support for data-driven decision making

Internet of Things (IoT) Sensors

IoT devices can be attached to equipment to collect specific performance data.

Key Features:

– Customizable sensors for specific metrics (e.g., fuel consumption, vibration)

– Wireless connectivity for real-time data transmission

– Integration with cloud-based analytics platforms

Benefits:

– Detailed performance data for individual equipment units

– Early detection of maintenance issues

– Support for predictive maintenance strategies

Benchmarking and Comparative Analysis

Efficiency measurements are most valuable when compared against industry benchmarks or historical performance:

Internal Benchmarking: Comparing the performance of similar equipment within the same operation over time.

Industry Benchmarking: Comparing equipment performance against industry standards or peer operations.

Best Practice Analysis: Identifying top-performing equipment and analyzing the factors contributing to their efficiency.

Challenges in Measuring Equipment Efficiency

Several challenges can complicate the accurate measurement of equipment efficiency:

Data Quality and Consistency: Ensuring that data is accurately collected and consistently measured across different equipment types and operational contexts.

Contextual Factors: Accounting for external factors that can affect efficiency, such as weather conditions, cargo types, or operational constraints.

Balancing Metrics: Ensuring that focus on one efficiency metric doesn’t negatively impact others (e.g., maximizing speed at the expense of safety or energy efficiency).

Integration of Legacy Equipment: Incorporating older equipment without built-in monitoring capabilities into modern efficiency measurement systems.

Comparison of Efficiency Measurement Approaches

To illustrate the range of efficiency measurement approaches, consider the following comparison:

| Measurement Approach | Advantages | Limitations |

|---|---|---|

| Manual Data Collection | Simple to implement, Low initial cost | Time-consuming, Prone to human error |

| Telematics Systems | Real-time data, Comprehensive coverage | High initial investment, Requires technical expertise |

| TOS Integration | Holistic view of operations, Advanced analytics | Complex implementation, Potential for data overload |

| IoT Sensors | Detailed equipment-specific data, Flexibility | Requires integration with existing systems, Potential cybersecurity risks |

Future Trends in Equipment Efficiency Measurement

As technology continues to advance, several trends are emerging in the field of equipment efficiency measurement:

Artificial Intelligence and Machine Learning: AI algorithms are being used to analyze vast amounts of operational data, identifying patterns and predicting efficiency trends.

Digital Twins: Virtual replicas of physical equipment and operations allow for advanced simulation and optimization of efficiency parameters.

Blockchain Technology: Blockchain is being explored for secure, transparent tracking of equipment performance and maintenance records.

Advanced Visualization Tools: New software tools are making it easier to visualize complex efficiency data, enabling quicker insights and decision-making.

Autonomous Systems: As cargo handling equipment becomes more autonomous, new metrics and measurement approaches will be needed to assess the efficiency of AI-driven operations.

Measuring equipment efficiency in cargo operations is a complex but crucial task. By leveraging advanced technologies and comprehensive measurement approaches, cargo handlers can gain valuable insights into their operations, identify areas for improvement, and drive continuous enhancement of their equipment performance. As the industry continues to evolve, the ability to accurately measure and optimize equipment efficiency will remain a key factor in maintaining competitiveness and meeting the growing demands of global trade.

What factors should be considered when choosing cargo handling equipment?

Selecting the right cargo handling equipment is a critical decision that can significantly impact the efficiency, safety, and profitability of logistics operations. Multiple factors must be carefully considered to ensure that the chosen equipment aligns with operational needs, budget constraints, and long-term strategic goals. Let’s explore the key factors that should be taken into account when choosing cargo handling equipment.

Operational Requirements

The specific needs of the operation should be the primary consideration:

Cargo Type and Characteristics

Different types of cargo require specialized handling equipment:

- Containerized cargo: Container cranes, reach stackers, straddle carriers

- Bulk cargo: Conveyor systems, bucket elevators, pneumatic systems

- Break-bulk cargo: Forklifts, mobile harbor cranes

- Liquid cargo: Pumps, pipelines, specialized tanker loading arms

Consideration: Analyze the types of cargo handled most frequently and ensure the equipment can efficiently manage these loads.

Handling Capacity

The volume of cargo that needs to be moved within a given timeframe:

- Throughput requirements: Daily, weekly, or monthly cargo volumes

- Peak handling periods: Equipment capacity to manage busiest times

Consideration: Choose equipment with sufficient capacity to handle current volumes with room for future growth.

Operating Environment

The physical conditions in which the equipment will operate:

- Indoor vs. outdoor operations

- Climate conditions (temperature, humidity, salt air exposure)

- Surface conditions (even concrete, uneven terrain, gravel)

Consideration: Select equipment designed to withstand the specific environmental challenges of the operating location.

Space Constraints

The available space for equipment operation and storage:

- Aisle widths in warehouses

- Stacking heights in container yards

- Turning radiuses for mobile equipment

Consideration: Ensure the equipment can operate effectively within the available space, considering both horizontal and vertical constraints.

Technical Specifications

The technical capabilities of the equipment must match operational needs:

Lifting Capacity

The maximum weight the equipment can safely handle:

- Safe Working Load (SWL) for cranes and lifting equipment

- Load capacity for forklifts and reach stackers

Consideration: Choose equipment with a lifting capacity that exceeds the heaviest expected loads to ensure safe operation.

Speed and Cycle Times

The operational speed of the equipment:

- Lifting and lowering speeds for cranes

- Travel speeds for mobile equipment

- Conveyor belt speeds

Consideration: Balance the need for speed with safety considerations and energy efficiency.

Reach and Range

The physical reach of the equipment:

- Boom length and height for cranes

- Lift height for forklifts and reach stackers

- Operational radius for straddle carriers

Consideration: Ensure the equipment can access all required areas of operation, including height and outreach requirements.

Power Source

The type of energy used to power the equipment:

- Electric: Lower emissions, quieter operation, suitable for indoor use

- Diesel: Higher power output, longer operating times between refueling

- Hybrid: Combines benefits of electric and diesel power

Consideration: Consider environmental regulations, operational costs, and infrastructure requirements for each power source.

Economic Factors

The financial implications of equipment selection are crucial:

Initial Investment

The upfront cost of purchasing or leasing the equipment:

- Purchase price

- Leasing terms and conditions

- Installation and setup costs

Consideration: Balance the initial cost against long-term operational benefits and expected return on investment.

Operational Costs

Ongoing expenses associated with running the equipment:

- Fuel or electricity consumption

- Maintenance and repair costs

- Labor costs for operators

Consideration: Evaluate the total cost of ownership over the expected lifespan of the equipment.

Productivity and Efficiency

The impact of the equipment on overall operational efficiency:

- Throughput capacity

- Energy efficiency

- Integration with existing systems

Consideration: Assess how the equipment will contribute to operational productivity and potential cost savings.

Flexibility and Scalability

The ability of the equipment to adapt to changing operational needs:

- Modularity and upgradability

- Ability to handle different cargo types

- Potential for automation or future technological integration

Consideration: Choose equipment that can evolve with the operation’s changing needs and technological advancements.

Safety and Compliance

Ensuring the safety of operators and compliance with regulations is paramount:

Safety Features

Built-in safety mechanisms and systems:

- Emergency stop systems

- Overload protection

- Anti-collision technology

Consideration: Prioritize equipment with advanced safety features that meet or exceed industry standards.

Regulatory Compliance

Adherence to local, national, and international regulations:

- Emissions standards

- Noise regulations

- Occupational health and safety requirements

Consideration: Ensure the equipment complies with all relevant regulations in the operating jurisdiction.

Ergonomics and Operator Comfort

Features that enhance operator comfort and reduce fatigue:

- Cab design and visibility

- Control layout and ease of use

- Vibration and noise reduction

Consideration: Choose equipment that promotes operator well-being and productivity over long shifts.

Maintenance and Support

The ease and cost of maintaining the equipment:

Maintenance Requirements

The frequency and complexity of required maintenance:

- Scheduled maintenance intervals

- Availability of spare parts

- Ease of access to components for repairs

Consideration: Evaluate the maintenance needs and their impact on operational downtime and costs.

Manufacturer Support

The level of support provided by the equipment manufacturer:

- Warranty terms

- Availability of technical support

- Training programs for operators and maintenance staff

Consideration: Choose equipment from manufacturers with strong support networks and comprehensive service agreements.

Technological Integration

The ability of the equipment to integrate with modern technological systems:

Automation Capabilities

The potential for automated or semi-automated operation:

- Integration with Terminal Operating Systems (TOS)

- Compatibility with Automated Guided Vehicle (AGV) systems

- Remote operation capabilities

Consideration: Assess how the equipment fits into current and future automation strategies.

Data Collection and Analytics

Built-in systems for performance monitoring and analysis:

- Telematics systems

- IoT sensor integration

- Compatibility with data analytics platforms

Consideration: Choose equipment that provides valuable operational data to support decision-making and continuous improvement.

Comparison of Factors for Different Equipment Types

To illustrate how these factors might be weighted differently for various types of cargo handling equipment, consider the following comparison:

| Factor | Container Cranes | Forklifts | Conveyor Systems | AGVs |

|---|---|---|---|---|

| Lifting Capacity | Critical | Important | N/A | Moderate |

| Speed | Important | Moderate | Critical | Important |

| Energy Efficiency | Moderate | Important | Critical | Critical |

| Automation Potential | High | Moderate | High | Critical |

| Initial Cost | Very High | Moderate | High | High |

| Maintenance Complexity | High | Moderate | Moderate | High |

| Flexibility | Low | High | Low | Moderate |

| Safety Features | Critical | Important | Important | Critical |

Choosing the right cargo handling equipment requires a comprehensive analysis of operational needs, technical specifications, economic factors, safety considerations, and future scalability. By carefully weighing these factors, logistics operators can select equipment that not only meets their current needs but also positions them for future growth and technological advancements. As the industry continues to evolve, the ability to make informed equipment choices will remain a key competitive advantage in the dynamic world of cargo handling and logistics.

How can cargo handling equipment be integrated into existing systems?

Integrating new cargo handling equipment into existing systems is a complex process that requires careful planning, execution, and ongoing management. The goal is to seamlessly incorporate new equipment to enhance overall operational efficiency without disrupting current processes. Let’s explore the key aspects of integrating cargo handling equipment into existing systems.

Assessment and Planning

Before integration begins, a thorough assessment of current systems and future needs is essential:

Current System Analysis

Evaluate the existing infrastructure, processes, and equipment:

- Inventory of current equipment and systems

- Identification of operational bottlenecks and inefficiencies

- Assessment of existing software and control systems

Consideration: Gain a comprehensive understanding of the current operational landscape to identify integration points and potential challenges.

Integration Goals

Define clear objectives for the integration process:

- Increased throughput capacity

- Enhanced safety and compliance

- Improved energy efficiency

- Greater operational flexibility

Consideration: Establish measurable goals to guide the integration process and evaluate its success.

Compatibility Assessment

Determine how new equipment will interact with existing systems:

- Physical compatibility (space, power requirements, connections)

- Software compatibility (control systems, data formats)

- Operational compatibility (workflow processes, operator skills)

Consideration: Identify potential compatibility issues early to inform equipment selection and integration strategies.

Physical Integration

The process of physically incorporating new equipment into the existing operational space:

Layout Optimization

Redesign the operational layout to accommodate new equipment:

- Traffic flow analysis for mobile equipment

- Placement of fixed equipment (cranes, conveyors)

- Consideration of future expansion needs

Consideration: Optimize the layout to maximize efficiency while ensuring safe operations.

Infrastructure Upgrades

Modify existing infrastructure to support new equipment:

- Power supply upgrades

- Foundation reinforcement for heavy equipment

- Installation of new data cabling or wireless networks

Consideration: Assess and implement necessary infrastructure changes to support the new equipment’s operational requirements.

Interfacing with Existing Equipment

Ensure new equipment can work alongside existing machinery:

- Mechanical interfaces (e.g., conveyor connections)

- Safety system integration (e.g., shared emergency stop systems)

- Coordinated operations (e.g., crane-to-AGV handoffs)

Consideration: Develop clear protocols for how new and existing equipment will interact in shared operational spaces.

System Integration

Integrating new equipment with existing software and control systems is crucial for seamless operations:

Control System Integration

Incorporate new equipment into the overall control architecture:

- Integration with Terminal Operating Systems (TOS)

- Updating Programmable Logic Controllers (PLCs)

- Implementing new Human-Machine Interfaces (HMIs)

Consideration: Ensure that new equipment can be controlled and monitored within the existing operational framework.

Data Integration

Align data flows between new equipment and existing systems:

- Standardizing data formats

- Implementing data translation layers if necessary

- Ensuring real-time data exchange capabilities

Consideration: Establish seamless data communication to support operational decision-making and performance analysis.

Software Updates

Modify or upgrade existing software to accommodate new equipment:

- TOS updates to recognize and manage new equipment

- Integration of equipment-specific software modules

- Development of new reporting and analytics capabilities

Consideration: Balance the need for software updates with minimizing disruption to ongoing operations.

Operational Integration

Adapting operational processes and workforce skills to incorporate new equipment:

Process Reengineering

Redesign operational processes to leverage new equipment capabilities:

- Updating standard operating procedures (SOPs)

- Optimizing workflow to include new equipment

- Developing new Key Performance Indicators (KPIs)

Consideration: Align operational processes with the capabilities of the integrated equipment to maximize efficiency gains.

Training and Skill Development

Prepare the workforce to operate and maintain new equipment:

- Comprehensive training programs for operators

- Maintenance and troubleshooting training for technical staff

- Change management initiatives to support adoption

Consideration: Invest in workforce development to ensure smooth adoption and optimal utilization of new equipment.

Safety Integration

Incorporate new equipment into existing safety systems and protocols:

- Updating risk assessments

- Modifying safety procedures and emergency protocols

- Integrating new equipment into safety monitoring systems

Consideration: Maintain a strong safety culture throughout the integration process and beyond.

Phased Implementation

A staged approach to equipment integration can minimize operational disruptions:

Pilot Testing

Implement new equipment in a limited operational context:

- Controlled testing in a designated area

- Gradual increase in operational involvement

- Continuous monitoring and adjustment

Consideration: Use pilot testing to identify and address integration issues before full-scale implementation.

Parallel Operations

Run new and existing systems in parallel during the transition:

- Gradual shift of operations to new equipment

- Maintaining operational redundancy

- Comparative performance analysis

Consideration: Ensure operational continuity while validating the performance of integrated equipment.

Incremental Scaling

Gradually expand the role of new equipment in operations:

- Phased introduction across different operational areas

- Progressive increase in handling volumes

- Staged retirement of older equipment

Consideration: Manage the pace of integration to balance efficiency gains with operational stability.

Continuous Improvement

Ongoing optimization of the integrated system is crucial for long-term success:

Performance Monitoring

Continuously assess the performance of integrated equipment:

- Real-time monitoring of operational metrics

- Regular analysis of efficiency and productivity data

- Comparison against pre-integration benchmarks

Consideration: Use performance data to identify areas for further optimization and improvement.

Feedback Loops

Establish mechanisms for ongoing refinement:

- Regular operator feedback sessions

- Continuous improvement teams

- Iterative process adjustments

Consideration: Foster a culture of continuous improvement to maximize the benefits of equipment integration over time.

Technology Updates

Stay current with technological advancements:

- Regular software updates

- Hardware upgrades when beneficial

- Exploration of emerging technologies (e.g., AI, IoT)

Consideration: Maintain the technological relevance of integrated equipment to preserve long-term operational advantages.

Challenges and Mitigation Strategies

Integrating new cargo handling equipment into existing systems presents several challenges:

| Challenge | Mitigation Strategy |

|---|---|

| Operational Disruption | Careful planning, phased implementation, off-peak testing |

| Resistance to Change | Comprehensive training, clear communication, involvement of staff in planning |

| Technical Incompatibilities | Thorough compatibility assessment, use of middleware or custom integrations |

| Budget Overruns | Detailed cost planning, contingency budgets, phased investment approach |

| Safety Concerns | Rigorous risk assessments, enhanced safety protocols during transition |

Successful integration of new cargo handling equipment into existing systems requires a holistic approach that considers physical, technological, and human factors. By carefully planning the integration process, addressing potential challenges proactively, and maintaining a focus on continuous improvement, organizations can significantly enhance their cargo handling capabilities while minimizing operational disruptions.

The key to successful integration lies in viewing it not as a one-time project, but as an ongoing process of optimization and adaptation. As the cargo handling industry continues to evolve, the ability to effectively integrate new equipment and technologies will be a critical factor in maintaining competitiveness and meeting the growing demands of global trade.